REU2424 Rinnai

4

1. Introduction

The brand name Continuum refers to “Endless Hot Water”. The new Continuum series has been developed

in response to the growing changes in the lifestyle of our customers, and the increasing diversification and

sophistication of demand in the marketplace.

The Continuum series offers reduced cost with advanced safety features, and an option to connect one,

two, or three remote temperature control pads.

The Continuum model REU2424-W is delivered with the maximum hot water temperature output set at

120 °F without the remote control. The REU2424-C is delivered set at 140°F without the remote control.

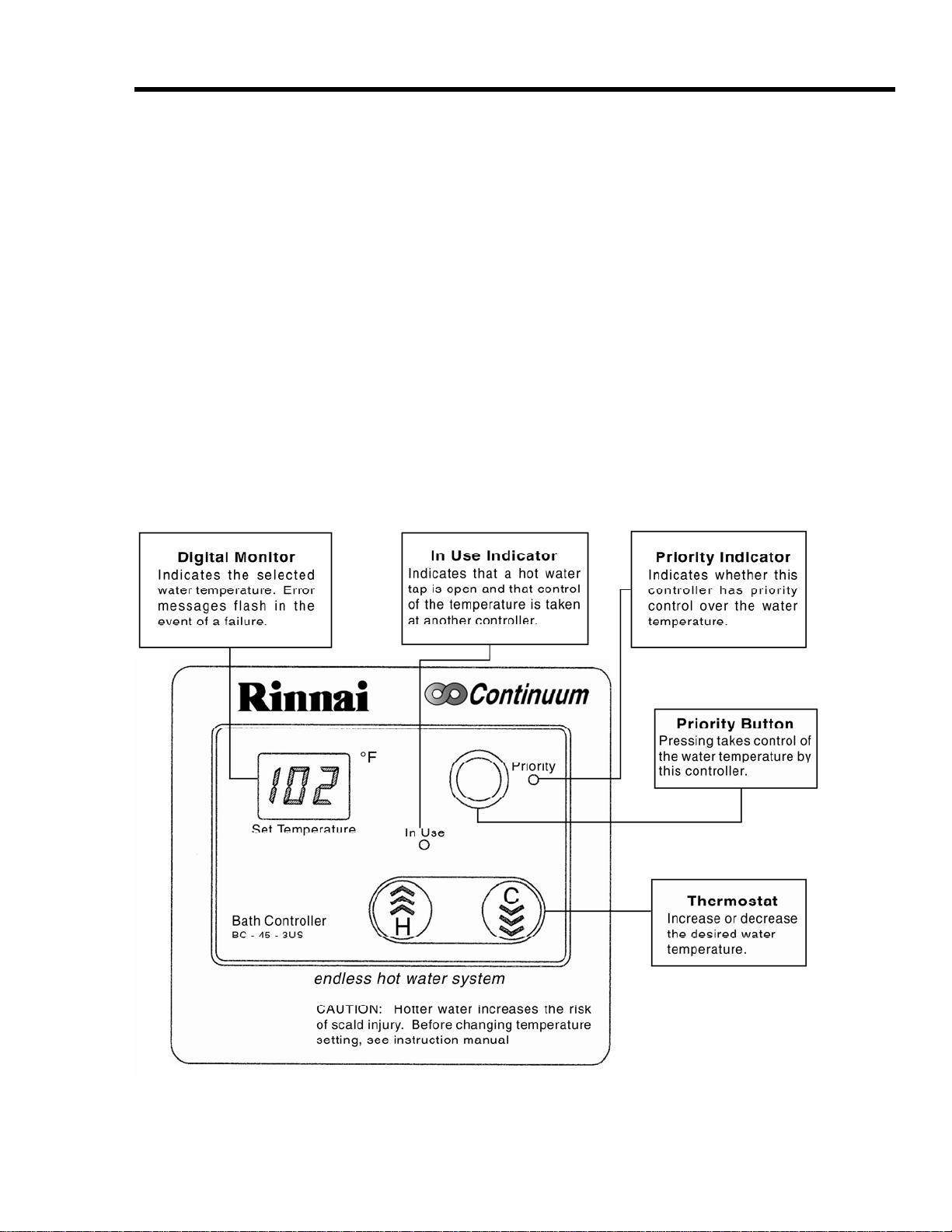

When using controllers you can adjust your hot water output from 96 – 120 °F using the “BC” and “BSC”

controllers. The “MC” control will allow water temperature adjustments from 96 – 140 °F and the “MCC”

control used with the commercial unit allows adjustments from 96 - 180°F. .

