Rigel 377 Instruction Manual – Version 1.0 - 7 -

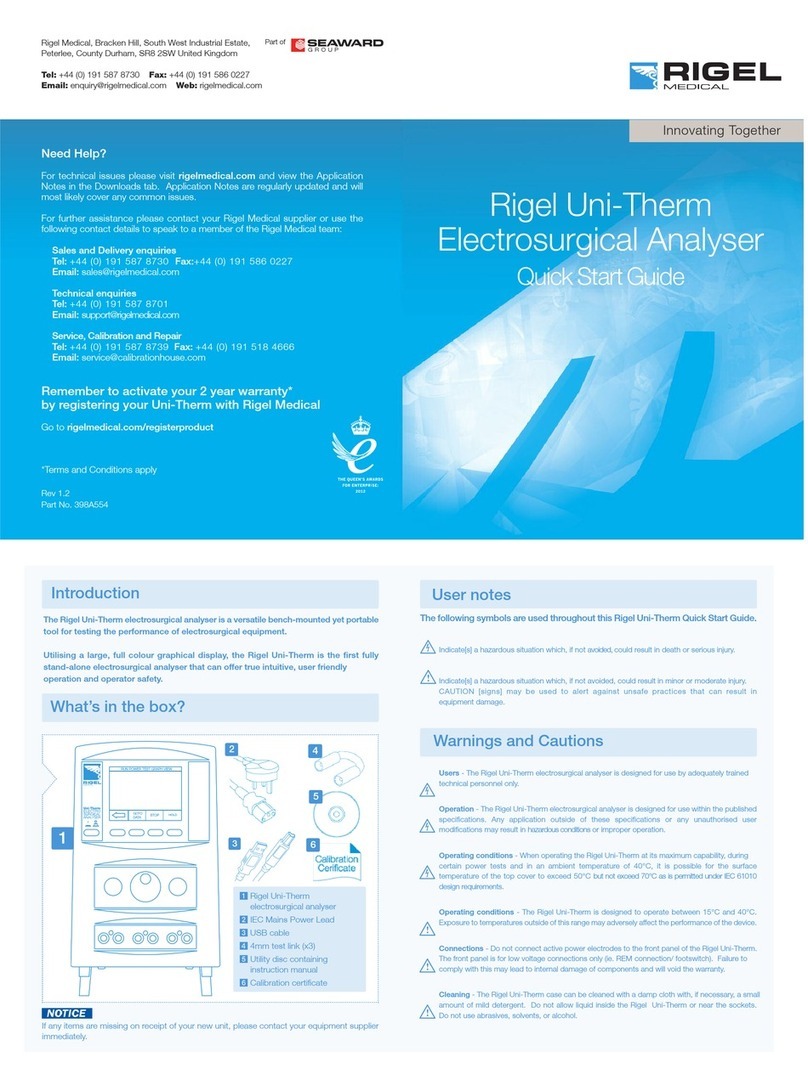

1. Introduction

The Rigel 377 Electrosurgical Analyser is a versatile bench-mounted yet portable tool,

for testing the performance of electrosurgical equipment.

Utilising a large, full colour graphical display, the Rigel 377 is the first fully stand-alone

electrosurgical analyser that can offer true intuitive, user friendly operation and operator

safety.

1.1. Analyser Functions

The Rigel 377 Electrosurgical Analyser enables biomedical engineers to efficiently

analyse the output of electrosurgical diathermy machines. The RF signal input is

simultaneously digitally analysed to provide all the characteristics of interest: Watts,

current, peak Voltage, crest factor. The Rigel 377 can also produce load/ power curves

automatically analysing the load/power performance of an electrosurgical diathermy

machine.

The Rigel 377 is able to measure the following parameters manually;

1. Power

2. HF Leakage

3. Plate Security (REM, Remote Electrode Monitoring)

For the power test, an internal array of resistors provide a safe variable load of 10-

5100Ωin 10Ωsteps; enabling the production of accurate and detailed power distribution

curves, with an instant tabular view of test results.

A unique feature of the HF leakage test is on screen graphics illustrating correct test

connection configurations, complete with user set pass fail limits.

The plate security (REM) test offers a unique isolated, electronically driven

potentiometer, which provides a continuous swept resistance change; enabling

accurate and fast testing of alarms, complete with user set pass fail limits.

Any future firmware upgrades can be efficently installed by users, without risk to stored

data.

The new Rigel 377 forms part of a comprehensive range of high performance specialist

biomedical test equipment supplied by Rigel Medical, part of the Seaward Group.