5

Use extra caution with large, very

small or awkward workpieces

• Never use this tool to finish pieces too

small to hold by hand.

• Use extra supports (tables, saw horses,

blocks, etc.) for any workpieces large

enough to tip when not held down to the

table top.

•Never use another person as a substi-

tute for a table extension, or as addi-

tional support for a workpiece or to help

feed, support or pull the workpiece.

• When cutting irregularly shaped work-

pieces, plan your work soit will not pinch

the blade. A piece of molding, for exam-

ple, must lay flat or be held by a fixture

or jig that will not let it twist, rock or slip

while being cut.

• Properly support round material such as

dowel rods or tubing. They have a ten-

dency to roll during a cut, causing the

blade to “bite”. To avoid this, always use

“V” blocks.

• Clear everything except the workpiece

and related support devices off the table

before turning the saw on.

Plan the way you will hold the work-

piece from start to finish.

• Do not hand hold pieces so small that

your fingers will go under the blade

guard. Keep your hands away from the

blade.

• Reduce the Risk of awkward operations

and hand positions where a sudden slip

could cause fingers or hand to move into

the blade.

•Don’t Overreach. Keep good footing

and balance.

• Keep your face and body to one side of

the blade, out of line with a possible

thrown piece if the blade should break.

Whenever Saw Is Running

WARNING: Don’t let familiarity

(gained from frequent use of your

scroll saw) cause a careless mistake.

A careless fraction of a second is

enough to cause a severe injury.

• Before starting your cut, watch the saw

while it runs. If it makes an unfamiliar

noise or vibrates excessively, stop imme-

diately. Turn the saw off. Unplug the saw.

Do not restart until finding and correcting

the problem.

•Keep Children Away. Keep all visitors a

safe distance from the saw. Make sure

bystanders are clear of the saw and

workpiece.

•Don’t Force Tool. It will do the job better

and safer at its designed rate. Feed the

workpiece into the saw blade only fast

enough to let it cut without bogging down

or binding.

Before Freeing Any Jammed Material.

• Turn switch “OFF”

• Wait for all moving parts to stop.

• Unplug the saw.

When backing up the workpiece, the

blade may bind in the kerf (cut). This is

usually caused by sawdust clogging

up the kerf. If this happens:

• Turn switch “OFF”.

• Wait for all moving parts to stop.

• Unplug the saw.

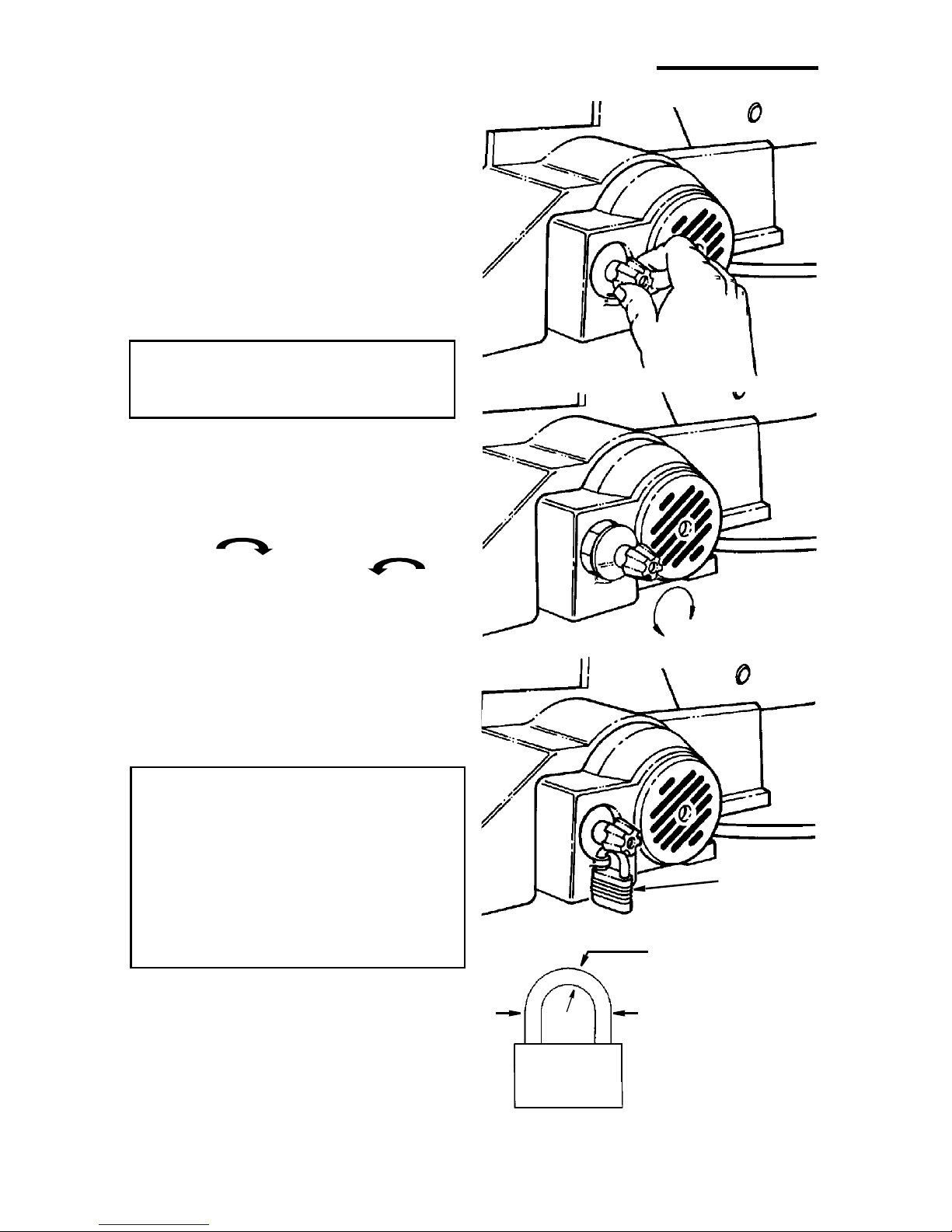

• With a flat blade screwdriver, turn motor

shaft by hand. Insert the screwdriver into

the slotted end of motor shaft located at

the center of the motor housing. Do this

while backing up the workpiece.

Before removing loose pieces from the

table, turn saw off and wait for all mov-

ing parts to stop.

Before Leaving the Saw

• Wait for all moving parts to stop.

•Make Workshop Child-proof. Unplug

the saw. Lock the workshop and ON/OFF

knob on the saw. Store the key awayfrom

children and others not qualified to use

the tool.