Aumuller KS 2 Training manual

KS 2 / KS 2 TWIN - CHAIN DRIVE

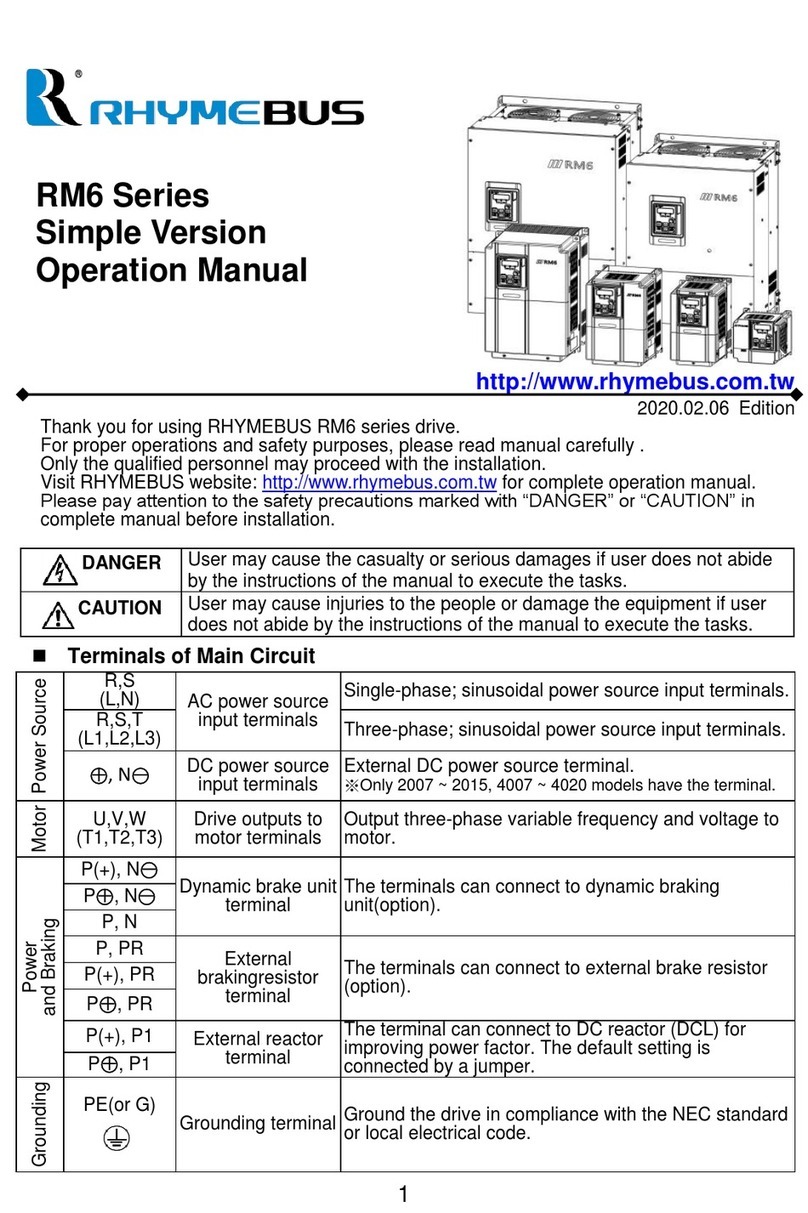

according to Machinery Directive 2006 / 42 / EC (annex VI)

Assembly and Commissioning

Instructions

Assembly Instruction

KS2 / KS2 TWIN

CONTENTS

08

07

06

05

04

03

02

01

Abbreviations

Risk Assessment

Warning and Safety Symbols

Safety Instructions

Explanations on the product label

Data sheet KS2 S2 24V DC R/L / KS2 S2 230V AC R/L

Data sheet KS2 S12 24V DC R / KS2 S12 24V DC L

Data sheet KS2 S12 230V AC R / KS2 S12 230V AC L

Data sheet KS2 TWIN S12 24V DC

Data sheet KS2 S12 230V AC TANDEM-SET

Intended Use

Drive positioning: Symmetrical or asymmetrical

Survey: Growing variants and minimum casement heights

Possible multi-drive operating

INSTALLATION STEP 1: Pre-assembly Checks

INSTALLATION STEP 2: Prerequisites for Assembly / Preparing assembly

INSTALLATION STEP 3: Determine the casement brackets

INSTALLATION STEP 4: Determine the frame brackets (Application examples)

INSTALLATION STEP 5: Hole layout for frame bracket and casement bracket

INSTALLATION STEP 6: Assembly casement bracket

INSTALLATION STEP 7: Assembly frame bracket

INSTALLATION STEP 8: Concealing the drive

INSTALLATION STEP 9: Electric Connection

Instructions on Connection

Checking Safety and Performing Test Run

Troubleshooting, Service and Repair

Maintenance and Modifi cation

Removal and Disposal

Target Groups

Warranty and After-Sales Service

Liability

Certifi cates

Survey: Growing variants and minimum casement heights

3-5

6 - 21

22 - 24

25 - 26

27 - 57

58 - 62

63 - 67

68 - 72

Assembly Instruction

KS2 / KS2 TWIN

Index of abbreviations

These abbreviations are used consistently throughout these assembly

& operating instructions. Unless stated differently, all dimensions indi-

cated in this document are in mm. General tolerances in accordance

with DIN ISO 2768-m.

