1 | P a g e R i g e l M e d i c a l U n i - T h e r m u s e r M a n u a l V 1 . 0

Index

Introduction............................................................................................................................. 2

Analyser Functions.............................................................................................................. 2

Key Features ....................................................................................................................... 3

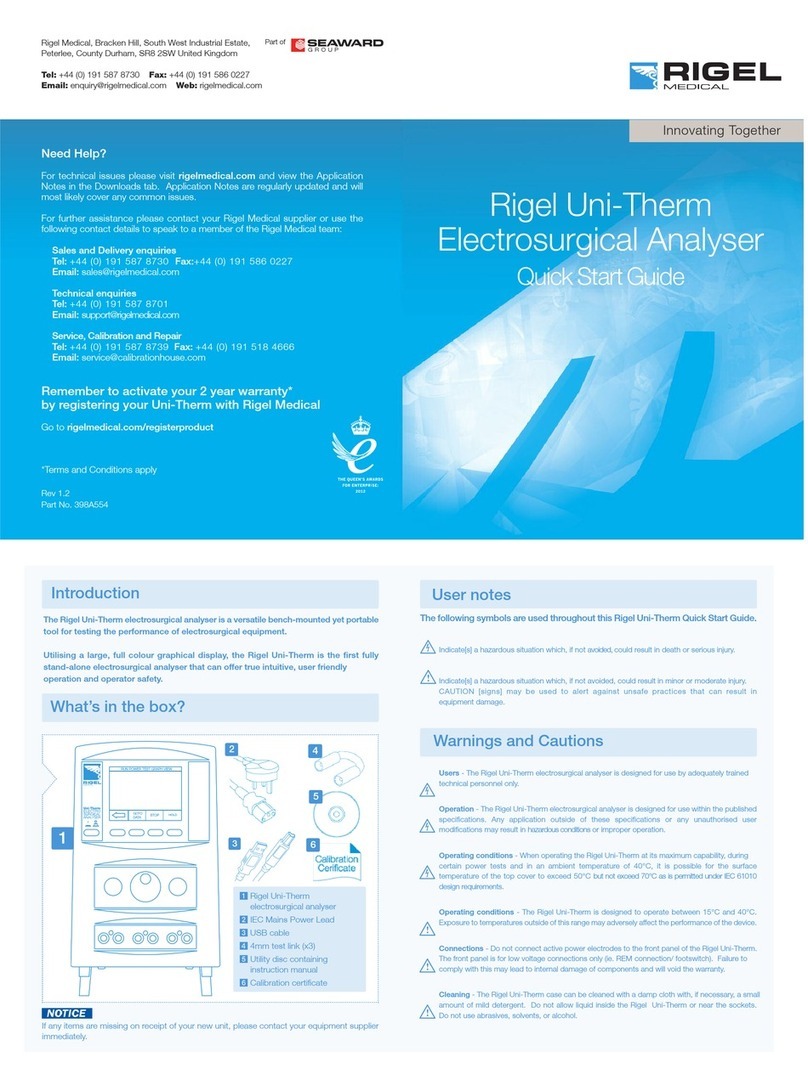

Unpacking the Uni-Therm.................................................................................................... 3

Optional Accessories........................................................................................................... 3

Warnings and Cautions ....................................................................................................... 4

User Notes........................................................................................................................... 4

Safety Notes........................................................................................................................ 4

Uni-Therm Overview............................................................................................................... 5

Front panel........................................................................................................................... 6

Side panel............................................................................................................................ 6

1 Getting started...................................................................................................... 7

1.1 Connecting your Analyser .................................................................................... 7

1.2 Rear panel............................................................................................................ 7

1.3 Front connection panel......................................................................................... 7

1.4 Side panel ESU to ESA connections.................................................................... 8

1.5 Home screen........................................................................................................ 8

2 Manual Mode........................................................................................................ 9

2.1 Plate Security (REM) test..................................................................................... 9

2.2 HF Leakage........................................................................................................ 10

2.3 Power Test......................................................................................................... 13

3 Automatic Mode ................................................................................................. 18

3.1 Stopping or failing a test sequence .................................................................... 21

4 Data.................................................................................................................... 23

4.1 View Data........................................................................................................... 23

4.2 Transfer Data ..................................................................................................... 24

4.3 Download data ................................................................................................... 25

4.4 Upload data........................................................................................................ 26

4.5 Import power reference curves........................................................................... 27

4.6 Transfer test sequences..................................................................................... 27

5 Bluetooth Favourites .......................................................................................... 29

6 Setup.................................................................................................................. 31

6.1 Test sequence.................................................................................................... 31

6.2 Time Date......................................................................................................... 36

6.3 Language ........................................................................................................... 36

6.4 Factory restore ................................................................................................... 37

6.5 About.................................................................................................................. 38

7 Maintaining the Rigel Uni-Therm........................................................................ 39

7.1 Cleaning the Analyser ........................................................................................ 39

7.2 User Maintenance .............................................................................................. 39

7.3 Firmware Upgrade.............................................................................................. 39

7.4 Return Instructions. ............................................................................................ 40

8 Specifications ..................................................................................................... 41

8.1 Technical Specification....................................................................................... 41

8.2 General Specification ......................................................................................... 42

8.3 Load Power rating Rigel Uni-Therm................................................................... 43

9 Support............................................................................................................... 45

9.1 Contact Us.......................................................................................................... 45

Appendix A IEC 60601-2-2 Leakage Tests.............................................................. 46

Appendix B IEC 60601-2-2 Power Tests.................................................................. 50

Appendix C Creating a power reference curve................................................................... 51

Appendix D Firmware Route Map.............................................................................. 53