RIX MB-115 User manual

RIX

COMPRESSORS

MICROBOOST

Owner’s

Manual

MB-115

MB-230

PLICABILITY

[CD]

February

19,

2004

AP

WARNING!!!

To

prevent

FIRE,

SERIOUS

INJURY

and/or

DEATH,

it

is

the

User's

responsibility

to

ensure

that

all

parts

used

in

the

compression

assembly

and

gas

plumbing

of

a

RIX

Oxygen

or

Nitrox

compressor

are

cleaned

for

oxygen

service.

Cleaning

should

be

in

accordance

with

Compressed

Gas

Association

G-4.1.

Factory

oxygen

cleaned

parts

are

denoted

by

an

“X”

prefix

at

the

beginning

of

the

part

number.

it

is

the

Buyers

responsibility

to

maintain

the

cleanliness

of

factory-cleaned

parts

throughout

installation

and

start-up.

Furthermore,

non-factory

supplied

parts

will

void

all

warranties,

as

improper

materials

can

cause

oxygen

fires

resulting

in

serious

fires

injury

and/or

death.

FOR

ALL

REPAIRS:

1)

Refer

to

the

applicable

service

manual

for

assembly

instructions

2)

Refer

to

applicable

compressor

start-up

instructions

after

all

repairs

INTRODUCTION

Congratulations

on

your

purchase

of

the

Rix

Microboost

compressor.

We

anticipate

that

with

proper

care

you

will

get

many

years

of

satisfactory

performance

from

this

compressor.

This

manual

is

prepared

to

help

you

operate

this

equipment

safely

and

so

that

you

get

the

most

benefit

from

this

package.

Please

read

it

carefully.

This

equipment

is

protected

by

warranty,

a

copy

of

which

should

have

been

provided

separately

by

your

dealer.

We

suggest

that

you

read

the

warranty

policy

to

fully

understand

your

coverage

and

your

responsibilities

of

ownership.

Rix

recommends

that

all

servicing

be

done

by

trained

and

qualified

personnel.

Rix

recommends

that

you

contact

our

offices

at

707-747-5900

for

a

list

of

qualified

service

centers.

Rix

Industries

4900

industrial

Way

Benicia,

CA

94510

Phone

(707)

747-5900

Fax

(707)

747-9200

APPLICABILITY

[

ABCD]

1

INTRODUCTION

Safety

This

electromechanical

equipment

is

designed

to

produce

high

pressure

gas.

Operating

personnel

must

follow

these

safety

requirements

at

all

times

to

avoid

injury

to

personnel

or

damage

to

property.

Keep

away

from

live

circuits.

Do

not

attempt

to

replace

components

or

make

adjustments

unless

the

power

to

the

compressor

has

been

disconnected

and

all

pressure

relieved.

Never

operate

with

safety

devices

removed

or

disabled. This

includes

guards

for

moving

objects,

protection

from

high

temperature

surfaces,

pressure

relief

valves,

pressure

switches,

or

covers

over

electrical

components.

When

compressing

oxygen

it

is

critical

that

surfaces

in

contact

with

oxygen

be

kept

clean

and

free

from

contamination,

especially

hydrocarbon

contamination

or

any

flammable

material.

This

compressor

is

shipped

oxygen

clean

and

must

be

maintained

that

way

to

avoid

the

hazard

of

explosion

or

fire.

Safety

warnings

are

provided

in

a

variety

of

forms,

including:

Safety

Labels-located

on

the

equipment

Safety

Messages-

provided

in

this

manual

and

proceeded

by

a

safety

alert

label,

DANGER,

WARNING,

CAUTION,

and

NOTE.

You

will

likely

be

killed

or

seriously

hurt

if

you

don’t

follow

instructions,

and

equipment

damage

is

certain.

You

may

be

killed

or

seriously

hurt

if

you

don’t

follow

instructions,

and

equipment

damage

is

certain.

CAUTION

You

can

be

hurt

if

you

don’t

follow

instructions,

and

equipment

damage

is

likely.

NOTE!

Highlights

a

certain

operation,

maintenance

condition,

or

statement,

which

is

useful

but not

associated

with

a

known

hazard,

as

indicated

by

a

warning

or

caution.

2

REVISION

A

,

2/14/03

APPLICABILITY

[

ABCD]

CONTENTS

JIntroduction

anne

1

Performance.........................,..................................….

4

Safety.........

sise

5

Controls

and

features...........................................

nen

6

IA

8

Operation

.ee

10

Servicing...................,............

iso

11

Troubleshooting............................................

13

了

Parts.

ee

eeaeeereemen

14

Technical

Data..........................................

