FIAMA EP43RS User manual

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 1/38

USER MANUAL AND MAINTENANCE GUIDE

DIGITAL ELECTRONIC INDICATORS WITH INDUSTRIAL FIELDBUS

(Profinet, EthernetIP, Ethercat, IO-Link, Modbus)

EP43RS, EP46RS

EP43NET, EP46NET

F4RS-MT, F4RS-M12

F4RS-AM, F4RS-EM43, F4RS-EM46

F4NET-MT, F4NET-M12

F4NET-AM, F4NET-EM43, F4NET-EM46

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 2/38

1 Manual purpose

This manual has been designed by the Manufacturer to provide the necessary information regarding the EP4

and F4 device series to those who are authorized to carry out safely its installation, maintenance, removal and

disposal. All the necessary information for the buyers and planners can be found in the Sales documentation.

In addition to adopting good technical construction practices, the information should be read carefully and

strictly applied. Failure to observe this information could cause risks for the health and safety of people and

economical damage. This information, provided by the Manufacturer in the original language (Italian) is also

available in other languages to satisfy legislative and/or commercial needs. This manual must be kept in good

conditions by a responsible person in an ideal place so that it is always available for consultation. In case this

manual is lost or deteriorates, a replacement should be requested directly from the manufacturer indicating

the manual’s code. This manual reflects the state of the instrument at the time of input on the market: however,

the manufacturer reserves the right to make changes, add or improve the manual without further notice.

1.1 Identification

The identification label is applied on the instrument.

To determine the identification code of the instrument, consult the sales documentation.

1.2 Environmental conditions

Temperature range: min. 0°C, max. + 50°C.

It is forbidden to use the instrument other than for its specific use and in potentially explosive conditions or

where anti-explosive elements are required.

1.3 Storage

Here below are some references to be followed for the storage of the instrument:

Avoid environments with excessive humidity and those exposed to bad weather (avoid open areas).

Avoid putting the instrument directly on the ground.

Store the instrument in its original packaging.

1.4 Conformity declaration and EC marking

The instrument respects the following Communitarian Directives:

2014/30/EU Electromagnetic compatibility, 2011/65/EU RoHS.

1.5 Maintenance

The instrument does not need particular maintenance except cleaning, only with a soft cloth dampened with

ethyl alcohol or water. Do not use hydrocarbon solvents (petrol, thinners, etc.): the use of these products could

affect the proper function of the instrument.

Repairs should be done only and exclusively at the FIAMA technical assistance centre.

1.6 Calibrations and tests

It is advisable to calibrate the instrument periodically, once every working year.

To conduct calibration, follow the calibration procedure described in the present manual.

1.7 Technical Support

For any kind of technical assistance, contact the sales department of the Manufacturer directly indicating the

information given on the identification label, the number of hours used and the type of defect.

1.8 Manufacturer’s responsibility

The manufacturer declines any responsibility in case of:

•Using the instrument contrary to applicable national safety and accident-prevention laws.

•Incorrect installation, inobservance of, or incorrect procedures in contrast with the instructions provided

in the present manual.

•Defective electrical power supply.

•Modifications or tampering.

•Operations carried out by untrained or unqualified staff.

The safety of the instrument also depends on the strict observance of the procedures indicated in the manual:

always operate the instrument in its functioning capacity and carry out a careful routine maintenance.

•All phases of inspection and maintenance should be carried out by qualified staff.

•The configurations indicated in the manual are the only ones permitted.

•Do not attempt to use the instrument in anyway which is contrary to the indications provided.

•The instructions in this manual do not substitute but are a complement to the obligations of the current

legislation regarding safety laws.

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 3/38

2 Installation

Before installing the instrument, heed the following warnings:

•Connect the instrument strictly following the instructions of the manual.

•It is the responsibility of the user to check, before using, the correct setting of all parameters of the

instrument to avoid damage to persons or things.

•The instrument CANNOT function in a hazardous environment (inflammable or explosive).

•The unit contains parts sensitive to electrostatic charge, therefore handling of the internal electronic

boards has to be carried out with appropriate care to avoid permanent damage.

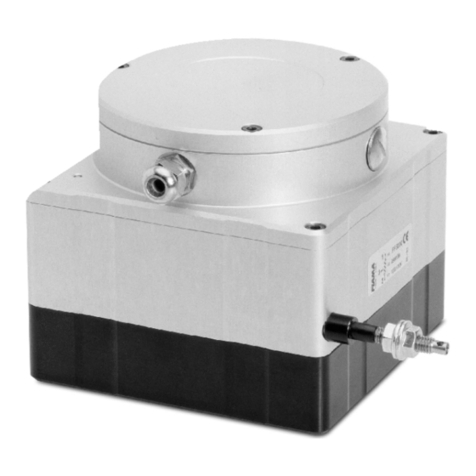

3 Description

The instruments of the F4 and EP4 series are position indicator units with an integrated position sensor,

providing a comprehensive system for measuring linear or rotary displacements.

The fieldbus output (available in Profinet, EthernetIP, Ethercat, IO-Link versions) allows connection to a PLC

or remote supervision system, enabling the creation of a compact measurement device that is easy to install

and applicable to various types of industrial machinery (such as packaging, woodworking, aluminum, sheet

metal, etc.) for implementing manual format changes using handwheels operated by the operator.

The following versions are available:

•F4 with a linear magnetic tape type P50 position transducer,

•F4 AM with a rotary position transducer with magnetic ring mounting with pass-through hollow shaft

with diameters 25mm (AM25), 20mm (AM20), 14mm (AM14),

•F4 EM43 with a rotary transducer with pass-through shaft diameter 14mm,

•F4 EM46 with a rotary transducer with pass-through shaft diameter 20mm or 25mm,

•EP43 with the position transducer with pass-through hollow shaft mounting of diameter 14mm

integrated into the container,

•EP46 with the position transducer with pass-through hollow shaft mounting of diameter 20mm

integrated into the container.

The backlit LCD display has 2 lines: the first indicates the current machine position to the operator, while the

second shows the position to reach for the new machine configuration. This target position is communicated

to the EP4 (or F4) via the fieldbus through the PLC, enabling manual format changes through handwheel

operation. Two LED indicators, green and red, indicate whether the new positioning position has been reached

or not.

With three buttons on the front panel, it is possible to program the value to be shown on the display for each

turn of the hollow shaft and activate functions such as reset/preset of the position, absolute/relative position,

mm/inch conversion (all of these functionalities are also accessible from the remote supervisor).

All activated functions are shown with symbols on the display.

The instrument must be externally powered with a voltage of 10-30VDC and has an internal backup battery

that ensures the maintenance and updating of the position, even in the absence of external power, for a period

of 6-8 years. In the absence of external power, the display is turned off, and communication on the bus is not

managed.

The robust housing of EP4 and F4 is made of solid machined and anodized aluminum alloy, while the

command hollow shaft is made of stainless steel and rotates on ball bearings.

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 4/38

4 Unit programming

4.1 User menu

Note: All the following parameters are also available on the fieldbus.

To access programming of the parameters, keep pressed until appears on the display. Then press O

2 times and 3 zeroes will appear. The first digit on the right will blink: using (digit increase) and. (digit

selection) insert the pass code which is 273 and confirm with O. In case of incorrect insertion of the password,

the unit exits the programming mode.

The various parameters can be scrolled with button and appear in the following order:

value to be shown after one complete rotation of the shaft

number of decimal places

button activation mode

preset quote

count direction

backlash compensation value

target value

tolerance around target value

device address

serial port communication baud rate

parity bit

To modify the selected parameter press O. The value can be changed with and . buttons. Confirm with

button O.

To exit programming press .

4.1.1 Firmware revision

In the password menu of the keypad, by entering the password 732, it will be possible to view information

regarding the version of the instrument and its firmware release.

Note: all versions are compatible with each other.

4.2 Configuration parameters

4.2.1 Value to be shown after one complete rotation of the hollow shaft: Vis

This parameter, together with the following one, defines the value which is shown after one rotation of the

hollow shaft. The allowable range is from 0,0001 to 99999. The decimal place is set after programming the

last digit on the left: after pressing, the decimal place will blink and with it can be moved to the desired position.

Confirm with O.

