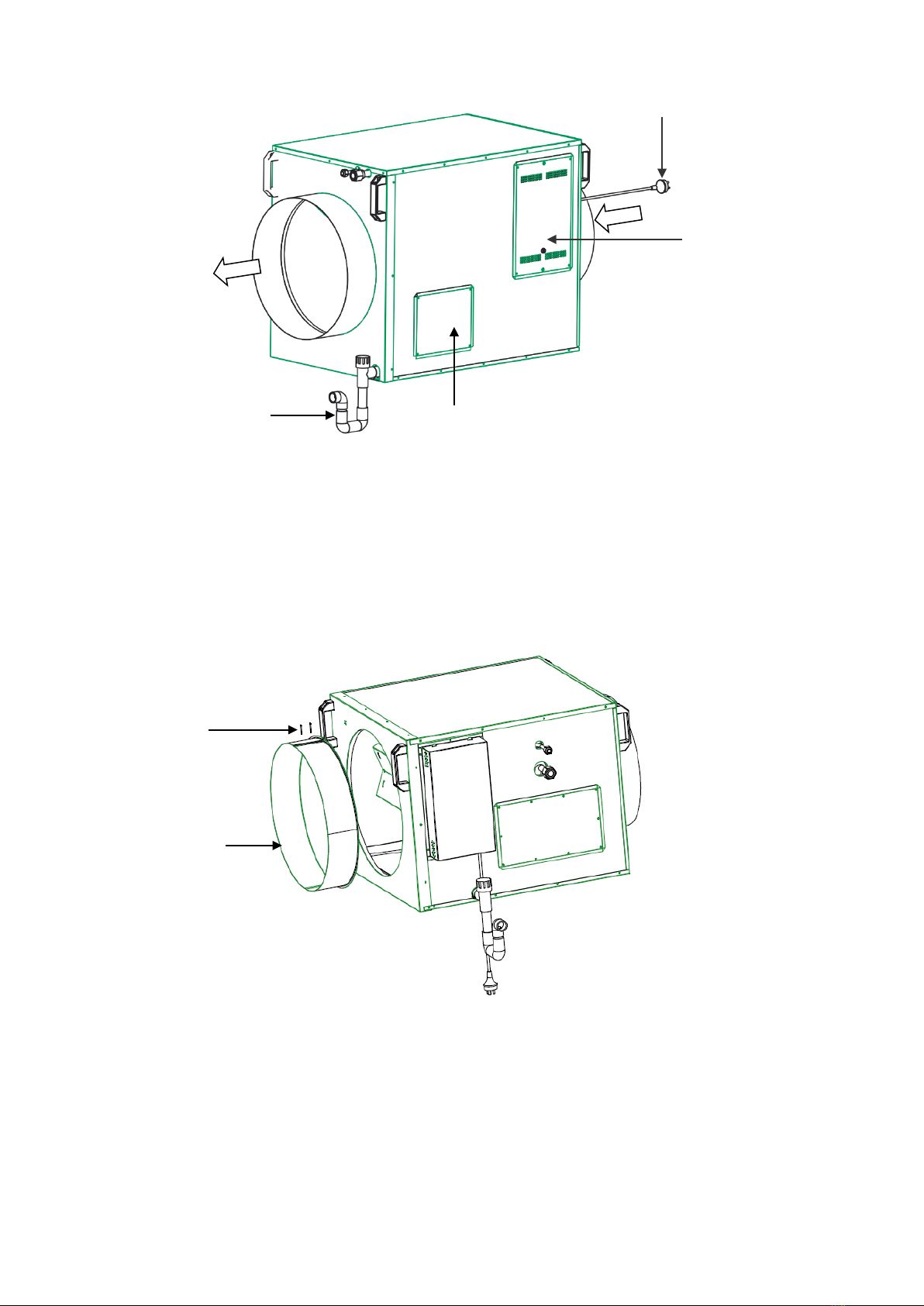

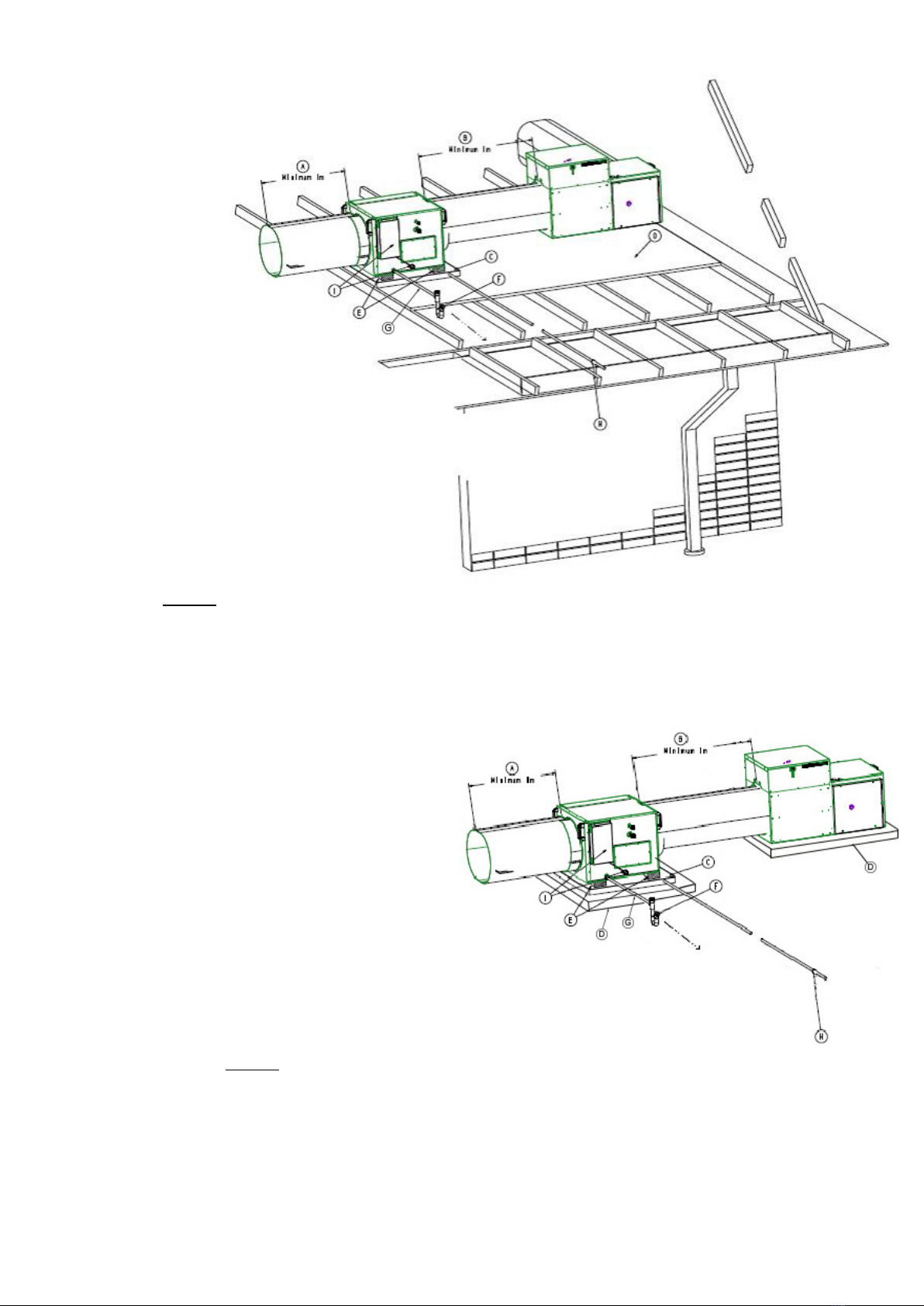

A. Ensure 1m minimum, or preferably 2½ times

the duct diameter, STRAIGHT duct length

before any take-offs occur

B. Ensure 1m minimum STRAIGHT duct between the

Gas Ducted Heater and ICE coil unit