A drive

AK connection cable / drive cable

AP cover cap

BD hinge

Fxxx casement bracket

FAB overall width of casement

FAH overall height of casement

FG casement weight

FL casement

FÜ casement overlap

HSK main closing edge

Kxxx frame bracket

L construction lenghth of drive

MB central hinge

NSK side closing edge

RA frame

RAB overall width of frame

RAH overall height of frame

SL snow load

opening direction

ABBREVIATIONS RISIK ANALYSIS

for power-operated windows and doors (machines)

according to ISO 12100

General Procedure

Before starting work, a risk analysis must be carried out to systematically

ensure compliance with the country-speci c legal regulations on occupatio-

nal safety and accident prevention regulations of the professional associa-

tions.

Once the risk assessment for power-operated windows and doors has

been carried out by the planner and laid down in the constructional re-

quirements, the installer of the power-operated windows and doors must

again carry out another risk assessment to examine whether the planning

requirements have been met. In case the protection class (see i. e. lea et

KB.01 of VFF [association windows + facade]) has not been met, further

steps to reduce risk are necessary.

Extract from the Machinery Directive 2006/42/EC

„The manufacturer of machinery or his authorized representative must

ensure that a risk assessment is carried out in order to determine the

health and safety requirements which apply to the machinery. The ma-

chinery must then be designed and constructed taking into account the

results of the risk assessment.“

Separate documentation relating to risk assessment can be downloaded

from the homepage of

Aumüller Aumatic GmbH (www.aumueller-gmbh.de).

In addition, the operator needs to be instructed about the residual risks.

It is essential to ensure compliance with the latest version of the guide-

lines, standards and national legislation applicable to the assembly and

the electrical connection of drives / controls, especially:

EN 60335-1 / EN 60335-2-103

„Household and similar electrical appliances - Safety - Part 1: General

requirements / - Part 2-103: Particular requirements for drives for gates,

doors and windows“

Directive 2006/24/EC of the European Parliament and of the

Council - „Machinery Directive“

Local accident prevention regulations.

Fire behaviour of building materials and building components.

Erection of power installations with rated voltages below 1000V

Failure to comply with the warning notes results

in irreversible injuries or death.

Failure to comply with the warning notes can

result in irreversible injuries or death.

Failure to comply with the warning notes can

result in minor or moderate (reversible) injuries.

Failure to comply with the warning notes can

lead to damage to property.

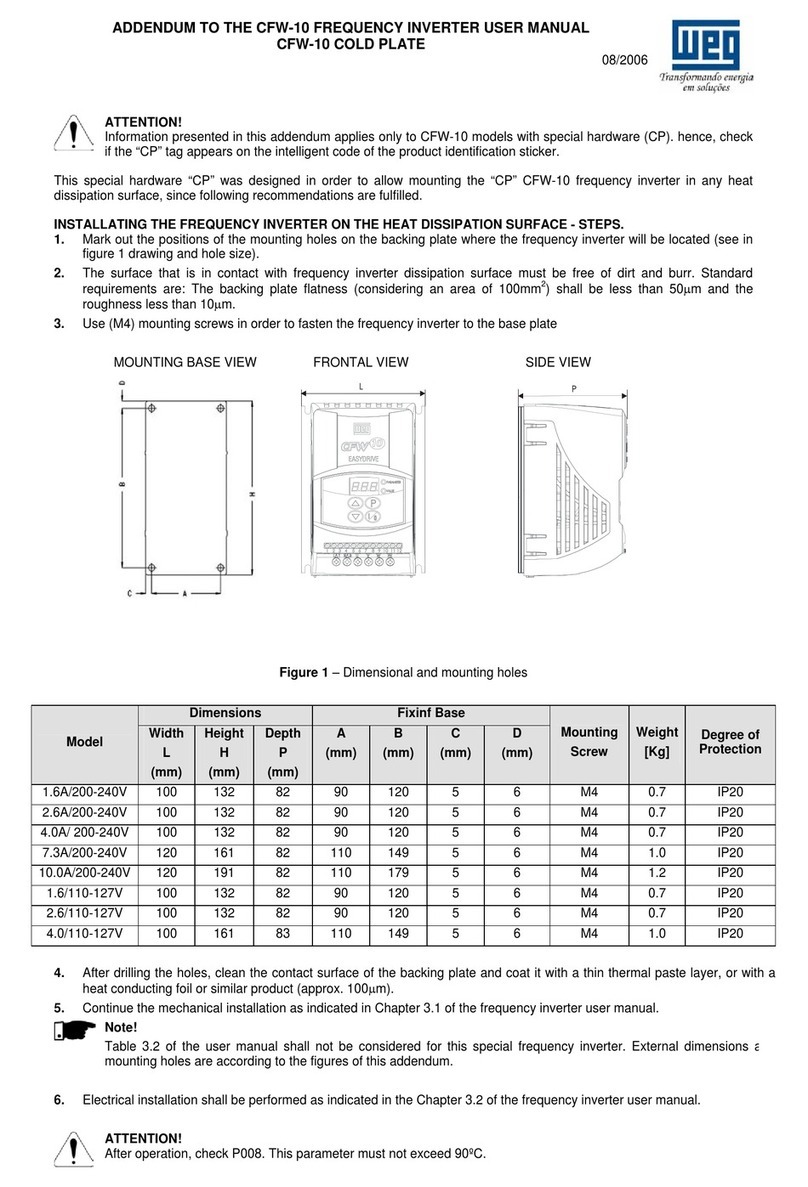

WARNING AND SAFETY SYMBOLS IN THESE INSTRUCTIONS:

The symbols used in the instructions shall be strictly observed and have the following meaning:

Caution / Warning

Danger due to electric current.

Caution / Warning

Risk of crushing and entrapment during device operati-

on (is provided as a sticker with the drive).

Attention / Warning

Risk of damage to / destruction of drives and / or win-

dows.

