1 SAFETY INSTRUCTIONS AND WARNINGS

When using an electrical appliance, basic precautions should always be followed including the

following:

READ ALL INSTRUCTIONS BEFORE USING THE MACHINE

CAUTION: The operator of this instrument is advised that if the

equipment is used in a manner not specified in this manual, the

protection provided by the equipment may be impaired.

WARNINGS

The manufacturer cannot be held responsible for damage caused when the appliance is not used

according to the instructions, or for uses other than those for which it was intended.

This special commercial machine is suitable for the applications mentioned in the operating

instructions. Do not use for purposes other than those for which it was designed, as these may

be dangerous. The manufacturer cannot be held responsible for damage caused by improper

use.

Do not allow children or unauthorised personnel access to the machine or its controls.

The process needs to be checked and documented by authorised persons regularly. See EN ISO

15883-1, -3, and IEC 61010-2-40.

The cycles must not be interrupted, as it would cause danger and affect the cleaning and

disinfection result. If interruption occurs, do not make an attempt to open either door and start the

process again. In case the fault condition occurs repeatedly, please call for service. In cases of

emergency e.g. fire or flooding, cut off the services to the machine using the safety controls

provided externally to the unit. The machine is completely isolated from the electricity supply only

when it is unplugged or the circuit breaker is turned off. This must be done before any repair work

is carried out.

The machine is constructed in accordance with current safety requirements. Any repairs shall

only be carried out by an authorised and a suitably qualified and competent engineer.

The electrical safety of this machine can only be guaranteed if connected to an electrical system

complying with all relevant regulations and checked by the regulating authority. The manufacturer

cannot be held responsible for damage caused by incorrect wiring.

The machine shall only be instaIIed by a suitably qualified and competent contractor. Before

connecting the machine, the Installer shall check that the voltage and frequency of the electrical

supply correspond with the details on the data plate of the machine.

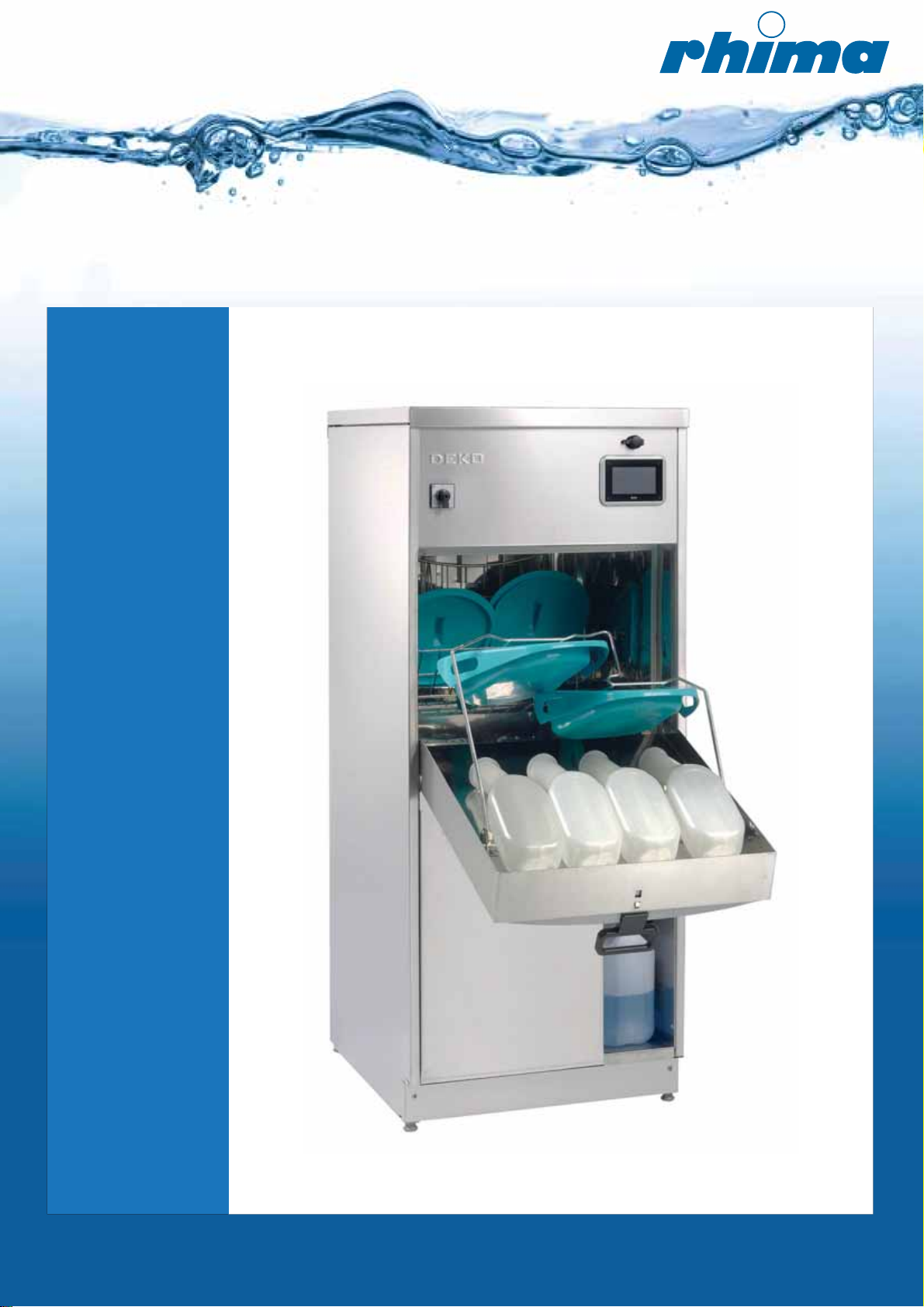

Only genuine Franke parts or accessories shall be used with the Deko 190 iX Ward Disinfector.

The performance and safety of non-genuine parts or accessories cannot be guaranteed, and use

of such parts or items may void the machine warranty. If you have specific questions about

machine options or accessories, please call your supplier.

The water in this machine must not be used as drinking water.

4