In the version with a linear transducer for linear magnetic tape (F4), this parameter corresponds to the value

shown on the screen for a displacement of 40mm. With the default value of 40.0, the display shows the

measurement in millimeters and tenths.

In the version with a rotary transducer, this parameter corresponds to the value to be shown on the screen for

each revolution of the hollow shaft.

4.2.2 Number of decimal places nDec

It is the number of decimal places to visualize on the display, allowed range from 0 to 4.

Example 1: if each rotation of the hollow shaft will cause a displacement of 50, set =50 and =0.

Example 2: if each rotation of the hollow shaft will cause a displacement of 12,345 and the desired output on

the display is 12.3, set =12.345 and =1.

4.2.3 Button activation mode: nTasti

This parameter programs the button functions.

The value is a number with 3 digits, each corresponding to a button: the digit on the right sets the O button,

the digit in the middle sets while the last digit on the left sets.

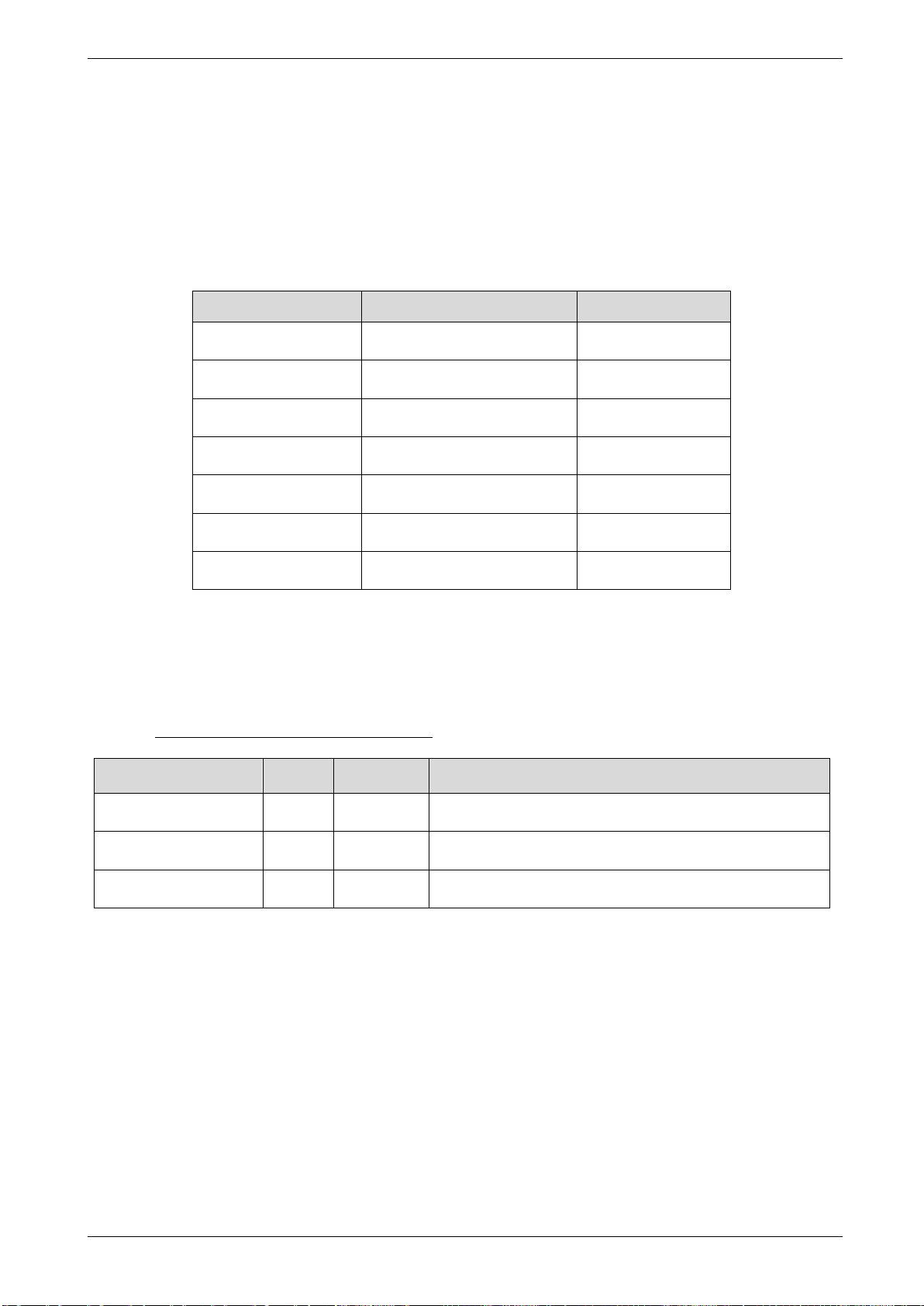

The possible values are in the following table:

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 5/38

VALORE

TASTO

TASTO O

TASTO

0

Not active

Not active

Not active

1

mm/inch conversion

Reset

ABS/REL measurement

2

Not active

Preset

Not active

3

Not active

Fast Preset

Not active

4

Not active

Delayed Reset after 3s (*)

Not active

5

Not active

Delayed Preset after 3s (*)

Not active

(*) Delayed means that to activate the function (reset or preset), it is necessary to keep Opressed for

approximately 3 s.

1) Reset: reset function of the shown value; after pressing Othe shown value is set to zero.

2) Preset: preset function of the shown value; after pressing Othe shown value becomes equal to the value

in the parameter, which can be set immediately after (when the digit on the right is set to 2).

3) Fast Preset: the fast setting of the shown value on the display; after pressing O, appears and

pressing 2 times Oit is possible to set the value directly (use and then confirm with O). This function is useful

when the shown value must be corrected often.

4) Delayed Reset: to activate the function reset it is necessary to keep Opressed for approximately 3 s

5) Delayed Preset: to activate the function preset it is necessary to keep Opressed for approximately 3 s

6) ABS/REL measurement: Enables switching from an absolute to relative value; after pressing, the shown

value is temporarily set to zero to measure a relative motion of the shaft. On the display the rel icon indicates

that the current display is relative to the reference point that has just been created. Pressing again causes the

absolute value to be shown and the abs icon will appear.

Note: The ABS/REL function is enabled only if the measurement is in mm units.

7) mm/inch conversion: Pressing converts the measurement from millimeters to inches and back. When in

inch mode, the inch icon will appear and the shown value will have an additional decimal place. When the

parameter =4 the mm/inch conversion is not available.

4.2.4 Count direction: dir

It sets the count direction, allowed values are 0 or 1.

By setting 0, the shown value increases turning the shaft clockwise.

By setting 1, the shown value decreases turning the hollow shaft clockwise.

4.2.5 Target Value: tgt

Value shown on the first line of the display which indicates the position which must be reached by manual

adjustment.

4.2.6 Backlash compensation value: Loop

If set different to zero, at each inversion of the rotation direction, the shown value does not change until the

shaft completes a rotation which is equal to or above the backlash compensation value.

Set a positive value for backlash compensation in the forward direction and a negative value for compensation

in the reverse direction.

4.2.7 Tolerance around target value: InPos

When the actual value reaches inside the window around the target value (which is defined by the tolerance)

the red LED is turned off the green LED is turned on.

Example: with target value =50 and =10, the green LED is on between 40,1 e 59,9.

4.2.8 Device address: Addr

4.2.8.1 Ethercat version

Default value: 0.

This parameter allows setting the address for Ethercat communication. Use this function ONLY if you are not

using the automatic addressing available with the Ethercat protocol.

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 6/38

Allowed values:

•0 [uses automatic addressing]

•[1-255]

4.2.8.2 Modbus version

This constant represents the address of the instrument for MODBUS communication with the MASTER unit.

Possible values range from 1 to 247. Default value: 1.

4.2.8.3 other versions

Unused in IO-Link, profinet e EthernetIP versions.

4.2.9 Baud rate serial communication: Baud

This parameter is only present in the version with RS485 Modbus serial output and is used to set the baudrate of

the serial communication:

VALORE

Baud rate

0

9600

1

19200

2

38400

3

57600

4

115200

4.2.10 Parity bit: Par

This parameter is only present in the version with RS485 Modbus serial output and is used to set the parity bit of

the serial communication:

VALORE

Parità

0

even

1

odd

2

no parity 2 stop bit

4.3 Status LEDs

The two LEDs positioned beside the display light up according to the current position value, the target position

value, and the InPos parameter value.