ドー

20

APPLICABILITY

[ABCD]

3

PERFORMANCE

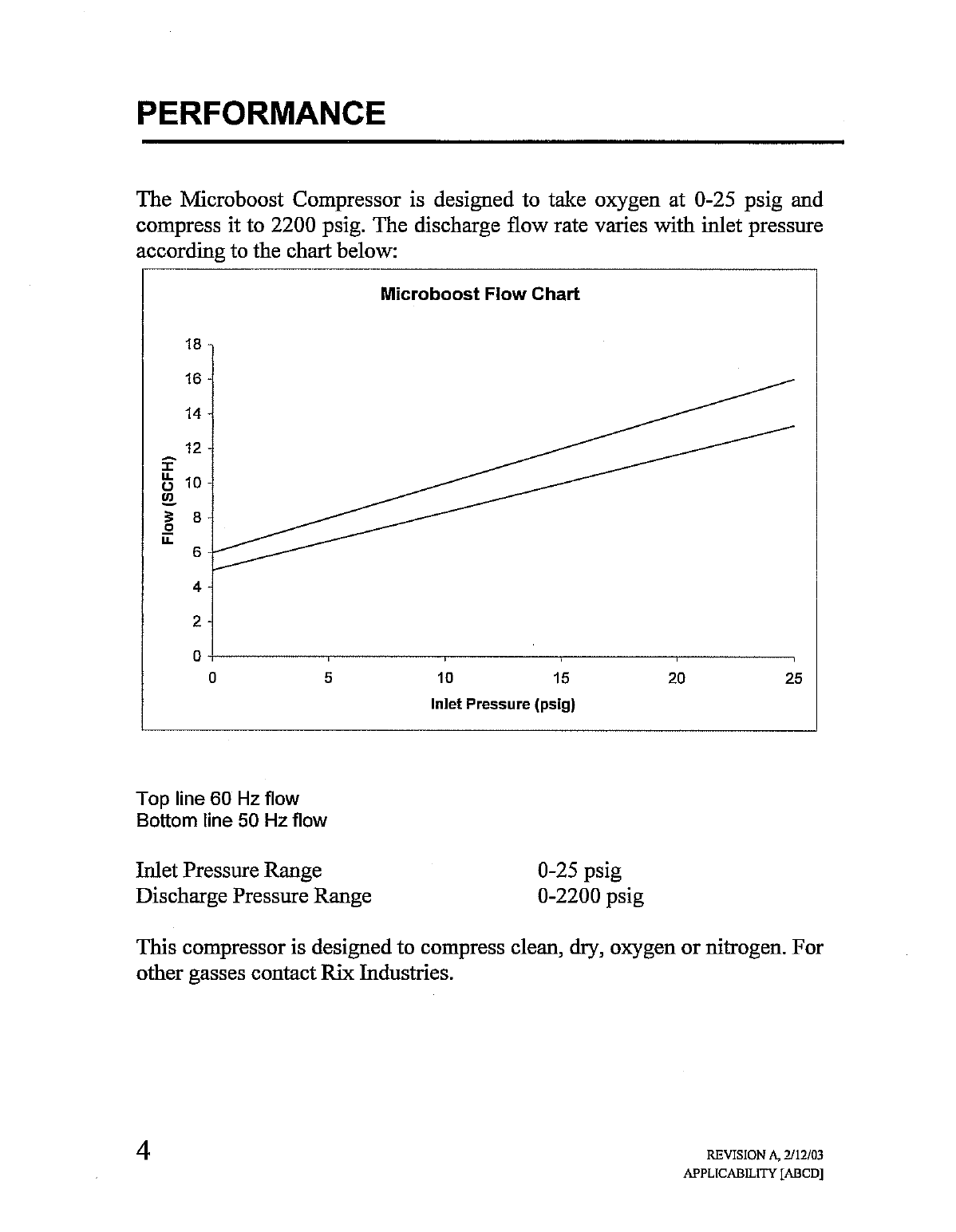

The

Microboost

Compressor

is

designed

to

take

oxygen

at

0-25

psig

and

compress

it

to

2200

psig.

The

discharge

flow

rate

varies

with

inlet

pressure

according

to

the

chart

below:

Microboost

Flow

Chart

18

16

-

14

-

12-

10-

Flow

(SCFH)

0

' :

一

; ,

10 15

20

25

Inlet

Pressure

(psig)

o

a

Top

line

60

Hz

flow

Bottom

line

50

Hz

flow

Inlet

Pressure

Range

0-25

psig

Discharge

Pressure

Range

0-2200

psig

This

compressor

is

designed

to

compress

clean,

dry,

oxygen

or

nitrogen.

For

other

gasses

contact

Rix

Industries.

4

REVISION

A,

2/12/03

APPLICABILITY

[ABCD]

SAFETY

DANGER

Keep

away

from

live

circuits.

Do

not

attempt

to

replace

components

or

make

adjustments

unless

the

power

to

the

compressor

has

been

disconnected

and

all

pressure

relieved.

DANGER

Never

operate with

safety

devices

removed,

modified,

or

disabled.

This

includes

guards

for

moving

objects,

protection

from

high

temperatures

surfaces,

pressure

relief

valves,

or

covers

over

electrical

components.

Surfaces

on

the

motor

and

compressor

can

become

hot

and

may

cause

pain

or

discomfort

when

touched.

Allow

the

equipment

to

cool

before

handling

it.

ID

R

To

prevent

FIRE,

SERIOUS

INJURY,

and/or

DEATH,

it

is

the

User’s

responsibility

to

ensure

that

all

parts

used

in

the

compression

assembly

and

gas

plumbing

of

this

Rix

Oxygen

compressor

and

any

other

portions

of the

gas

stream

that

may

be

exposed

during

the

installation

of

new

or

replacement

parts

are

cleaned

for

Oxygen

Service

prior

to

installation.

Any

work

to

be

done

on

the

compressor

where

the

gas

stream

may

be

exposed

must

be

done

in

accordance

with

safe

Oxygen

Equipment

handling

procedures.

|

No

attempt

should

be

made

to

work

on

the

machine

without

full

knowledge

of

Oxygen

handling

equipment

handling

and

the

potential

hazards

of

contamination.

