AdvantagePlus Fault Tree Troubleshooting

1706.doc

8

a. Equivalent footage for combustion air and exhaust may not exceed the specified limitations in the

vent table.

5. How many feet of pipe in the combustion air?

a. See the vent table in the Installation Manual for equivalent footage impact.

6. How is the venting system terminated?

a. Two pipe, concentric vent kit, or V-1000 aluminum kit. See the Use and Care Manual for

examples of proper vent termination on the exterior wall or roof.

7. Are both the combustion air and exhaust terminated on the same plane?

8. Is the separation, and offset within specification for a two-pipe termination?

a. See the Use and Care Manual for examples of proper vent termination on the exterior wall or roof.

9. Is the coupling on the exhaust, and the tee on the combustion air and oriented correctly?

a. A concentric vent assembly must have every joint glued, or exhaust will contaminate the

combustion air. Is the "Y" on the concentric vent horizontal termination only pointing up

perpendicular to the ground?

b. If using the V-1000, the combustion air pipe must be butted to the "L" bracket spot welded to the

inside of the vent assembly cover, and the exhaust pipe glued to the exhaust coupling in the vent

assembly cover.

10. Is the termination adjacent to an inside vertical corner, or roof overhang? Is it within 3 feet of either?

a. This will cause the combustion gases to re-circulate back in to the fresh air intake.

11. Is the termination behind bushes or shrubs?

a. This will cause the combustion gases to re-circulate back in to the fresh air intake. And it will kill

the shrubs.

12. If the termination is horizontal, is there a wall or other vertical obstruction within 4' of the exhaust line of

travel?

a. This will cause the combustion gases to re-circulate back in to the fresh air intake.

13. Are all horizontal exhaust pipe runs pitched 1/4" to the foot back to the heater?

14. Is the pipe supported so there are not traps for condensate in the exhaust?

15. Is the exhaust pipe pitched upward when exiting the no hub fitting on the unit?

a. This point almost always seems to get pitched down because they don't support that short piece of

pipe between the no hub fitting and the first elbow. The elbow becomes a trap for water, thus

adding equivalent footage to the vent.