WARNING

DANGER

CAUTION

NOTE

01

ABBREVIATIONS; RISIK ASSEMBLY

WARNING AND SAFETY SYMBOLS IN THESE INSTRUCTIONS

Assembly Instruction

KS2 / KS2 TWIN

01

SAFETY INSTRUCTIONS

Danger spots by crush and shear points

Side-hung Bottom-hung Roof windows / skyskylight domes Louvre windows

Danger spots: crush and shear points

SAFETY INSTRUCTIONS

Important safety instructions: To ensu-

re safety of persons, these instructions

must be strictly observed.

Always keep these instructions available.

Risk of crushing and entrapment!

Window closes automatically!

When closing or opening the drive is stopped

by the drive-integrated or external electronic

load disconnection.

There is always enough pressure force to

crush ngers in case of carelessness.

Do not put your hand into the window rabbet or into the

moving chain during assembly work and operation !

Make sure that entrapment between the moving casement

and the x elements (i. e. wall), due to openings, is not pos-

sible.

Crush and shear points

Crush and shear points between casements and frames

must be secured up to a height of 2.5 m (bottom edge of

moving element) by devices that will stop the movement

by touch or interruption initiated by a person and prevent

any injury. A warning sign must be clearly attached to the

opening element.

On power-operated doors and gates danger spots of crush

and shear points must be secured against entrapment by

appropriate measures to prevent injuries.

Casements must be hung or secured such way that, in case

one of the mounting elements fails, it will not break away /

slam down or move in an uncontrolled manner by providing

double suspensions, safety scissors, casement stays.

Bottom-hung windows must be provided with safety scis-

sors or similar devices. Safety stays prevent damage and

injuries to persons which might result from improper instal-

lation and handling.

The safety scissors must match the opening stroke of the

drive (see technical data). This means: the opening width of

the safety scissors must be greater than the drive stroke in

order to avoid any blocking.

Mounting, Operation and Maintenance Instructions

These instructions shall allow professional assembly, com-

missioning and maintenance carried out by quali ed and

safety-minded electricians and/or skilled staff with in-depth

knowledge of electrical and mechanical drive assembly.

To ensure safe operation and avoid damage and risks the

system must be carefully assembled and adjusted according

to these assembly instructions. All dimensions have to be

veri ed at the place of installation and must be adjusted,

if required.

Please note the connection assignment, the

permissible drive voltage (see type plate), the

minimum and maximum performance data

(see technical data) and the assembly and in-

stallation notes and strictly adhere to them!

Never connect 24 V DC drives to 230 V supply!

Danger to life !

safety scissors

WARNING

Secure the window in front of inadvertent or

unintentional opening and against falling.

Assembly Instruction

KS2 / KS2 TWIN

01

SAFETY INSTRUCTIONS

Cable routing and electrical connection

Cable routing and electrical connections may only be car-

ried out by approved contractors. Secure power supply lines

230 / 400V AC separately on site. Before working on the

system the mains voltage supply and the emergency power

supply (i. e. batteries) shall be disconnected in all poles and

secured against unintended operation.

Never operate the drives, controllers, manual switches and

sensors on operating voltages and connections contrary to

the speci cations in the operating instructions.

All relevant regulations must be observed for the installa-

tion:

Erection of power installations with rated voltages below

1000 V

Installation of cables and lines

Fire behaviour of building materials and building compo-

nents

Specify suitable types of cable on consultation with the

competent local authorities, energy supply companies and

Employers’ Liability Insurance Associations. Please pay

especially regard to: All extra low-voltage lines (24 V DC)

must be laid separately from power cables. Flexible lines

must not be ush-mounted. Freely suspended lines must be

provided with strain relief.

All lines must be laid such way that they can

be neither sheared off, nor twisted or kinked

during operation.

All junction boxes and external drive controllers must be

positioned to allow access for maintenance work. The cable

type, lengths and sizes must comply with the technical

speci cations. Check connection points for tight t of the

screwed connections and cable ends.

All 230 V components shall allow disconnec-

tion in all poles from the mains power supply

prior to maintenance and repair work.

After mounting

and each modi cation to the structure, check all functions

in a test run. Once the system is completely installed, the

end-user must be instructed on all important operating

steps. The end-user must also be noti ed of the remaining

risks / hazards.

Ambient Conditions

The product must not be hit, dropped or exposed to vibra-

tions, moisture, aggressive gases or other damaging envi-

ronments unless it is approved for one or several of these

ambient conditions by the manufacturer.

Accident prevention regulations and guidelines is-

sued by the employers’ liability insurance association

When working at, in or on a building or part of a building

the speci cations and notes of the respective accident pre-

vention regulations (UVV) and the regulations and rules of

the employers’ liability insurance association (BGR) must be

observed and adhered to.

Declaration of Incorporation

The devices are manufactured and tested in accordance

with the European Directives. The appropriate declaration

of incorporation has been issued. You may only operate the

drive if there is a declaration of conformity within the mea-

ning of the Machinery Directive for the entire system.

Spare parts, fasteners, ttings and controllers

Only operate the drive with controllers built by the same

manufacturer. There is no liability, warranty or customer

service if third-party parts are used. If spare parts/ ttings

or extension parts are required, only original replacement

parts from the manufacturer may be used.

Range of Application

Exclusively suited for the automatic opening and closing of

the window types speci ed in these assembly instructions.

For any application not included in these instructions plea-

se consult the manufacturer or his authorized reseller for

further information.

Do not misuse device for any other lifting

operations.

