a. Do Not conduct any wiring during the system power ON to avoid the electric shock.

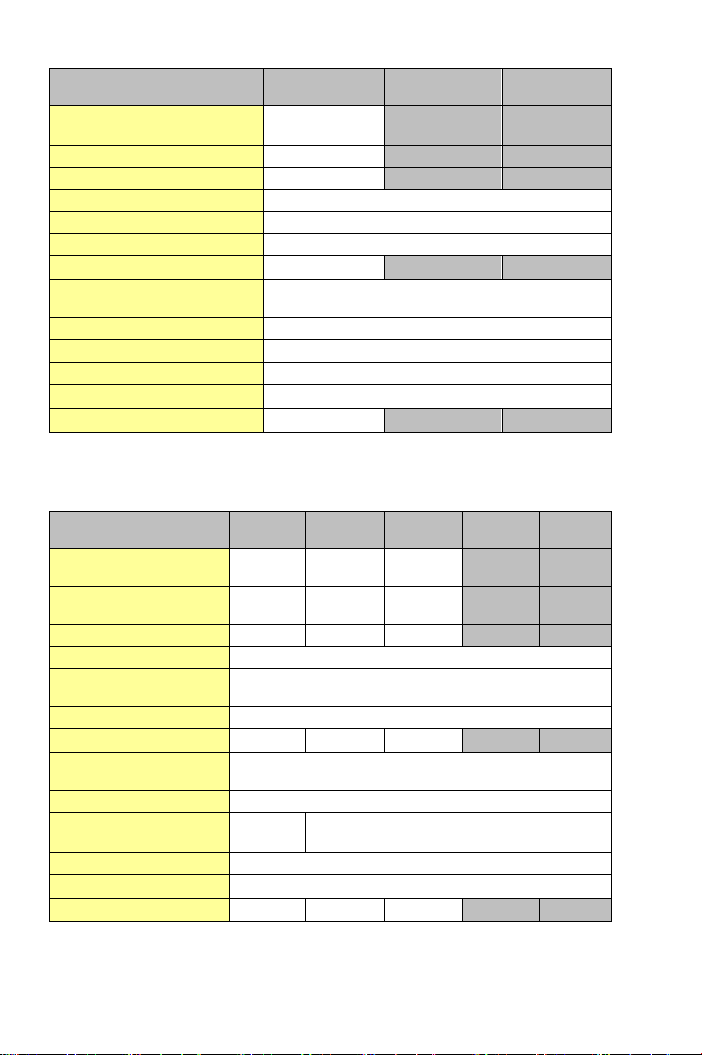

b. R/L1,S/L2,T/L3 are power inputs (electric source terminals) and U/T1,V/T2,W/T3

are drive’s outputs connecting to a motor. Please Do Not connect these input and

output terminals to P, P○

+, N, N○

-, P1 and PR terminals.

c. Once the wiring is completed, the cover of the drive must be put back and must

seal the drive to avoid other’s accidental contact.

d. 100V or 200V series drives must not be connected to the electric source of

346/380/415/440/460/480V.

e. The main circuit and multi-function terminals cannot connect to ground

terminal(PE).

f. PE terminal must be exactly grounded. Ground the drive in compliance with

the NEC standard or local electrical code.

g. Please refer to the “section Description of Terminals”for the screwing torque

of the wiring terminal.

h. Please refer to the national or local electric code for the appropriate spec. of the

cords and wires.

i. Please install the thermal relay between the individual motor and the drive when

using one drive to propel several motors.

j. Do Not connect power factor leading capacitor, surge absorber, or

non-three-phase motor to drive’s U/T1,V/T2,W/T3 side.

k. AC reactor (ACL) installation is required when the power capacity exceeds

500kVA or 10 times or more than the drive rated capacity.

l. After power off (30HP below models must wait at least 5 minutes; 40HP~75HP

models must wait at least 10 minutes; 100HP above models must wait at least

20 minutes). Do Not touch the drive or perform any unwiring actions before drive

indicator light (CHARGE) turns off. Use a multimeter with the DC voltage stage

to measure the cross voltage between P(+) and N(-) ports (DC bus voltage must

be less than 25V).

m. When the motor do the voltage-proof, insulation testing, unwiring the

U/T1,V/T2,W/T3 terminal of drive at first.