Factory

oxygen

cleaned

parts

are

denoted

by

an

“X”

prefix

at

the

beginning

of

the

part

number.

It

is

the

User’s

responsibility

to

maintain

the

cleanliness

of

factory

cleaned

parts

and

any

other

existing

portions

of

the

gas

stream

that

may

be

exposed

during

the

initial

installation,

start-up,

or

during

installation

of

replacement

parts.

Rix

Industries

recommends

the

customer

establish

a

procedure

for

working

with

oxygen

machinery.

Refer

to

Compressed

Gas

Association,

Inc.

publication

number

CGA

G-4.1,

Cleaning

Equipment

for

Oxygen

Service.

REVISED

2/24/03

i

5

APPLICABILITY

[ABCD]

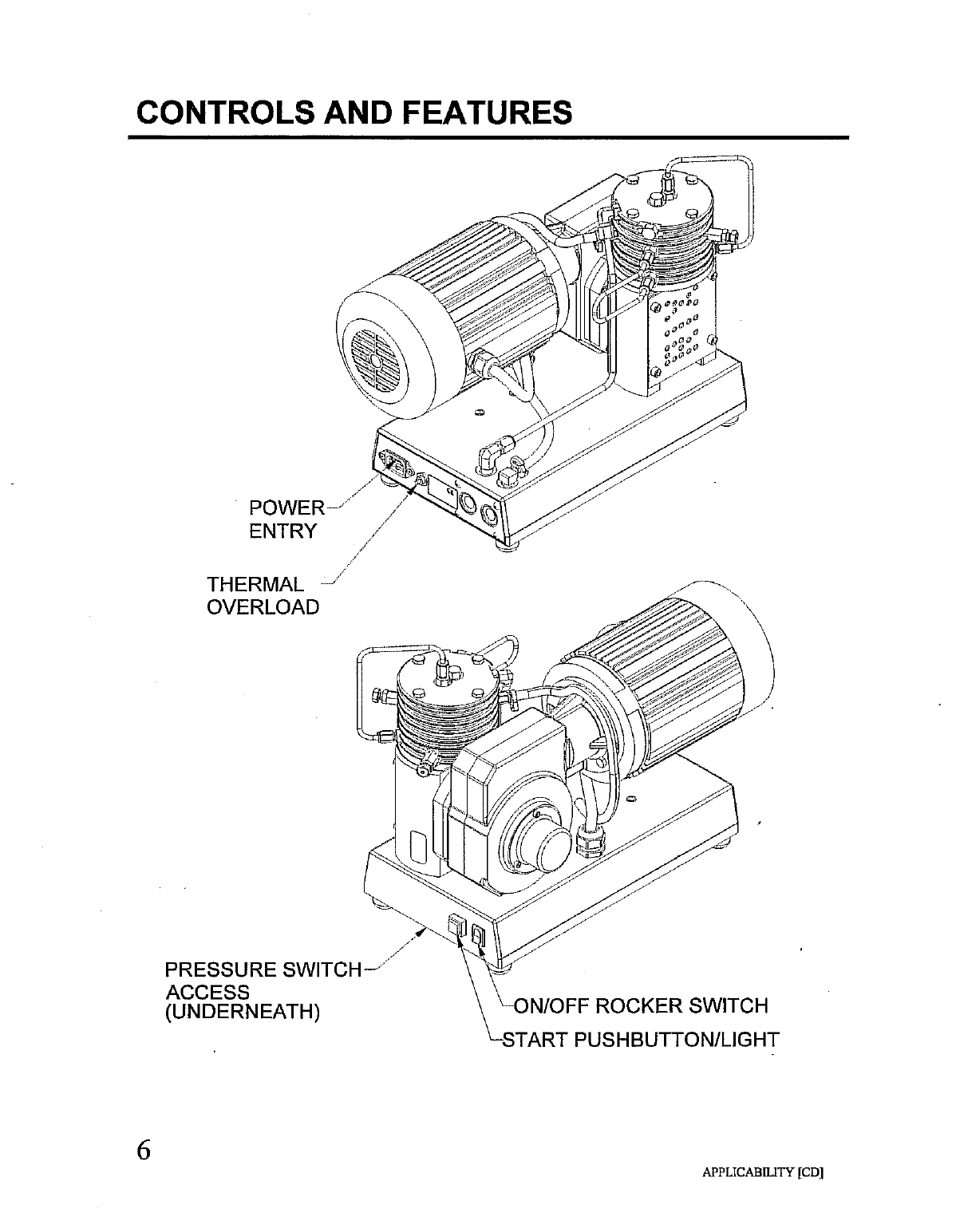

CONTROLS

AND

FEATURES

THERMAL

一

OVERLOAD

PRESSURE

SWITCH

(UNDERNEATH)

ON/OFF

ROCKER

SWITCH

START

PUSHBUTTON/LIGHT

APPLICABILITY

[CD]

CONTROLS

AND

FEATURES

Power

Entry

Medule-

The

Microboost

is

connected

to

a

source

of

power

using

a

power

cord

connected

to

the

Power

Entry

Module

(conforming

to

IEC-320-C13).

A

power

cord

suitable

for

the

intended

voltage,

115

VAC

or

230

VAC,

at

10

amps

should

be

used

to

connect

the

Microboost

to

the

source

of

power.

Overload-

The

pushbutton

reset

overload

is

provided

to

protect

the

equipment

if

the

motor

current

draw

exceeds

10

amps.

