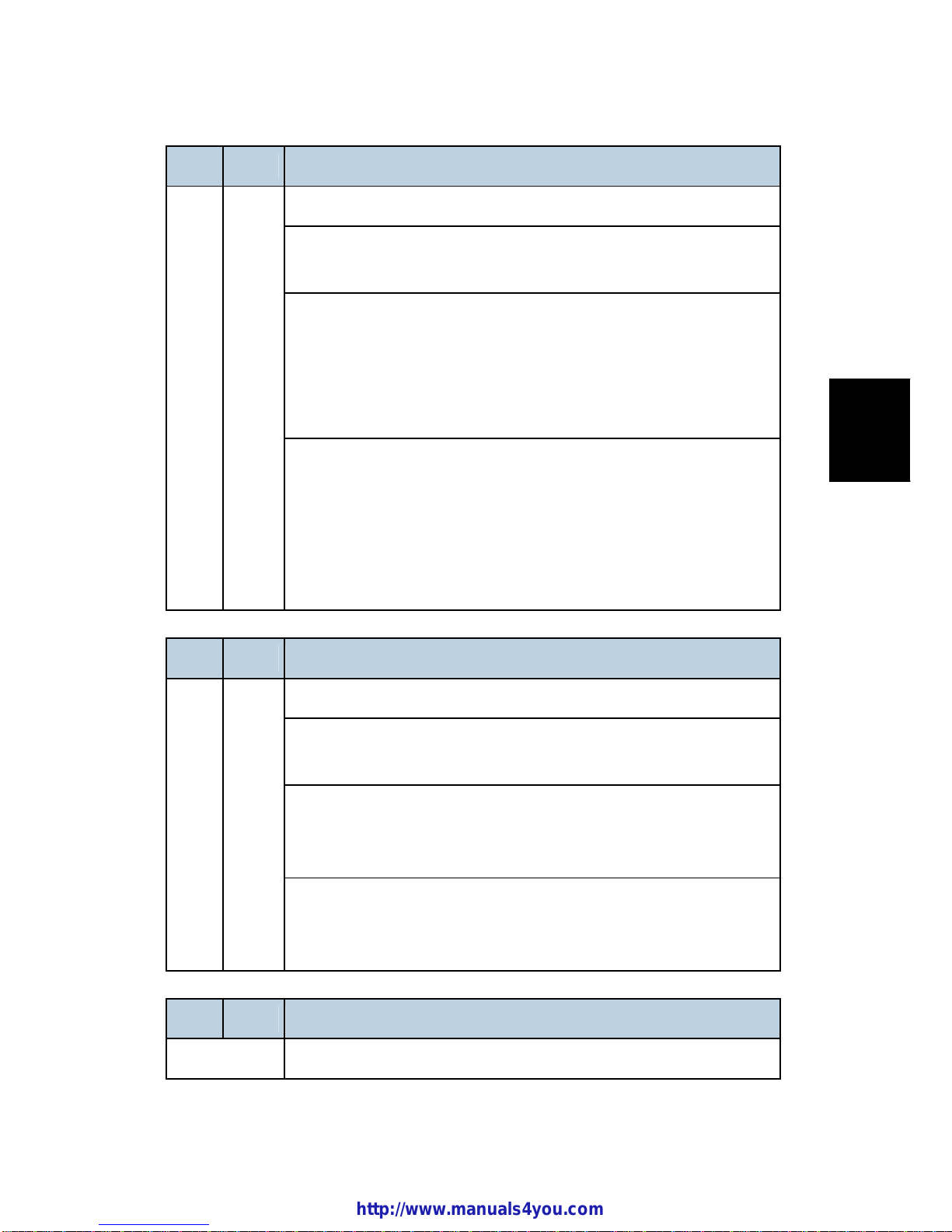

Ricoh D027 User manual

Other Ricoh All In One Printer manuals

Ricoh

Ricoh Aficio 2022 User manual

Ricoh

Ricoh SP 150 Quick start guide

Ricoh

Ricoh Aficio SP 5210SF User manual

Ricoh

Ricoh Aficio SP C210 User manual

Ricoh

Ricoh Aficio SP 100SF e User manual

Ricoh