Always check that your system complies with the applicable

regulations. Special attention shall be given to opening

width and opening area of the window, permissible t-

ting dimensions, opening time and opening speed, exerted

forces, temperature resistance of drive/devices and cables

as well as to the cross-section of the connection cable de-

pending on the cable length and the power consumption.

Required fastening material shall be selected and, if

necessary, completed to suit the drive and the exerted loads.

Make sure that all products installed are per-

manently protected from dirt and moisture

unless the drive is expressly suited for use in

damp or humid environments (see technical

data).

Mounting and fastening material

Required or supplied fastening material shall be selected

and, if necessary, supplemented to suit the building’s struc-

ture and the corresponding strain.

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S2 24V DC R/L

DATA SHEET KS2 S2 24V DC R/L

02

Application: Natural ventilation as single-drive

Internal load dependend cut-off switch S2 in OPEN / CLOSE direction

TECHNICAL DATA

UNRated voltage 24V DC (± 20 %), max. 2 Vpp

INRated current 0,5 A

IACut-off current 0,7 A

PNRated power 12 W

ED Duty cycle 30 % (ON: 3 min. / OFF: 7 min.)

Protection rating IP 32

Ambient temperature range -5 °C ... +75 °C

FZPulling force max. 200 N

FAPushing force 500150100200500400600300200ZugPullSchubPushs (mm)

F

(N)

800s > 600 mm only for pulling application

FHPullout force 1.800 N (fastening depended)

Chain Stainless steel

Connecting cable Non-halogen, grey 2 x 0,75 mm², ~ 3 m

v Speed 10,0 mm/s 10,0 mm/s

s Stroke 200 – 800 mm (± 5 %)

L Length see order data

OPTIONS

Special model PU / pcs. Part.-No.

Drive housing painted/powder coated in other RAL colours

Specify at order stage:

1 – 4 516004

5 – 9 516004

10 – 49 516004

50 – 99 516004

up 100 516004

Extra length connecting cable:

5 m – non-halogen, grey – 2 x 0,75 mm² 501024

10 m – non-halogen, grey – 2 x 0,75 mm² 501026

24V

(Right)

(Left)

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S2 24V DC R/L

EXPLANATIONS ON THE PRODUCT LABEL

02

Order Data

s [mm] L [mm] Version Finish PU / pcs. Part.-No.

200 335

KS2 200 S2 24V R (Right) E6/C-0 1 521120

RAL 9016 1 1001521120

KS2 200 S2 24V L (Left) E6/C-0 1 521420

RAL 9016 1 1001521420

300 380

KS2 300 S2 24V R (Right) E6/C-0 1 521130

RAL 9016 1 1001521130

KS2 300 S2 24V L (Left) E6/C-0 1 521430

RAL 9016 1 1001521430

400 430

KS2 400 S2 24V R (Right) E6/C-0 1 521140

RAL 9016 1 1001521140

KS2 400 S2 24V L (Left) E6/C-0 1 521440

RAL 9016 1 1001521440

500 545

KS2 500 S2 24V R (Right) E6/C-0 1 521150

RAL 9016 1 1001521150

KS2 500 S2 24V L (Left) E6/C-0 1 521450

RAL 9016 1 1001521450

600 545

KS2 600 S2 24V R (Right) E6/C-0 1 521160

RAL 9016 1 1001521160

KS2 600 S2 24V L (Left) E6/C-0 1 521460

RAL 9016 1 1001521460

800 625

KS2 800 S2 24V R (Right) E6/C-0 1 521180

RAL 9016 1 1001521180

KS2 800 S2 24V L (Left) E6/C-0 1 521480

RAL 9016 1 1001521480

KS2 400 S2 24V R

Made in Germany

Date: 14W36 V2.0

SN: 33942410002

Part.-No.: 521140

s: 400 mm

U: 24V DC

IA: 0,7 A

F: 200 N

ED: 30%

IP: 32

D-86672 Thierhaupten

Tel. 08271 / 8185-0 +75°C

-5°C

Version:

Right

load dependend

cut-off switch

24V

NOTE

The product label provides information on the most import-

ant caracteristics, such as:

• manufacturer‘s address

• article reference number and name

• technical caracteristics

• date of manufacturing with rmware version

• serial number

Never install and operate damaged

products.

In the event of any complaints, please indicate the

product serial number (SN) (see product label).

serial numberDuty cycle

ON: 3 minutes

OFF: 7 minutes article reference

number

date of manufacturing

with rmware version

EXPLANATIONS ON THE PRODUCT LABEL

stroke

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S2 230V AC R/L

DATA SHEET KS2 S2 230V AC R/L

02

Application: Natural ventilation as single-drive

Internal load dependend cut-off switch S2 in OPEN / CLOSE direction

Parallel connection up to 8 drives in one group

TECHNICAL DATA

UNRated voltage 230V AC (50 Hz)

INRated current 0,13 A

IACut-off current 0,2 A

PNRated power 30 W

ED Duty cycle 30 % (ON: 3 min. / OFF: 7 min.)

Protection rating IP 32

Ambient temperature range -5 °C ... +60 °C

FZPulling force max. 200 N

FAPushing force

s > 600 mm only for pulling application

FHPullout force 1.800 N (fastening depended)

Chain Stainless steel

Connecting cable Non-halogen, grey 6 x 0,75 mm², ~ 3 m

v Speed 10,0 mm/s 10,0 mm/s

s Stroke 200 – 800 mm (± 5 %)

L Length see order data

500150100200500400600300200ZugPullSchubPushs (mm)

F

(N)

800230V

(Right)

(Left)

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S2 230V AC R / L

02

Order Data

s [mm] L [mm] Version Finish PU / pcs. Part.-No.