A

separate

automatic

reset

thermal

switch

is

located

inside

the

motor

to

protect

the

motor

from

overheating.

Power

On/Off

Rocker

Switch-

The

rocker switch

is

used

to

turn

power

on

to

the

Microboost

control

system.

This

switch

is

also

used

to

stop

the

unit

manually

when

it

is

running.

Start

Pushbutton-

The

momentary

lighted

pushbutton

is

provided

for

starting

the

compressor.

With

the

unit

plugged

into-a-seurce

of

electric

power

and

the

On/Off

rocker

switch

in

the

On

position

the

Start

Pushbutton

can

be

pressed

to

start

the

compressor

motor.

The

compressor

runs

until

the

pressure

switch

signals

it

to

stop

or

until

the

On/Off

rocker

switch

is

switched

Off.

Pressure

Switch-

The

pressure

switch

is

provided

to

automatically

stop

the

compressor

when

the

set

pressure

is

reached.

This-is-usuatty-factory

set

at

2200

psig.

The

switch

is

located

inside

the

Mitrotoost

tase

and

is

accessible

for

adjusting

through

a

rectangular

opening

provided

in

the

underside

cover.

Relief

Valves-

Relief

valves

are

provided

for

all

compression

stages.

The

first

stage

(set

at

359-psig)

and

second

stage-(set-at-1200-psig)

relief

valves

are

located

on

the

outside

of

the

compressor

as

shown.

The

third

stage

relief

valve

(set

at

2400

psig)

is

located—-inside—the

compressor

base.

These

prevent

pressures

from

rising

to

levels

that:

might

cause

damage.

REVISION

B,

2/12/03

7

APPLICABILITY

[ABCD]

INSTALLATION

13.2

DISCHARGE

CONNECTION

(1/4

NPT)

POWER

ENTRY

MODULE,

<

‚/АМЕЕТ

CONNECTION

(ANP)

APPLICABILITY

[CD]

INSTALLATION

The

Microboost

is

a

free

standing

package

weighing

61

lbs

and

is

meant

to

be

located

in

open

air

on

a

table,

shelf,

or

on

the

floor.

It

may

also

be

mounted

inside

a

frame

or

cabinet

as

long

as

sufficient

air

circulation

is

provided

to

prevent

overheating.

Locate

the

compressor

in

an

area

with

good

ventilation.

An

ambient

temperature

of

90°

F

or

less

is

preferable.

Circulating

air

across

the

compressor

with

an

external

fan will

make

it

operate

better

and

last

longer.

Rix

recommends

installing

a

flow

check

valve

after

the

Microboost

discharge

to

prevent

reverse

flow

when

the

compressor

is

off.

Pressure

gauges

should

be

installed

at

the

suction

and

discharge

to

help

in

monitoring

performance

and

for

troubleshooting.

Plug

into

a

source

of

power

that

is

protected

for

15

amps

(115

V)

or

10

amps

(230

V).

Connect

the

compressor

inlet

to

a

source

of

clean,

dry gas

regulated

not

to

exceed

25

psig.

Inlet

filtration

to

2

micron

max

particle

size

is

recommended.

Particle

contamination

can

cause

failure.

Connect

the

compressor

discharge

to

a

high

pressure

cylinder

or

manifold

designed

to

handle

pressures

at

2300

psig.

A

discharge

filter

of

at

least

5

micron

is

recommended

to

remove

seal

wear

(Teflon)

particles.

The

customer

is

responsible

for

designing

and

adequately

protecting

the

plumbing

and

equipment

he

attaches

to

the

Microboost.

Exposed

surfaces

of the

operating

motor

and

compressor

can

reach

180°

F

and

may

cause

pain

or

discomfort

if

touched.

Locate

the

unit

in

a

safe

location

where

it

is

protected

from

human

contact.

REVISION

B,

2/12/03

9

APPLICABILITY

[ABCD]

OPERATION

Check

that

power

is

connected

to

the

Microboost.

Check

that

the

compressor

suction

is

connected

to

a

source

of

clean,

dry

oxygen

or

nitrogen

gas.

Check

that

the

compressor

discharge

is

connected

to

a

fill

system

suitable

for

2300

psig

and

that

there

are

no

restrictions

in

the

line.

Check

that

the

compressor

discharge

is

relieved

of

any

pressure

build-

up.

Caution

Do

not

attempt

to

start

the

compressor

against

discharge

pressure.

Vent

all

gas

pressure

at

the

compressor

discharge

prior

to

starting.

If

the

compressor

stalls

it

is

probably

because

there

is

residual

pressure

in

the

system.

Push

the

Power

On

rocker

switch

to

the

ON

position.

Push

the

Start

pushbutton,

the

compressor

should

come

on.

Verify

that

the

compressor

comes

on

and

the

Start

pushbutton

light

is

illuminated.

Periodically

monitor

the

compressor

for

proper

operation.

Observe

that

there

are

no

leaks

or

unusual

noises.

Make

sure

there

is

adequate

air

circulation

around

the

compressor

and

that

the

location

temperature

where

the

compressor

is

operating

does

not

exceed

110°

F.

Compressor

Shutdown

Press

the

On/Off

rocker

switch

to

the

OFF

position.

10

APPLICABILITY

[ABCD]

SERVICING

Oxygen

compression

equipment

has

very

special

requirements

because

of

the

hazards

of

explosion

and

fire

associated

with

compressed

oxygen.