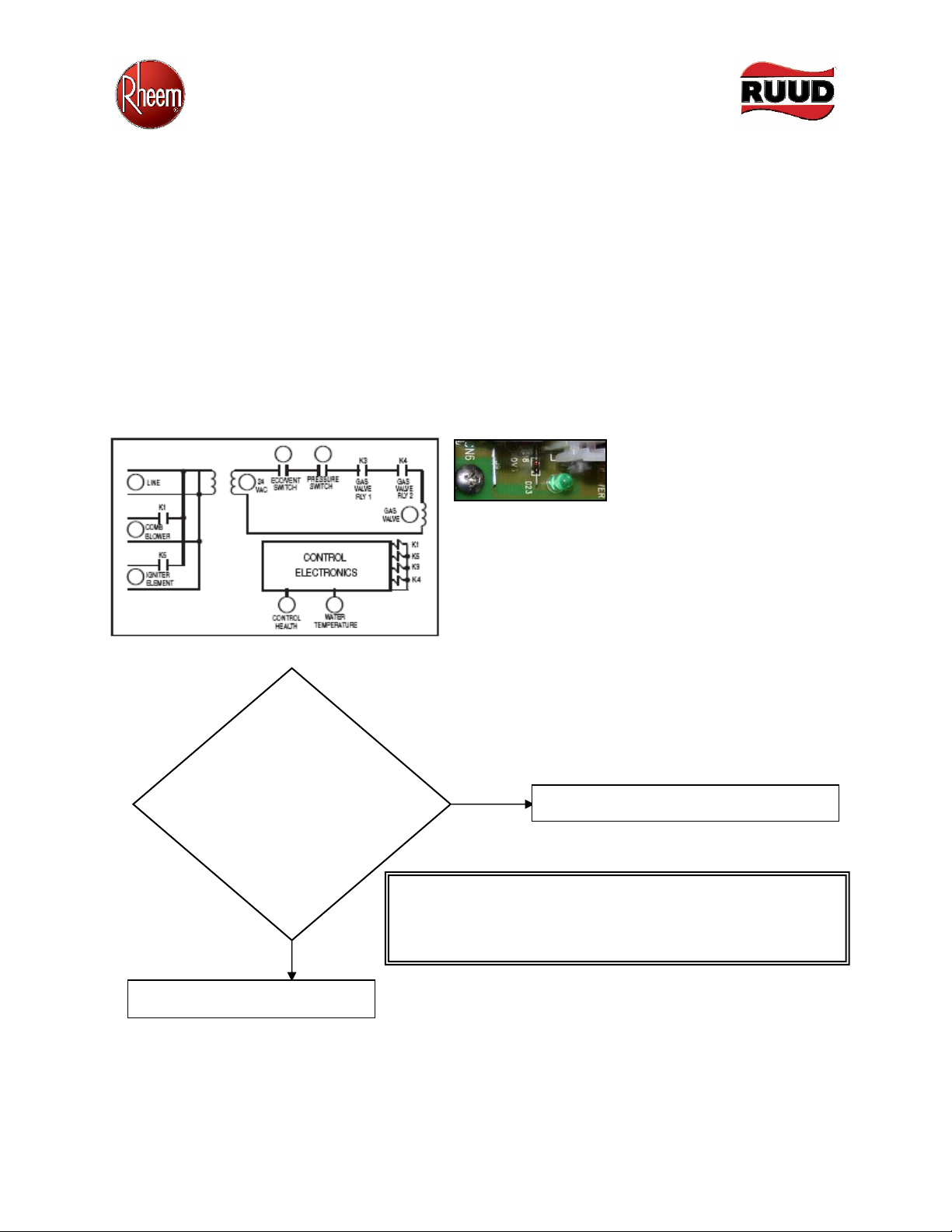

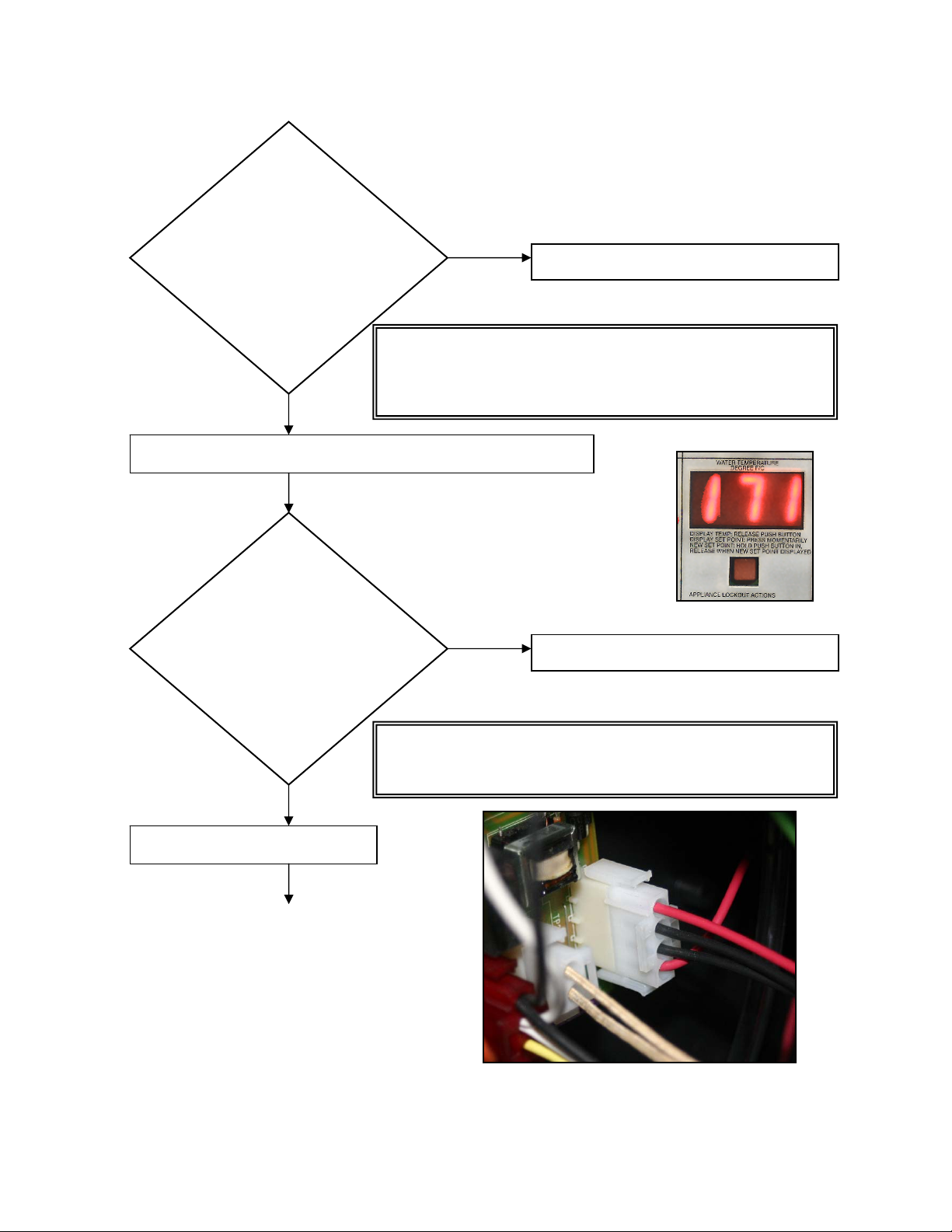