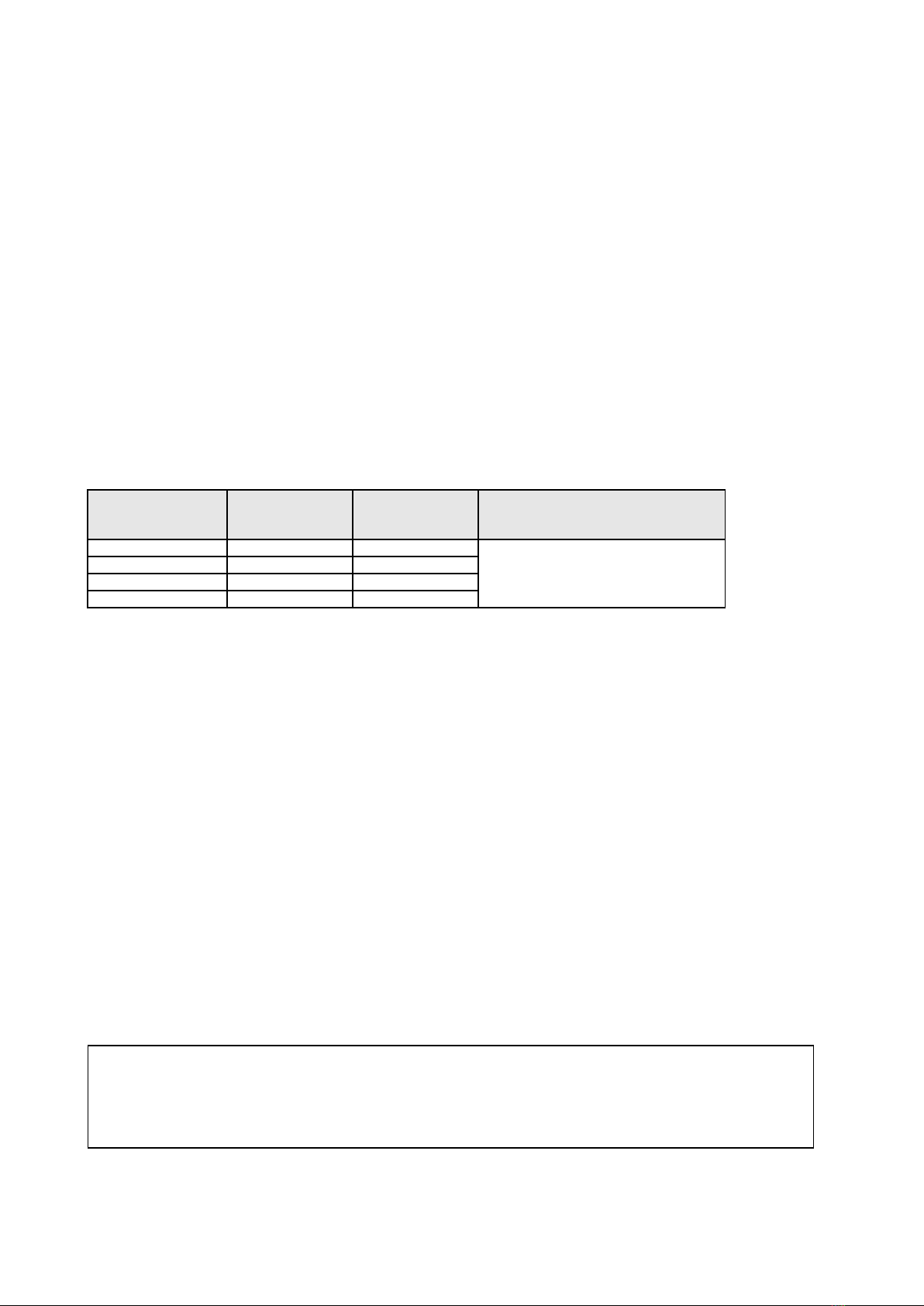

C. Safety Drain Tray (field supplied), independently

drained

D. Working Platform (field supplied)

E. Unit Mounts (field supplied) to be fitted under unit

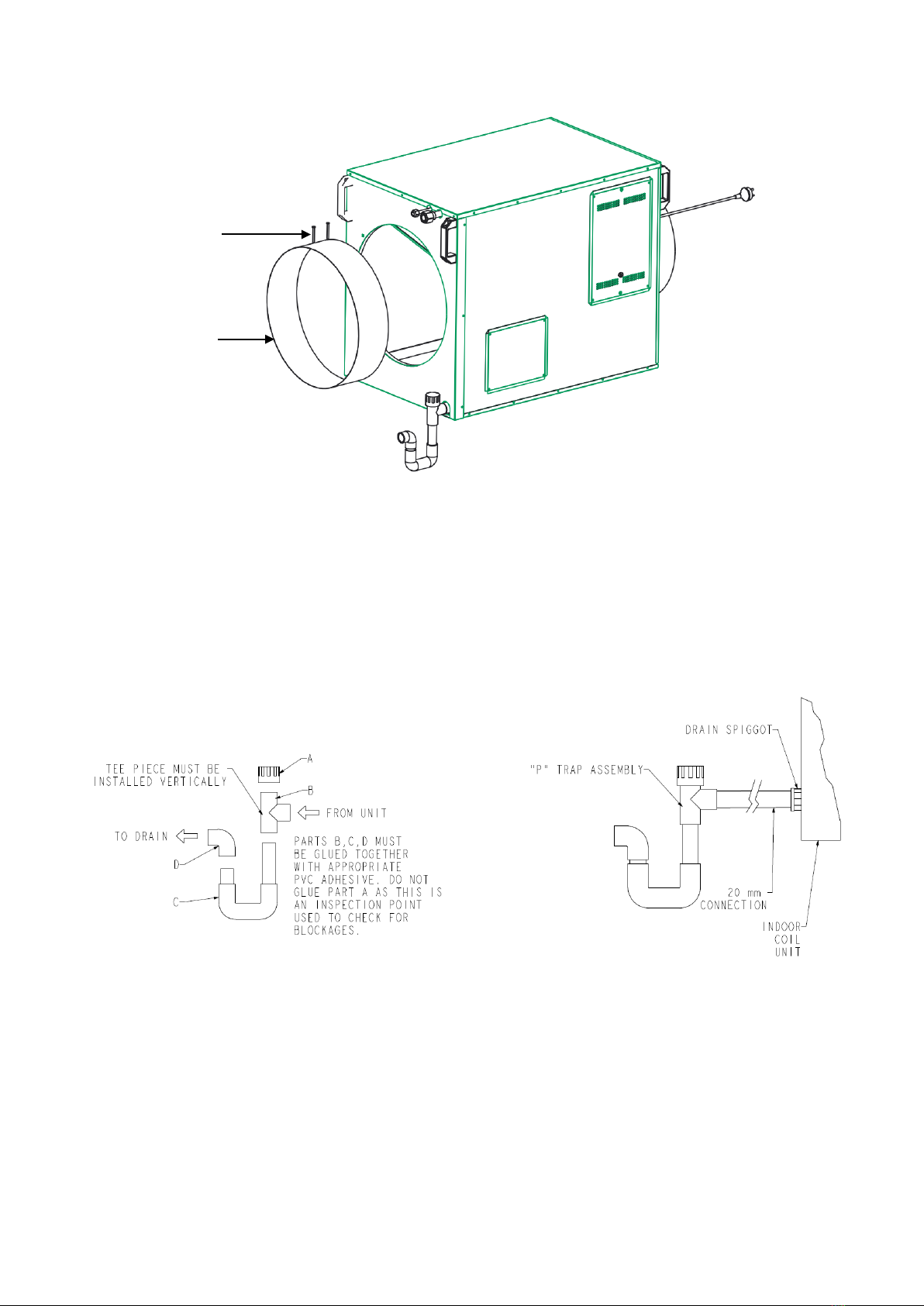

F. P Trap Assembly (supplied) on primary condensate

drain – fit as close as possible to unit

G. Condensate drain pipe to be pitched down and to be

terminated in an approved manner as specified by

local codes

H. Terminate the Safety Drain Tray in a position so as not

to cause a nuisance, but where the home owner can

see if water is dripping. Instruct owner to contact

Installer or Brivis if Safety Drain Tray outlet drips water

I. Electric box with standard 10 A power plug

•Run 2 core shielded communication cable from

indoor coil electric box

(Terminals Q, P) to the outdoor unit (S1,S2).

•Run 24VAC from the heater into the indoor coil

electric box (Terminals A1, A2)

