4

RS/03-GT-016-2019 日期:2020-3-9

CATALOG

1. Manual Introduction......................................................................................................................................... 5

2. Applicable Products ........................................................................................................................................ 5

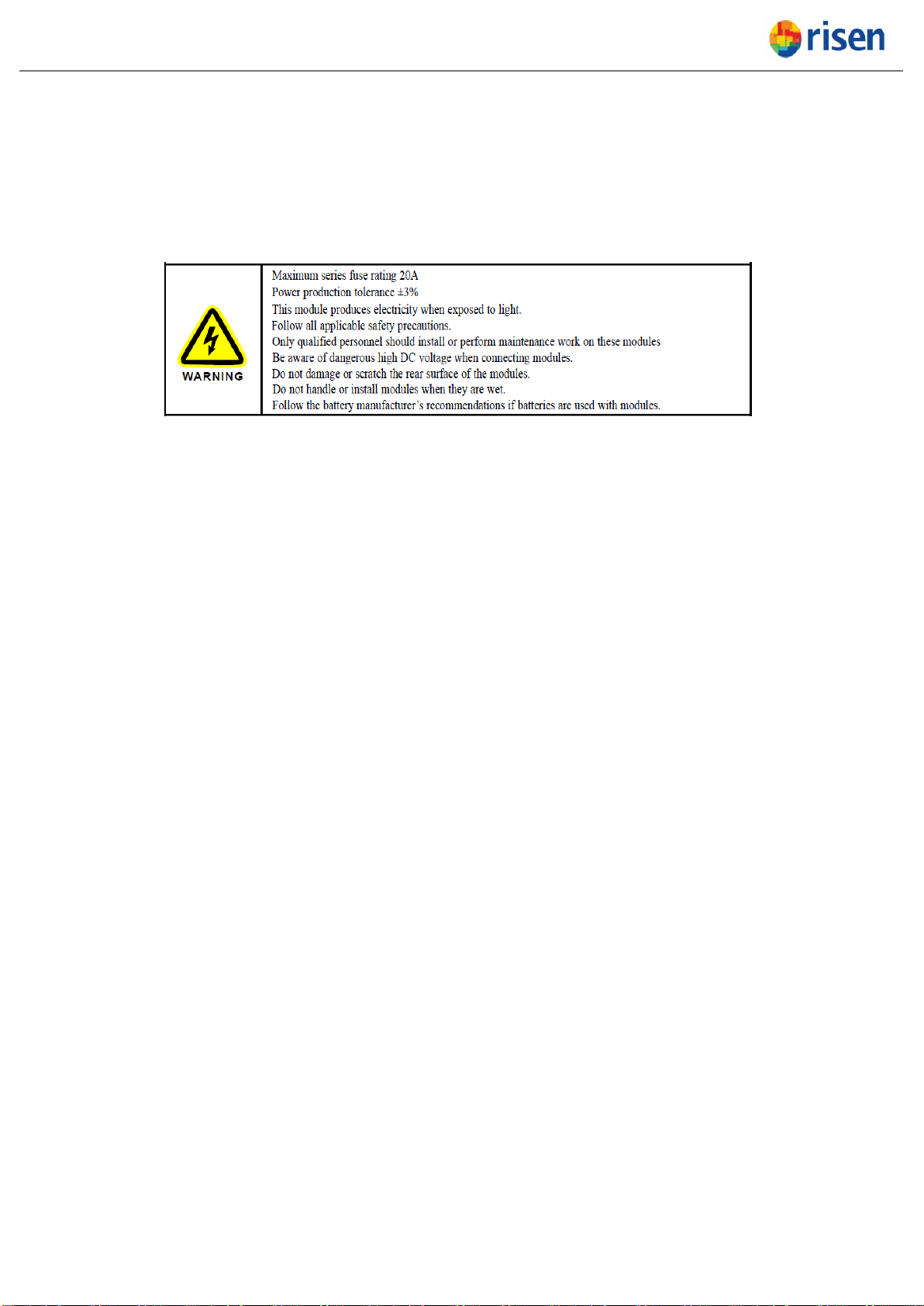

3. Warning ............................................................................................................................................................. 6

4. Safety Cautions................................................................................................................................................ 6

5. Unloading, Transportation and Storage ..................................................................................................... 10

5.1. Markers on outer packaging..................................................................................................................... 10

5.2. Unloading cautions .................................................................................................................................... 10

5.3. Secondary transportation and Warning.................................................................................................. 11

5.4. Storage ........................................................................................................................................................ 12

5.5. Markings on module .................................................................................................................................. 13

6. Unpacking....................................................................................................................................................... 13

7. Installation....................................................................................................................................................... 14

7.1. Environment conditions and site selection............................................................................................. 14

7.2. Tilt angle of Installation.............................................................................................................................. 15