If the current position is within the range [target position - InPos; target position + InPos], the green LED will light

up. Otherwise, the red LED will light up.

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 7/38

4.4 Position calibration (via keypad)

After mounting the instrument on the machine and setting all the parameters, to show the correct measurement

on the screen, it is necessary to perform the reset or preset of the position. Position the machine at a point

where the correct measurement to be shown is known precisely (e.g., reference stop) or measure the position

at that point on the axis. Program the parameter with the value 3 in the middle digit and exit

programming. Now press the Obutton, and the word "Preset" will appear. Press Oand set the correct

measurement to be shown on the screen, confirm with O, and the correct measurement will appear on the

display. If the calibration position were to be zero, instead of the preset, it is possible to use the reset by setting

the value 1 in the middle digit of the parameter. Then, pressing Owill zero the measurement on the

display.

Now that the instrument is calibrated, it is necessary to restore the parameter to the desired value to

avoid accidental reset/preset of the position.

5 Battery

The battery status is indicated by the icon on the display and is reported in the specific registers of the fieldbus.

Note: the battery status indicators (icon on display and value on the bus) are updated when the instrument is

powered exclusively by the battery, without external power supply.

5.1 Battery replacement

The battery ensures the maintenance and updating of the position in the absence of external power for at least

6-8 years depending on usage conditions (there is no battery consumption when the instrument is powered).

When the battery icon appears on the display or under the previously indicated conditions, the battery

replacement must be carried out within 15 days.

The replacement procedure is as follows:

1. Power the instrument with external power (to prevent the loss of machine position). If it is necessary to

remove the 24V power supply, proceed with recalibrating the position afterward.

2. Unscrew the two hex screws and remove the battery cover (note: the cover is connected to a flexible cable

and requires maximum attention not to damage or bend it at sharp angles).

3. Remove the depleted battery.

4. Insert the new battery type ½ AA 3.6V, respecting the polarity (negative pole inward).

5. Close the cover, ensuring that the cable is correctly inserted along the length of the battery.

6 Communication protocols

In the following paragraphs, the operation mode of the EP4 and F4 units is described in all available versions

(Modbus, Profinet, EthernetIP, Ethercat, IO-Link).

Please refer ONLY to the version in use.

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 8/38

6.1 Modbus

The EP4 and F4 series instruments are equipped with serial communication, following the Modbus RTU

standard, on an RS485 line. When a power supply is not available, the serial port is not active and the

instrument does not respond to the master.

The data format exchanged consists of 8-bit words with 1 stop bit and a parity bit according to what is set in

the programming parameter Par. The protocol is based on a QUERY/RESPONSE structure: slave devices

respond to queries from a master with a message containing the identifying address and the requested data.

The MODBUS protocol ensures the validity of the exchanged data over the line with a "Cyclic Redundancy

Check" error control; two CRC bytes are appended to the messages.

Further Information on the creation of two CRC bytes are available on www.modicon.com.

The activated MODBUS commands are:

0x03: multiple reading of registers

0x10: writing of several registers.

0x06 writing of one register.

6.1.1 Reading registers

To read the registers of the device, the network master must send a query composed as follows (every element

is a single byte):

ADDRESS | 0x03 | START_REG_HI | START_REG_LO | N_REG_HI | N_REG_LO | CRC_HI | CRC_LO

START_REG_HI | START_REG_LO is the address at the starting 16 bit for the reading

N_REG_HI | N_REG_LO is the number (16 bit) of the registers to be read

The device replies with the following message:

ADDRESS | 0x03 | NBYTE | DATA_1_HI | DATA_1_LO | DATA_2_HI | DATA_2_LO | … | CRC_HI | CRC_LO

NBYTE is the sequence of the data read

DATA_1_HI | DATA_1_LO | DATA_2_HI | DATA_2_LO | … is the stream of data read.

6.1.2 Register writing

To write the registers of the device, the network master must send a query composed as follows (every element

is a single byte):

ADDRESS | 0x10 | START_REG_HI | START_REG_LO | N_REG_HI | N_REG_LO | NBYTE | DATA_1_HI |

DATA_1_LO | DATA_2_HI | DATA_2_LO | … | CRC_HI | CRC_LO

The device replies with the following message:

ADDRESS | 0x10 | START_REG_HI | START_REG_LO | N_REG_HI | N_REG_LO | CRC_HI | CRC_LO

Note:

In case the writing of registers is implemented with a sequence of single writes (i.e., a query to write the first

register, followed by a second query to write the second register, and so on), it is MANDATORY to insert a

delay of at least 100ms (milliseconds) between writing register 0 (Vis) and writing register 2 (vDec).

