RM-6000 - 1 -

<Contents>

1. Outline of the Product........................................................................................................... 2

1-1. Preface........................................................................................................................... 2

1-2. Purpose of use ............................................................................................................... 2

1-3. Definition of DANGER, WARNING, CAUTION, and NOTE ............................................ 3

1-4. Method of confirmation for CE marking type .................................................................. 3

2. Important Notices on Safety ................................................................................................. 4

2-1. Danger cases ................................................................................................................. 4

2-2. Warning cases................................................................................................................ 5

2-3. Precautions .................................................................................................................... 6

3. Product Components............................................................................................................ 7

3-1. Main unit and accessories .............................................................................................. 7

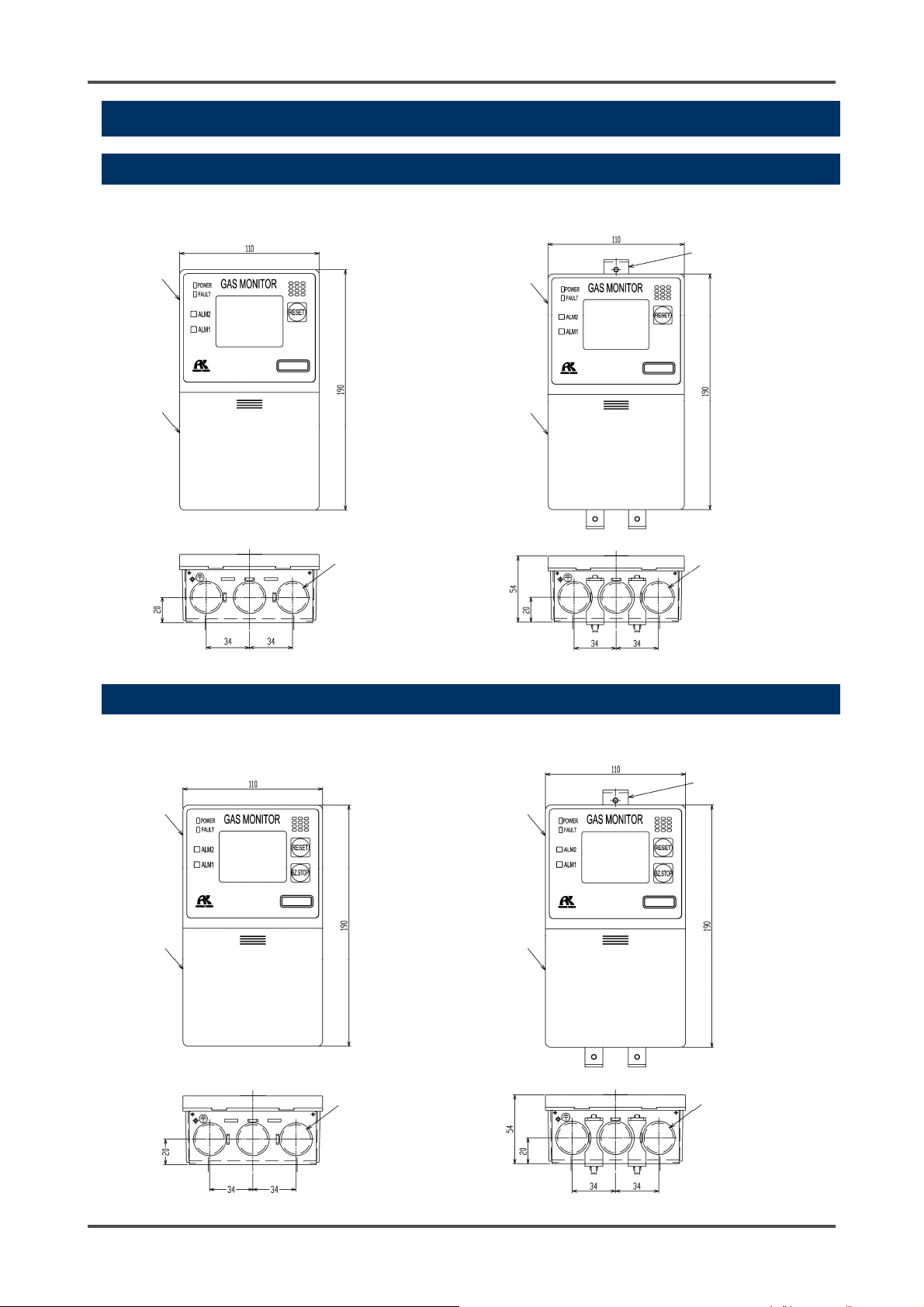

3-2. Outline drawing .............................................................................................................. 8

3-2-1. Self-latching/auto-reset operation specifications ...................................................... 8

3-2-2. Lock-in operation specifications ............................................................................... 8

3-3. Names and functions for each part................................................................................. 9

3-4. Block diagram................................................................................................................. 12

4. How to Use........................................................................................................................... 13

4-1. Before using the indicator/alarm unit .............................................................................. 13

4-2. Precautions for installation points................................................................................... 13

4-3. Precautions for system designing................................................................................... 15

4-4. How to install .................................................................................................................. 17

4-5. How to wire..................................................................................................................... 19

5. How to Operate .................................................................................................................... 27

5-1. Preparation for start-up................................................................................................... 27

5-2. Basic operating procedures............................................................................................ 28

5-3. How to start the indicator/alarm unit ............................................................................... 29

5-4. Modes ............................................................................................................................ 30

5-5. Detection mode .............................................................................................................. 32

5-6. Alarm test mode ............................................................................................................. 33

5-7. User mode...................................................................................................................... 34

5-8. How to exit...................................................................................................................... 38

6. Operations and Functions .................................................................................................... 39

6-1. Gas alarm activation....................................................................................................... 39

6-2. Fault alarm activation ..................................................................................................... 42

6-3. External output operation ............................................................................................... 43

6-4. Other functions ............................................................................................................... 45

7. Maintenance......................................................................................................................... 47

7-1. Maintenance intervals and items .................................................................................... 47

7-2. Regular maintenance mode ........................................................................................... 49

7-3. Gas calibration method .................................................................................................. 65

7-4. How to clean................................................................................................................... 68

7-5. How to replace the fuse.................................................................................................. 68

8. Storage, Relocation and Disposal ........................................................................................ 69

8-1. Procedures to store the indicator/alarm unit or leave it for a long time........................... 69

8-2. Procedures to relocate the indicator/alarm unit or use it again....................................... 69

8-3. Disposal of products....................................................................................................... 69

9. Troubleshooting.................................................................................................................... 70

10. Product Specifications ..................................................................................................... 73

10-1. List of specifications ..................................................................................................... 73

10-2. List of accessories........................................................................................................ 75

11. Definition of Terms .............................................................................................................. 76