1.4.4 Notation methods

The following method of notation is used in the software user instructions:

A button is indicated as follows: the Start button.

A field is indicated as follows: the Connect string field.

A setting is indicated as follows: the Language setting.

A window is indicated as follows: the Log On window.

1.4.5 Glossary

A glossary has been included in the appendix (see Bijlage: "Glossary" on page60).

1.5 Documentation included

A full set of documentation has been included with the HortiJet. This manual is part of

that documentation. You will also find:

Additional information on, for example: pumps, measuring equipment, etc. can

be found in the Original Equipment Manufacturer (OEM) manuals, supplied

separately. Please consult these OEM manuals for the correct use and

maintenance of the relevant components.

Electrical wiring diagrams.

HortiMaX-Go! documentation, such as the "HortiMaX-Go! User Manual" and the

"HortiMaX-Go! Installation Manual". Visit help.hortimax-go.com for online

support.

ONLINE HELP

Scan the QR code to access the online help.

help.hortimax-go.com

1.6 Disclaimer

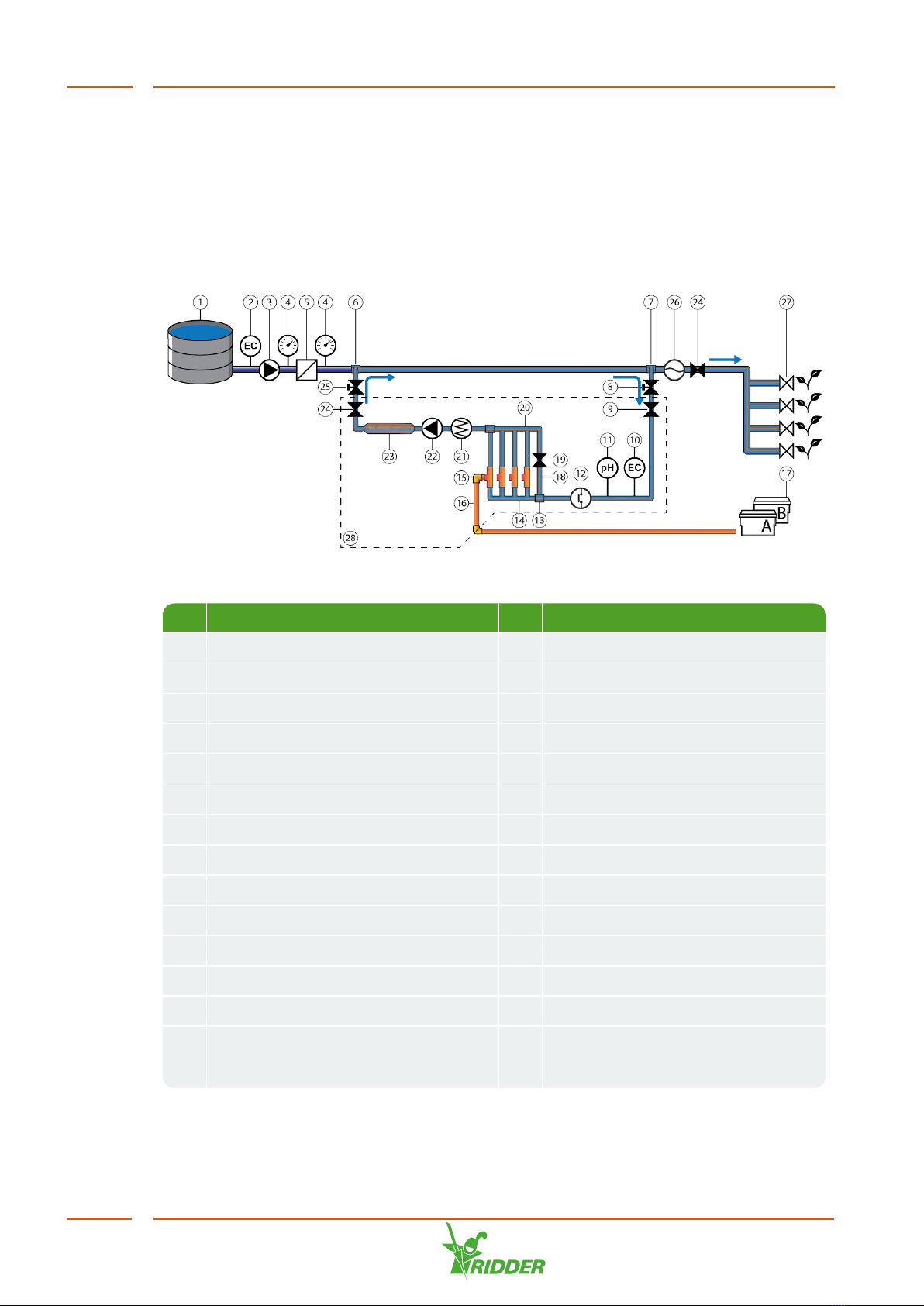

The HortiJet-Go! series and all its components have been developed specifically for a

horticultural environment. The equipment and accompanying software must be used

as delivered and are subject to the instructions in the Ridder Growing Solutions

documentation provided with the equipment and software.

The HortiJet-Go! series is designed for irrigation and fertigation applications in a

horticultural environment.

For other conditions of use, please refer to our General Conditions of Sale.

HortiJet-Go!

8