7.3. Installation requirements for bi-facial dual glass module..................................................................... 16

8. Installation Guidelines................................................................................................................................... 17

8.1. Bolting method for framed Bi-facial dual glass module........................................................................ 18

8.2. Clamping Method....................................................................................................................................... 21

8.3. Tracking system ......................................................................................................................................... 23

9. Cable layout.................................................................................................................................................... 25

10. Electrical Connection .................................................................................................................................... 26

10.1. Bypass secondary .................................................................................................................................. 29

10.2. Grounding ................................................................................................................................................ 30

10.3. Inspection and Maintenance................................................................................................................. 31

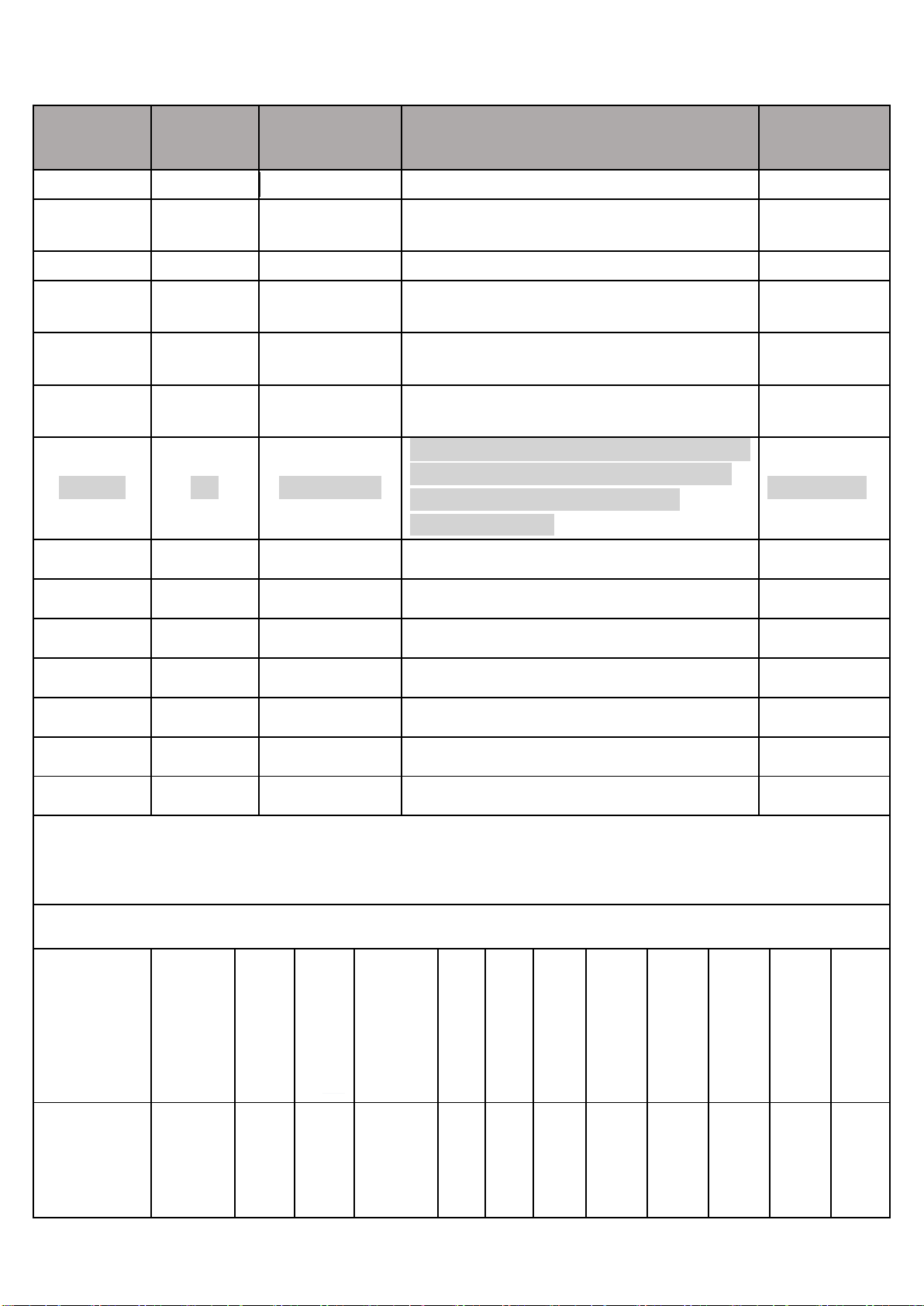

11. Electrical Parameters……………………………………………………………………………………….

12. Module visual inspection and replacement ............................................................................................... 32

12.1. Cleaning................................................................................................................................................... 33

12.2. Troubleshooting ...................................................................................................................................... 34

13. DISCLAIMER ................................................................................................................................................. 35