Connecting to Internet:

5

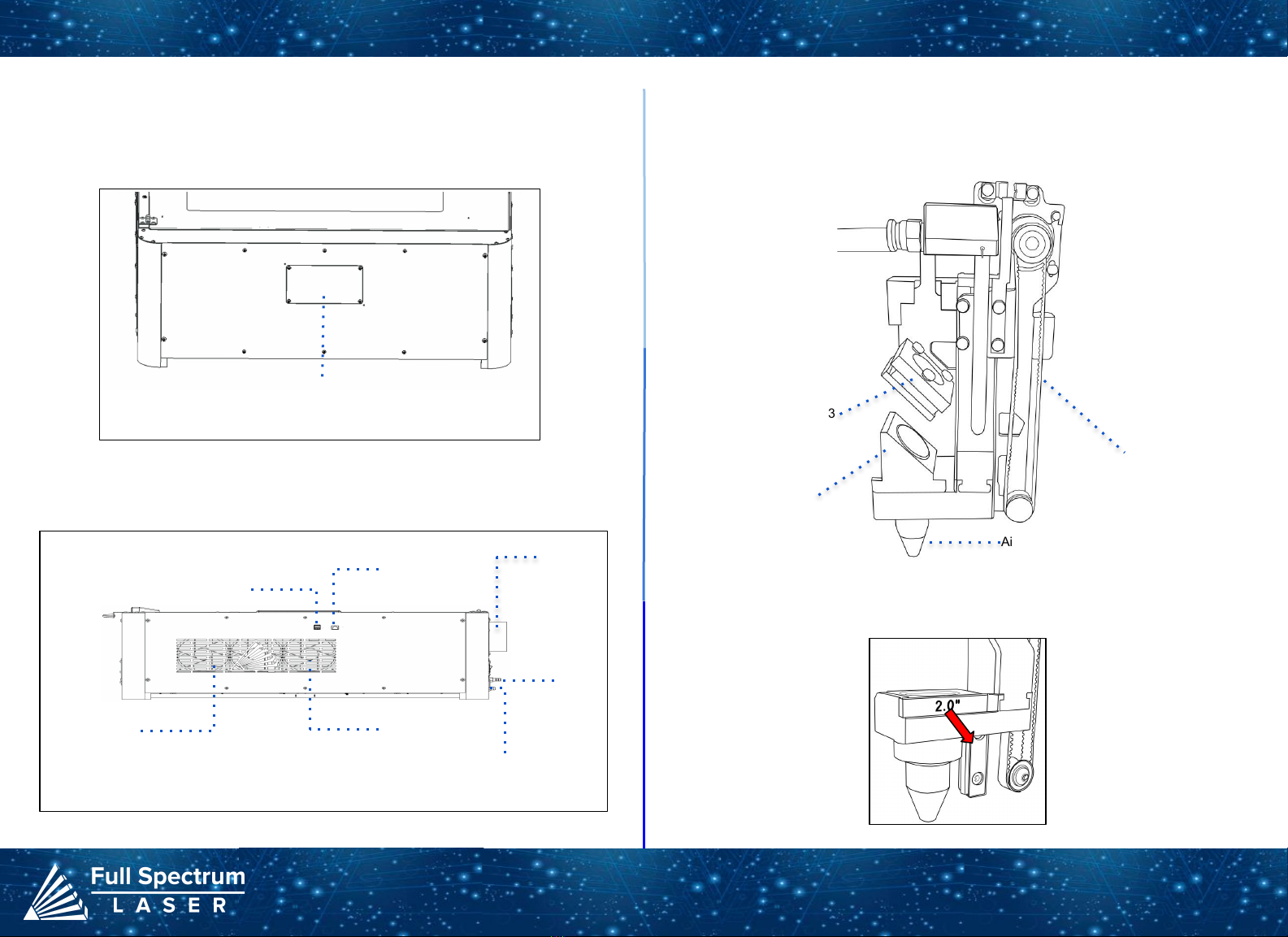

Focusing:

There are two ways to use the autofocus feature on your machine. The first method

involves pressing the autofocus button on the touchscreen. The second method requires

accessing the autofocus icon located under the Jog Controls Tab in RE3.

If your machine is experiencing excessive shaking or vibrations during autofocusing, it may

be necessary to adjust the machine's stallguard component.

What is Stallguard?

The stallguard is a crucial component in the machine that regulates the amount of tension

it can handle before coming to a stop. We want your machine to detect the material and

move towards its focus distance. However, if the stalling value is too low, the machine may

hit the material and cause damage.

How to Adjust Stallguard?

To adjust the stallguard, follow these steps:

1. Connect to the Setup Page: Access the software's Setup page by using the

format IP address/setup (e.g., 000.000.00.000/setup).

2. Select the Laser Tools Tab: Once in the Setup window, locate and select the

Laser Tools tab.

3. Locate the Set Motor Type Section: Look for the Z-axis settings and navigate to

the Autofocus Stall Guard Value.

4. Adjust the Value: Change the Autofocus Stallguard Value as needed.

Adjusting the Stallguard:

Connect Via Router (Recommended):

To establish a reliable link to RE3, it is recommended to connect the Fiber

Galvo to the router. The Fiber Galvo is equipped with an ethernet cable that

should be plugged into the ethernet ports of both devices

Note: Ethernet port looks the same on all devices

Fig. 18

Connect to Wi-Fi:

Make sure that the dongle, a device attached to the USB port of your machine,

is present and connected as it enables your machine to connect to the WiFi

network.

Fig. 19

1. To connect to the WiFi network, select the Network button located

on the top right of the Touchscreen.

2. Then, choose the WiFi option and search for your network. Once

you have located your network, select it and enter your password.

Connecting Directly Using Computer:

This option is only advisable when the other two methods are not possible.

The Fiber Galvo can connect to the computer through Ethernet, but an

adapter might be required for your computer.