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 9/38

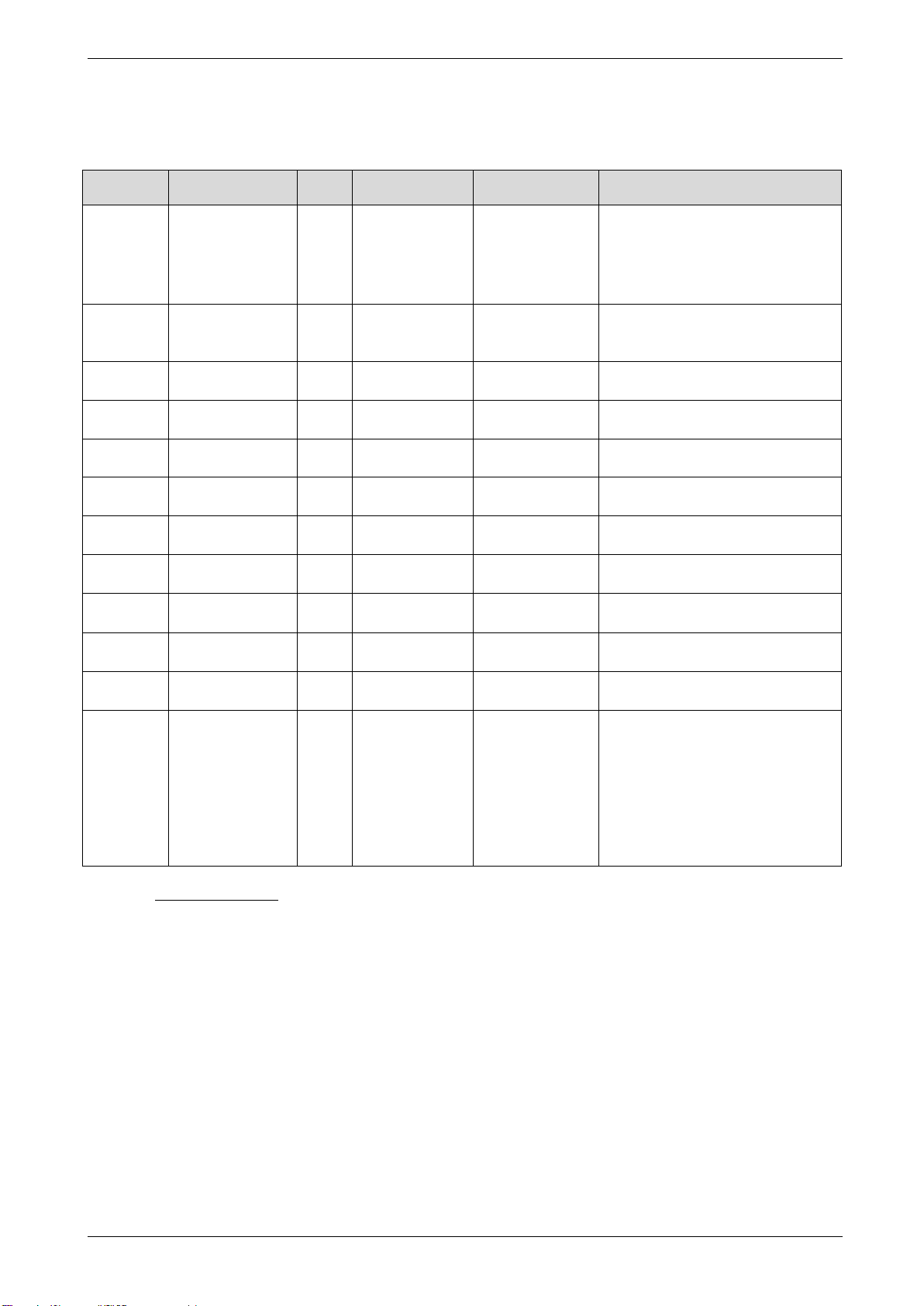

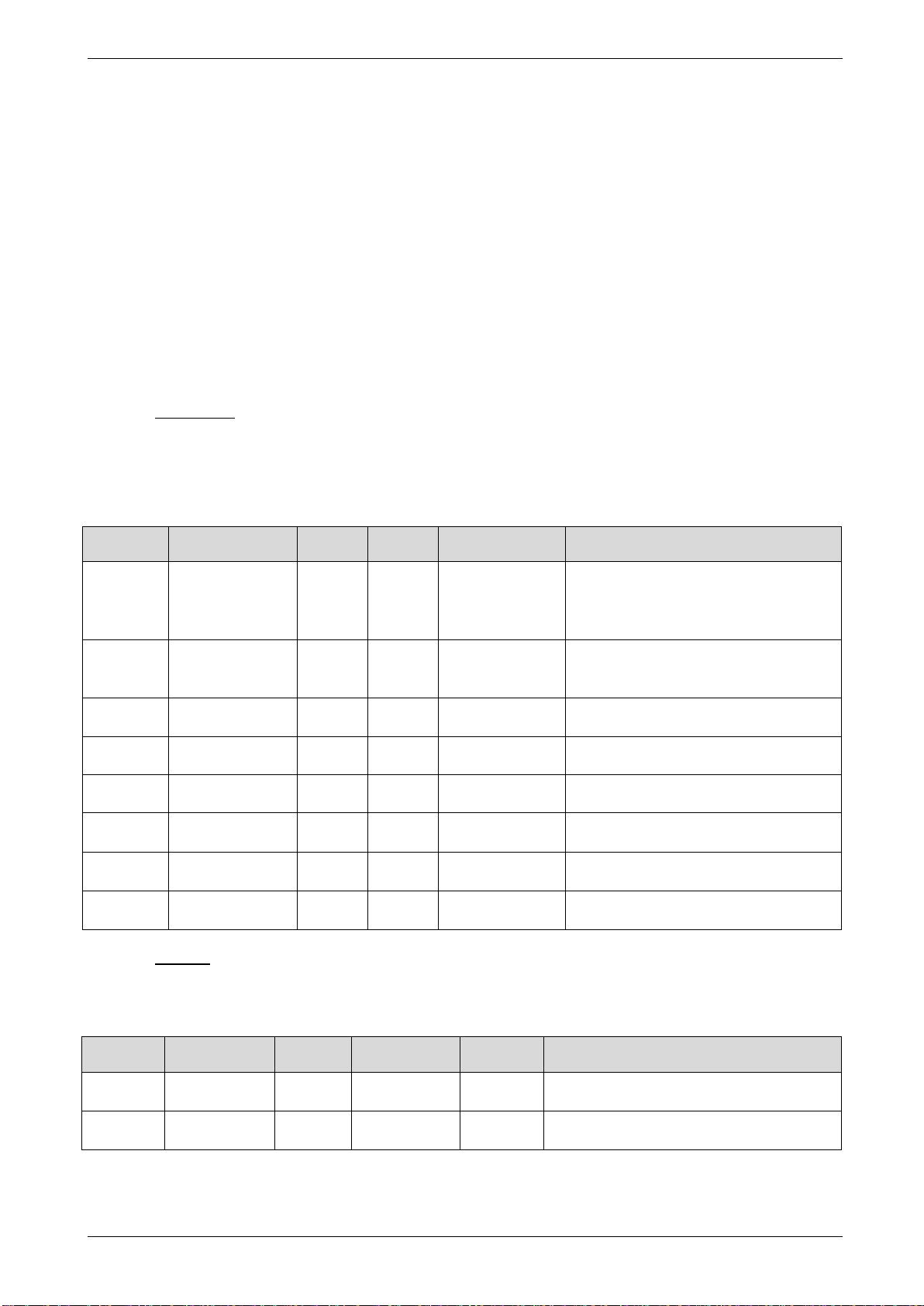

6.1.3 Parameters

The parameters that can be read/written through serial communication are listed in the table below.

A more detailed explanation of the following parameters is available in the "User Menu" chapter.

Indirizzo

modbus

Parametro

Size

Range

Default value

Funzione

0

Visual

4

1..99999

•1000 (EP4)

•400 (F4)

•value to be shown after one

complete rotation of the shaft

(EP4)

•value to be shown after 40mm

displacement (F4)

2

vDec

2

0..4

1

It is the number of decimal places

in the Visual parameter

3

nDec

2

0..4

1

It is the number of decimal places

to visualize on the display

4

nTasti

2

0..0x151

0x111

It is the button activation mode

5

Dir

2

0..1

0

Counting direction

6

Preset

4

-99999

+99999

0

Preset position value

8

Loop

4

-99999

+99999

0

Backlash compensation value

10

Positioning

window

2

0..30000

10

Positioning window value

11

Error

2

Refer to the next section “battery

status”

12

Quota

4

-99999

+99999

14

Target

4

-99999

+99999

16

Control

2

By writing the indicated values via

Modbus, it is possible to activate

the corresponding functionalities:

0x4141: Activates the always-on

display feature.

0x4040: Deactivates the always-on

display feature.

6.1.3.1 Always on display

By writing (via Modbus) 0x4141 to the Control register, the EP4 activates the "always-on display" functionality.

The device will display the target position and the current position even in the absence of external power.

Additionally, the configuration menu and the three buttons remain active. However, the status LEDs and the

display backlight are turned off. The impact on battery consumption of this functionality is approximately 15%.

By writing 0x4040 to the Control register, the EP4 deactivates the "always-on display" functionality.

By writing 0x1111 to the Control register, the EP4 resets the Error register to the value 0.

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 10/38

6.1.3.2 Battery status

The battery status is indicated by the icon on the display and the Modbus Error register.

The Modbus Error register can take the following values to indicate the battery status:

•0x0000: In case of optimal operating condition.

•0xFFFF: If the battery level has dropped below a critical threshold. In this case, it is necessary to proceed

with replacement within 15 days.

•0x00FF: If the battery is completely discharged, absent, or faulty. In this case, the battery must be

immediately replaced because in this state, it is not guaranteed that the instrument can save the current

position value when the 24V power supply is removed.

WARNING: If this value is present in the Error register at machine startup, it is necessary to perform the

machine repositioning procedure (homing or reset) because the position detected by the EP4 is no longer

aligned with the actual position of the machine.

