Contents

1 Introduction to this manual 6

1.1 Introduction 6

1.2 Aims 6

1.3 Target groups 6

1.4 Symbols and annotations 6

1.5 Documentation overview 7

2 Product information 8

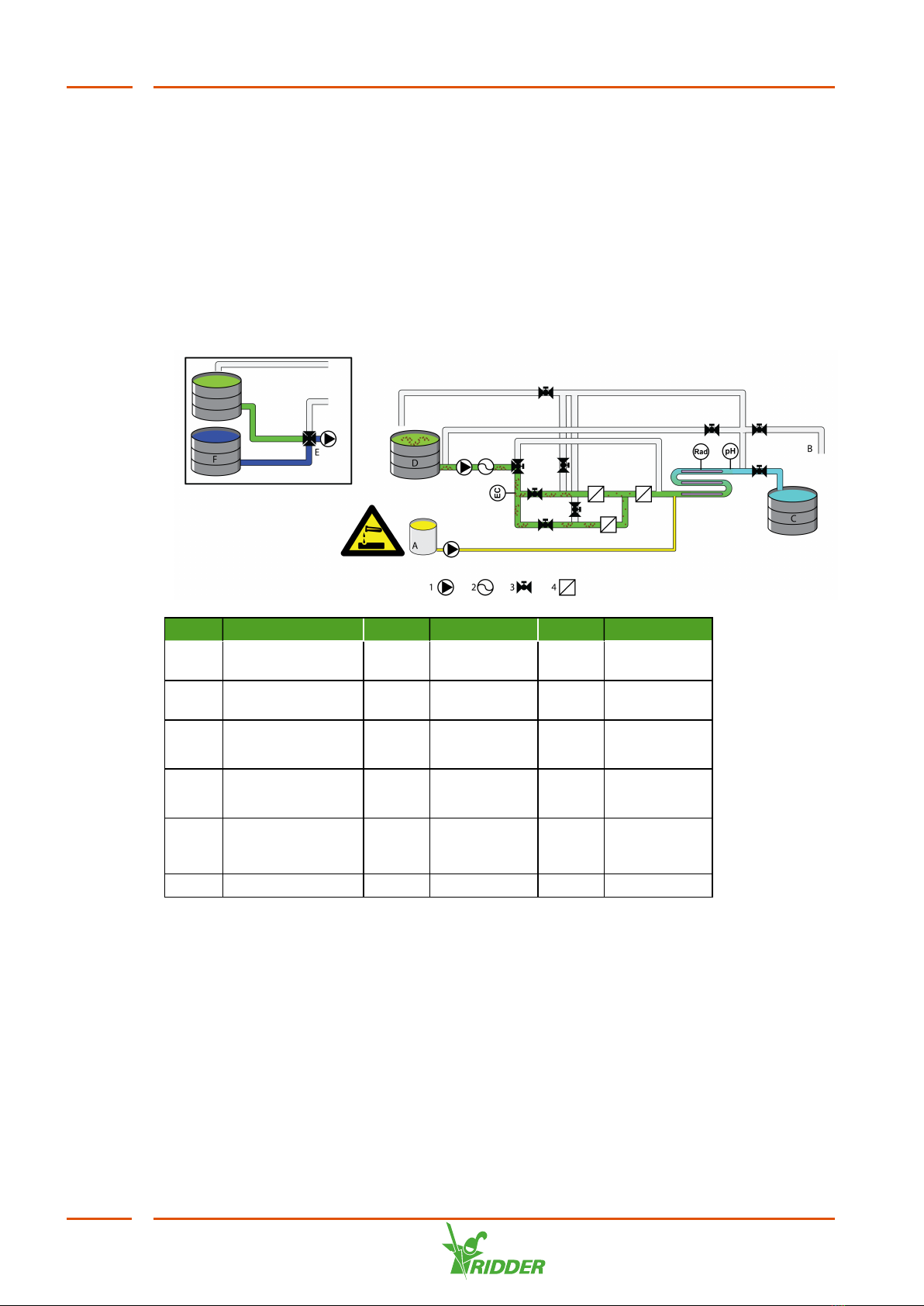

2.1 Schematic representation of the unit 8

2.2 Basic configuration 9

2.3 Description of I/O modules 9

2.3.1 Replacing I/O modules 10

2.3.2 Removing I/O modules 11

2.4 Intended use 12

2.5 Other product characteristics 12

2.5.1 Type plate 13

2.5.2 Quality control 13

2.5.3 Components, stickers and names 14

2.5.4 Certificates and declarations 16

2.5.5 Original Equipment Manufacturers (OEM) information 16

2.6 Packaging, storage and shipment 17

2.7 Recycling and disposal 17

3 Safety precautions and requirements 19

3.1 General safety requirements 19

3.2 Personal protective equipment 19

3.3 UV-C radiation 20

3.4 Chemicals 21

3.5 Emergency stop 21

4 Installation procedure 22

4.1 Installation requirements 22

4.1.1 Dealer/installer requirements 22

4.1.2 Installation requirements 22

4.1.3 Water installation requirements 24

4.1.4 Electrical installation requirements 24

4.1.5 Requirements for installing water tank sensors 24

4.2 Installation checklist 25

4.3 Connecting water components (water installation) 27

4.3.1 Pre-blending control (optional) 28

4.3.2 Filters 28

4.4 Connecting electrical components 29

4.5 Connecting acid dosing components 29

4.5.1 pH calibration 31

4.6 Connecting EC sensors (if present) 31

4.6.1 EC calibration 31

4.7 Installing quartz tubes and lamps 32

4.7.1 Installing quartz tubes 32

4.7.2 Quartz tube breakages 35

4.7.3 Pressurizing the unit 36

4.7.4 Installing UV-C lamps 37

4.8 Other installation work 38