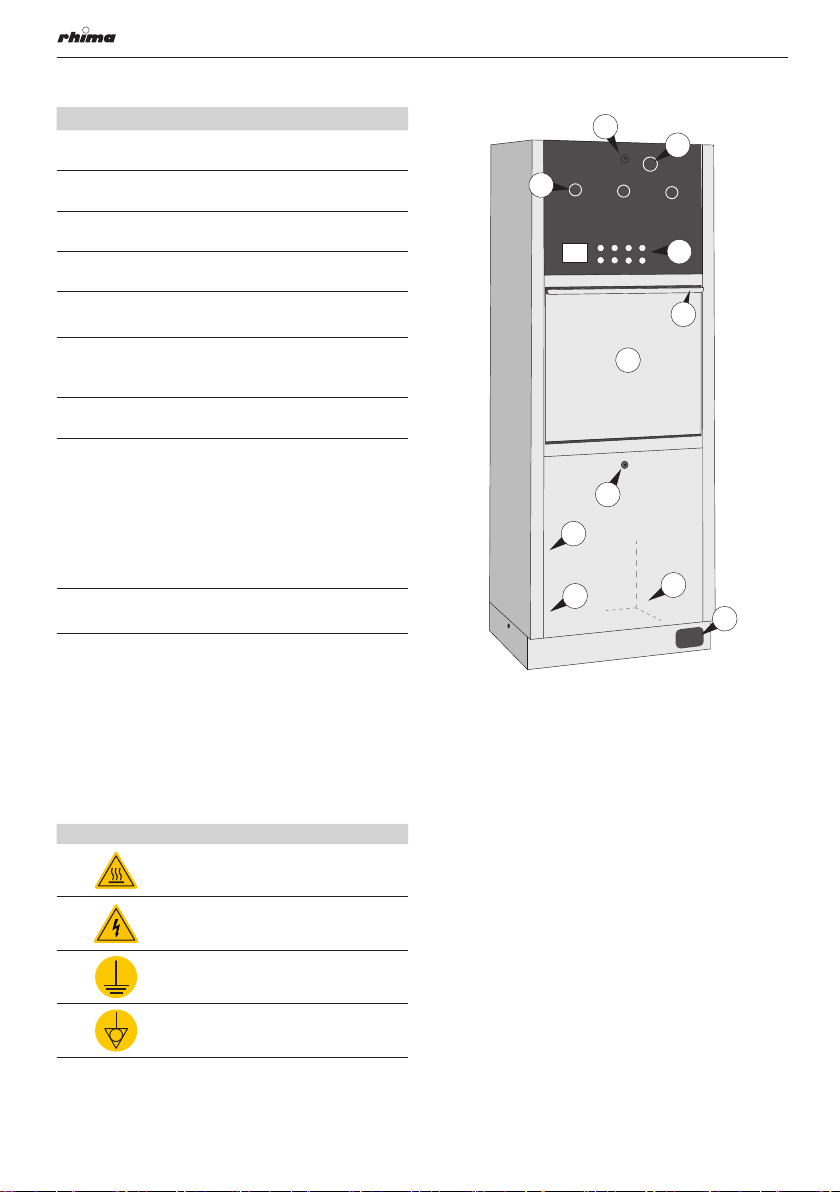

Operave Instrucons

10