200 475

KS2 200 S2 230V R (Right) E6/C-0 1 494920

RAL 9016 1 1001494920

KS2 200 S2 230V L (Left) E6/C-0 1 494720

RAL 9016 1 1001494720

300 520

KS2 300 S2 230V R E6/C-0 1 494930

RAL 9016 1 1001494930

KS2 300 S2 230V L E6/C-0 1 494730

RAL 9016 1 1001494730

400 570

KS2 400 S2 230V R E6/C-0 1 494940

RAL 9016 1 1001494940

KS2 400 S2 230V L E6/C-0 1 494740

RAL 9016 1 1001494740

500 685

KS2 500 S2 230V R E6/C-0 1 494950

RAL 9016 1 1001494950

KS2 500 S2 230V L E6/C-0 1 494750

RAL 9016 1 1001494750

600 685

KS2 600 S2 230V R E6/C-0 1 494960

RAL 9016 1 1001494960

KS2 600 S2 230V L E6/C-0 1 494760

RAL 9016 1 1001494760

800 765

KS2 800 S2 230V R E6/C-0 1 494980

RAL 9016 1 1001494980

KS2 800 S2 230V L E6/C-0 1 494780

RAL 9016 1 1001494780

OPTIONS

Special model PU / pcs. Part.-No.

Drive housing painted/powder coated in other RAL colours

Specify at order stage:

1 – 4 516004

5 – 9 516004

10 – 49 516004

50 – 99 516004

up 100 516004

Extra length connecting cable:

5 m – non-halogen, grey – 6 x 0,75 mm² 501164

10 m – non-halogen, grey – 6 x 0,75 mm² 501166

230V

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S12 24V DC R

DATA SHEET KS2 S12 24V DC R

02

Application: natural ventilation, SHEV, ferralux®-NSHEV

Internal intelligent cut-off switch S12

Z-Version: Programmable feedback limit position „OPEN“ and „CLOSE“ (max. 24V, 500 mA)

Programmable special functions

M-COM for automatic synchronised run of multi drive systems and automatic sequence

control with FV locking drives (S3/S12 SW V2)

TECHNICAL DATA

UNRated voltage 24V DC (± 20 %), max. 2 Vpp

INRated current 0,7 A

IACut-off current 1,0 A

PNRated power 17 W

ED Duty cycle 30 % (ON: 3 min. / OFF: 7 min.)

Protection rating IP 32

Ambient temperature range -5 °C ... +75 °C

FZPulling force max. 250 N

FAPushing force 500250150100200500400600300200s (mm)

F

(N)

800ZugPullSchubPushs > 600 mm only for pulling application

FHPullout force 1.800 N (fastening depended)

Chain Stainless steel

Connecting cable Non-halogen, grey 3 x 0,5 mm², ~ 3 m

Z-Version: 5 x 0,5 mm² ~ 3 m

v Speed s < 400 8,0 mm/s 8,0 mm/s

s 500 – 600 12,0 mm/s 8,0 mm/s

s > 600 13,5 mm/s 8,0 mm/s

s Stroke 200 – 800 mm (± 5 %)

L Length see order data

24V

(Right)

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S12 24V DC R

02

Order Data

s [mm] L [mm] Version Finish PU / pcs. Part.-No.

200 335

KS2 200 S12 24V R (Right) E6/C-0 1 521620

RAL 9016 1 1001521620

KS2 200 S12 24V R Z E6/C-0 1 521623

RAL 9016 1 1001521623

300 380

KS2 300 S12 24V R E6/C-0 1 521630

RAL 9016 1 1001521630

KS2 300 S12 24V R Z E6/C-0 1 521633

RAL 9016 1 1001521633

400 430

KS2 400 S12 24V R E6/C-0 1 521640

RAL 9016 1 1001521640

KS2 400 S12 24V R Z E6/C-0 1 521643

RAL 9016 1 1001521643

500 545

KS2 500 S12 24V R E6/C-0 1 521650

RAL 9016 1 1001521650

KS2 500 S12 24V R Z E6/C-0 1 521653

RAL 9016 1 1001521653

600 545

KS2 600 S12 24V R E6/C-0 1 521660

RAL 9016 1 1001521660

KS2 600 S12 24V R Z E6/C-0 1 521663

RAL 9016 1 1001521663

800 625

KS2 800 S12 24V R E6/C-0 1 521680

RAL 9016 1 1001521680

KS2 800 S12 24V R Z E6/C-0 1 521683

RAL 9016 1 1001521683

OPTIONS

Special model PU / pcs. Part.-No.

Drive housing painted/powder coated in other RAL colours

Specify at order stage:

1 – 4 516004

5 – 9 516004

10 – 49 516004

50 – 99 516004

up 100 516004

Extra length connecting cable:

5 m – non-halogen, grey – 3 x 0,5 mm² 501034

10 m – non-halogen, grey – 3 x 0,5 mm² 501036

5 m – non-halogen, grey – 5 x 0,5 mm² 501054

10 m – non-halogen, grey – 5 x 0,5 mm² 501056

Microprocessor programming S12

Electronic stroke reduction 524190

Special functions 524180

Optional accessories PU / pcs. Part.-No.

M-COM Comm. module for synchronised multi-drive systems 1 524177

24V

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S12 24V DC L

DATA SHEET KS2 S12 24V DC L

02

Application: natural ventilation, SHEV, ferralux®-NSHEV

Internal intelligent cut-off switch S12

Z-Version: Programmable feedback limit position „OPEN“ and „CLOSE“ (max. 24V, 500 mA)

Programmable special functions

M-COM for automatic synchronised run of multi drive systems and automatic sequence

control with FV locking drives (S3/S12 SW V2)

TECHNICAL DATA

UNRated voltage 24V DC (± 20 %), max. 2 Vpp

INRated current 0,7 A

IACut-off current 1,0 A

PNRated power 17 W

ED Duty cycle 30 % (ON: 3 min. / OFF: 7 min.)