Rix

recommends

that

only

trained

and

qualified

personnel

work

on

this

equipment.

Rix

recommends

returning

the

compressor

to

Rix

or

to

an

approved

Rix

service

center

when

repairs

are

to

be

made.

Simple

operations

such

as

repairing

leaks

or

replacing

valves

or

relief

valves

may

be

done

locally

by

competent

mechanics

trained

in

working

on

oxygen

equipment.

Care

must

be

taken

when

handling

these

parts

so

that

surfaces

in

contact

with

oxygen

do

not

become

contaminated.

Changing

Suction

and

Discharge

Valves

(first

and

second

stages)

The

compression

valves

are

designed

into

the

tube

fittings

for

the

first

and

second

stages

suction

and

discharge.

These

valves

are

not

designed

to

be

serviceable

except

by

the

factory.

To

replace

a

valve,

remove

the

fitting

nut

and

tube

line

and

then

remove

the

valve.

When

reinstalling

a

valve

make

sure

that

the

O-ring

is

in

place

and

is

lightly

lubricated

with

oxygen

compatible

grease

such

as

KrytoxBo.

Valves

are

marked

with

an

‘S’

for

suction

and

a

‘D’

for

discharge.

Make

sure

the

proper

valve

is

used

when

reinstalling.

Do

not

interchange

suction

and

discharge

valves.

Reinstall

the

tube

line

and

tighten

the

nut

as

necessary

to

eliminate

leakage.

Use

a

soap

type

leak

test

fluid

to

check

for

leaks

while

the

compressor

is

running.

Tighten

just

enough

to

eliminate

all

leakage.

Caution

Do

not

over-tighten

as

this

may damage

the

sealing

surfaces

making

it

more

difficult

to

attain

a

leak-free

joint.

11

APPLICABILITY

[ABCD]

SERVICING

Changing

Suction

Valve

(third

stage)

This

suction

valve

is

similar

to

the

first

and

second

stage

suction

valve

but

is

marked

“3S”.

It

should

not

be

interchanged

with

any

other

stage

valve,

but

otherwise

may

be

serviced

in

the

same

way

as

the

suction

valves

for

the

first

and

second

stages.

Changing

Discharge

Valve

(third

stage)

The

discharge

valve

is

located

under

the

hex

plug

on

top

of

the

third

stage

head.

It

is

critically

important

to

keep

the

internal

parts

from

becoming

contaminated

and

this

valve

should

be

serviced

by

personnel

trained

in

handling

oxygen

systems.

Lightly

lubricate

the

small

O-ring

on

the

tip

of

the

poppet

with

an

oxygen

compatible

lubricant

such

as

Krytoxe.

Changing

Relief

Valves

The

relief

valves

are

not

meant

to

be

serviced

except

by

the

factory.

If

it

becomes

necessary

they

may

be

replaced

with

new

valves

using

care

so

that

the

surfaces

in

contact

with

oxygen

do

not

become

contaminated.

The

first

and

second

stage

relief

valves

are

located

on

the

side

of

the

compressor.

The

third

stage

or

final

relief

valve

is

located

inside

the

base

of

the

compressor.

Setting

The

Pressure Switch

A

pressure

switch

is

located

inside

the

base

of

the

compressor

and

is

factory

set

at

2200

psig.

It is

important

that

the

set

point

never

exceeds

this

pressure.

If

it

becomes

necessary

to

reset

this

switch

it

is

accessible

through

a

square

shaped

cutout

in

the

plate

covering

the

underside

of

the

base.

Push

the

sleeve

on

the

body

of

the

pressure

switch

back

to

expose

the

pressure

adjustment

mechanism.

Insert

a

flat

bladed

tool

such

as

a

screwdriver

in

the

slot

and

rotate

the

adjustment

mechanism

clockwise

to

increase

pressure

and

counterclockwise

to

decrease

it.

12

APPLICABILITY

[ABCD]

TROUBLESHOOTING

Circuit

breaker

in

Microboost

base

trips

Likely

causes:

1.

A

short

circuit

in

the

motor

or

electrical

wiring.

2.

A

bearing

is

failing

in

the

drive

system.

3.

A

problem

internal

to

the

compressor

or

gearbox

has

increased

the

motor

load.

Thermal

switch

in

motor

trips

(note:

this

will

reset

automatically)

Likely

causes:

1.

Inadequate

air

circulation

where

the

compressor

is

operating.

2.

Motor

current

draw

is

high

(see

overload

causes

listed

above).

Relief valves

leaks

or

relieves

Likely

causes:

1.

A

valve

problem

(either

suction

or

discharge)

in

the

next

higher

stage

of

compression.

2.

A

faulty

relief

valve

(damaged

seat

or

maladjustment).

Low

flow

Likely

causes:

1.

A

leak

in

a

tube

or

pipe

fitting

on

the

compressor.

2.

A

leaking

relief

valve.

3.

Worn

piston

seals

in

the

compressor.

Compressor

stalls

Likely

causes:

1.

Mechanical

failure

such

as

a

bearing

seizure.

Compressor

will

not

start

Likely

causes:

1.

The

compressor

pressure

is

above

the

pressure

switch

setting.

2.

The

motor

has

overheated

and

tripped

the

thermal

switch.

3.

The

circuit

breaker

tripped.

