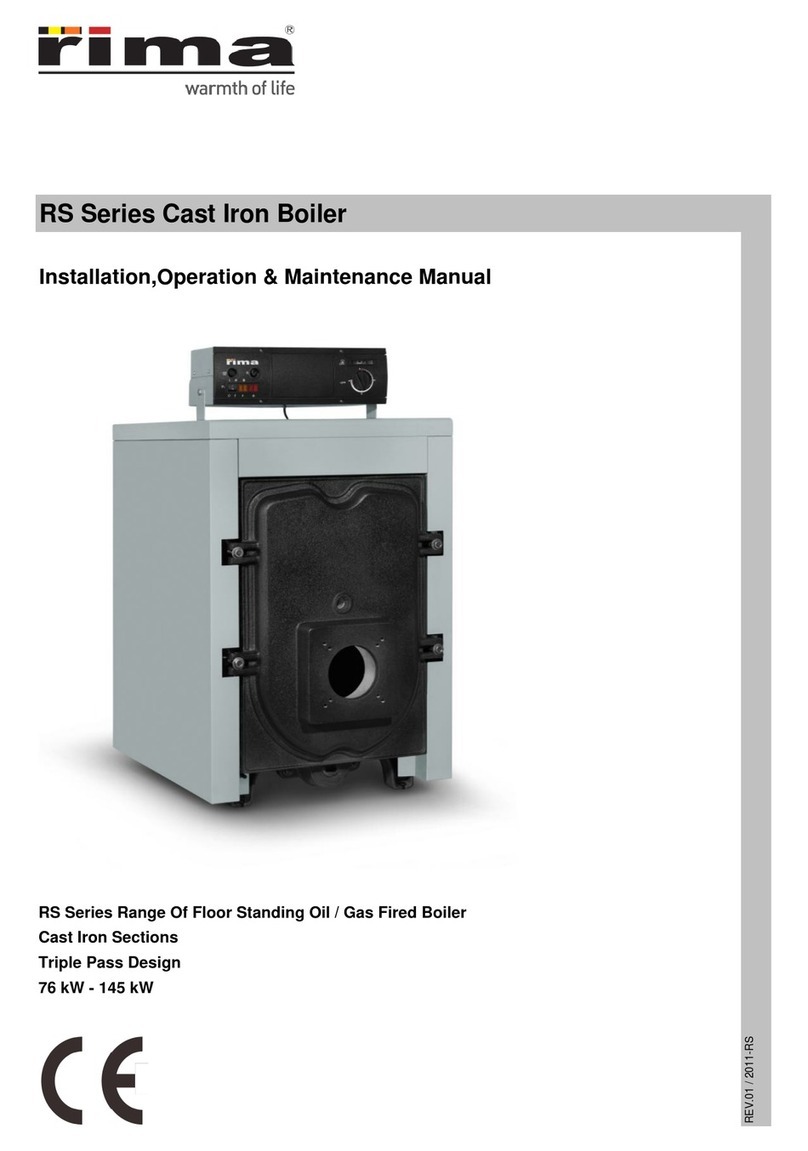

• All electrical and electronic controls are supported on the control panel located at the top of the boiler.

• The cleaning of the installation is of utmost importance for the transformation projects from boilers

with solid fuel or liquid fuel to boilers with gas fuel. The installation shall be washed, any leaks shall be

detected and repaired and a plate type heat exchanger shall be used.

• Boilers shall be installed in a place with no risk of frost. When the boiler is not operated, the water remaining

in the radiators shall be drained to prevent freezing.

• Boilers shall not be installed in a location that contains moisture, vapor or dust. Otherwise the boiler shall not

operate correctly and efficiently.

• The floor of the installation location of the boiler shall be stable, firm and wide, and it shall be positioned

high above the ground in order not to be affected by floods.

• The supply of fresh air shall be free of halogen hydrocarbons (sprays, paints and some chemicals), otherwise

these shall cause corrosion and erosion of the boiler and flue.

• Flammable materials shall not be placed on or near the boiler.

• Fresh air intake shall comply with the instructions of the local gas supplier and the instructions for gas

connection, otherwise there is a risk of poisoning.

• Condensate and flue connections shall be made in accordance with the rules and standards.

• Before starting to work on the boiler, always disconnect the main power line and turn off the main gas valve.

• If you smell gas, turn off the main gas valve and call the emergency number for gas leaks in your

neighbourhood. If you smell flue gas, turn off the boiler and call the authorized service immediately

Combustibility (flammability) levels of construction materials and products

Granite, sandstone, concrete, brick, ceramic, fireproof plasters

B- Very Difficult to Burn

acumin, isumin, heraclith, lignose, fiberglass components

Products made of beech or oak, hobrex plates, werzalit, umuakart

C2- Medium Combustibility

Wet wood, black pine, cork and tree crumbs, rubber sole

Asphalt Components, Fiber components, cellulose materials, polyurethane, polystyrene, PVC, polyethylene

Keep the boilers at least 200 mm away from flammable materials with B, C1, C2 burning classes as specified

in the table during their installation and operation.

• For materials that burn rapidly and by themselves after any spark, that are easily ignitable with a burning

class of C3, increase the safety distance to at least 400 mm.

The boiler is set for natural gas H/E (G20, 20 mbar) in the factory.

• The boiler shall only be installed in a room that meets proper ventilation requirements and that is separated

from living areas. Otherwise there is a risk of suffocation or poisoning.

• To prevent incorrect circulation, control valves shall be used in conjunction with the circulation pump

system. A strainer (filter) shall be used in the return water lines of the new/old buildings and new/old

installation systems.

• A relief valve (max. 6 bar) and a manometer shall be used in the installation system. No other valves shall be

present between the boiler and the relief valve, otherwise pipes or other parts may explode in the over-

pressurized boiler (risk of evaporation).