Protection rating IP 32

Ambient temperature range -5 °C ... +75 °C

FZPulling force max. 250 N

FAPushing force 500250150100200500400600300200s (mm)

F

(N)

800ZugPullSchubPushs > 600 mm only for pulling application

FHPullout force 1.800 N (fastening depended)

Chain Stainless steel (1.4310)

Connecting cable Non-halogen, grey 3 x 0,5 mm², ~ 3 m

Z-Version: 5 x 0,5 mm² ~ 3 m

v Speed s < 400 8,0 mm/s 8,0 mm/s

s 500 – 600 12,0 mm/s 8,0 mm/s

s > 600 13,5 mm/s 8,0 mm/s

s Stroke 200 – 800 mm (± 5 %)

L Length see order data

24V

(Left)

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S12 24V DC L

02

ORDER DATA

s [mm] L [mm] Version Finish PU / pcs. Part.-No.

200 335

KS2 200 S12 24V L (Left) E6/C-0 1 521720

RAL 9016 1 1001521720

KS2 200 S12 24V L Z E6/C-0 1 521723

RAL 9016 1 1001521723

300 380

KS2 300 S12 24V L E6/C-0 1 521730

RAL 9016 1 1001521730

KS2 300 S12 24V L Z E6/C-0 1 521733

RAL 9016 1 1001521733

400 430

KS2 400 S12 24V L E6/C-0 1 521740

RAL 9016 1 1001521740

KS2 400 S12 24V L Z E6/C-0 1 521743

RAL 9016 1 1001521743

500 545

KS2 500 S12 24V L E6/C-0 1 521750

RAL 9016 1 1001521750

KS2 500 S12 24V L Z E6/C-0 1 521753

RAL 9016 1 1001521753

600 545

KS2 600 S12 24V L E6/C-0 1 521760

RAL 9016 1 1001521760

KS2 600 S12 24V L Z E6/C-0 1 521763

RAL 9016 1 1001521763

800 625

KS2 800 S12 24V L E6/C-0 1 521780

RAL 9016 1 1001521780

KS2 800 S12 24V L Z E6/C-0 1 521783

RAL 9016 1 1001521783

OPTIONS

Special model PU / pcs. Part.-No.

Drive housing painted/powder coated in other RAL colours

Specify at order stage:

1 – 4 516004

5 – 9 516004

10 – 49 516004

50 – 99 516004

up 100 516004

Extra length connecting cable:

5 m – non-halogen, grey – 3 x 0,5 mm² 501034

10 m – non-halogen, grey – 3 x 0,5 mm² 501036

5 m – non-halogen, grey – 5 x 0,5 mm² 501054

10 m – non-halogen, grey – 5 x 0,5 mm² 501056

Microprocessor programming S12

Electronic stroke reduction 524190

Special functions 524180

Optional accessories PU / pcs. Part.-No.

M-COM Comm. module for synchronised multi-drive systems 1 524177

24V

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S12 230V AC R

DATA SHEET KS2 S12 230V AC R

02

Application: natural ventilation

Internal intelligent cut-off switch S12

Parallel connection up to 8 drives in one group

Z-Version: Programmable feedback limit position „OPEN“ and „CLOSE“

(max. 24V, 500 mA)

Programmable synchronised run (max. 4 drives) and special functions

TECHNICAL DATA

UNRated voltage 230V AC (50 Hz)

INRated current 0,13 A

IACut-off current 0,2 A

PNRated power 30 W

ED Duty cycle 30 % (ON: 3 min / OFF: 7 min.)

Protection rating IP 32

Ambient temperature range -5 °C ... +60 °C

FZPulling force max. 250 N

FAPushing force 500250150100200500400600300200s (mm)

F

(N)

800ZugPullSchubPushs > 600 mm only for pulling application

FHPullout force 1.800 N (fastening depended)

Chain Stainless steel

Connecting cable Non-halogen, grey 6 x 0,75 mm², ~ 3 m

v Speed 8,0 mm/s 8,0 mm/s

s Stroke 200 – 800 mm (± 5 %)

L Length see order data

230V

(Right)

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S12 230V AC R

02

ORDER DATA

s [mm] L [mm] Version Finish PU / pcs. Part.-No.

200 475

KS2 200 S12 230V R (Right) E6/C-0 1 494020

RAL 9016 1 1001494020

KS2 200 S12 230V R Z E6/C-0 1 494023

RAL 9016 1 1001494023

300 520

KS2 300 S12 230V R E6/C-0 1 494030

RAL 9016 1 1001494030

KS2 300 S12 230V R Z E6/C-0 1 494033

RAL 9016 1 1001494033

400 570

KS2 400 S12 230V R E6/C-0 1 494040

RAL 9016 1 1001494040

KS2 400 S12 230V R Z E6/C-0 1 494043

RAL 9016 1 1001494043

500 685

KS2 500 S12 230V R E6/C-0 1 494050

RAL 9016 1 1001494050

KS2 500 S12 230V R Z E6/C-0 1 494053

RAL 9016 1 1001494053

600 685

KS2 600 S12 230V R E6/C-0 1 494060

RAL 9016 1 1001494060

KS2 600 S12 230V R Z E6/C-0 1 494063

RAL 9016 1 1001494063

800 765

KS2 800 S12 230V R E6/C-0 1 494080

RAL 9016 1 1001494080

KS2 800 S12 230V R Z E6/C-0 1 494083

RAL 9016 1 1001494083

OPTIONS

Special model PU / pcs. Part.-No.

