RIDGID R4511 User manual

Other RIDGID Saw manuals

RIDGID

RIDGID Dry Cut Saw User manual

RIDGID

RIDGID R3030 User manual

RIDGID

RIDGID 550 User manual

RIDGID

RIDGID R3210 User manual

RIDGID

RIDGID R3205 User manual

RIDGID

RIDGID 550-1 User manual

RIDGID

RIDGID R8643VN User manual

RIDGID

RIDGID CM1450 User manual

RIDGID

RIDGID R8642VN User manual

RIDGID

RIDGID MS1290LZA User manual

RIDGID

RIDGID MaxSelect R885 User manual

RIDGID

RIDGID R32102 User manual

RIDGID

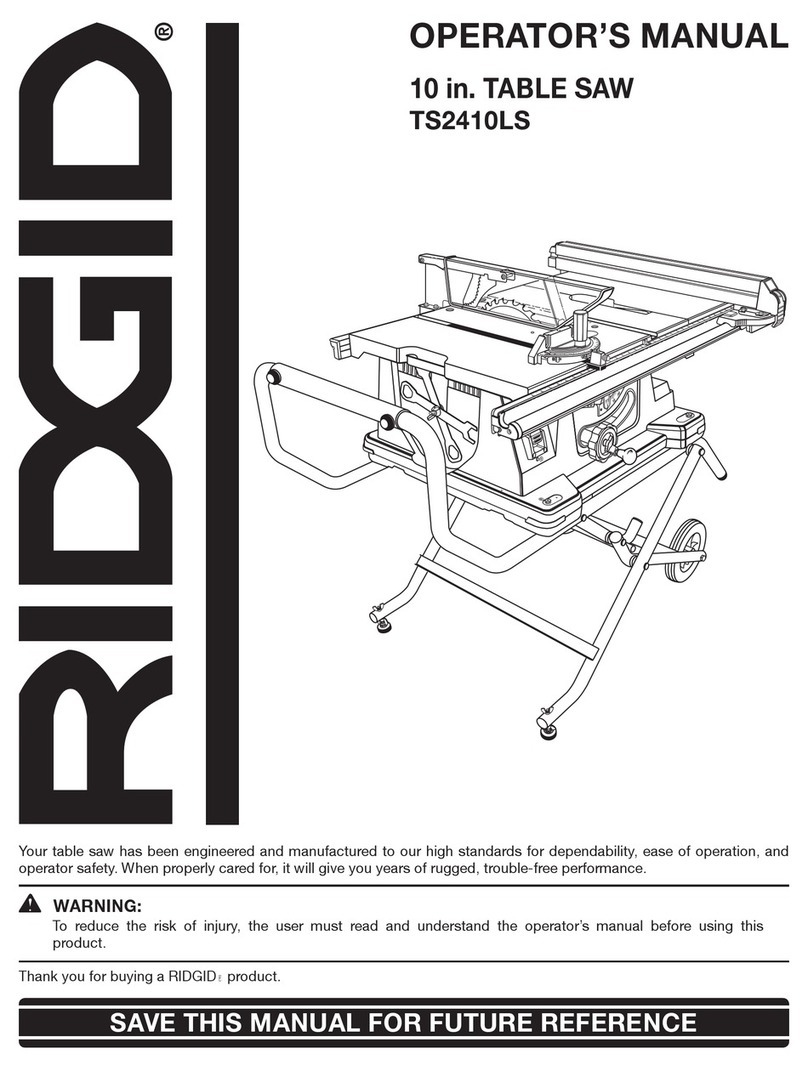

RIDGID TS2410LS User manual

RIDGID

RIDGID RS-570 User manual

RIDGID

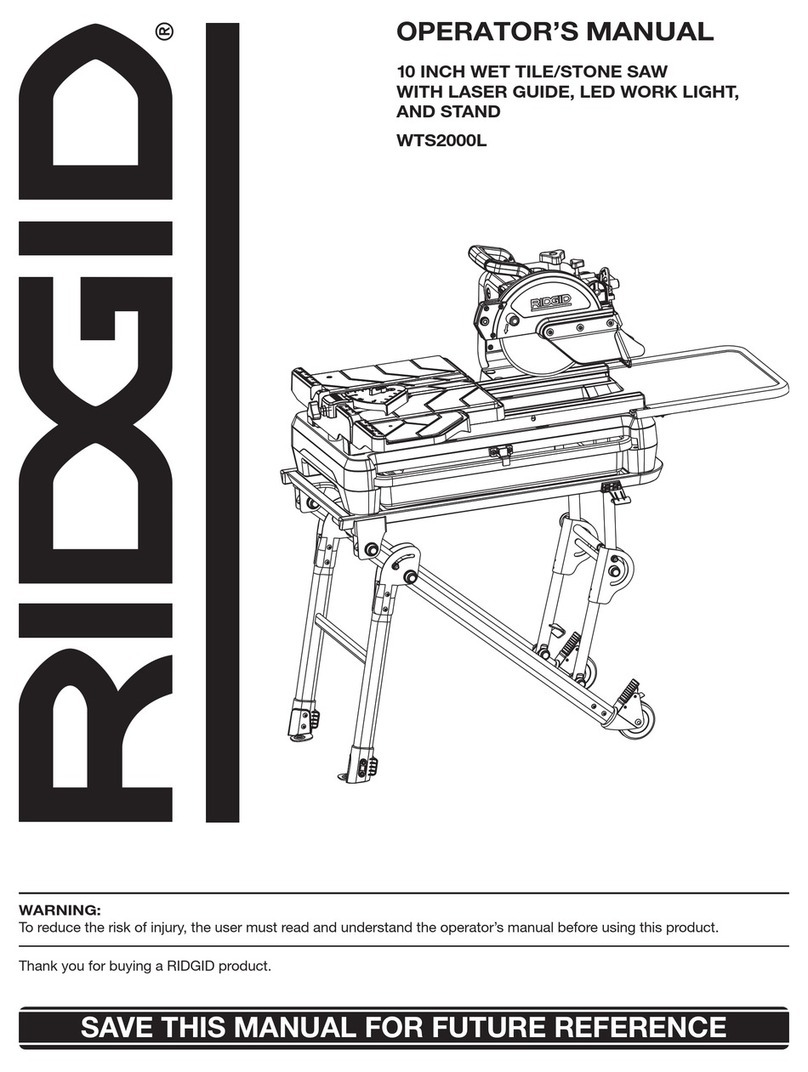

RIDGID WTS2000L User manual

RIDGID

RIDGID MS1290LZ User manual

RIDGID

RIDGID R845 User manual

RIDGID

RIDGID R8648 User manual

RIDGID

RIDGID JOBMAX R8223412 User manual

RIDGID

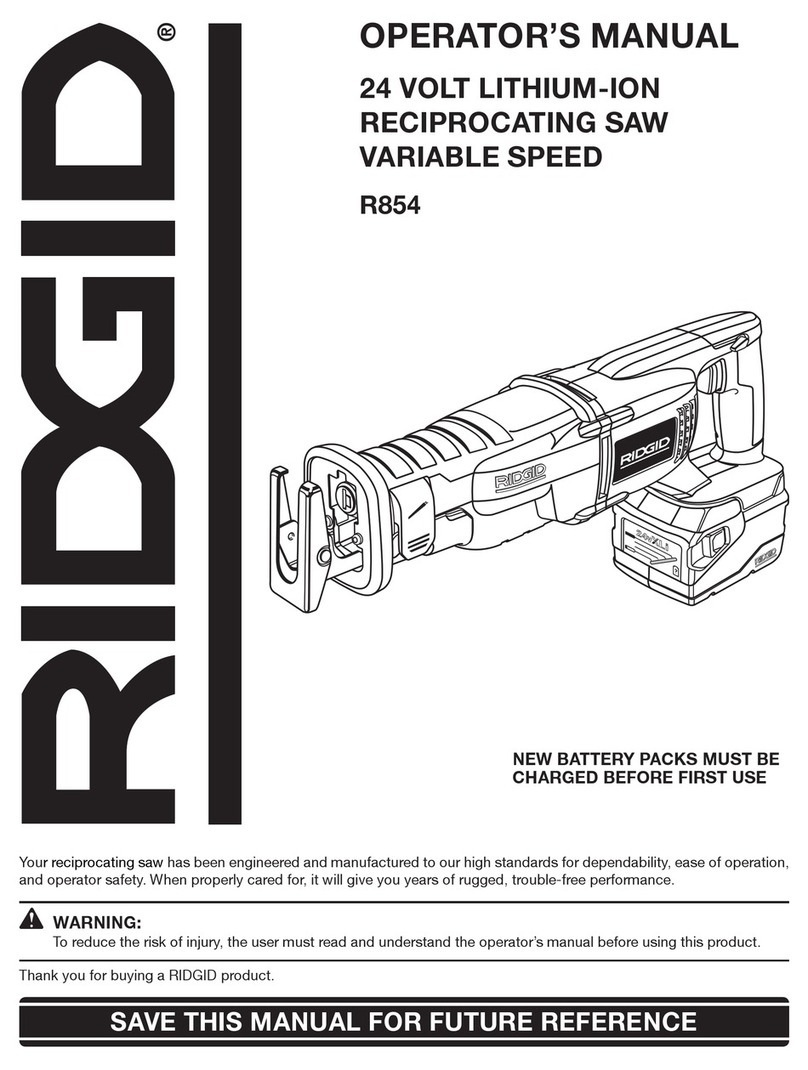

RIDGID R854 User manual