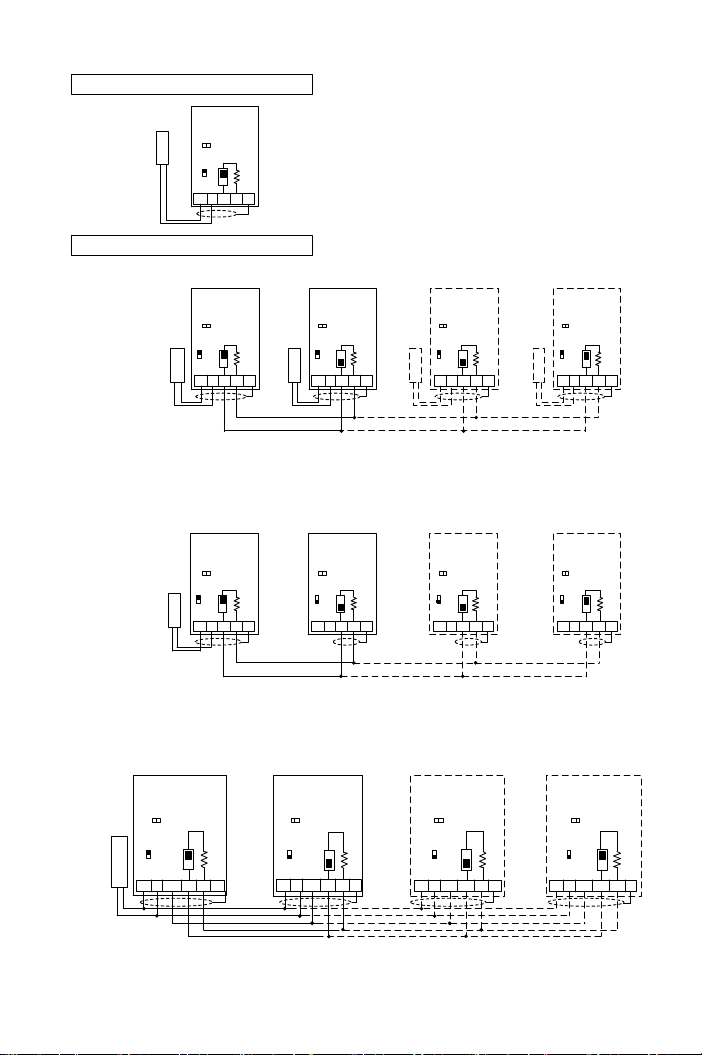

Drive #0

I

V

Pressure

transmitter

Drive #0 Drive #1 Drive #2

I

V

I

V

I

V

Pressure

transmitter

1. JP4: Drive #0 àI position; Drive #1 ~ #3 àV position

2. JP1: Drive #0 àopen; Drive #1 ~ #3 àclose

3. DSW3: Drive #0 and Drive #3 àON position; Drive #1 and #2 à1 position

4. Set the number for every drive by F_016

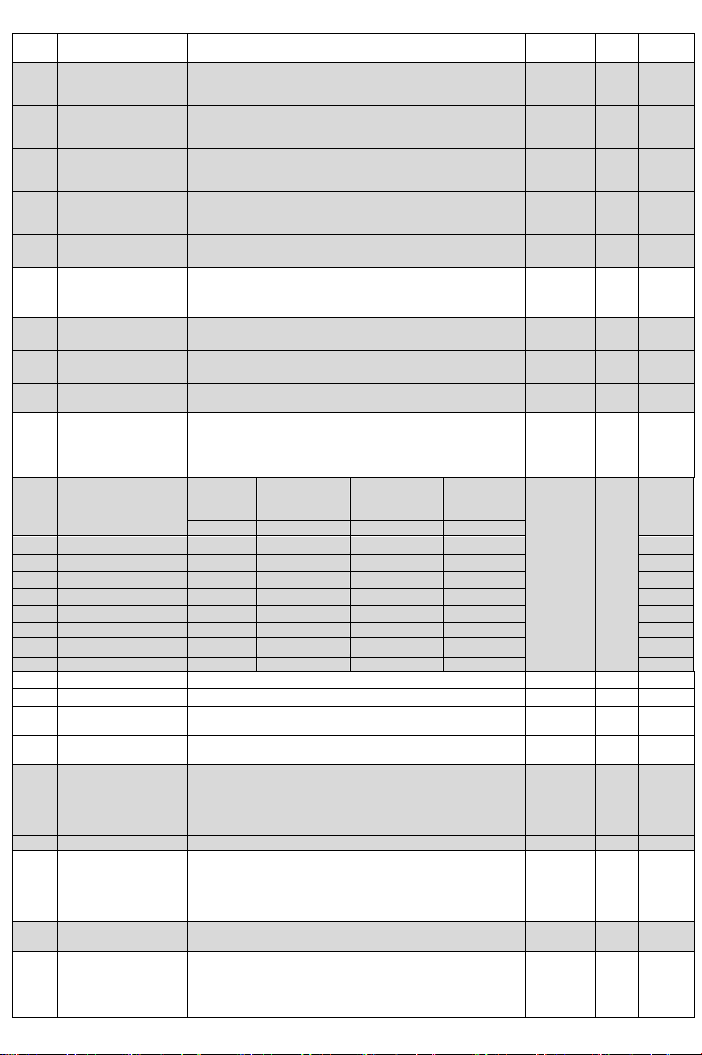

Single Pump Control(F_015=1)

2. Parallel control for four pumps with one pressure transmitter (special wiring)

1. Parallel control for four pumps with four pressure transmitters (standard wiring)

Drive #0 Drive #1 Drive #2

ON

I

V

I

V

I

V

Pressure

transmitter Pressure

transmitter Pressure

transmitter

1. JP4: Drive #0 àI position; Drive #1 ~ #3 àV position

2. JP1: Drive #0 àopen; Drive #1 ~ #3 àclose

3. DSW3: Drive #0 and Drive #3 àON position; Drive #1 and #2 à1 position

4. Set the number for every drive by F_016

3. Parallel control for four pumps with one pressure transmitter (special wiring)

1. JP4: Drive #0 ~ #3 àI position

2. JP1: Drive #0 ~ #3 àopen

3. DSW3: Drive #0 and Drive #3 àON position; Drive #1 and #2 à1 position

4. Set the number for every drive by F_016

Multi-Pump Control(F_015=2,3,4)