13

APPLICABILITY

[ABCD]

PARTS

BREAKDOWN

APPLICABILITY

[CD]

14

PARTS

BREAKDOWN

Compressor

Assembly

Major

Components

MICROBOOST

Model

MB-D-115

115

V,

50/60 Hz

ITEM

QTY

PART

NUMBER

DESCRIPTION

1

1

107-7309

MOTOR/GEARBOX

2

1

G100-MB-B

COMPRESSOR

(see

separate

parts

list,

page

17)

3

1

G200-MB-115-B

BASE

(see

separate

parts

list,

page

19)

4

1

138-5777

POWER

CORD

MICROBOOST

Model

MB-D-230

230

V,

50/60

Hz

ТЕМ

QTY

PART

NUMBER

DESCRIPTION

1

1

107-7309

MOTOR/GEARBOX

2

1

G100-MB-B

COMPRESSOR

(see

separate

parts

list,

page

17)

3

1

G200-MB-230-B

BASE

(see

separate

parts

list,

page

19)

4

1

МА

POWER

CORD

(provided

by

customer)

15

APPLICABILITY

[BCD]

PARTS

BREAKDOWN

16

X

NX

q

X

X

X

NOON

SON

ON

NOON

X

Sc

\

X

|

APPLICABILITY

[BCD]

