2

TABLE OF CONTENTS

FUNCTIONAL DESCRIPTION

FUNCTIONAL DESCRIPTION ............................................2

Specications.................................................................... 2

FEATURES..........................................................................3

IMPORTANT SAFETY INSTRUCTIONS ................................ 4

SAFETY SYMBOLS-DEFINITIONS........................................ 4

GENERAL POWER TOOL SAFETY RULES............................. 5

TABLE SAW SAFETY RULES................................................. 6

Saw Blade Guard, Anti-Kickback Pawls and ...........................

Riving Knife Assembly ....................................................... 8

Kickbacks......................................................................... 8

PROPOSITION 65 WARNING ............................................8

POWER CONNECTIONS....................................................... 7

Power Source .................................................................. 9

Grounding Instructions..................................................... 9

Extension Cords................................................................ 9

UNPACKING......................................................................... 9

Package Contents ............................................................10

Hardware Package ...........................................................11

ASSEMBLY...........................................................................12

Stand..............................................................................12

Fixed Wheels and Stationary Feet......................................12

Front and Rear Rails.........................................................13

Extension Wings ..............................................................14

Fence Guide and Power Control Box..................................15

Throat Plate.....................................................................16

Blade and Riving Knife......................................................16

Installing the Handles to the Elevation..................................

and Bevel Hand Wheels....................................................17

Installing the Handles to the Rip Fence..............................17

Anti-kickback Pawls..........................................................18

Blade Guard ....................................................................18

Rip Fence........................................................................19

Miter Gauge.....................................................................19

On-Board Storage............................................................19

Adjusting the 90° and 45° Positive Bevel Stops ..................20

Securing Saw to Floor ......................................................20

ALIGNMENT ........................................................................21

Riving Knife Alignment With The Blade..............................21

Adjusting the Miter Gauge Scale........................................22

Adjusting the Miter Gauge Fitment....................................22

Aligning Fence Parallel To Miter Slot ..................................23

Aligning Fence Perpendicular to the Table..........................23

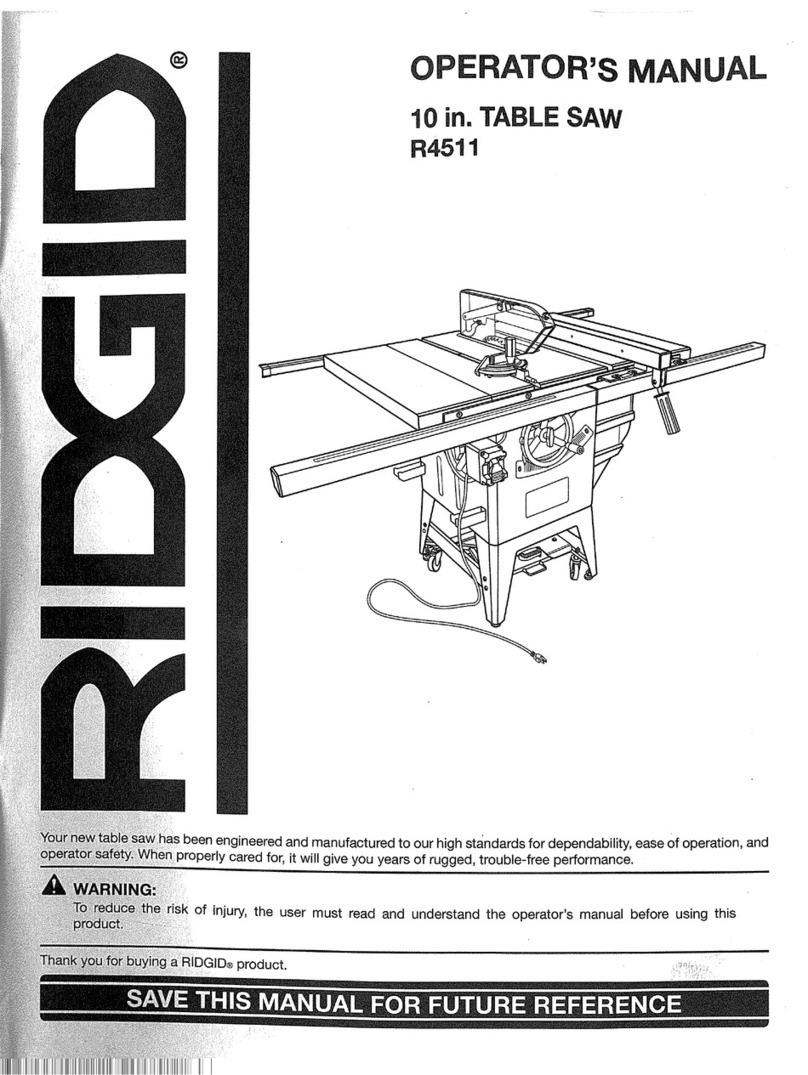

The RIDGID®#R4560 10 inch Contractor Table Saw has been

designed for mobility and high quality performance. It includes:

basic machine, sturdy tubular steel stand, integral dust chute, a

Stay Square fence, t-slot miter gauge, 15 amp induction motor,

on/off switch, cast iron table, extension wings, see-through blade

guard with anti-kickback pawls, and 10 inch carbide blade.

Dust Collection .............................................................23

PREPARING TO CUT ...........................................................24

Raising and Lowering the Blade ........................................24

Tilting the Blade...............................................................24

Selecting and Storing Saw Blades......................................25

Changing the Saw Blade...................................................25

Riving Knife Position.........................................................26

Riving Knife Height Settings...........................................26

Checking Riving Knife Alignment....................................27

Checking Blade Parallelism to Miter Gauge Groove (Heel)....27

Using the Miter Gauge......................................................28

Using Blade Guard Assembly.............................................28

Checking Fence Alignment................................................28

To Move Saw .........................................................................28

OPERATION ........................................................................29

Starting and Stopping the Saw..........................................29

Overload Protection..........................................................30

Making Cuts.....................................................................30

Rip Cuts.......................................................................31

Bevel Ripping ...............................................................31

Crosscutting .................................................................32

Bevel Crosscutting ........................................................33

Miter Cuts ....................................................................33

Compound Miter Cuts....................................................33

Large Panel Cuts...........................................................33

Non-Through Cuts............................................................34

Making Non-Through Cuts .............................................34

Cutting Aids and Accessories.............................................35

Push Sticks...................................................................35

Auxiliary Rip Fence Facing .............................................35

Auxiliary Miter Gauge Facing..........................................35

Flip Down Fence...........................................................36

Push Blocks..................................................................36

Grooving and Rabbeting................................................37

Featherboard................................................................37

CutoGauge ...............................................................38

Jigs..............................................................................38

MAINTENANCE....................................................................40

TROUBLESHOOTING...........................................................41

ACCESSORIES.....................................................................41

PARTS, SERVICES AND WARRANTY ASSISTANCE............42

SPECIFICATIONS

NOTICE: The manual cover illustrates the current production model. All other illustrations contained in the manual are representative

only and may not be exact depictions of the actual labeling or accessories included. They are intended for illustrative purposes only.

Max depth of cut at 90°: 3 1/8 inch

Max depth of cut at 45°: 2 1/4 inch

Max rip to right of blade: 30 inch

Max rip to left of blade: 15 inch

Max width of dado: 13/16 inch

MOTOR SPECIFICATIONS:

Amps 15

Voltage 120

RPM 3,600