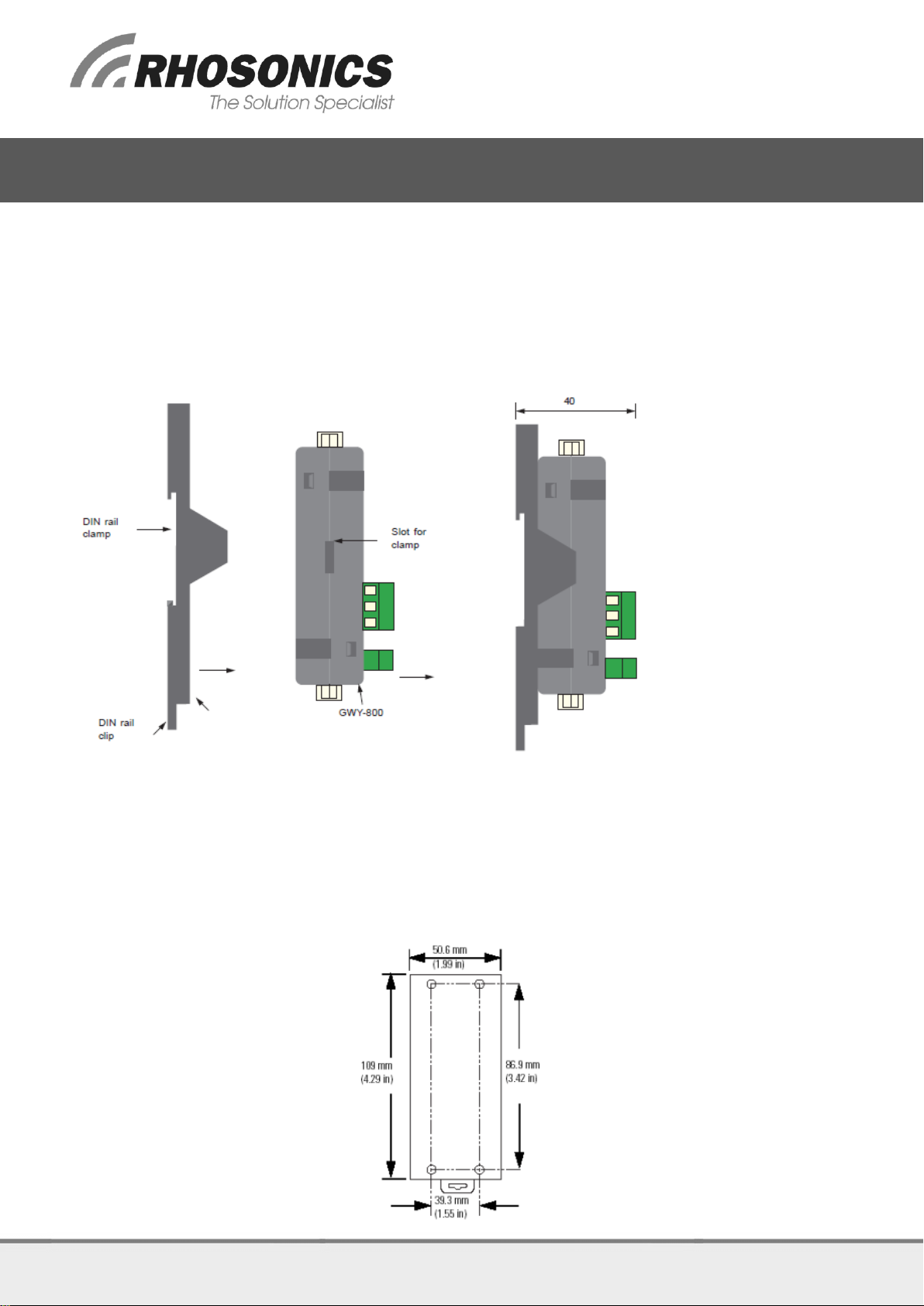

2.2 Dimensional Details and Mounting Instructions

GWY-800 -B unit can be mounted on a back panel or on a DIN rail or can be left hanging. It comes with a

separate DIN rail plate when it is packed. User will have to attach the DIN rail plate to the unit if it has to be

mounted on a panel or DIN rail. If it has to be left hanging, make sure to screw the cables to the DB9

connectors on the Gateway unit. DIN rail plate also has the provision to screw the unit to the back panel.

Following drawing shows how to attach the DIN rail plate to the unit:

Follow instructions given below:

1. Attach the DIN rail plate to the unit using the clamps on the DIN rail plate.

2. Pull out the clip of the plate.

3. Put the unit on the DIN rail.

4. Push the clip in to secure the unit on the DIN rail.

GWY-800-B unit is shipped with a separate DIN rail plate which has to be attached to the unit, if needed.

User can use the unit with or without the DIN rail plate. Following sketch shows mounting details of GWY-

800-B with the DIN rail plate.