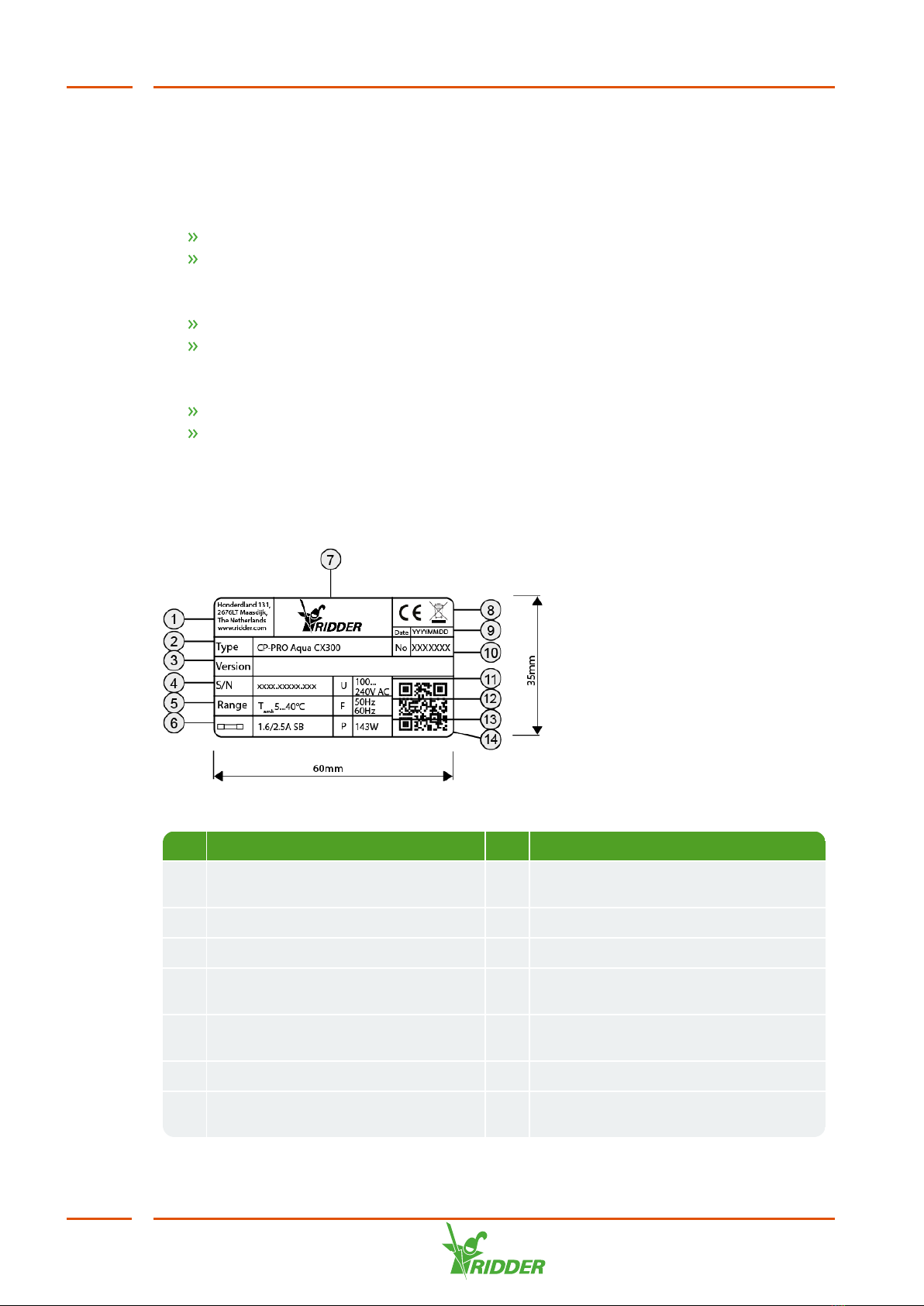

The type plates of some components also specify the version numbers of the software

installed.

1.2 How the Aqua CX300 works

The Aqua CX300 is designed to control irrigation and fertilizer application (collectively

called 'fertigation'). These processes are controlled based on a number of factors,

such the desired EC and pH levels in the irrigation water, and the amount of solar

radiation received by the plants. To maximize crop growth, these factors need to be

set at specific levels. These desired values (or 'setpoints') depend on a number of

variables, such as the crop variety, the time of day and the season.

Irrigation control is a process of continuous adjustment that is subject to a number of

external factors, such as the weather. To respond to these factors effectively, the

controller needs to be able to measure them. Examples of such measurements are

the EC level, pH level, solar radiation sum, flow rate and contact start level.

The controller calculates the actual control setpoints based on the difference between

the pre-set setpoints and the corresponding measured values. The controller uses

these calculated setpoints to control or operate the ‘corrective mechanisms’, such as

the irrigation unit or the valves.

1.3 Valve groups and valves

Valves can be assigned to valve groups in any combination. Each of these valve

groups can then be assigned to one of the pre-set irrigation programs. An irrigation

program is a group of settings that enable you to control the EC level (i.e. the

concentration of fertilizers) and pH level (i.e. the acidity) of the irrigation water

according to the precise needs of your crop. See also: "Programs" on page20.

A valve group consists of a number of valves. An irrigation percentage can be set for

each individual valve. Up to 160 valves can be divided among the valve groups. See

also: "Assign valves to group" on page16.

Up to six valves can be operated simultaneously. If both an irrigation program and

fogging program are active at the same time, this maximum will apply for both

programs in total. The following restrictions also apply:

the current of each output may not exceed 1 A;

the total current of each valve module side may not exceed 2 A;

the total current of all outputs in a system may not exceed 4 A (this value is

determined by the power supply).

1.4 Irrigation programs

Each irrigation program consists of a number of controls (e.g. Radiation Start, Contact

Start and Time Start). Each control, in turn, consists of a number of settings that

enable you to tailor irrigation (or fertigation) to your exact needs. For example, the

Radiation Start control includes the 'Radiation start active' and 'Start time of radiation

start' settings.

Aqua CX300

7