Ricoh MP 2553 User manual

Ricoh

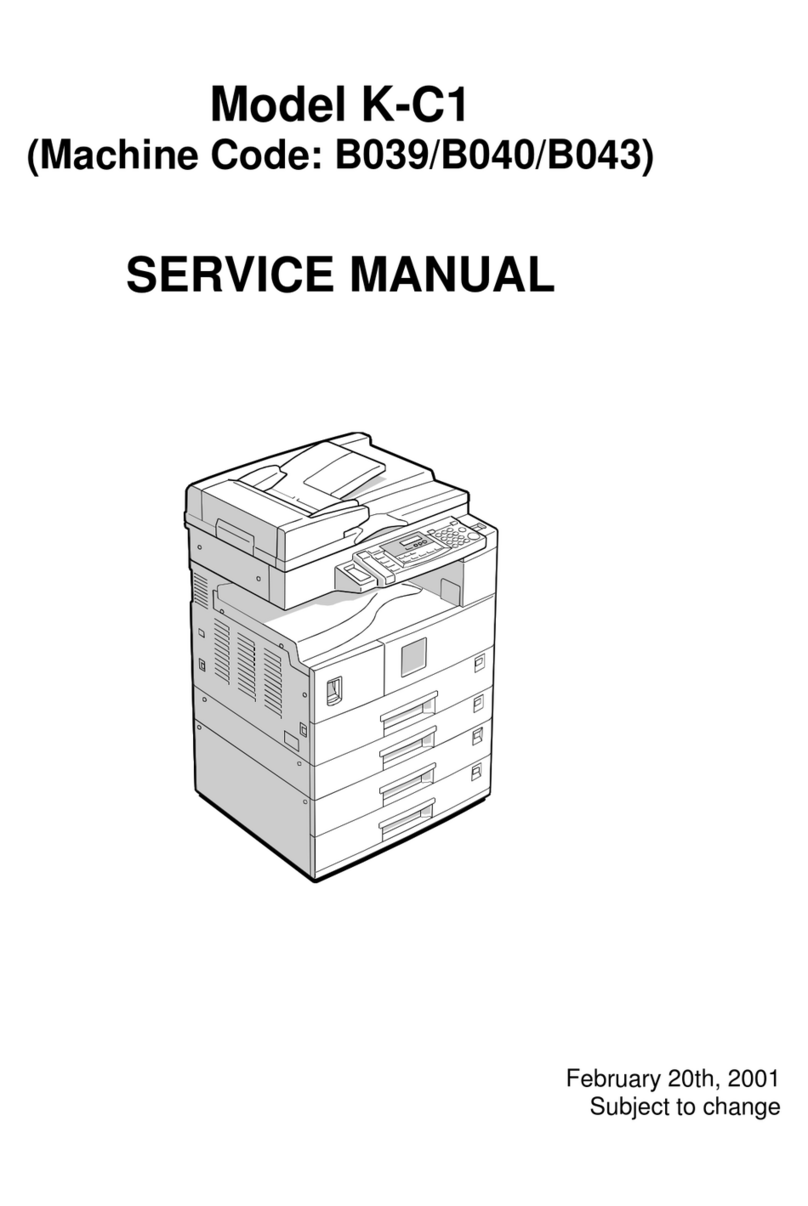

Ricoh K-C1 User manual

Ricoh

Ricoh Aficio SGC 1506 User manual

Ricoh

Ricoh D096 User manual

Ricoh

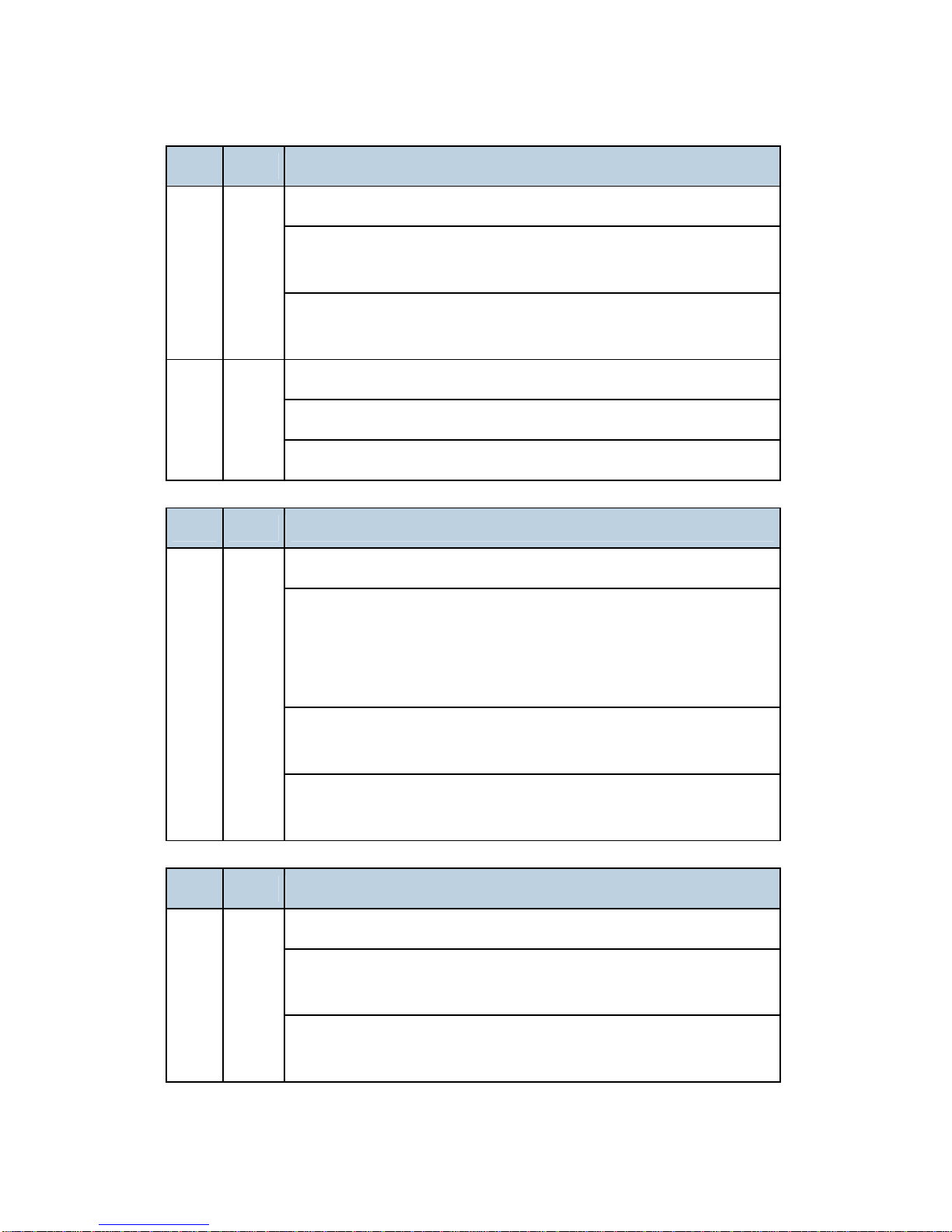

Ricoh Aficio MP 161F User manual

Ricoh

Ricoh SP 203 SF User manual

Ricoh

Ricoh Aficio 3035 User manual

Ricoh

Ricoh Pro C7100s Instruction sheet

Ricoh

Ricoh C9020L User manual

Ricoh

Ricoh Aficio Color 6010 User manual

Ricoh

Ricoh Aficio SP C232SF User manual

Ricoh

Ricoh Aficio CL3000 Operating manual

Ricoh

Ricoh Pro C900 User manual

Ricoh

Ricoh Aficio MP 9002 User manual

Ricoh

Ricoh Aficio MP 2500SPF User manual