Ricoh M080 User manual

Other Ricoh Printer manuals

Ricoh

Ricoh D124 Manual

Ricoh

Ricoh AFICIO MP 6001 User manual

Ricoh

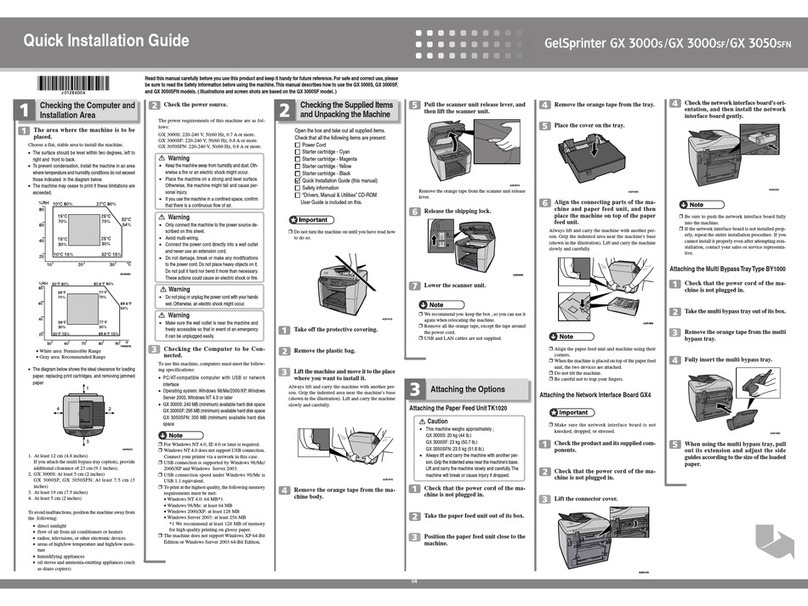

Ricoh GX 3000S User manual

Ricoh

Ricoh Aficio CL5000 User manual

Ricoh

Ricoh P 502 User manual

Ricoh

Ricoh 9016 User manual

Ricoh

Ricoh VD4007001 User manual

Ricoh

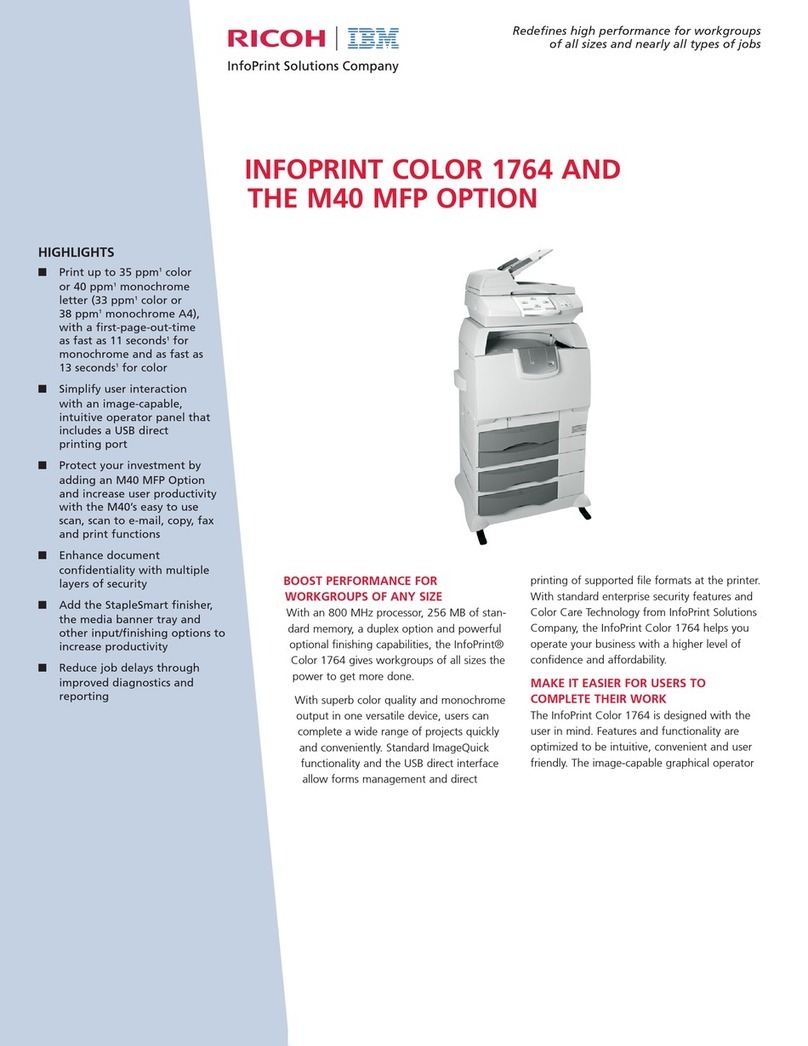

Ricoh InfoPrint 1764 User manual

Ricoh

Ricoh MD-P1 User manual

Ricoh

Ricoh Priport HQ7000 Service manual

Ricoh

Ricoh SP 200S User manual

Ricoh

Ricoh PRIPORT VT1730 User manual

Ricoh

Ricoh Aficio CL3000 Manual

Ricoh

Ricoh L5160 Installation guide

Ricoh

Ricoh CL2000N - 420116 Color Laser 16.9PPM Network... Owner's manual

Ricoh

Ricoh Aficio SG 3110DN User manual

Ricoh

Ricoh SP 220NW User manual

Ricoh

Ricoh Ri 2000 User manual

Ricoh

Ricoh Pro 8100S User manual

Ricoh

Ricoh SP 8400DN User manual