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 11/38

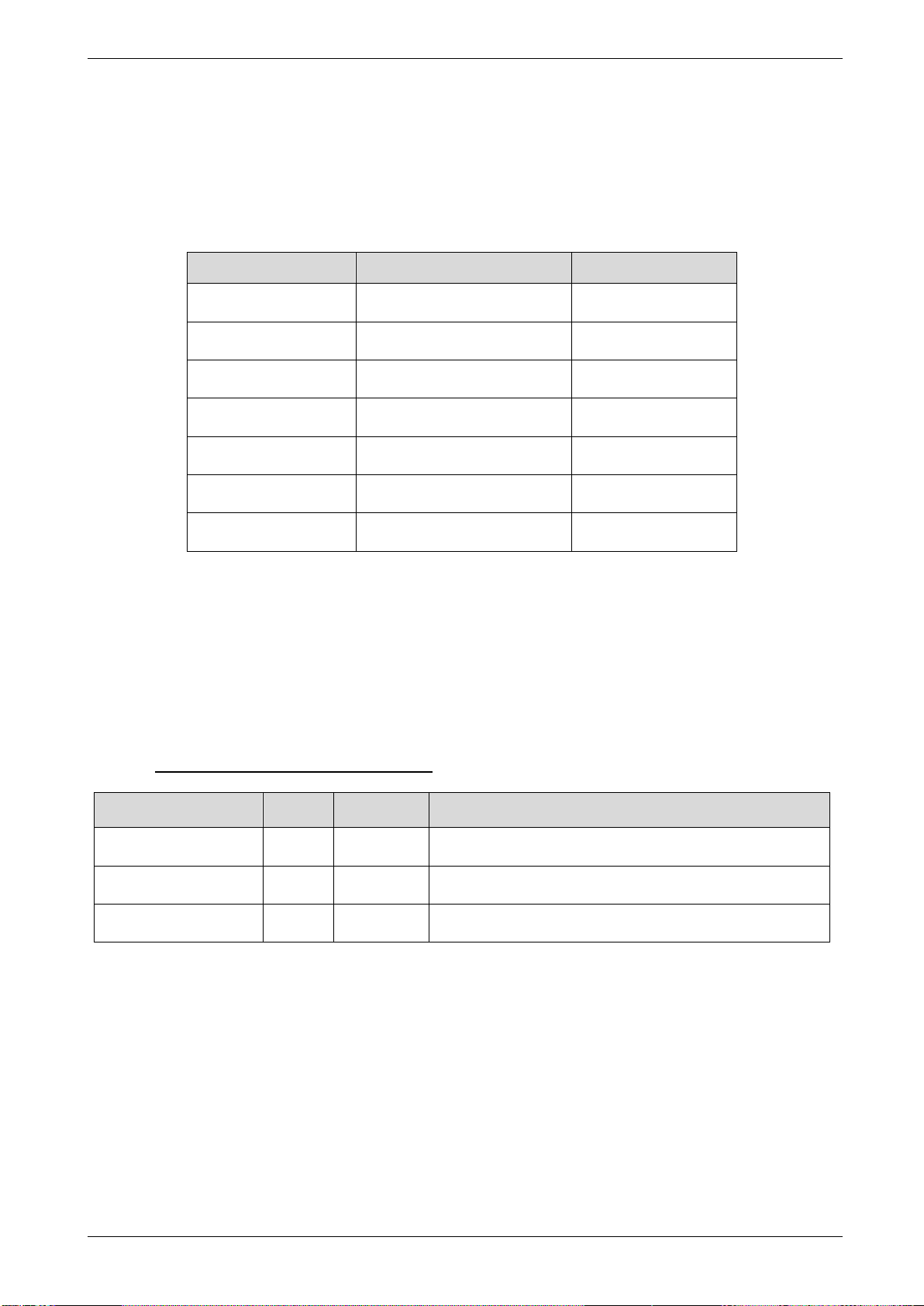

6.2 Profinet

EP4 and F4 implement the Profinet IRT protocol (conformity class C) for IO-Device units, Ethernet interface.

Communication consists of a cyclic part (Status e Target) and an acyclic part (Parameters).

To correctly associate EP4 and F4 devices with the appropriate Profinet ProductFamily, please refer to the

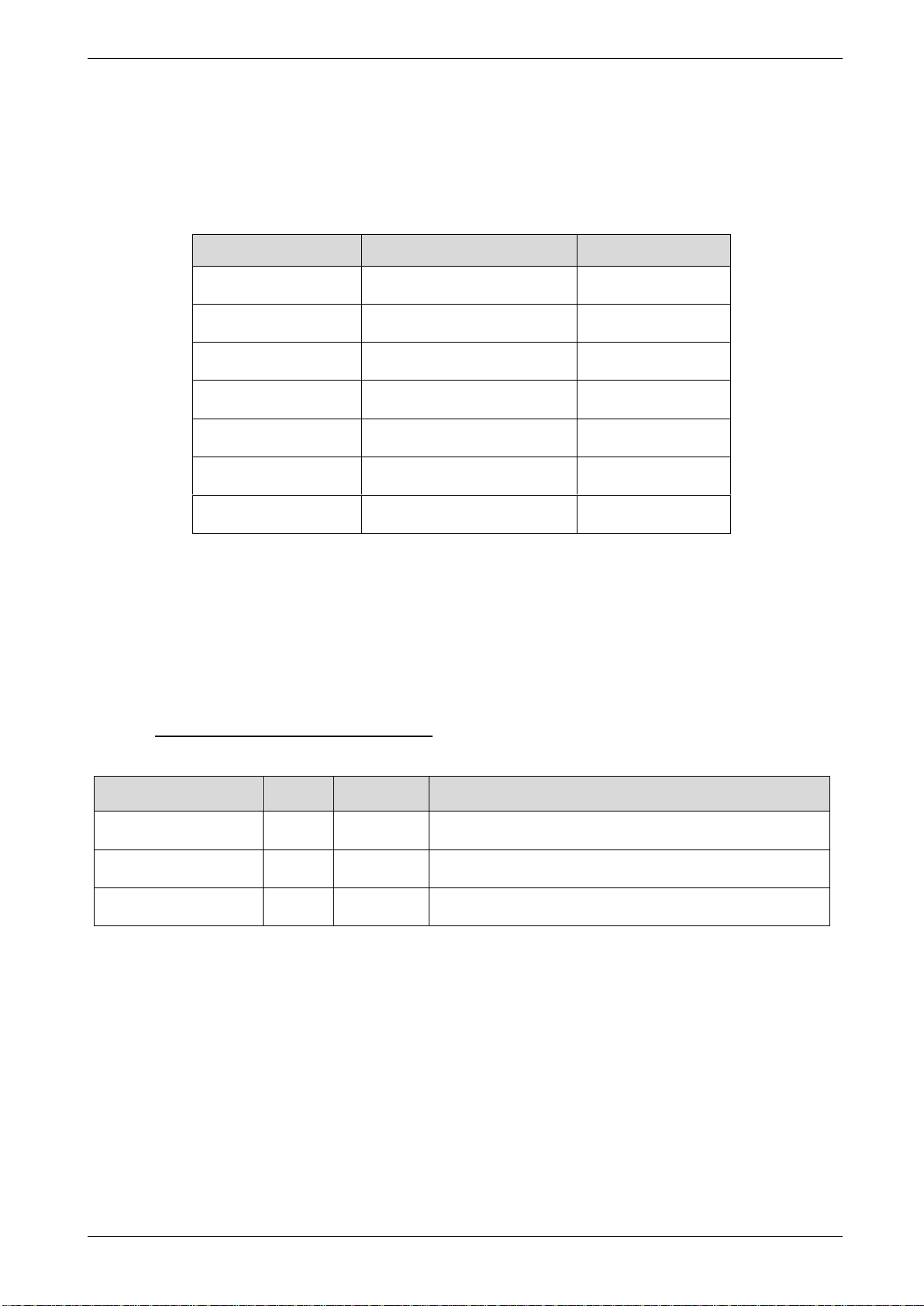

table below:

Codice

Profinet device name

Profinet device id

EP43NET

EP4NET

0x0111

EP46NET

EP4NET

0x0111

F4NET-AM

EP4NET

0x0111

F4NET-MT

F4NET

0x0112

F4NET-M12

F4NET

0x0112

F4NET-EM43

EP4NET

0x0111

F4NET-EM46

EP4NET

0x0111

Please ensure to select the appropriate Profinet ProductFamily corresponding to your EP4 or F4 device model.

The communication (I/O) part of the two product families is identical.

The communication is structured into a cyclic part (State and Target) and an acyclic part (Parameters).

6.2.1 Cyclic communication (Process Data)

The cyclic communication of the EP4/F4 families is designed for the exchange of 10 input bytes and 4 output

bytes. A punctual description of each byte is provided later on to make their understanding easier.

6.2.1.1 Inputs (Slave → Master): 10byte, 5 word

Nome

Size

(byte)

Tipo

Funzione

Status word

2

UINT

Word showing the device status (Status word table).

Actual position

4

DINT

Actual position

Actual target position

4

DINT

Target position which is currently shown on the display

Status word: when moving from 0 to 1, each bit in this word warns about a different status of the device. The

meaning of each status is explained below.

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 12/38

Bit

Nome

Descrizione

0

Ready

Device ready

1

Target reached

The current position is within the positioning window.

2

Battery low

The battery charge level is below a critical threshold: in this case it is necessary

to substitute it within 15 days.

3

Battery fault

The battery is completely discharged, absent, or malfunctioning. In this case the

battery must be immediately replaced because in this state it is not guaranteed

that the instrument will be able to maintain the correct value when the 24VDC

power supply is off.

NOTE: if this bit is present when the machine is turned on, it is necessary

to execute a homing or reset procedure because the value measured by the

EP4NET is no longer consistent with the actual position of the machine.