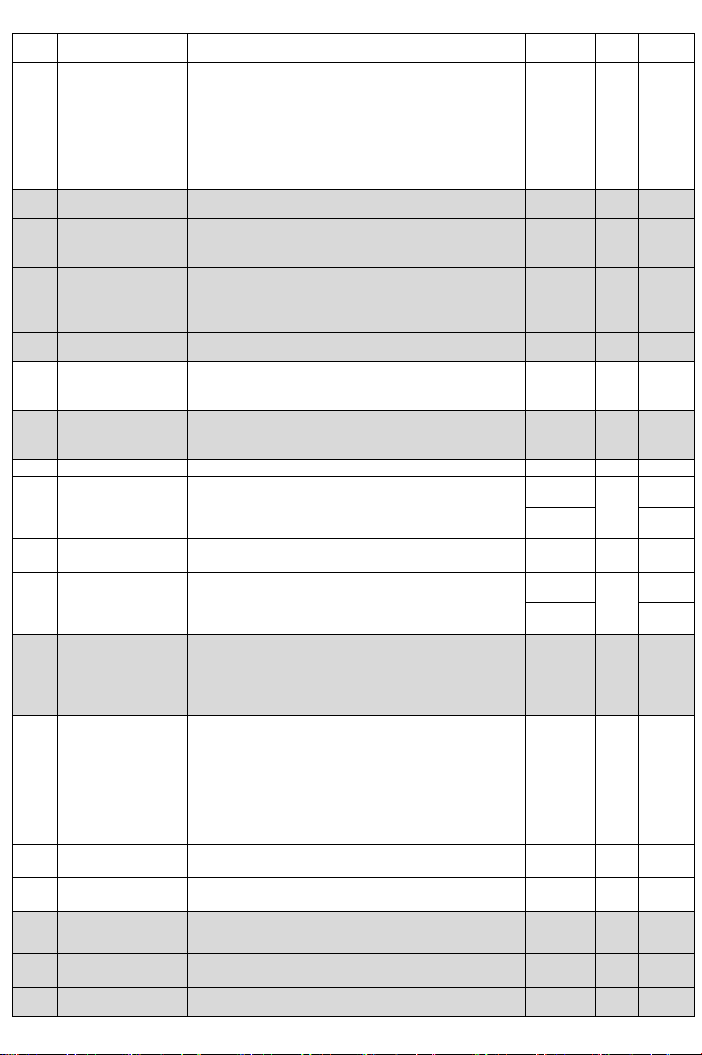

Drive #3

I

V

Pressure

transmitter

Drive #3

I

V

DSW3

JP4 JP4 JP4 JP4

JP4 JP4 JP4 JP4

JP4

ON

DSW3

1

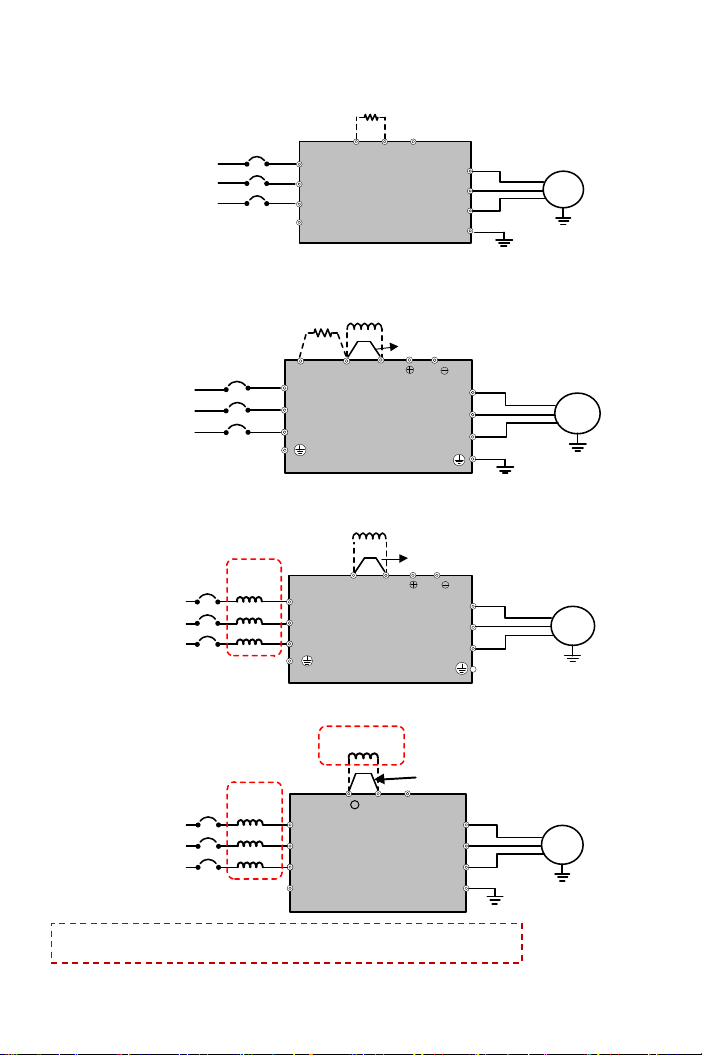

1. JP4: I position

2. JP1: Open

3. DSW3: ON position

4.F_015=1

JP4: Input signal type selection of Iin

JP1: Input impedance selection of Iin

DSW3: Terminal resistor switch

F_015: Selection of Pump Control Mode

F_016: Set Drive’s No for Parallel Control

1

ON

DSW3

1

ON

DSW3

1

ON

DSW3

1

ON

DSW3

1

ON

DSW3

1

ON

DSW3

1