Drive housing painted/powder coated in other RAL colours

Specify at order stage:

1 – 4 516004

5 – 9 516004

10 – 49 516004

50 – 99 516004

up 100 516004

Extra length connecting cable:

5 m – non-halogen, grey – 6 x 0,75 mm² 501164

10 m – non-halogen, grey – 6 x 0,75 mm² 501166

Microprocessor programming S12

Synchronised multi-drive set functions 495588

Electronic stroke reduction 495590

Special functions 524180

230V

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S12 230V AC L

DATA SHEET KS2 S12 230V AC L

02

Application: natural ventilation

Internal intelligent cut-off switch S12

Parallel connection up to 8 drives in one group

Z-Version: Programmable feedback limit position „OPEN“ and „CLOSE“

(max. 24V, 500 mA)

Programmable synchronised run (max. 4 drives) and special functions

TECHNICAL DATA

UNRated voltage 230V AC (50 Hz)

INRated current 0,13 A

IACut-off current 0,2 A

PNRated power 30 W

ED Duty cycle 30 % (ON: 3 min / OFF: 7 min.)

Protection rating IP 32

Ambient temperature range -5 °C ... +60 °C

FZPulling force max. 250 N

FAPushing force

500250150100200500400600300200s (mm)

F

(N)

800ZugPullSchubPushs > 600 mm only for pulling application

FHPullout force 1.800 N (fastening depended)

Chain Stainless steel (1.4310)

Connecting cable Non-halogen, grey 6 x 0,75 mm², ~ 3 m

v Speed 8,0 mm/s 8,0 mm/s

s Stroke 200 – 800 mm (± 5 %)

L Length see order data

230V

(Left)

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S12 230V AC L

02

OPTIONS

Special model PU / pcs. Part.-No.

Drive housing painted/powder coated in other RAL colours

Specify at order stage:

1 – 4 516004

5 – 9 516004

10 – 49 516004

50 – 99 516004

up 100 516004

Extra length connecting cable:

5 m – non-halogen, grey – 6 x 0,75 mm² 501164

10 m – non-halogen, grey – 6 x 0,75 mm² 501166

Microprocessor programming S12

Synchronised multi-drive set functions 495588

Electronic stroke reduction 495590

Special functions 524180

ORDER DATA

s [mm] L [mm] Version Finish PU / pcs. Part.-No.

200 475

KS2 200 S12 230V L (Left) E6/C-0 1 494120

RAL 9016 1 1001494120

KS2 200 S12 230V L Z E6/C-0 1 494123

RAL 9016 1 1001494123

300 520

KS2 300 S12 230V L E6/C-0 1 494130

RAL 9016 1 1001494130

KS2 300 S12 230V L Z E6/C-0 1 494133

RAL 9016 1 1001494133

400 570

KS2 400 S12 230V L E6/C-0 1 494140

RAL 9016 1 1001494140

KS2 400 S12 230V L Z E6/C-0 1 494143

RAL 9016 1 1001494143

500 685

KS2 500 S12 230V L E6/C-0 1 494150

RAL 9016 1 1001494150

KS2 500 S12 230V L Z E6/C-0 1 494153

RAL 9016 1 1001494153

600 685

KS2 600 S12 230V L E6/C-0 1 494160

RAL 9016 1 1001494160

KS2 600 S12 230V L Z E6/C-0 1 494163

RAL 9016 1 1001494163

800 765

KS2 800 S12 230V L E6/C-0 1 494180

RAL 9016 1 1001494180

KS2 800 S12 230V L Z E6/C-0 1 494183

RAL 9016 1 1001494183

230V

Assembly Instruction

KS2 / KS2 TWIN

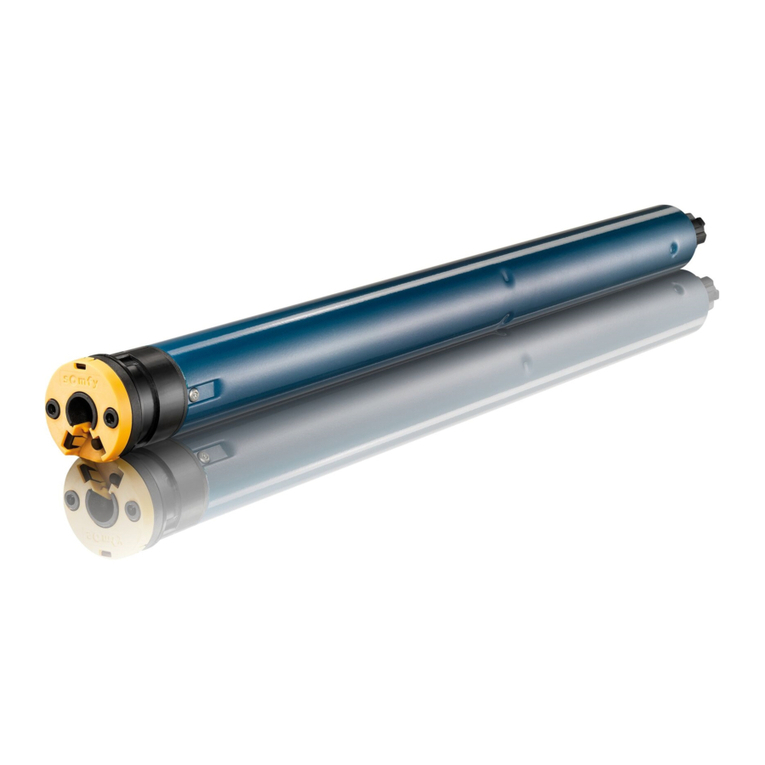

DATA SHEET KS2 TWIN S12 24V DC

DATA SHEET KS2 TWIN S12 24V DC

02

Application: natural ventilation, RWA

Internal intelligent cut-off switch S12

Z-Version: Programmable feedback limit position „OPEN“ and „CLOSE“ (max. 24V, 500 mA)