4

Encoder fault

Internal encoder fault

6.2.1.2 Outputs (Master → Slave): 4 byte, 1 dword

Nome

Size

(byte)

Tipo

Funzione

Target position

4

DINT

Target position to be shown on the display

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 13/38

6.2.2 Acyclic communication (record data)

The EP4 and F4 device uses two groups of acyclic parameters which contain the 11 parameters used for

configuration.

The first group contains the configuration parameters for visualization (the same parameters which are

accessible from the device menu). These parameters are mapped as initial record data, that is as acyclic

parameters whose value is written by the PLC ad every new connection of the unit (and so also when the unit

is powered on). These (initial) values are contained within the GSDML file and can be modified by the

development environment of the control unit which is used.

Since they are acyclic parameters, they can be read and written, with the specific commands, also during

operation; note that each time the unit is turned on, the PLC will restore the initial configuration.

All of these parameters can be read and written.

The second group contains only the current position and the target position in order to allow both a preset and

acyclic reset. These two parameters are NOT mapped as initial record data. It is possible to conduct an acyclic

write using a web server which is available at the IP address of the device, or through a function block.

All of the parameters can be modified in any moment.

6.2.2.1 Parameters

Index: 3

This set of parameters is used as Initial Record Data, i.e. as the initial values that the PLC automatically

sends to the EP4_NET unit whenever it is switched on.

For a more detailed description of the following parameters please refer to the Unit programming section.

Indice

parametro

Parametro

Tipo

Range

Default value

Funzione

0

Visual

UDINT

1..99999

•1000 (EP4)

•400 (F4)

•value to be shown after one

complete rotation of the shaft (EP4)

•value to be shown after 40mm

displacement (F4)

1

vDec

UINT

0..4

1

It is the number of decimal places in the

Visual parameter

2

nDec

UINT

0..4

1

It is the number of decimal places to

visualize on the display

3

nTasti

UINT

0..0x151

0x111

Button activation mode

4

Dir

UINT

0..1

0

count direction

5

Preset

DINT

-99999

+99999

0

Preset value

6

Loop

DINT

-99999

+99999

0

backlash compensation value

7

Positioning

window

UINT

0..30000

10

target value tolerance

6.2.2.2 Position

Index: 4

This set contains exclusively the two useful positions of the device.

It is possible to reset the positions or preset them to a desired value by using acyclic access.

Indice

parametro

Parametro

Tipo

Range

Accesso

Funzione

0

Position

DINT

-99999

+99999

R/W

Actual position of device

1

Target position

DINT

-99999

+99999

R/W

Target position of device

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 14/38

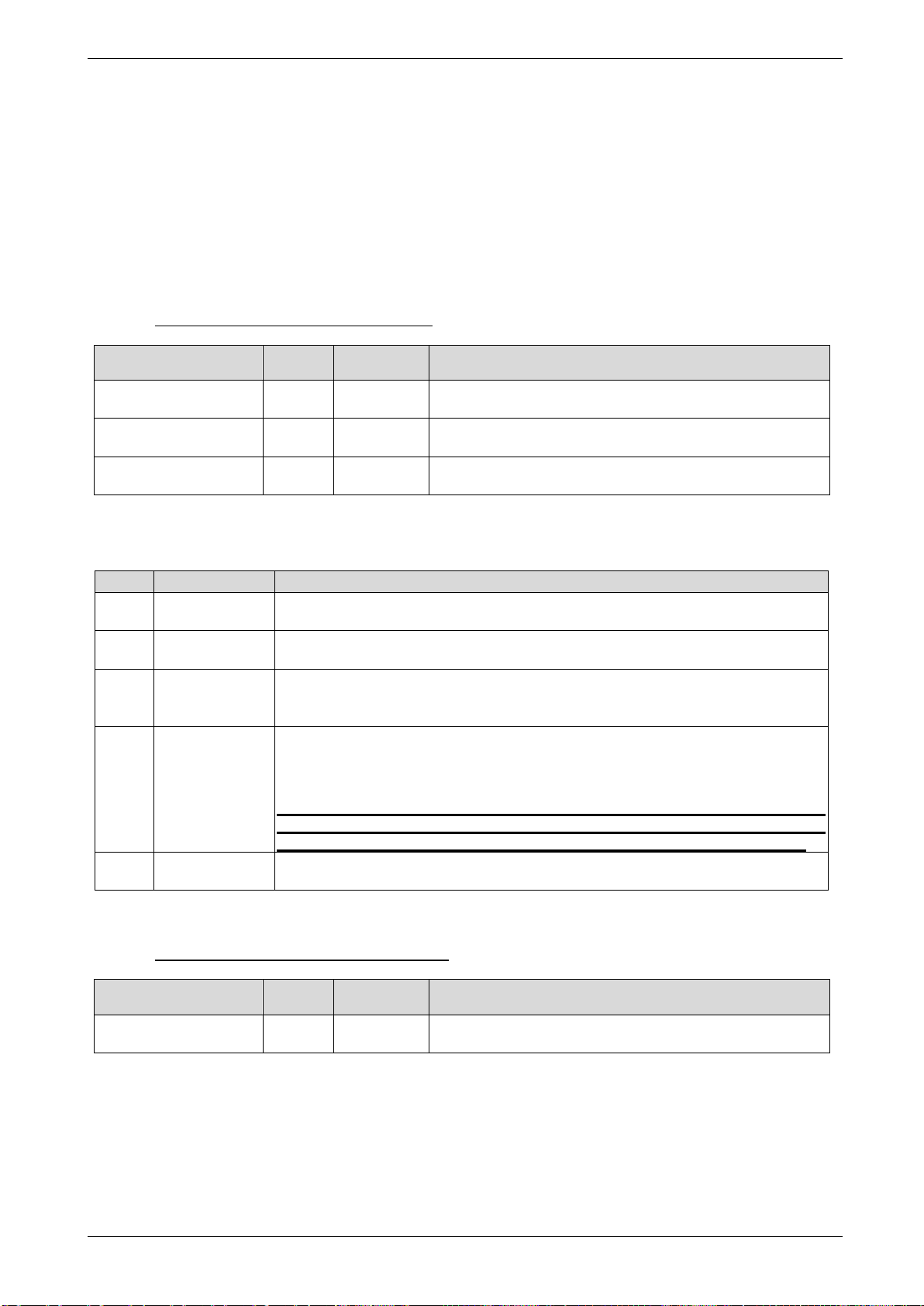

6.3 Ethernet IP communication protocol

EP4 and F4 implement the EthernetIP protoco for IO-Device units, Ethernet interface. Communication consists

of a cyclic part (Status e Target) and an acyclic part (Parameters).

To correctly associate EP4 and F4 devices with the appropriate EthernetIP ProductFamily, please refer to the

table below:

Codice

Ethernet IP prodName

EthernetIP prodCode

EP43NET

Fiama EP4NET

0x0111

EP46NET

Fiama EP4NET

0x0111

F4NET-AM

Fiama EP4NET

0x0111

F4NET-MT

Fiama F4NET

0x0112

F4NET-M12

Fiama F4NET

0x0112

F4NET-EM43

Fiama EP4NET

0x0111

F4NET-EM46

Fiama EP4NET

0x0111

Please ensure to select the appropriate Profinet ProductFamily corresponding to your EP4 or F4 device model.

The communication (I/O) part of the two product families is identical.

The communication is structured into a cyclic part (State and Target) and an acyclic part (Parameters)

6.3.1 Cyclic communication (Process Data)

The cyclic communication of the EP4/F4 families is designed for the exchange of 10 input bytes and 4 output

bytes. A punctual description of each byte is provided later on to make their understanding easier.

6.3.1.1 Inputs (Slave → Master): 10byte, 5 word

Nome

Size

(byte)

Tipo

Funzione

Status word

2

UINT

Word showing the device status (Status word table).

