DN300 Operation & Maintenance Manual Revision A Page8

Power Supply and Fuses

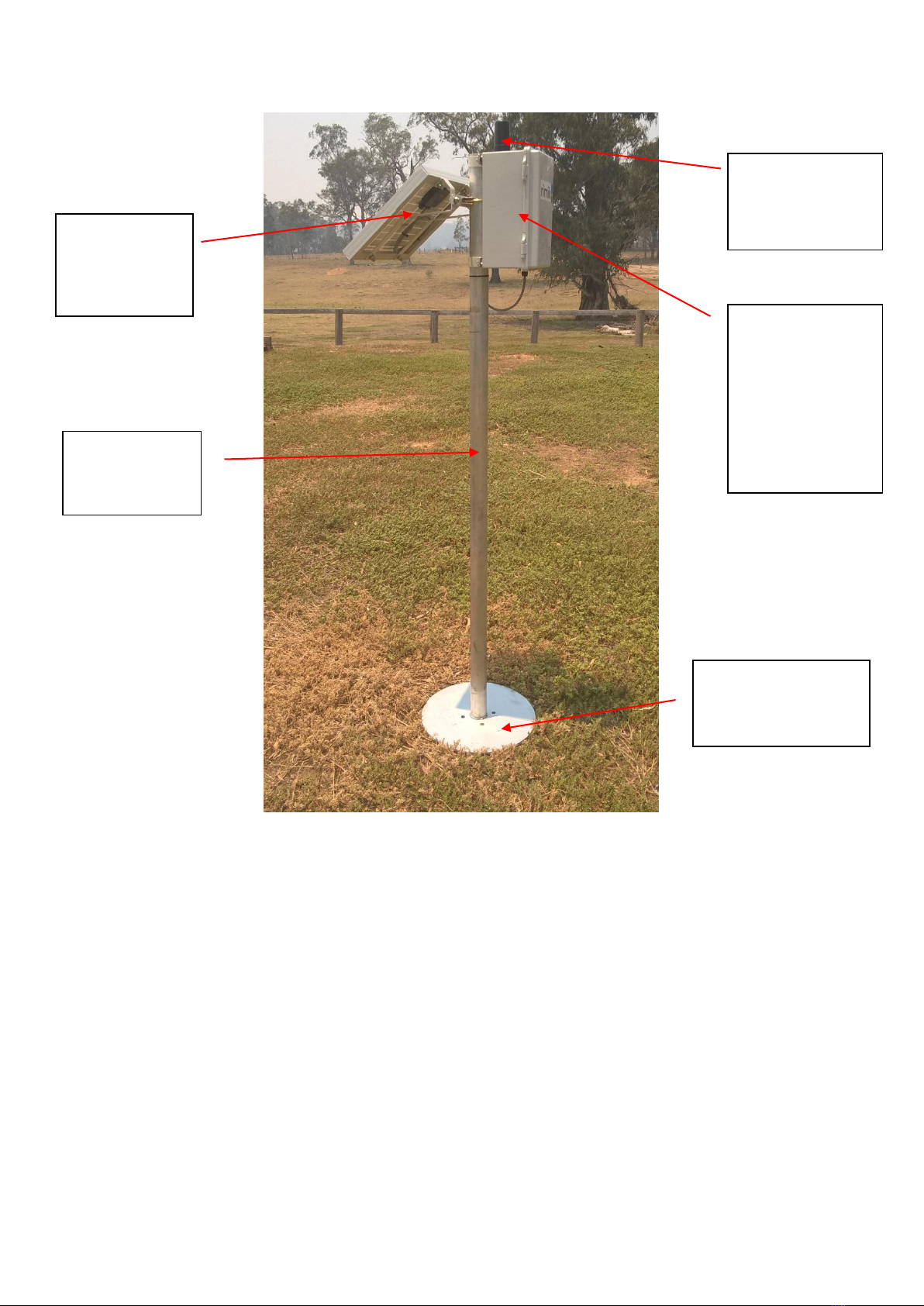

The DN300 unit has been designed for 24 hour operation at remote unpowered sites where solar

recharge is necessary. However, it can operate solely on mains power at mains powered sites with

or without a backup battery. Battery only operation is also possible for short term logger placement.

The battery life in this situation depends on the requirements of the connected sensors and use of

ultra low power mode with the DN300 Unit.

Where a solar panel is fitted the solar charger regulates the input voltage to approximately 18V DC

to capture the maximum current output from the panel. At mains powers sites where solar recharge

is not required, an 18V DC plug pack is the preferred option.

Where fitted, backup batteries are specified as 12V SLA (AGM or GEL type). The standard enclosure

can accept a number of different capacities i.e. 3AH, 7AH, 9AH and 12AH. The battery is generally

fitted vertically on the battery holder tray. The unit can also operate in a horizontal position. In that

case, a secondary battery plate may be required and particularly if using the 12AH capacity in order

to carry the additional weight.

Batteries and solar panel kits are rated for the duty they need to perform. Battery capacity is usually

determined by the load placed on the system by connected devices. Solar panel rating is

determined by the relationship between available sunlight and recharge requirements for the

battery. In general, where a low capacity battery is specified it will be matched with a lower rated

panel.

