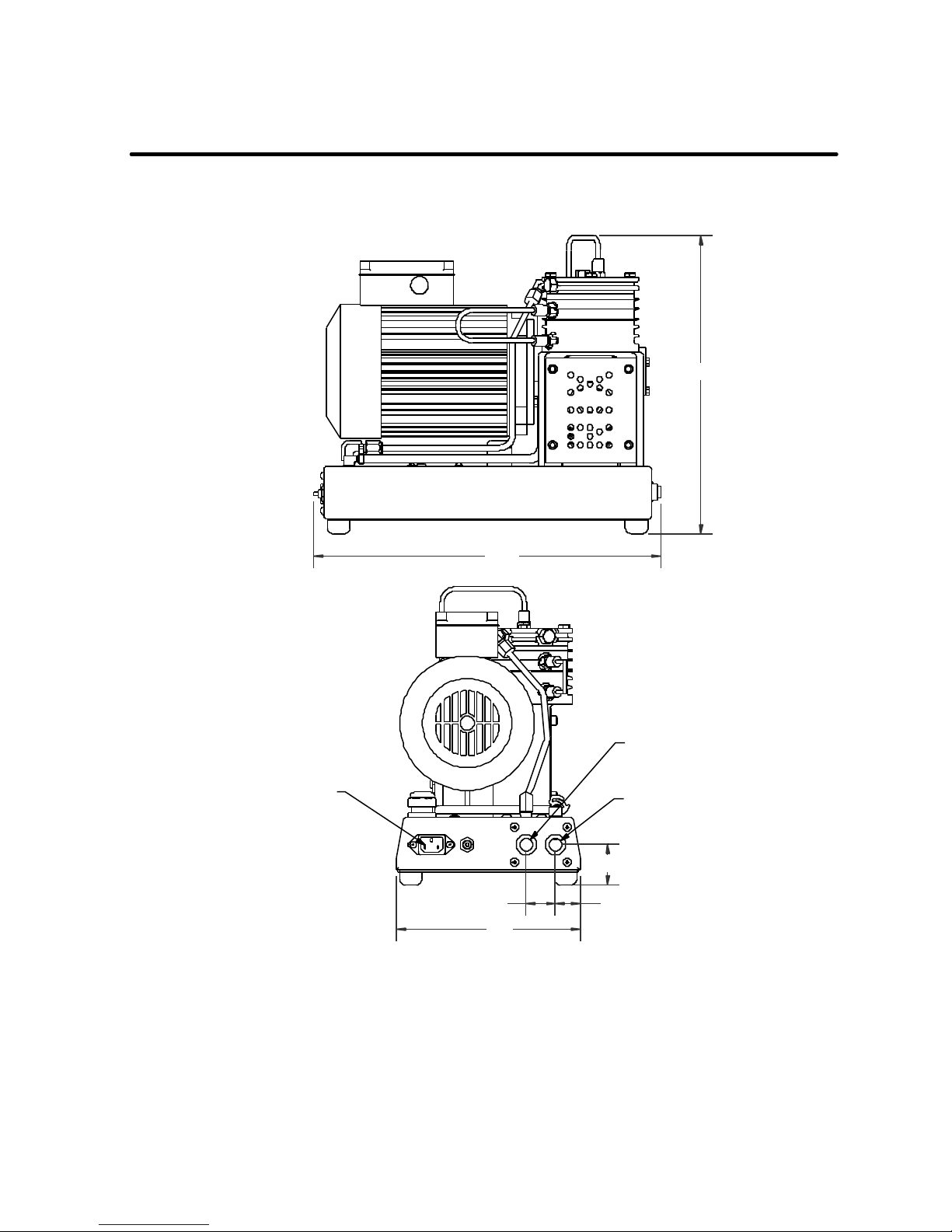

RIX MB-115 User manual

Other manuals for MB-115

1

This manual suits for next models

1

Table of contents

Other RIX Air Compressor manuals

Popular Air Compressor manuals by other brands

Sealey

Sealey SAC2103B.V2 instructions

California Air Tools

California Air Tools SP-9421 owner's manual

California

California 8010ALFC owner's manual

Bitzer

Bitzer OS.70 series operating instructions

General Air Products

General Air Products L20033 Installation, operation and maintenance manual

Atlas Copco

Atlas Copco LT2 Instruction book

Porter-Cable

Porter-Cable CPFAC2600P instruction manual

Clarke

Clarke CFP10H Operating & maintenance instructions

Metabo

Metabo Mega 350 W + D operating instructions

Sealey

Sealey Power PRODUCTS SA5040 instructions

Einhell Global

Einhell Global Airbase 8/2 operating instructions

Bisonte

Bisonte SC012-015 user guide

AmazonBasics

AmazonBasics B074DD8NVY manual

Ingersoll-Rand

Ingersoll-Rand IRN 15K instructions

Briggs & Stratton

Briggs & Stratton 74045 instruction manual

KAESER

KAESER Aircenter SX 3 Service manual

General Air Products

General Air Products Q Series Installation, operation and maintenance manual

VIAIR

VIAIR 15010 manual