Actual position

4

DINT

Actual position

Actual target position

4

DINT

Target position which is currently shown on the display

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 15/38

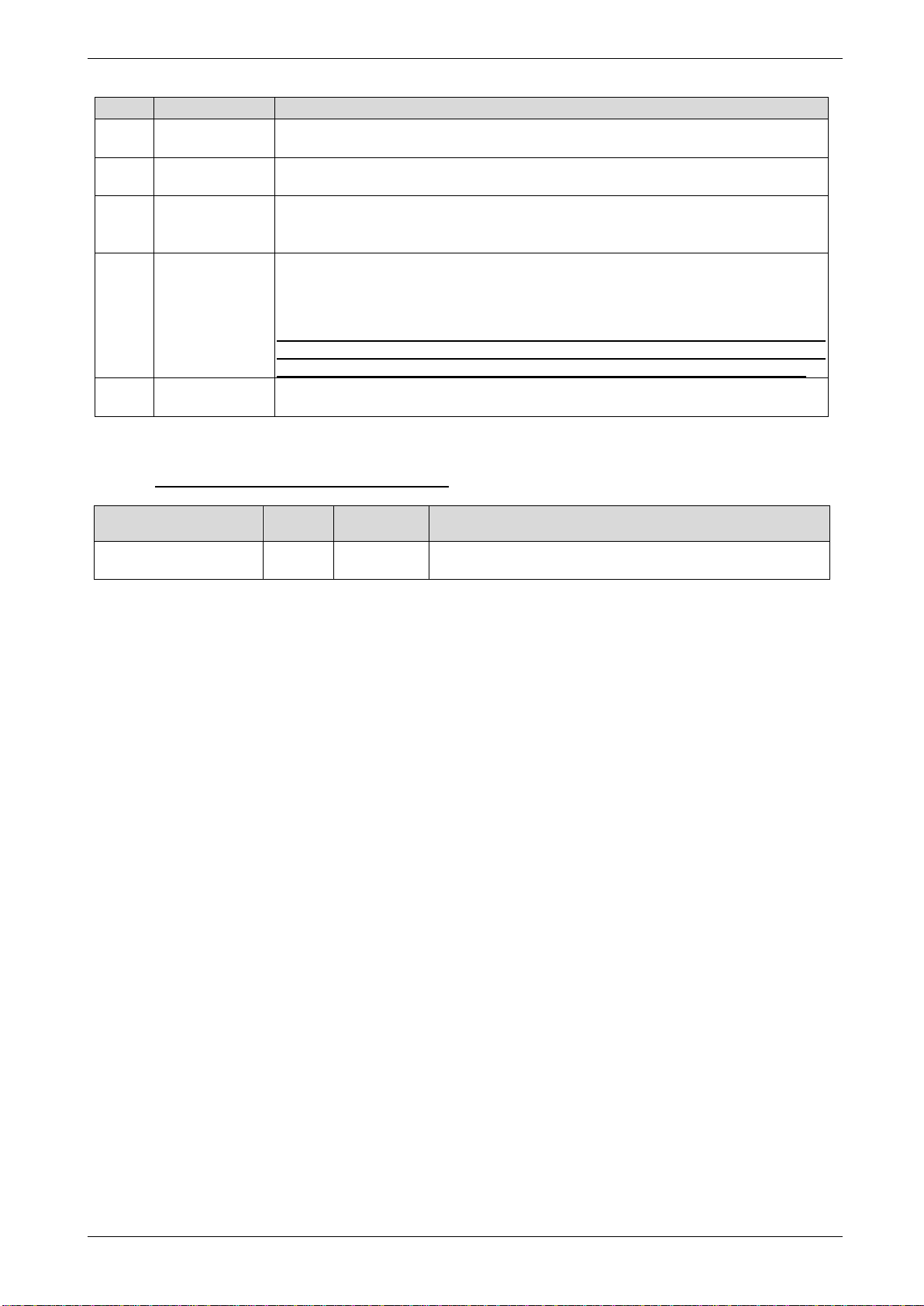

Status word: when moving from 0 to 1, each bit in this word warns about a different status of the device. The

meaning of each status is explained below.

Bit

Nome

Descrizione

0

Ready

Device ready

1

Target reached

The current position is within the positioning window.

2

Battery low

The battery charge level is below a critical threshold: in this case it is necessary

to substitute it within 15 days.

3

Battery fault

The battery is completely discharged, absent, or malfunctioning. In this case the

battery must be immediately replaced because in this state it is not guaranteed

that the instrument will be able to maintain the correct value when the 24VDC

power supply is off.

NOTE: if this bit is present when the machine is turned on, it is necessary

to execute a homing or reset procedure because the value measured by the

EP4NET is no longer consistent with the actual position of the machine.

4

Encoder fault

Internal encoder fault

6.3.1.2 Outputs (Master → Slave): 4 byte, 1 dword

Nome

Size

(byte)

Tipo

Funzione

Target position

4

DINT

Target position to be shown on the display

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 16/38

6.3.2 Acyclic communication (record data)

The EP4 and F4 device uses two groups of acyclic parameters which contain the 11 parameters used for

configuration.

The first group contains the configuration parameters for visualization (the same parameters which are

accessible from the device menu). These parameters are mapped as initial record data, that is as acyclic

parameters whose value is written by the PLC ad every new connection of the unit (and so also when the unit

is powered on). These (initial) values are contained within the GSDML file and can be modified by the

development environment of the control unit which is used.

Since they are acyclic parameters, they can be read and written, with the specific commands, also during

operation; note that each time the unit is turned on, the PLC will restore the initial configuration.

All of these parameters can be read and written.

The second group contains only the current position and the target position in order to allow both a preset and

acyclic reset. These two parameters are NOT mapped as initial record data. It is possible to conduct an acyclic

write using a web server which is available at the IP address of the device, or through a function block.

All of the parameters can be modified in any moment.

6.3.2.1 Parameters

Index: 3

This set of parameters is used as Initial Record Data, i.e. as the initial values that the PLC automatically

sends to the EP4_NET unit whenever it is switched on.

For a more detailed description of the following parameters please refer to the Programming section.

Indice

parametro

Parametro

Tipo

Range

Default value

Funzione

0

Visual

UDINT

1..99999

•1000 (EP4)

•400 (F4)

•value to be shown after one

complete rotation of the shaft (EP4)

•value to be shown after 40mm

displacement (F4)

1

vDec

UINT

0..4

1

decimal point position for

2

nDec

UINT

0..4

1

decimal point position on display

3

nTasti

UINT

0..0x151

0x111

button activation mode

4

Dir

UINT

0..1

0

count direction

5

Preset

DINT

-99999

+99999

0

Preset value

6

Loop

DINT

-99999

+99999

0

backlash compensation value

7

Positioning

window

UINT

0..30000

10

target value tolerance

6.3.2.2 Position

Index: 4

This set contains exclusively the two useful positions of the device.

It is possible to reset the positions or preset them to a desired value by using acyclic access.

Indice

parametro

Parametro

Tipo

Range

Accesso

Funzione

0

Position

DINT

-99999

+99999

R/W

Actual position of device

1

Target position

DINT

-99999

+99999

R/W

Target position of device

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 17/38

To access the previous data structures acyclically, it is necessary to set the msg functions as follows (the

example image is taken from the function available for rslogix5000):

With this command, the entire parameter block is read from the PLC and saved in the structure set as the

'Destination element'. Similarly, for writing, the 'Set attribute single' command should be used to send a

structure containing all the configuration bytes to the unit.

