Ridder Drive Systems T+31 (0)341 416 854 F+31 (0)341 416 611 I www.ridder.com

2

This product manual contains important informaon for installers on how to connect and

commission a Ridder LogicDrive RLD200. All acvies in this respect should be carried out by

qualied and skilled mechanical and / or electrical installers in proper and safe condions.

Table of contents

1.1 LogicDrive RLD200 product manual

1.1 LogicDrive RLD200 product manual ............................................. 2

2.1 LogicDrive RLD200 descripon .................................................3

2.2 LogicDrive RLD200 applicaon .................................................3

2.3 LogicDrive RLD200 technical specicaons .......................................4

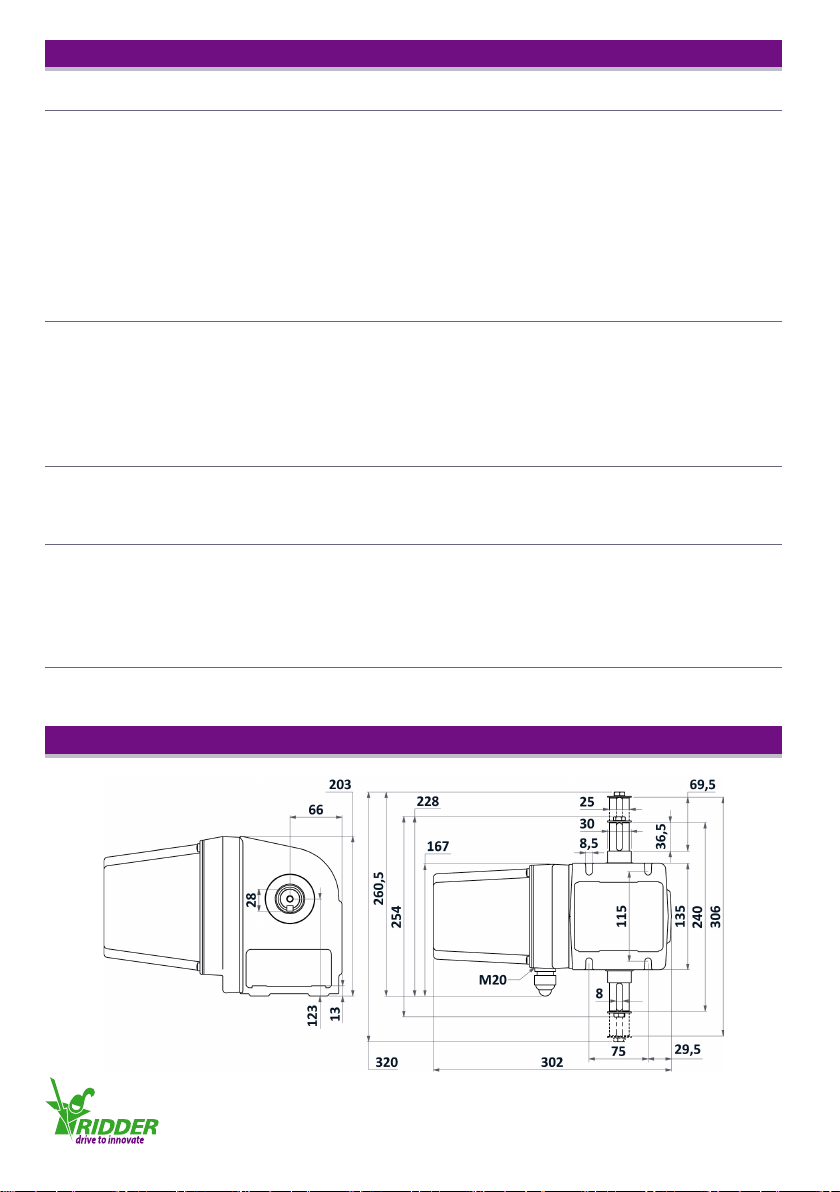

2.4 LogicDrive RLD200 dimensions..................................................4

2.5 LogicDrive RLD200 winch belt pull force for venlaon systems ...................... 5

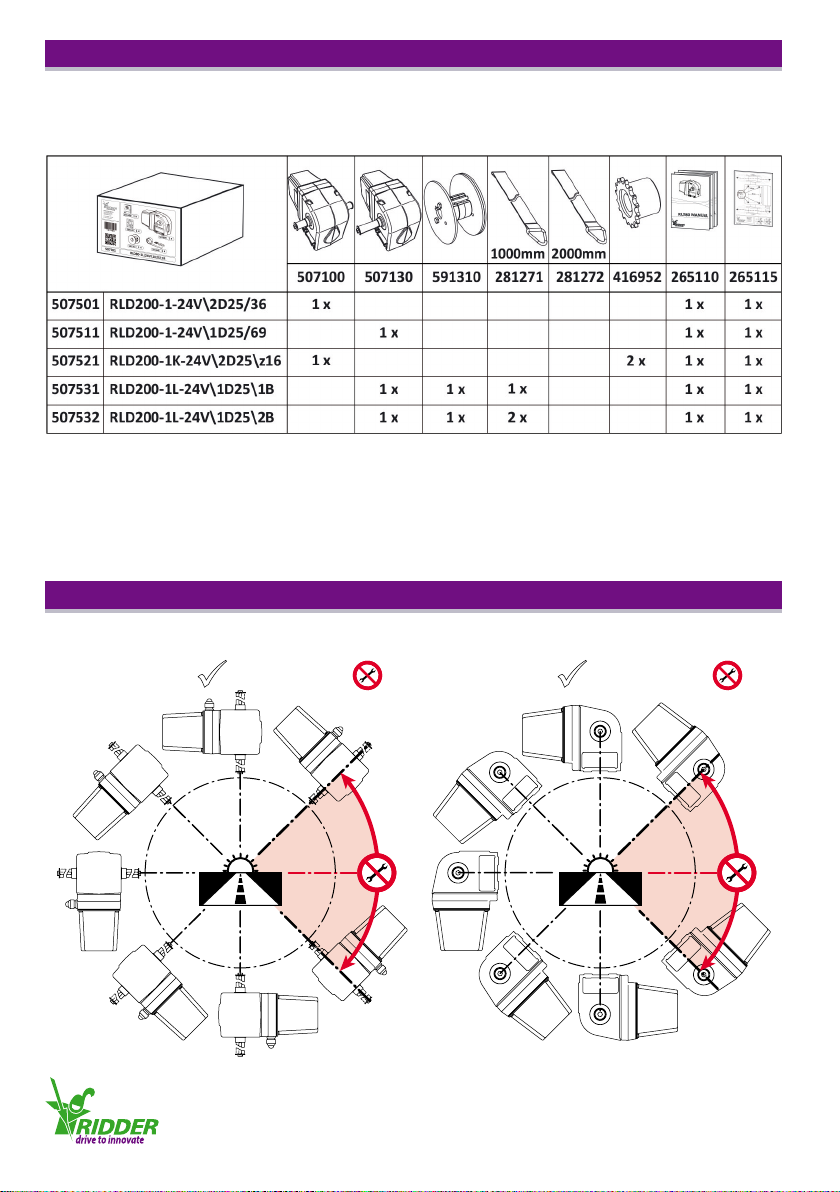

2.6 LogicDrive RLD200 packaging contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 LogicDrive RLD200 mounng posions .......................................... 6