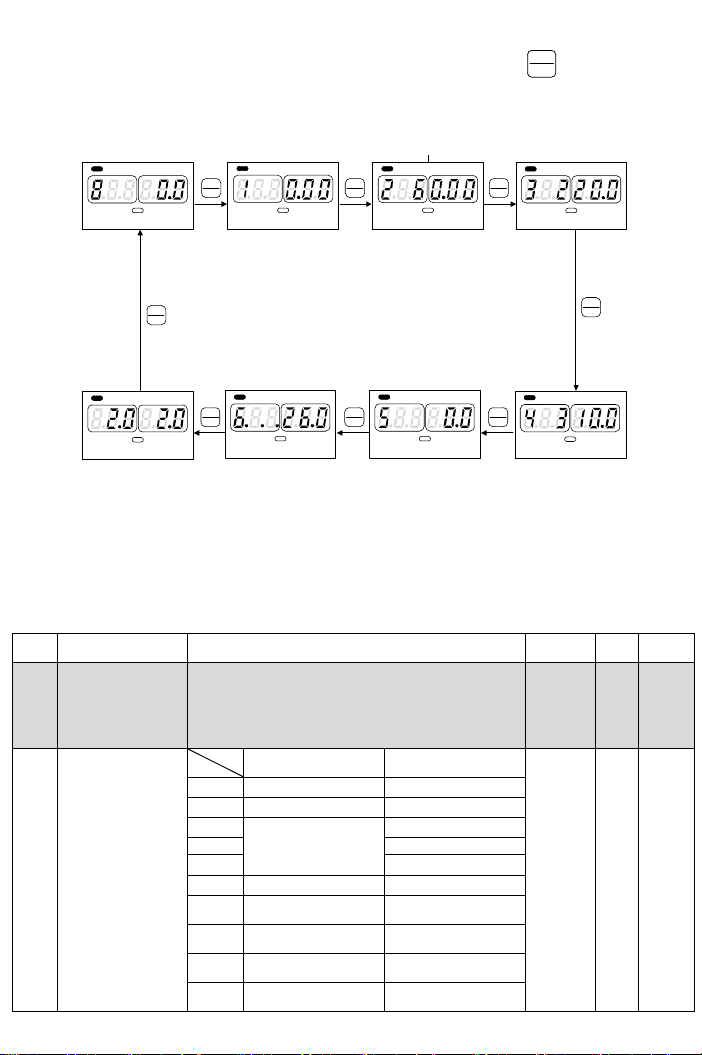

P24 Iin DX+DX- FG

P24 Iin DX+ DX- FG

P24 Iin DX+ DX- FG P24 Iin DX+ DX- FG P24 Iin DX+ DX- FG

P24 Iin DX+DX- FG P24 Iin DX+DX- FG

ON

DSW3

1

P24 Iin DX+ DX- FG

P24 Iin DX+ DX- FG

JP1

JP1 JP1 JP1 JP1

JP1 JP1 JP1 JP1

–+

–+–+–+–+

–+

Drive #0

- +

Drive #1 Drive #2

ON

I

V

I

V

I

V

Pressure

transmitter

Drive #3

I

V

DSW3

JP4 JP4 JP4 JP4

1ON

DSW3

1ON

DSW3

1ON

DSW3

1

P24 Iin DX+DX- FG P24 Iin DX+ DX- FG P24 Iin DX+ DX- FG

P24 Iin DX+DX- FG

JP1 JP1 JP1 JP1

GND GND GND GND