Programmable special functions

M-COM for automatic synchronised run of multi drive systems and automatic sequence

control with FV locking drives (S3/S12 SW V2)

TECHNICAL DATA

U

N

Rated voltage 24V DC (± 20 %), max. 2 Vpp

I

N

Rated current 1,4 A

I

A

Cut-off current 2,0 A

P

N

Rated power 34 W

ED Duty cycle 30 % (ON: 3 min / OFF: 7 min.)

Protection rating IP 32

Ambient temperature range -5 °C ... +75 °C

F

Z

Pulling force max. 500 N

F

A

Pushing force

1000500300200400500400600300200s (mm)

F

(N)

ZugPullSchubPush

F

H

Pullout force 1.800 N (fastening depended)

Chain Stainless steel

Connecting cable Non-halogen, grey 3 x 0,5 mm², ~ 3 m

Z-Version: 5 x 0,5 mm² ~ 3 m

v Speed s < 400 8,0 mm/s 8,0 mm/s

s 500 – 600 12,0 mm/s 8,0 mm/s

s Stroke 200 – 600 mm (± 5 %)

L Length see order data

LM Distance in between chains see order data

24V

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 TWIN S12 24V DC

02

Order Data

s [mm] L [mm] LM [mm] Version Finish PU / pcs. Part.-No.

200 640 350 KS2 TWIN 200 S12 24V E6/C-0 1 521820

KS2 TWIN 200 S12 24V Z E6/C-0 1 521823

400 830 540 KS2 TWIN 400 S12 24V E6/C-0 1 521840

KS2 TWIN 400 S12 24V Z E6/C-0 1 521843

500 1060 770 KS2 TWIN 500 S12 24V E6/C-0 1 521850

KS2 TWIN 500 S12 24V Z E6/C-0 1 521853

600 1060 770 KS2 TWIN 600 S12 24V E6/C-0 1 521860

KS2 TWIN 600 S12 24V Z E6/C-0 1 521863

OPTIONS

Special model PU / pcs. Part.-No.

Drive housing painted/powder coated in other RAL colours

Specify at order stage:

1 – 4 516004

5 – 9 516004

10 – 49 516004

50 – 99 516004

up 100 516004

Extra length connecting cable:

5 m – non-halogen, grey – 3 x 0,5 mm² 501034

10 m – non-halogen, grey – grau 3 x 0,5 mm² 501036

5 m – non-halogen, grey – 5 x 0,5 mm² 501054

10 m – non-halogen, grey – 5 x 0,5 mm² 501056

Microprocessor programming S12

Elektronische Strokeverkürzung ( Antriebe 24V DC) 524190

Special functions 524180

Optional accessories PU / pcs. Part.-No.

M-COM Comm. module for synchronised multi-drive systems 1 524177

24V

Assembly Instruction

KS2 / KS2 TWIN

DATA SHEET KS2 S12 230V AC TANDEM-SET

DATA SHEET KS2 S12 230V AC TANDEM-SET

02

TECHNICAL DATA

U

N

Rated voltage 230V AC (50 Hz)

I

N

Rated current 0,15 A

I

A

Cut-off current 0,2 A

P

N

Rated power 35 W

ED Duty cycle 30 % (ON: 3 min. / OFF: 7 min.)

Protection rating IP 32

Ambient temperature range -5 °C ... +60 °C

F

Z

Pulling force max. 2 x 250 N

F

A

Pushing force

1000500300200400500400600300200s (mm)

F

(N)

ZugPullSchubPush

s > 600 mm only for pulling application

F

H

Pullout force 1.800 N (fastening depended)

Chain Stainless steel

Connecting cable Master: Non-halogen, grey

Slave: Non-halogen, grey

6 x 0,75 mm², ~ 3 m

3 x 0,5 mm², ~ 3 m

3 x 0,5 mm², ~ 3 m

v Speed 8,0 mm/s 8,0 mm/s

s Stroke 200 – 800 mm (± 5 %)

L Length see order data

Application: natural ventilation

Factory-confi gured set includes:

Master: KS2 S12 230V AC R / L with voltage output 24V DC

Slave: KS2 S12 24V DC R / L with conection cable on the motor side

KS2 S12 24V DC L-K with conection cable on the chain side

Sequence control with FV locking drives (S3/S12 SW V2)

Parallel connection up to 8 sets of drives in one group

Junction box to be site supplied

Programmable special functions and sequence control with FV locking drives (S3/S12 SW V2)

Screw terminal connections in drive housing upon request

230V

This manual suits for next models

1

Table of contents

Other Aumuller DC Drive manuals

Aumuller

Aumuller KS 15 800 S12 Training manual

Aumuller

Aumuller KS4 S12 24V DC R Training manual

Aumuller

Aumuller KS4 S12 24V DC R Training manual

Aumuller

Aumuller PLS15 S12 24V DC Series Training manual

Aumuller

Aumuller FV1 Training manual

Aumuller

Aumuller FVM2 Training manual

Aumuller

Aumuller LKS S2 24V DC Training manual

Aumuller

Aumuller KS2 S2 24V DC R/L Training manual

Aumuller

Aumuller PLS S12 24V DC Training manual

Aumuller

Aumuller ferralux KSA Series User manual