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 18/38

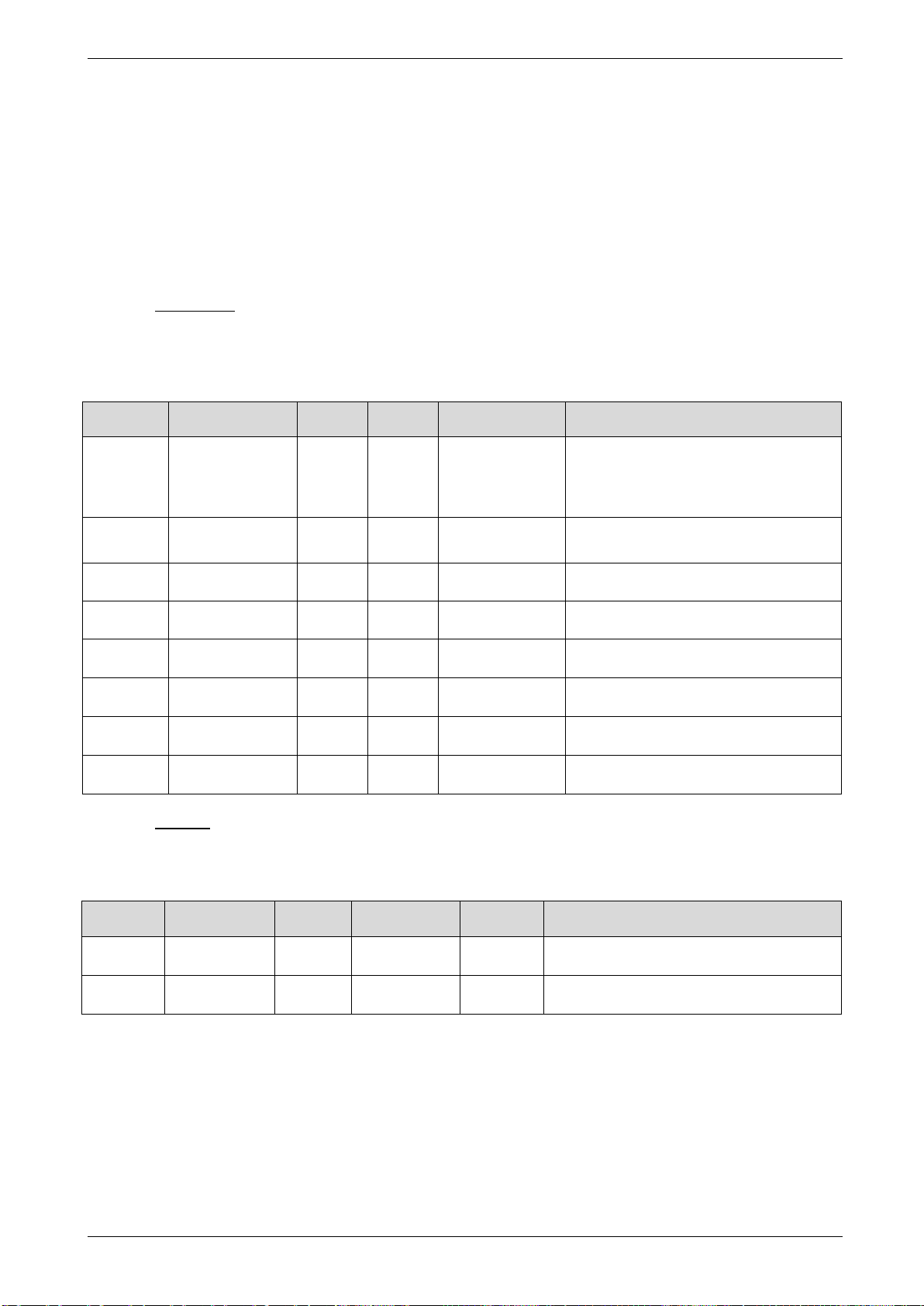

6.4 Ethercat communication protocol

EP4 and F4 implement the Profinet IRT protocol (conformity class C) for IO-Device units, Ethernet interface.

Communication consists of a cyclic part (Status e Target) and an acyclic part (Parameters).

The communication (I/O) part of the two product families is identical.

6.4.1 Cyclic communication (Process Data)

The cyclic communication of the EP4/F4 families is designed for the exchange of 10 input bytes and 4 output

bytes. A punctual description of each byte is provided later on to make their understanding easier.

6.4.1.1 Inputs (Slave → Master): 10byte, 5 word

Nome

Size

(byte)

Tipo

Funzione

Status word

2

UINT

Word showing the device status (Status word table).

Actual position

4

DINT

Actual position

Actual target position

4

DINT

Target position which is currently shown on the display

Status word: when moving from 0 to 1, each bit in this word warns about a different status of the device. The

meaning of each status is explained below.

Bit

Nome

Descrizione

0

Ready

Device ready

1

Target reached

The current position is within the positioning window.

2

Battery low

The battery charge level is below a critical threshold: in this case it is necessary

to substitute it within 15 days.

3

Battery fault

The battery is completely discharged, absent, or malfunctioning. In this case the

battery must be immediately replaced because in this state it is not guaranteed

that the instrument will be able to maintain the correct value when the 24VDC

power supply is off.

NOTE: if this bit is present when the machine is turned on, it is necessary

to execute a homing or reset procedure because the value measured by the

EP4NET is no longer consistent with the actual position of the machine.

4

Encoder fault

Internal encoder fault

6.4.1.2 Outputs (Master → Slave): 4 byte, 1 dword

Nome

Size

(byte)

Tipo

Funzione

Target position

4

DINT

Target position to be shown on the display

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 19/38

6.4.2 Acyclic communication (SDO)

The EP4 and F4 device uses two groups of acyclic parameters which contain the 11 parameters used for

configuration.

The first group contains the configuration parameters for visualization (the same parameters which are

accessible from the device menu).

The second group contains only the current position and the target position in order to allow both a preset and

acyclic reset. It is possible to conduct an acyclic write using a web server which is available at the IP address

of the device, or through a function block.

All of the parameters can be modified in any moment.

6.4.2.1 Parameters

Index: 3

This set of parameters is used as Initial Record Data, i.e. as the initial values that the PLC automatically

sends to the EP4_NET unit whenever it is switched on.

For a more detailed description of the following parameters please refer to the Programming section.

Indice

parametro

Parametro

Tipo

Range

Default value

Funzione

0

Visual

UDINT

1..99999

•1000 (EP4)

•400 (F4)

•value to be shown after one

complete rotation of the shaft (EP4)

•value to be shown after 40mm

displacement (F4)

1

vDec

UINT

0..4

1

decimal point position for

2

nDec

UINT

0..4

1

decimal point position on display

3

nTasti

UINT

0..0x151

0x111

button activation mode

4

Dir

UINT

0..1

0

count direction

5

Preset

DINT

-99999

+99999

0

Preset value

6

Loop

DINT

-99999

+99999

0

backlash compensation value

7

Positioning

window

UINT

0..30000

10

target value tolerance

6.4.2.2 Position

Index: 4

This set contains exclusively the two useful positions of the device.

It is possible to reset the positions or preset them to a desired value by using acyclic access.

Indice

parametro

Parametro

Tipo

Range

Accesso

Funzione

0

Position

DINT

-99999

+99999

R/W

Actual position of device

1

Target position

DINT

-99999

+99999

R/W

Target position of device

6.4.3 Ethercat address

The indicators of EP4 and F4 series allow the use of automatic addressing functions defined by the Ethercat

protocol. However, it is still possible to set the Ethercat address using the ADDR parameter in the instrument's

menu. In case the automatic addressing feature is used, leave ADDR at the default value (0).

Digital position indicators with fieldbus –user manual

31/01/2024 EP4_F4 user manual.docx rev: 1.2 pag 20/38

6.5 IO-Link communication protocol

EP4 and F4 implement the IO-Link protoclfor IO-Device units. Communication consists of a cyclic part (Status

e Target) and an acyclic part (Parameters).

To correctly associate EP4 and F4 devices with the appropriate IO-Link ProductFamily, please refer to the

table below:

Codice

IO-Link device name

IO-Link device id

EP43NET

EP4NET

0x0111

EP46NET

EP4NET

0x0111

F4NET-AM

EP4NET

0x0111

F4NET-MT

F4NET

0x0112

F4NET-M12

F4NET

0x0112

F4NET-EM43

EP4NET

0x0111

F4NET-EM46

EP4NET

0x0111

The communication (I/O) part of the two product families is identical.

6.5.1 Cyclic communication (Process Data)

The cyclic communication of the EP4/F4 families is designed for the exchange of 10 input bytes and 4 output

bytes. A punctual description of each byte is provided later on to make their understanding easier.

6.5.1.1 Inputs (Slave → Master): 10byte, 5 word

Nome

Size

(byte)

Tipo

Funzione

Status word

2

UINT

Word showing the device status (Status word table).

Actual position

4

DINT

Actual position

Actual target position

4

DINT

Target position which is currently shown on the display

Other manuals for EP43RS

1

This manual suits for next models

13

Table of contents

Other FIAMA Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Kapro

Kapro Prolaser Vector 873 user manual

REED

REED ST-332 instruction manual

Sencore

Sencore ReZolver LC103 Operation and application manual

Pepperl+Fuchs

Pepperl+Fuchs WS-UC F406-B41 Series manual

AUTOFLAME

AUTOFLAME MK8 EGA EVO Setup guide

Seikom Electronic

Seikom Electronic NLSW45-3Ex operating instructions