About the Continuum

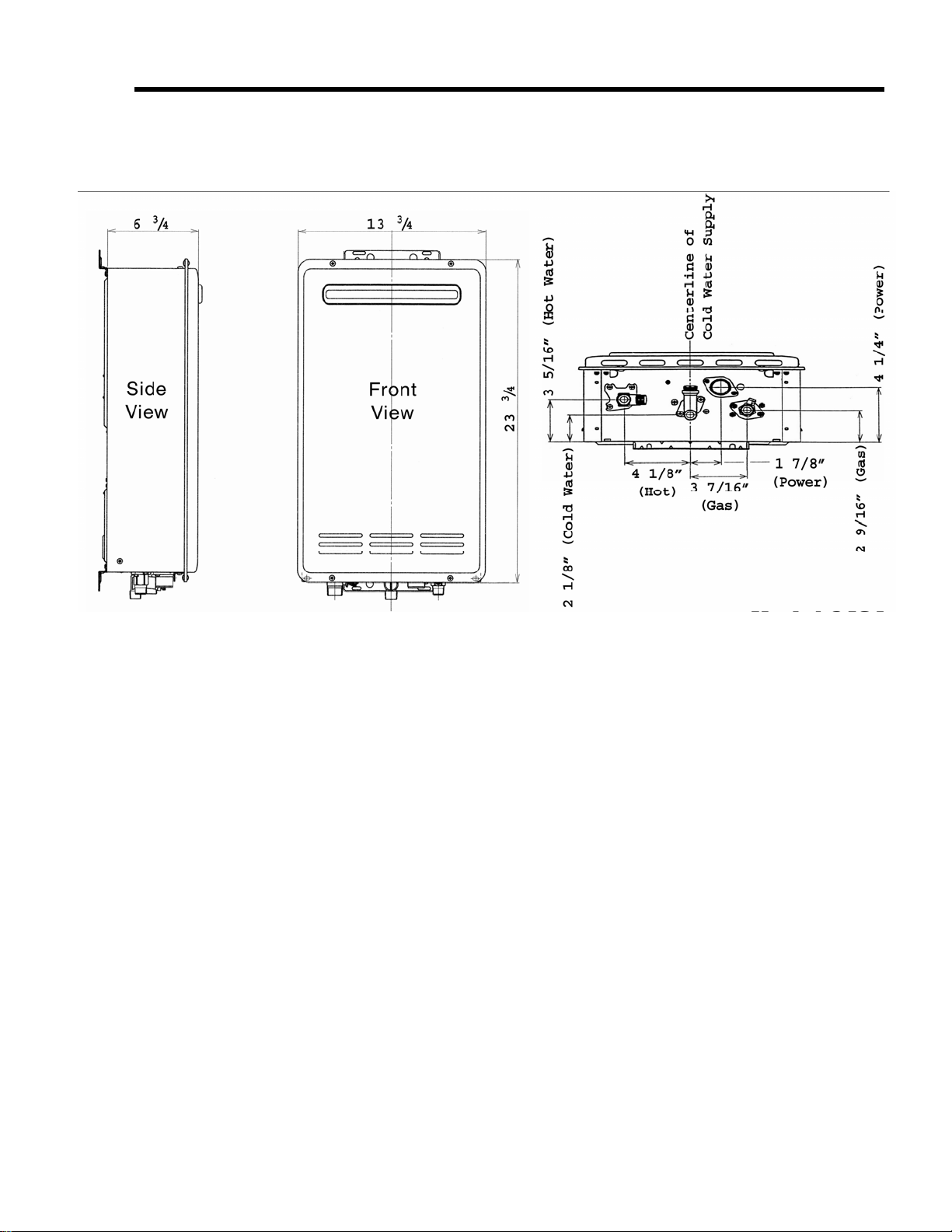

The front cover of each appliance in the new series is formed from 0.6 mm coated steel. Secured to the

main box assembly by (4) screws. Seals around the front cover and the flue outlet prevent water from

entering the appliance.

Air inlets are situated in the front panel of the 2424 external unit. Air passes through the inlets and is drawn

into the combustion chamber at the rear of the fan housing. The by-products of combustion on the external

unit are expelled from the appliance through a flue outlet situated on the front of the appliance, at the top.

The general layout of components can be seen in the cut-away diagram, see table of contents for page

number. All components are supported within the unit’s casing, which is made from 0.8 mm coated steel.

The heat exchanger occupies the top section of the casing, and the burner is situated in a chamber formed

from 0.8 mm aluminized steel, attached to the bottom of the heat exchanger. The copper tubing material

used in the heat exchanger consist of, Phosphorus Dioxide Copper, (C1220P). The material used to solder

the heat exchanger pipes is, Phosphorus Bronze Brazing, (main components are P, Ag, and Cu) (JIS No.

BcuP-2). None of these materials contain lead.

The air for combustion is supplied by a fan, which is connected to the burner box by a duct at the left side

of the appliance, directly under the burner.

Gas and water controls are situated at the bottom right of the appliance, directly under the manifold. The

“O”ring material on the water and gas connections are made from EPDM, (Ethylene Propylene Diene)

rubber.

The burner assembly is made up of (18) identical stainless steel Bunsen burners, secured by an aluminized

steel framework. Each burner is capable of handling up to 10,000 BTU’s. An aluminum manifold with

(18) integrally molded injectors supplies gas to the burners, and is attached to the front lower cover of the

burner box.