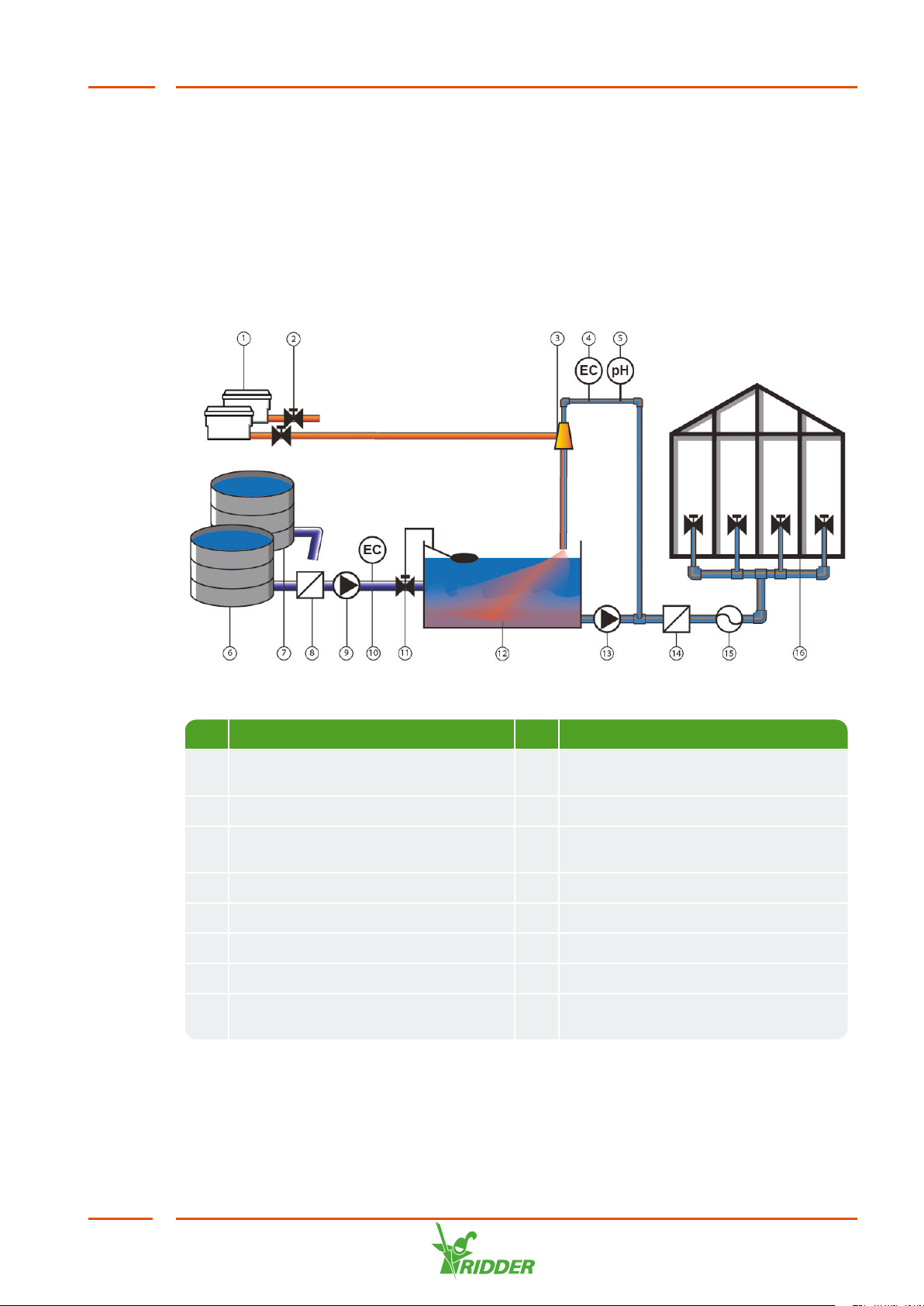

2.2 Process description

The FertiMiX works as follows:

Fresh water is supplied (optionally pre-blended with drain water).

The supply pipe is fitted with:

(optionally) a filter for filtering water,

(if the pre-pressure is less than two bars) a filling pump for pumping

water into the mixing tank,

(optionally) an EC sensor for pre-blending control.

The water flows into the mixing tank via the filling module. The filling module

regulates the water supply to the mixing tank.

The system pump pumps the water from the mixing tank towards the pressure

module.

From the pressure module, the water is directed to the dosing module.

Some of the water flows to the measurement module. The measurement

module is a branch line where the EC and/or pH is measured.

A dosing module consists of one or more dosing channels. Each fertilizer (or

other additive) requires its own dosing channel equipped with a venturi.

Fertilizers (or other additives) are sucked out of the stock tanks connected to

the venturis.

The fertilizers and other additives are dosed using the dosing valves based on

the fertigation recipe.

From the dosing module and measurement module, the water is fed into the

mixing tank.

The design of the supply pipe creates a swirling motion in the mixing tank. This

swirling motion effectively mixes and aerates the water and fertilizers. This

ensures that the fertilizers dissolve completely and allows the equilibrium

reaction of the acid or alkali (lye) with the water to stabilize. This reaction

creates CO2gas. The residence time of the water inside the mixing tank plays a

key role in the mixing process. It also allows the CO2gas to escape from the

mixture, preventing gas bubbles from clogging the pipes.

A float and valve prevent the mixing tank from overflowing.

Once the water and fertilizers have been mixed sufficiently, the system pump

pumps the irrigation water from the mixing tank to the pressure module. This

module has a branch line for distributing the irrigation water.

The water flows to the irrigation valves and is then supplied to the crop. If

required, the water can first be filtered and the flow rate can be measured.

The entire process is controlled by the Ridder CX500 process controller. Its tasks

include:

ensuring that the correct fertigation recipe is prepared (proportion of fertilizers

and water).

controlling the valves to ensure that the water reaches the crop.

FertiMiX

10