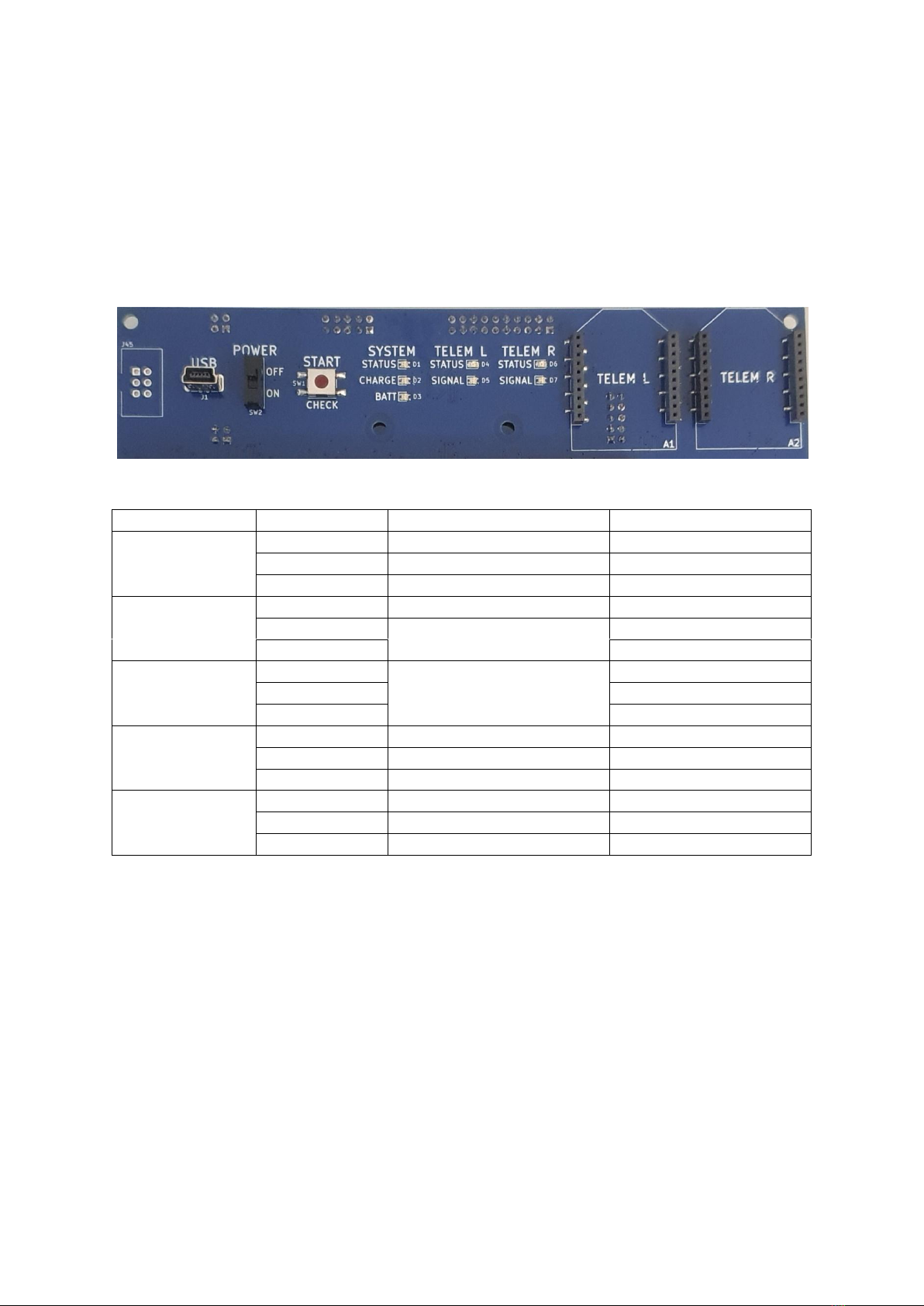

External relay power can be supplied via a 2 pin connector on the left side of the battery input (5).

In general the supply voltage is limited to 24 V AC/DC but in certain cases can be up to 60V DC.

Bay default, each DN Unit is configured to operate relay module on a maximum of 12V DC supplied

by the backup battery. Where external relay power is necessary to operate any equipment that

cannot be powered from the 12V DC backup battery e.g. 24V AC solenoid valves the connect board

is configured for external relay power and fitted with a 2 pin socket.

Three fuse positions are provided on the DN connect board, one each for the External Relay Power,

Battery, and Solar Panel. In case of a short circuit or reverse polarity connection, the fuse will fail. If

you unit will not start, charge or operate external relays, please check the fuses as a first step. IF

checking the battery fuse make sure that you are not running equipment manually or in a schedule

before you turn the unit of. Do not remove fuses while the DN unit is running.

Note that the Solar Panel and battery fuses are each 1A to protect the internal circuits. Do not

increase the fuse rating.

The External Relay Power fuse is rated at 5A in earlier DN connect board revisions and 7.5A in later

DN Connect board revisions. Some special purpose DN units may be rated to 10A. Please ensure

you do not insert a fuse larger than the rating listed on the connect board otherwise damage may

occur to the DN connect board in the event of inadvertent short circuit.