3.0 TYPICAL INSTALLATION

Fig. 6 - Typical Indoor Unit Installation

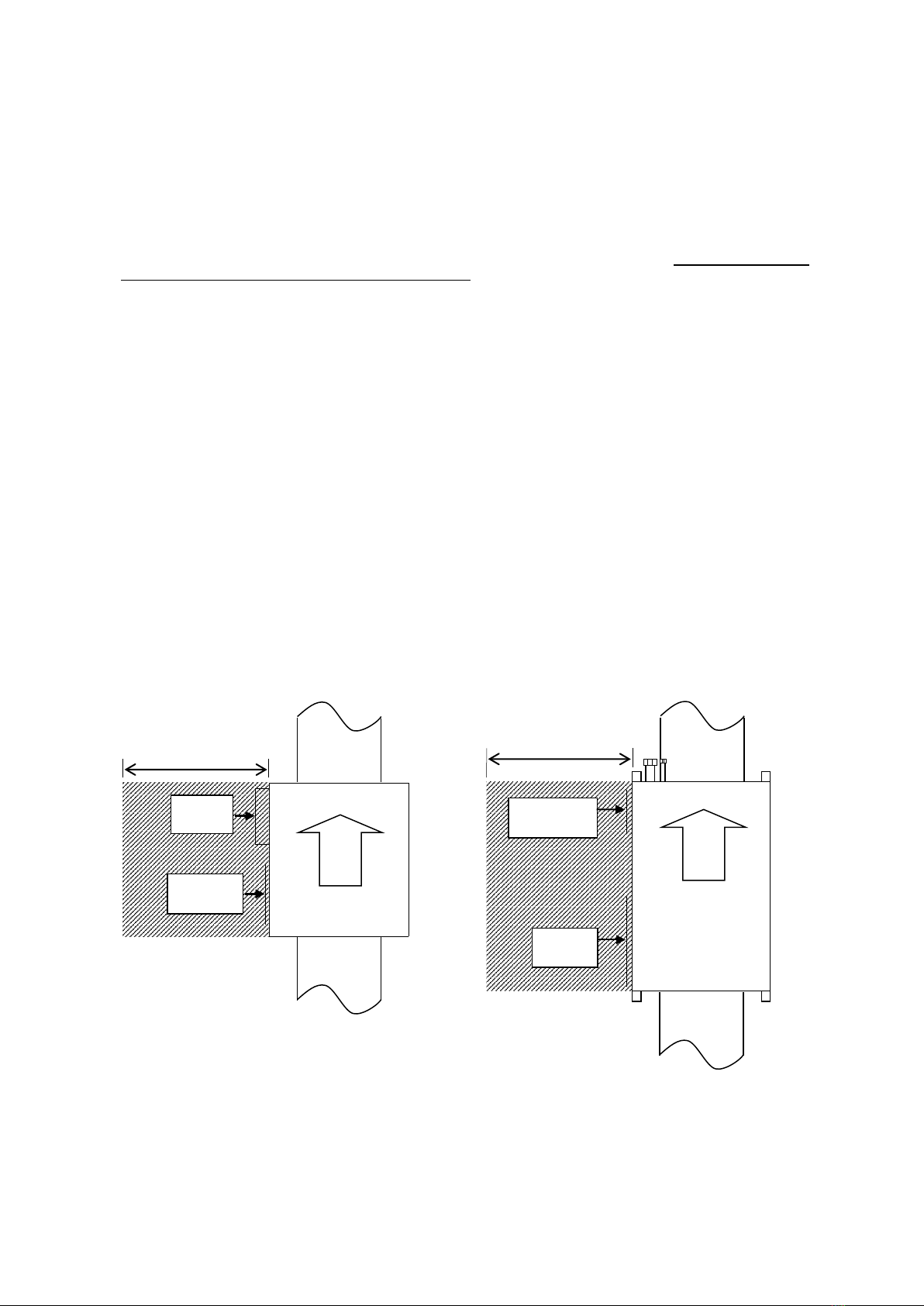

Fig. 7 - Typical Under Floor Installation

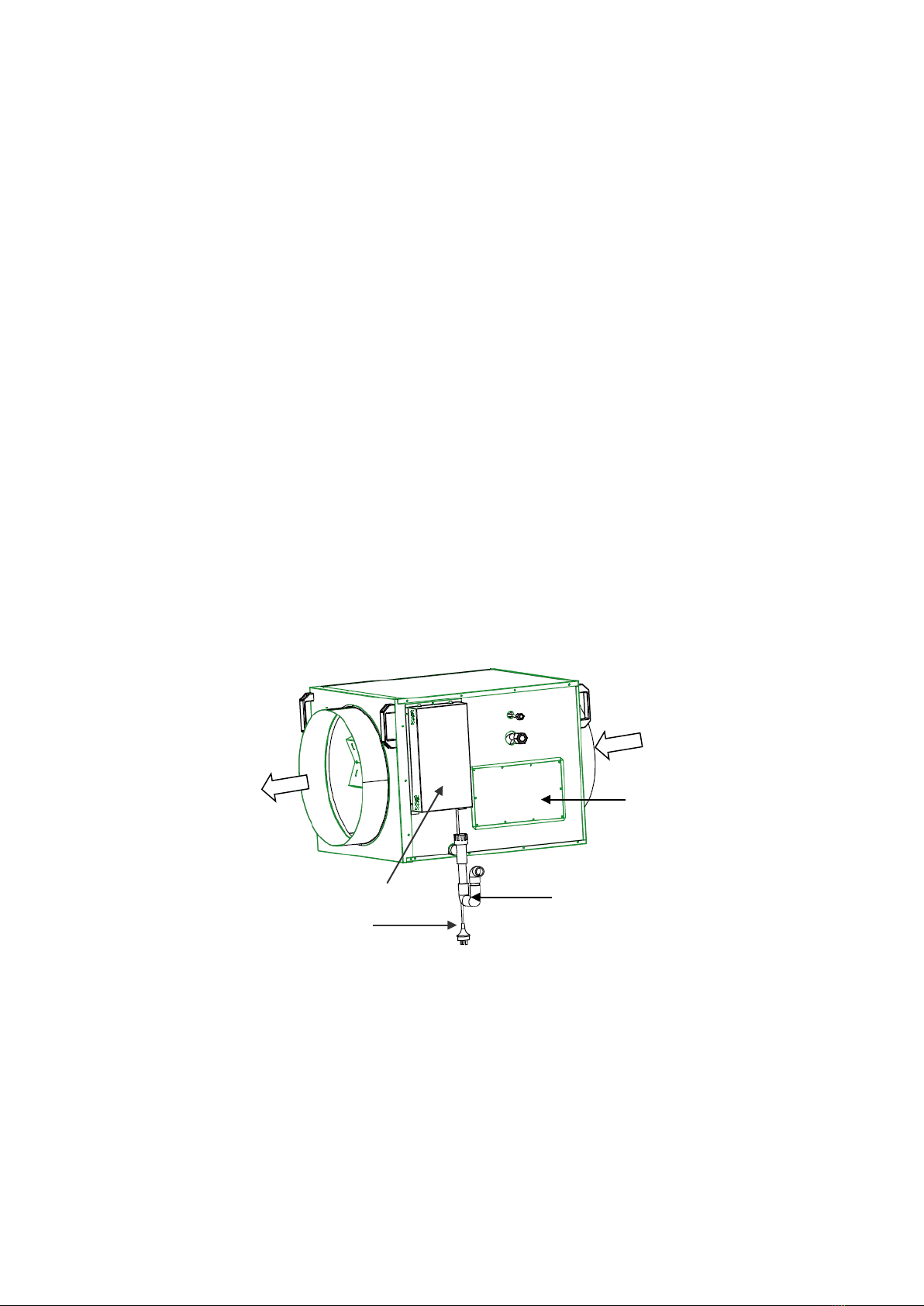

A. Ensure 1m minimum, or preferably 2½ times the

duct diameter, STRAIGHT duct length before any

take-offs occur

B. Ensure 1m minimum STRAIGHT duct between the

Gas Ducted Heater and ICE coil unit

C. Safety Drain Tray (field supplied), independently

drained

D. Working Platform (concrete slab)

E. Unit Mounts (field supplied) to be fitted under unit

F. P Trap Assembly (supplied) on primary

condensate drain – fit as close as possible to unit

G. Condensate drain pipe to be pitched down and to

be terminated in an approved manner as specified

by local codes

H. Terminate the Safety Drain Tray in a position so

as not to cause a nuisance, but where the home

owner can see if water is dripping. Instruct owner

to contact Installer or Brivis if Safety Drain Tray

outlet drips water

I. Electric box with standard 10 A power plug

•Run 2 core shielded communication cable from indoor coil electric box

(Terminals Q, P) to the outdoor unit (S1,S2).

•Run 24VAC from the heater into the indoor coil electric box (Terminals A1, A2)

IMPORTANT NOTE

1. Ensure unit is sitting on something that is ‘weather/waterproof’

2. Make sure there is adequate ventilation to help prevent condensation

3. Ensure the P-Trap and drain are working effectively

4. Always mount the coil on (field supplied) supports to create an air gap to prevent moisture/condensation

5. Always mount coil over safety tray