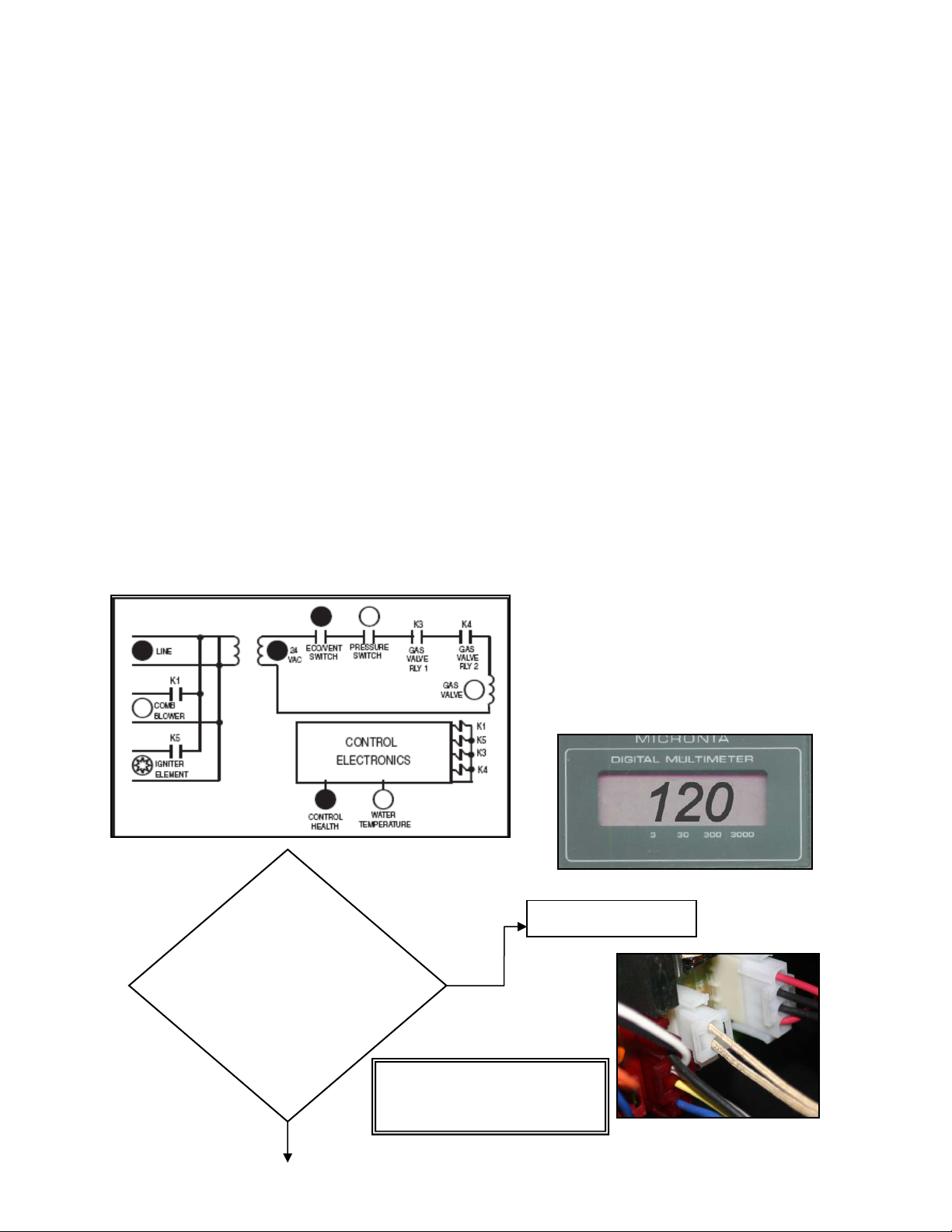

GAS VALVE; no flame rectification; maximum ignition attempts.