X

a

o

ペー

ジ

\

\

VE

A

な

ο

一

À

PARTS

BREAKDOWN

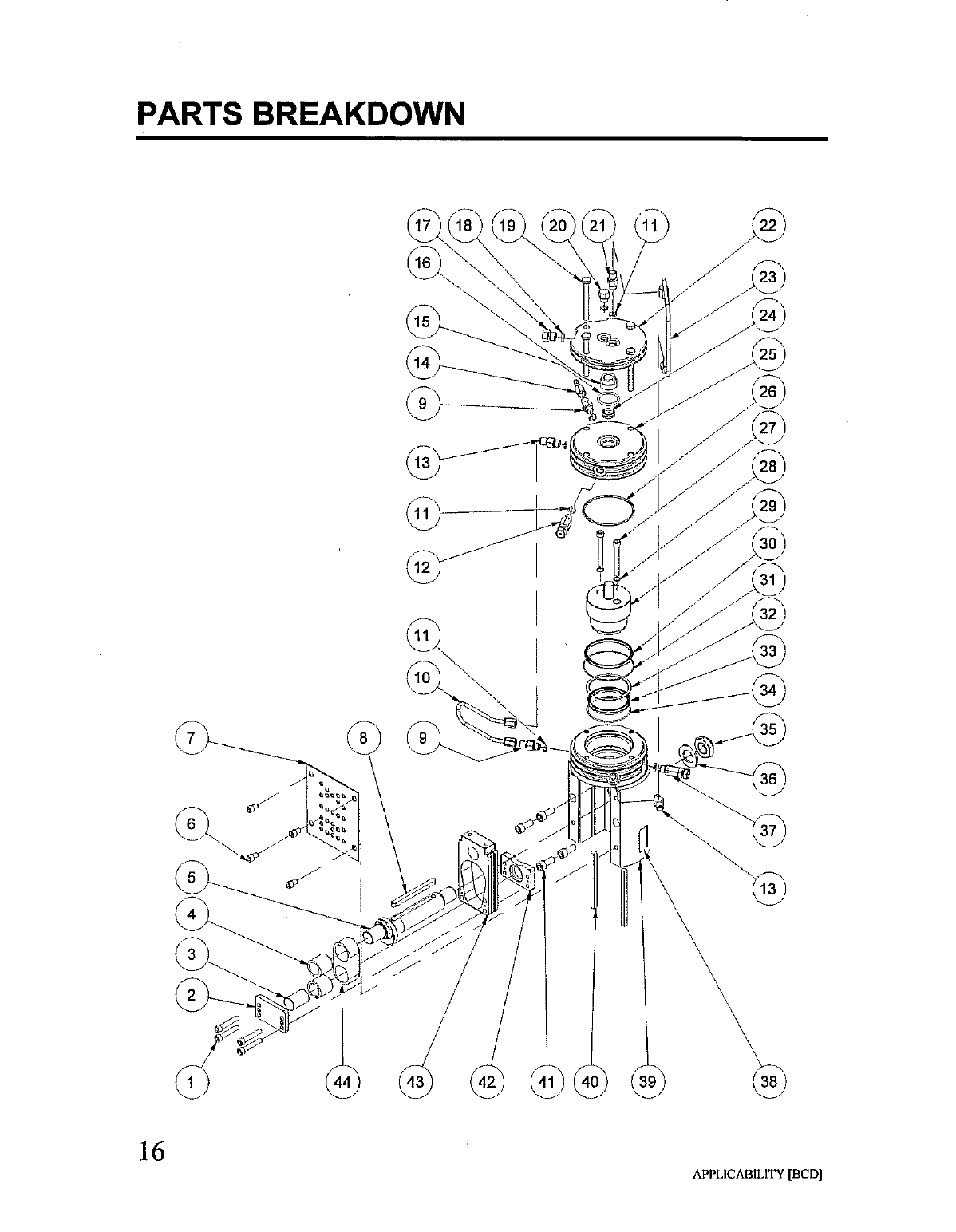

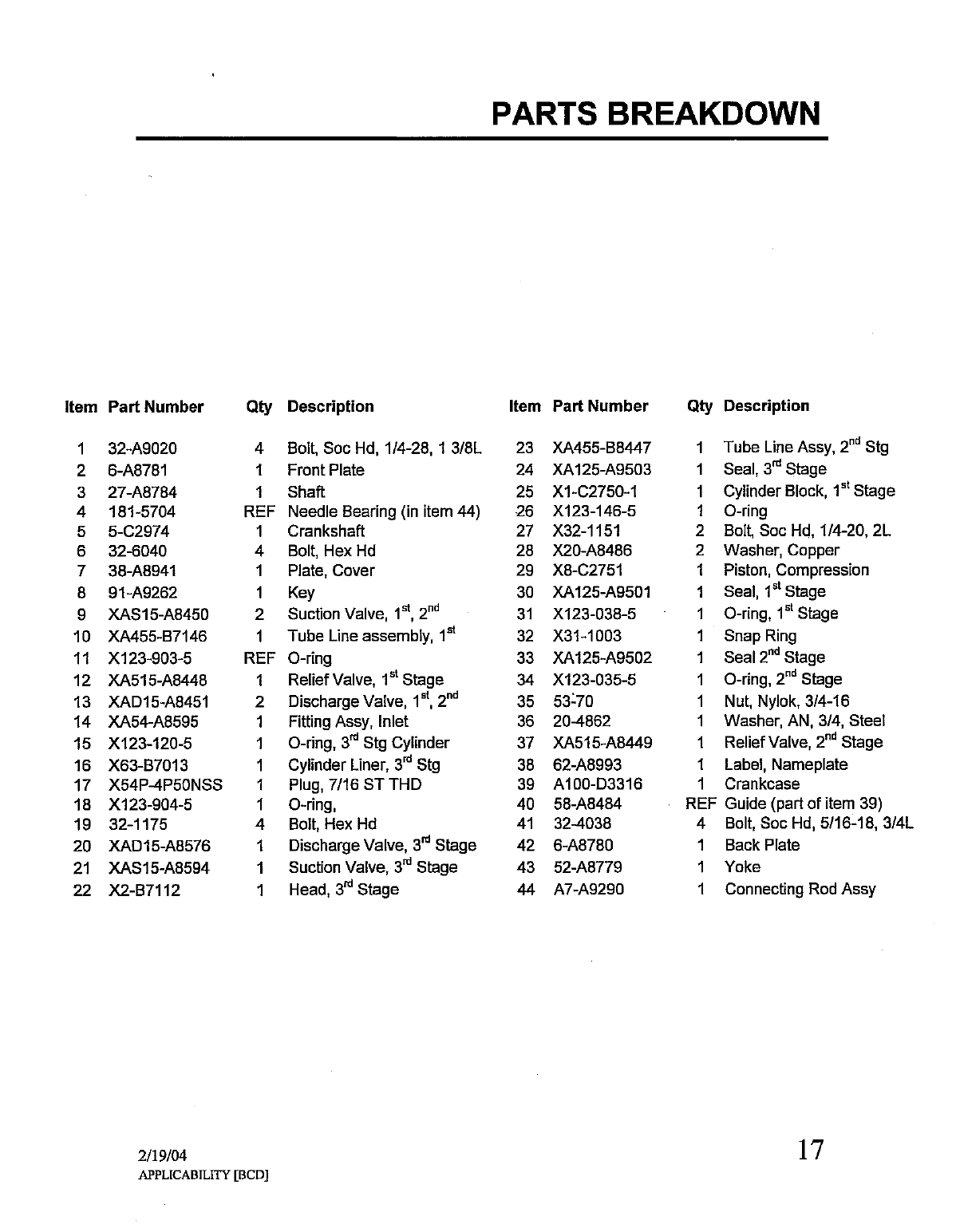

Item

Part

Number

On

AaAhwW

ND

=

NON

N

dad

SÅ

A

A

A

ーー

D

> © ©

©

JO

0

B w D = © ©

32-A9020

6-A8781

27-A8784

181-5704

5-C2974

32-6040

38-A8941

91-A9262

XAS15-A8450

XA455-B7146

X123-903-5

XA515-A8448

XAD15-A8451

XA54-A8595

X123-120-5

X63-B7013

X54P-4P50NSS

X123-904-5

32-1175

XAD15-A8576

XAS15-A8594

X2-B7112

2/19/04

Qty

Description

A

ода

Я

a

Ma-

Ti

n

APPLICABILITY

[BCD]

Bolt,

Soc

Hd,

1/4-28,

1

3/8L

Front

Plate

Shaft

Needle

Bearing

(in

item

44)

Crankshaft

Bolt,

Hex

Hd

Plate,

Cover

Key

Suction

Valve,

1%,

2%

Tube

Line

assembly,

1*

O-ring

Relief

Valve,

1°

Stage

Discharge

Valve,

1%,

2"

Fitting

Assy,

Inlet

O-ring,

3% Stg

Cylinder

Cylinder

Liner,

3"

Stg

Plug,

7/16

ST

THD

O-ring,

Bolt,

Hex

Hd

Discharge

Valve,

gi

Stage

Suction

Valve,

3"

Stage

Head,

3"

Stage

Item

Part

Number

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

XA455-B8447

XA125-A9503

X1-C2750-1

X123-146-5

X32-1151

X20-A8486

X8-C2751

XA125-A9501

X123-038-5

X31-1003

XA125-A9502

X123-035-5

53-70

20-4862

XA515-A8449

62-A8993

A100-D3316

58-A8484

32-4038

6-A8780

52-A8779

A7-A9290

Qty

4

4

1

1

2

2

1

4

1

1

1

1

1

1

1

1

1

REF

4

1

1

1

Description

Tube

Line

Assy,

2

Stg

Seal,

3%

Stage

Cylinder

Block,

1º

Stage

O-ring

Bolt,

Soc

Hd,

1/4-20,

2L

Washer,

Copper

Piston,

Compression

Seal,

1º

Stage

O-ring,

1°

Stage

Snap

Ring

Seal

2™

Stage

O-ring,

2" Stage

Nut,

Nylok,

3/4-16

Washer,

AN,

3/4,

Steel

Relief

Valve,

2"!

