6

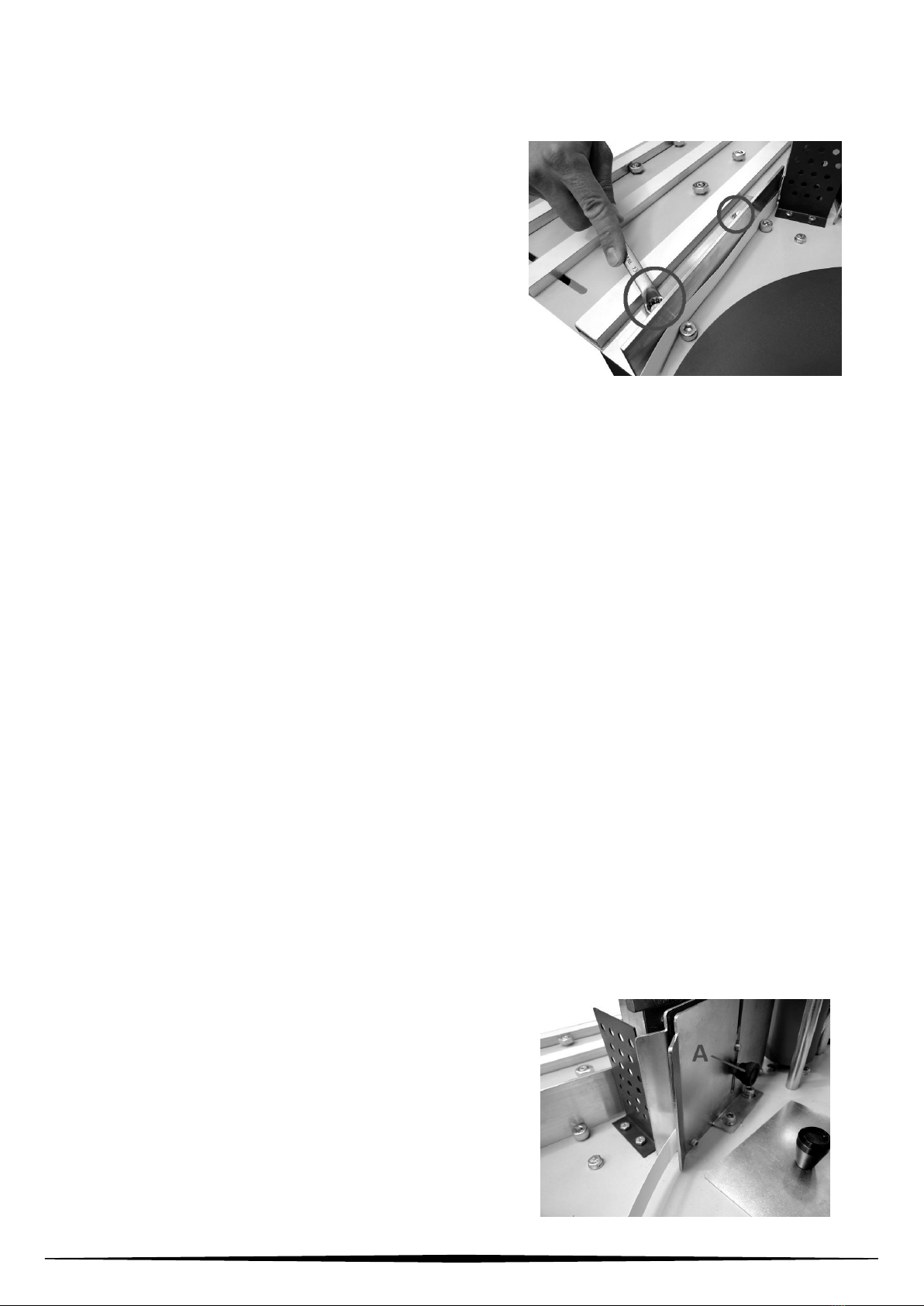

- Position the tape to the zero point, in other words, at

the point where the wood touches the tape, taking it with

a little left over to be cutted.

- Your tape is regulated.

The operations made by the Edgebander CBC.E, as well

as any other machine, can pose risks to the operator if

the instructions in this section are not taken into account.

These instructions are written with the understanding

that the operator has the knowledge and skills

necessary to operate this machine. If at any time you

feel difficulty performing any operation, stop using the

machine. If you are an inexperienced operator, we

recommend that you read books, technical papers, or

seeks training from an experienced operator before

performing any operation unknown. The machine must

operate with all the protections and security systems that

comes standard.

Above all, your safety must come first.

1. STARTING AND CONTROL

To turn on your CBC.E MAKSIWA proceed as follows:

- Connect the previously installed outlet at 110V single

phase supply.

- On the control panel you will find different commands.

Get to know each of them and their functions:

1. Turn the main switch (1). This key energizes the

machine's panel, without turning it on.

2. Emergency Button (2) (red mushroom): When

triggered, instantly shuts down all machine controls. To

release it, just rotate clockwise.

3. On Button (3) (green): This button turns the machine,

activates other commands and starts the process of

heating the glue. If the machine does not turn on and the

light does not turn on when you press this button, make

sure the main switch has been turned on and the

emergency button is not activated.

4. Off Button (4) (red): This button turns off the machine

by turning off all the functions, including heating the

glue.

5. Feeder Switch (5): This button activates the feeder

(rubber and glue axis). But this button will only be

released after the glue reaches the set temperature.

6. Temperature controller (6): It has two displays - the

upper display indicates the actual temperature of the

glue (red numbers) and the lower display shows the

temperature adjustable (green in numbers) - and the

following keys: SET - LEFT ARROW - DOWN ARROW -

UP ARROW.

Follow these instructions to change the temperature

controller.

- Turn on the power button 3(green).

- Select the temperature according to the specification of

the glue. To change the working temperature press the

LEFT ARROW key, making it possible to change

parameters (press this button until the digit you want to

change). Then press the DOWN ARROW or UP

ARROW keys to change the temperature. At the end,

press the SET button, which will save the change,

continuing the temperature change.

NOTE: The feeder process is activated only when the

temperature is below 10°C or 10°C above the set

temperature. Outside this range, the process is disabled.

NOTE: The CBC.E temperature controller is

programmable to a maximum temperature of 220°C

(428°F), for near and above this temperature MAKSIWA

do not recommended work with glues for high

temperatue because they can melt the tape.

- Once connected and adjusted with the temperature,

CBC.E takes some 20 to 30 minutes to reach set

temperature, starting from room temperature.

- Upon reaching the set temperature, the feeder switch 5

is ready to be turned on, activating the axes.