Explanation: The LED is ON when power is applied to

the gas valve. Controls are looking for flame

rectification, meaning there is main burner. Unit will

make three successive trials; then lock out

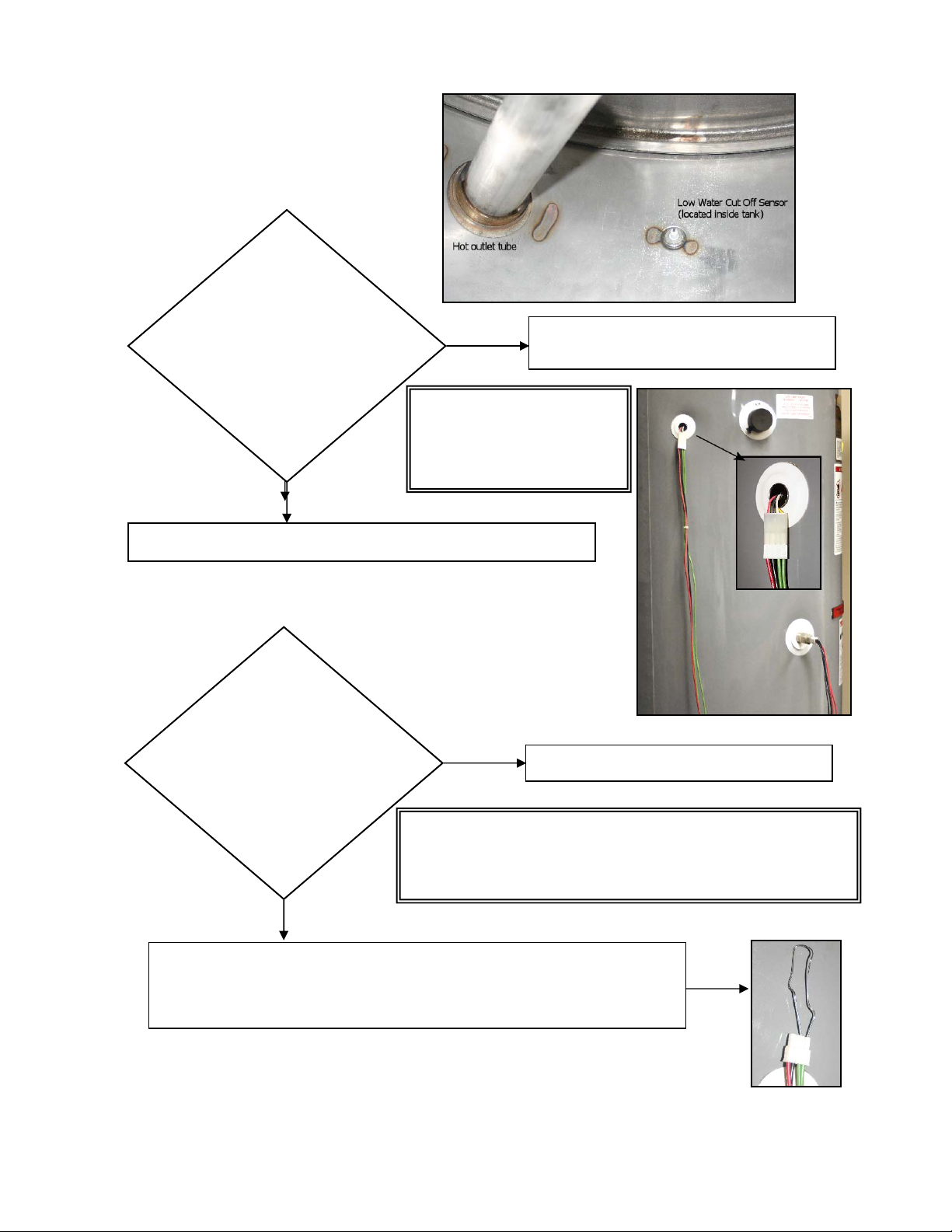

At a minimum check the following:

1. Gas valve shut OFF

2. Broken or corroded flame sensor wire

3. Connectors on control panel unplugged

4. Tubing between valve and air inlet is present

5. Unit has proper service pressure

6. Gas fuel supply or piping problem

7. Gas valve improperly adjusted

8. Verify green polarity light on board