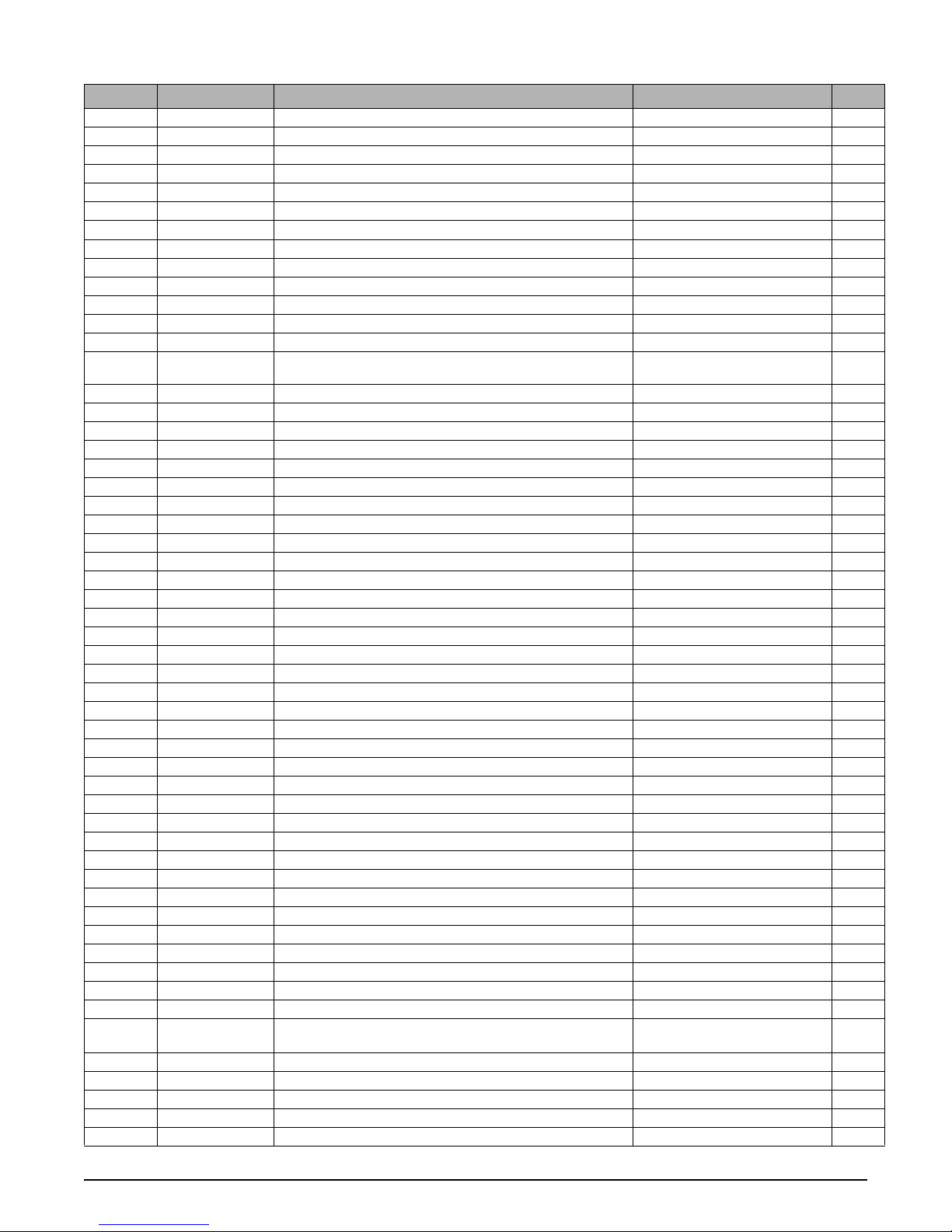

Parts 5

46 Center Stud – Bearing Cylinder Stainless Steel 304 1

47 Circle Clip Ø21 Stainless Steel A2 1

49 Ball Bearing (608 2rs) Ø22/8 E.7 Stainless Steel 1

51 Support Bracket – Housing – Rail Slide Stainless Steel 304 1

52 Screw CHC M6-16 Stainless Steel A2 2

53 Circle Clip Ø8 Stainless Steel A2 1

54 Elastic Band, F5-13-13-10 Polyvinyl 2

55 Ring – Bronze, Ø14/12 Lg,12 Bronze 2

56 Spring Stainless Steel 2

57 Spring Cylinder Stainless Steel 304 1

58 Screw M6-8 Stainless Steel A2 1

59 Screw – Front Slide Rail Stainless Steel 304 1

60 Spring Stainless Steel 2

61 Cylinder Bearing - Round Slide Rail Ø28/25,

C3-151-25-28-20

PTFE 2

63 Screw – Rear Slide Rail Stainless Steel 304 1

71 Front Slide Rail 1

102 Screw – Index Control Excentrique, Sans Tete M8 Stainless Steel A2 2

103 153681 Foot 4

120 153686 Roller Bearing – Knife, 6004 2RS 1

132 Knob – Shaft – Knife Cover Stainless Steel 304 1

GR1 Body/Base Stainless Steel 304 1

GR100 Cover - Screw - Product Grip Slide Rail Stainless Steel 304 1

GR110 153683 Belt Polyvinyl 1

GR112 Pulley Shaft Stainless Steel 304 1

GR113 Pulley Shaft Alunimnium 2017 1

GR12 153677 Bronze Screw M8-30 Bronze 2

GR121 Cirle cliip Ø19 Stainless Steel A2 1

GR122 Circle Clip Ø42 Stainless Steel A2 1

GR123 Knife Cover Stainless Steel 304 1

GR130 Pilot - Screw - Upper Ring Guard - Knife Stainless Steel 304 1

GR131 Shaft - Knife Cover Stainless Steel 304 1

GR134 Gasket - Knife NBR 1

GR14 Body Rail Stainless Steel 304 1

GR140 Motor Stand P2 Stainless Steel 304 1

GR144 Screw M8-20 Stainless Steel A2 1

GR145 Motor Stand P1 Stainless Steel 304 1

GR146 Belt Protection Stainless Steel 304 1

GR15 153679 Excentrique ERTACETAL 1

GR150 Spring Stainless Steel A2 1

GR151 Housing - Rail Slide Bolt Stainless Steel 304 1

GR152 Bearing 1

GR153 Pilot Ring - Bronze bronze 1

GR154 Plastic Washer Plastique 1

GR16 Ring Excentrique Stainless Steel 304 1

GR2 Gauge Plate Stainless Steel 304 1

GR20 Gasket - Indexing Control Knob PTFE 1

GR21 Indexing Control Knob Stainless Steel 304 1

GR27 153680 Knife Shaft Gasket PTFE 1

GR6 Mount - Gauge Plate Stainless Steel 304 +

Stainless Steel RECTIFIE

1

GR62 Round Slide Rail ACIER CHROME 1

GR70 Ring Guard - Knife Stainless Steel 304 1

GR8 Coupling Guide Stainless Steel 304 1

GR81 Carriage Tray Support Stainless Steel 304 1

VT22 133084 Knife Ø300 ACIER CHROME 1

Item # Part No. Description Reference Qty