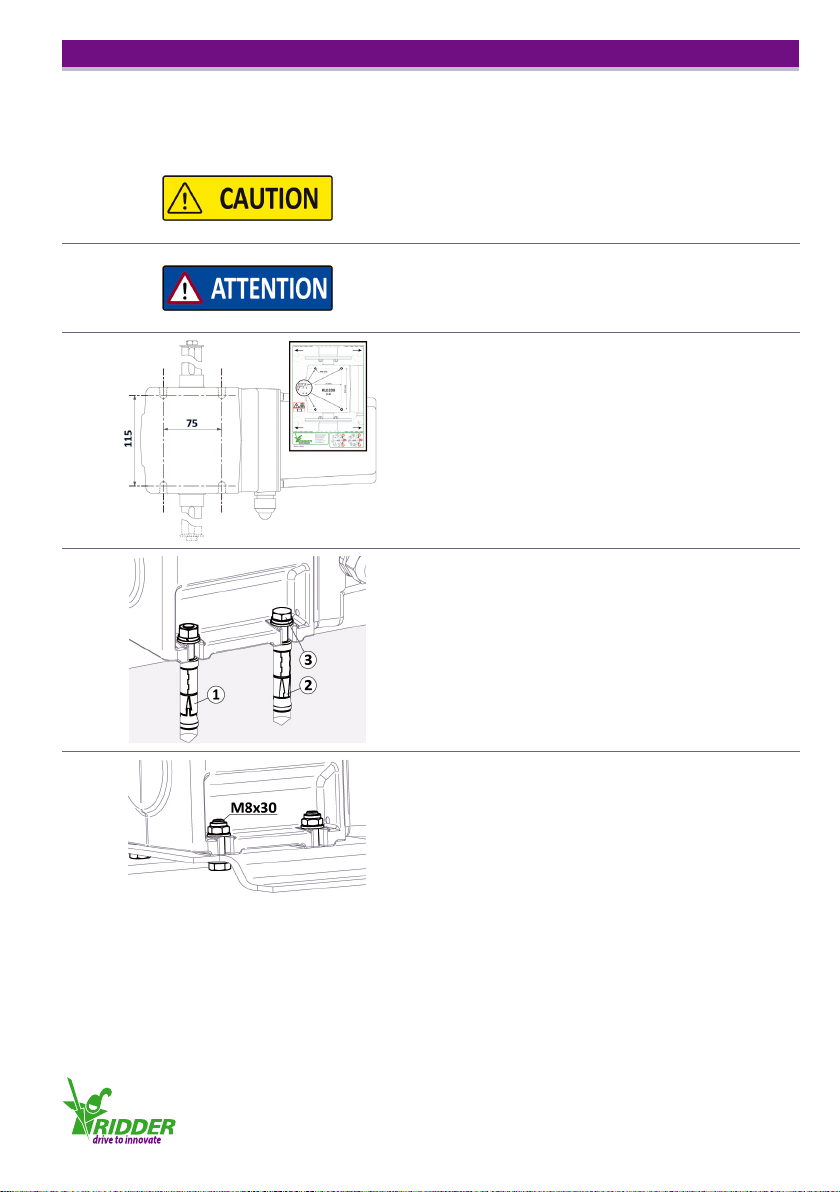

3.2 Mounng the LogicDrive RLD200 ...............................................7

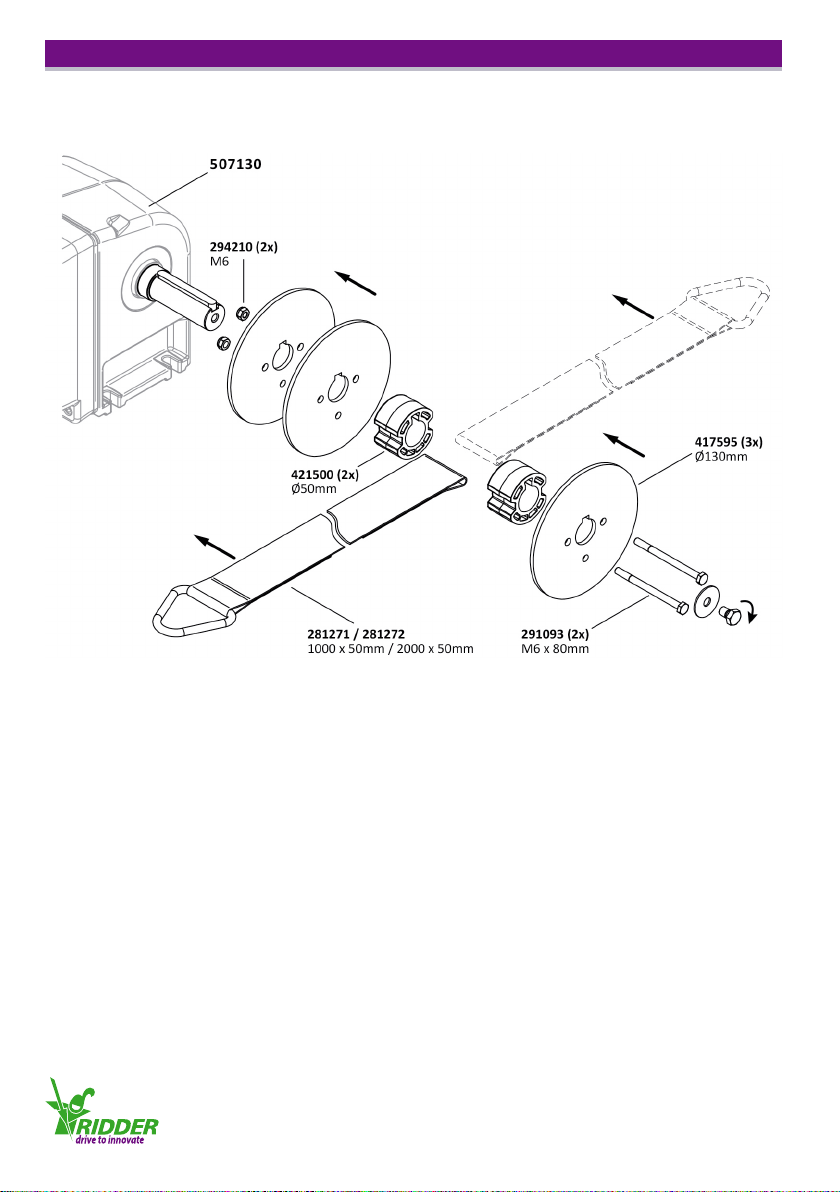

3.3 Mounng the belt drum and winch belt .........................................8

3.4 Pre-winding the winch belt onto the belt drum ....................................9

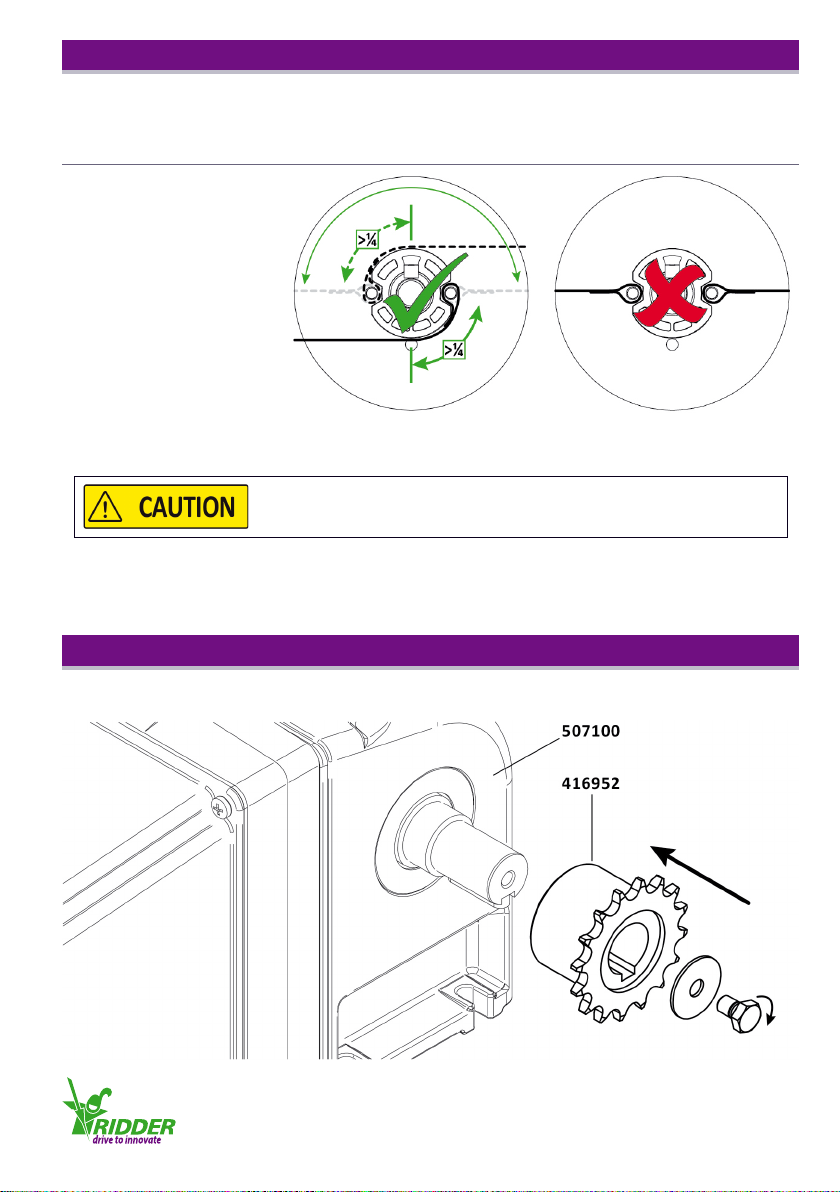

3.5 Mounng the sprocket ........................................................9

4.1 Connecon and operaon - abbreviaons ....................................... 10

4.2 Connecng the control components and switch materials, and cable lengths .......... 10

4.3 LogicDrive RLD200 wiring diagram and operang elements ........................11

4.4 LogicDrive RLD200 rotaonal direcon, and end and emergency posions ............12

5.1 Condions and criteria for teaching in the LogicDrive RLD200 . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Operang the LogicDrive RLD200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3 LogicDrive RLD200 status LEDs ................................................15

5.4 Control signal of climate controller and emergency posion ........................15

6.1 Teaching in the LogicDrive RLD200 - Programming the end posions .................16

6.2 Teaching in the LogicDrive RLD200 - Programming an emergency posion ............18

6.3 Teaching in the LogicDrive RLD200 - Erasing an end posion ........................19

6.4 Teaching in the LogicDrive RLD200 - Erasing the emergency posion .................20

7.1 LogicDrive RLD200 alarm contact .............................................. 21

8.1 LogicDrive RLD200 blink codes of status LEDs .................................... 21

9.1 LogicDrive RLD200 maintenance ...............................................24

10.1 LogicDrive RLD200 troubleshoong ............................................24

10.2 Technical Support ...........................................................25

10.3 Environment ...............................................................25

11.1 LogicDrive RLD200 accessories ................................................ 26

12.1 Meaning of warnings in this product manual ..................................... 27