3/56

1Safety Instructions.................................................................................................................................7

1.1 Terms................................................................................................................................................. 7

1.1.1 Operation....................................................................................................................................... 7

1.1.2 Maintenance .................................................................................................................................. 7

1.1.3 Qualified Staff ................................................................................................................................ 7

1.2 Symbols............................................................................................................................................. 7

1.3 General safety information................................................................................................................. 9

2Delivery, internal transportation, unpacking.....................................................................................10

2.1 Delivery............................................................................................................................................ 10

2.2 Internal transport.............................................................................................................................. 10

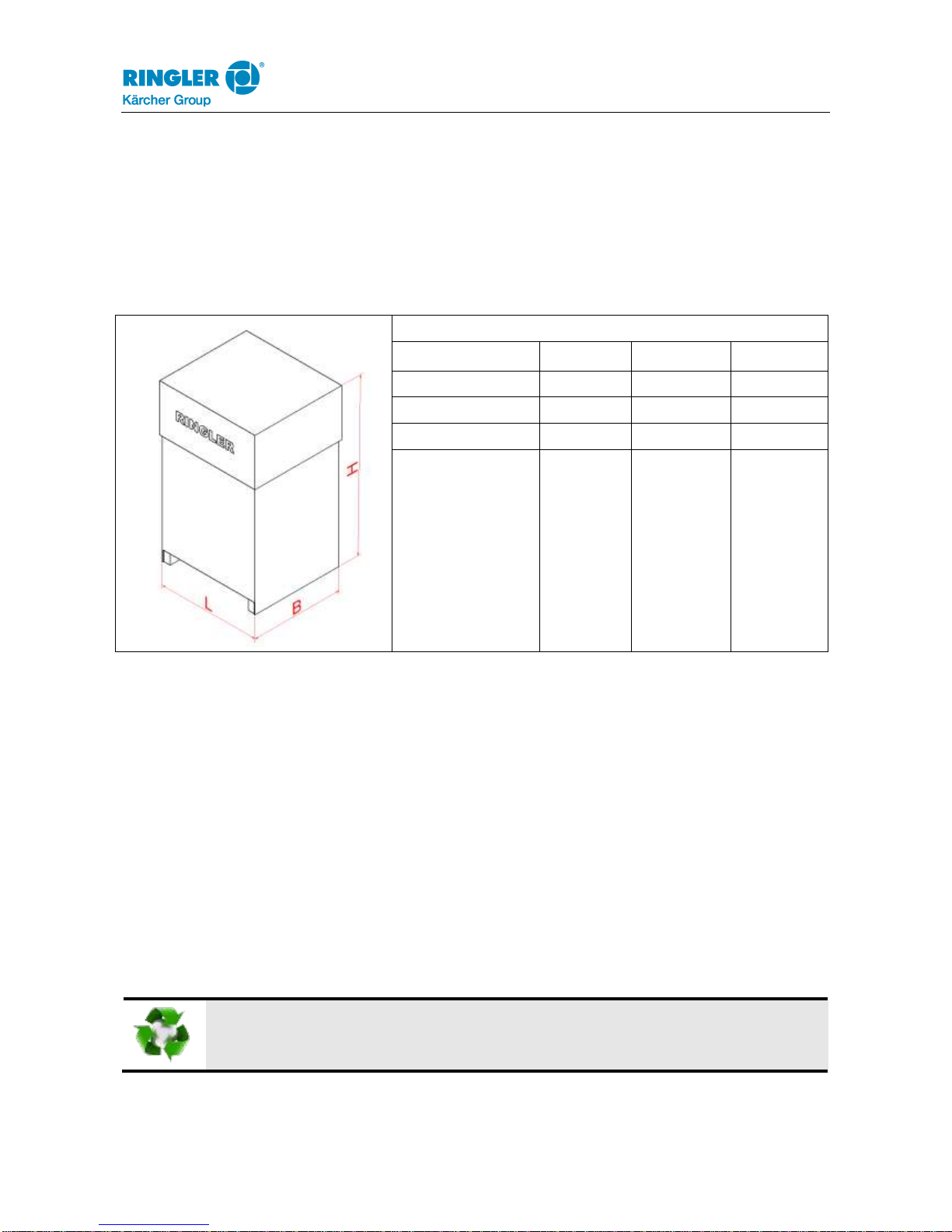

2.2.1 Dimensions and weight................................................................................................................ 10

2.3 Unpacking........................................................................................................................................ 10

2.4 Packaging material.......................................................................................................................... 10

2.5 Storage conditions........................................................................................................................... 11

2.5.1 Information for storage................................................................................................................. 11

3Appliance description..........................................................................................................................12

3.1 Intended Use ................................................................................................................................... 12

3.1.1 Dust class "L"............................................................................................................................... 12

3.1.2 Dust class "M".............................................................................................................................. 12

3.2 Non-Intended Use............................................................................................................................ 13

3.2.1 Dust class "L"............................................................................................................................... 13

3.2.2 Dust class "M".............................................................................................................................. 13

4Layout and function.............................................................................................................................14

4.1 Main dimensions.............................................................................................................................. 14

4.2 Technical data total device RA 240................................................................................................. 14

4.3 Technical Data D3 IE2..................................................................................................................... 15

4.4 Technical Data D2x3 IE2................................................................................................................. 15

4.5 Technical Data D5.5 IE2.................................................................................................................. 15

5Main components.................................................................................................................................16

5.1 Components RA 240 ....................................................................................................................... 16

5.2 Function Description........................................................................................................................ 16

6Initiation.................................................................................................................................................17

6.1 Assembly Instructions...................................................................................................................... 17

6.2 Initial operation ................................................................................................................................ 17

6.3 Connection to the electric mains ..................................................................................................... 17

6.4 Switching the suction system on and off at the control cabinet....................................................... 18

6.5 Incorrect rotational direction ............................................................................................................ 18

6.6 Check the following before switching it on:...................................................................................... 18

7Operation...............................................................................................................................................19

7.1 Operation......................................................................................................................................... 19

7.1.1 ON / OFF switch Three-phase current ........................................................................................ 19

7.2 Function description Ringler control cabinets.................................................................................. 19

7.3 Button for manual mode .................................................................................................................. 19

7.4 Indicator lamps ................................................................................................................................ 20

7.5 Suction process ............................................................................................................................... 21

7.6 Filter cleaning .................................................................................................................................. 21