Stage

Label,

Nameplate

Crankcase

Guide

(part

of

item

39)

Bolt,

Soc

Hd,

5/16-18,

3/4L

Back

Plate

Yoke

Connecting

Rod

Assy

17

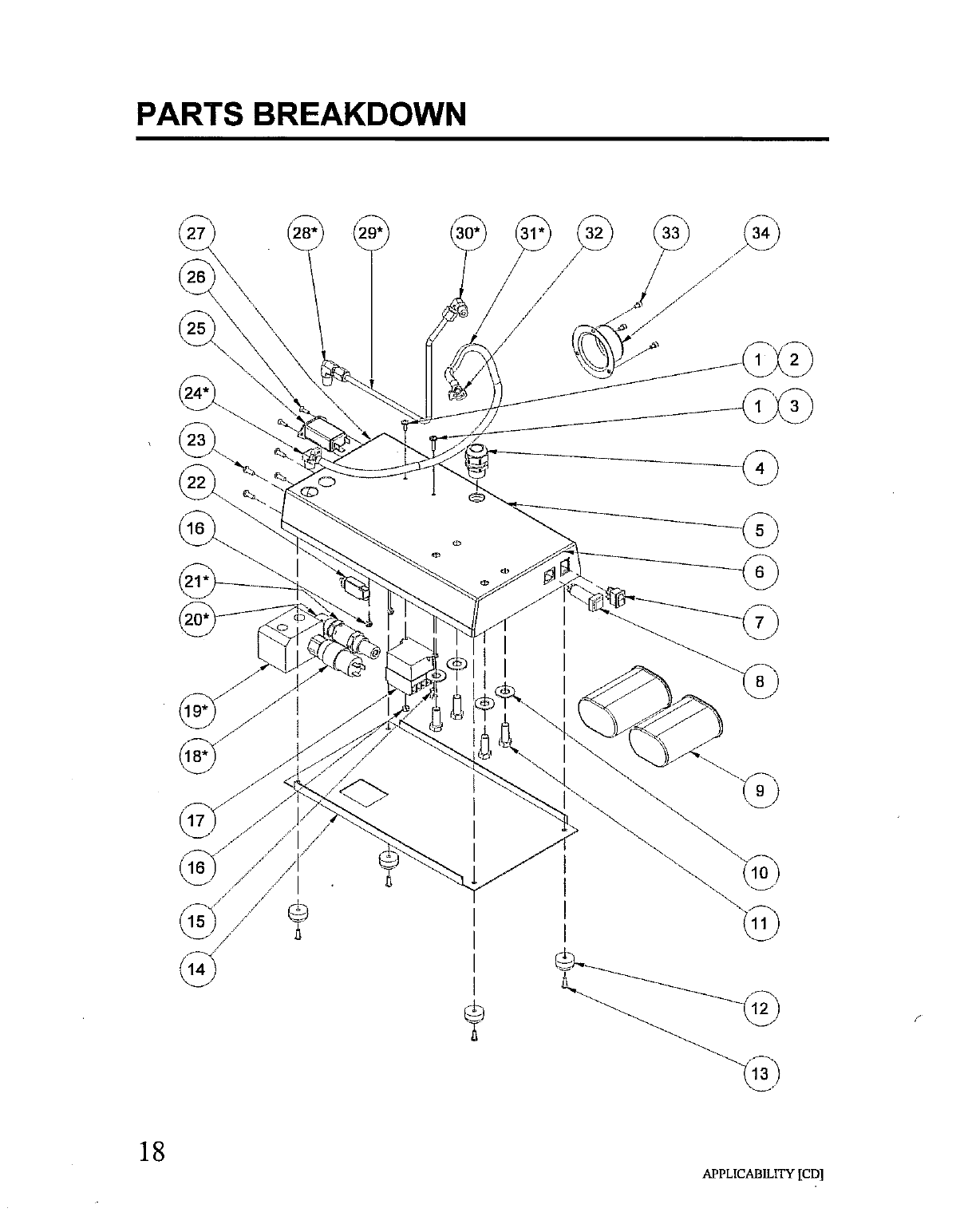

PARTS

BREAKDOWN

18

APPLICABILITY

[CD]

Other manuals for MB-115

1

This manual suits for next models

1

Table of contents

Other RIX Air Compressor manuals

Popular Air Compressor manuals by other brands

Clarke

Clarke RAIDER 15/1000 Operation & maintenance instructions

Oasis

Oasis YC4000 owner's manual

Campbell Hausfeld

Campbell Hausfeld CE3000 operating instructions

Ingersoll-Rand

Ingersoll-Rand P130WJDU Operating, Maintenance & Parts Manual

York

York VSD 270 Operation manual

KING

KING KC-5280V3-MS instruction manual