RMG SailWinch SmartWinch 280D User manual

RMG SAILWINCH

SmartWinch

U S E R G U I D E

Contents

1.Introduction .................................................. 1

2.SummaryofFeatures........................................... 1

3. Special SmartWinch Features .................................... 1

4.Batteries..................................................... 3

5.Wiring ...................................................... 4

6.StandardConnections .......................................... 5

7.AlternateConnections .......................................... 5

8.Mounting.................................................... 6

9.Sheeting..................................................... 7

10.SettingUp................................................... 8

11. Setting TX End Points, Travel and Battery Monitoring . . . . . . . . . . . . . . . . 9

12. Adjusting Deceleration, Scaled Linear Travel, Speed & Dead Band . . . . . 10

13.Maintenance ................................................ 12

14.Warranty................................................... 12

15.MechanicalSpecifications ..................................... 13

16.ElectricalSpecifications ....................................... 13

The SmartWinch is manufactured by

RMG SAILWINCH

66 Radford Rd

Angaston 5353

South Australia

Phone: 61 (0)8 8564 2444

Fax: 61 (0)8 8564 3474

E-mail: [email protected]

Internet: www.rmgsw.com

0307

SmartWinch User Guide page 1

1. Introduction

Thank-you for purchasing a SmartWinch. We hope you have many

years of trouble free and successful sailing using our product. If there are any

problems to be solved or queries to be answered please do not hesitate to call.

Please take the time to read this booklet through. There are a few do's and don'ts,

some very important points and some helpful hints.

2. Summary of Features

•3.8 to 9 volt operating range

COptional battery monitoring and low battery shutdown

CIntegral 5 volt regulator for single battery operation

CTravel adjustable from 1 to 6 revolutions depending on model

CAutomatic shutdown when stalled

CDynamic Pulse Width Modulation drive

CProgrammable forTX end point limits for overrun protection

CAdjustable deceleration rate

CAdjustable Speed

CAdjustable Scaled Linear Travel.

CAdjustable Input Dead Bnad

CBall bearing output.

3. Special SmartWinch Features

Dynamic Pulse Width Modulation

Servo systems use Pulse Width Modulation to reduce power and speed

as the desired position is approached. This gives finer and smoother control when

small movements are required. But the problem with standard P.W.M. is that as

the desired position is approached, the reduction in power can cause the servo to

stop short. This can result in excess power consumption, overheating and

damage. This is what's happening when a servo is not moving but is buzzing.

However, unlike other winches and servos the SmartWinch has dynamic P.W.M.

If the SmartWinch controller detects that it has not reached the desired position,

it will increase power up to 100% if necessary until it does. If once 100% power

is reached and the SmartWinch is still not able to reach its desired position then

the stall protection feature can be activated.

SmartWinch User Guide page 2

Stall Protection

When a conventional winch becomes stalled, it will stay stalled until the problem

is solved or the battery is flattened or the electronics damaged etc. But the

SmartWinch knows when it is stalled and can protect itself by shutting down.

The winch then signals that it is stalled by sounding a two-tone beep at 2 second

intervals until reset. To reset the winch simply move the tx stick in the opposite

direction or turn the TX or winch off and on again.

Battery Monitoring

If desired, the winch can monitor NiCad or NimH packs of 5 or 6 cells or 6 volt

sealed lead acid gel cells. If the voltage is below the warning level a warning

signal (5 rising tones) will sound when the winch is switched on. If, during

normal operation the voltage falls below the shutdown level, the winch will drive

to half way and hold there until the battery is replaced or voltage recovers.

Adjustable Deceleration Rate

The time taken to decelerate from full speed to stopped can be adjusted. At

minimum, deceleration takes around 1 second. Maximum is around 0.1 seconds.

Depending on supply voltage used, the SmartWinch may over shoot and hunt so

experimentation is advised. The default setting is 70% of maximum.

Scaled Linear Travel Response

Travel response to the first 25% of TX stick movement out from close hauled is

adjustable from 1:1 at minimum to a maximum of 4:1. The default setting is 1:1.

For example, if 50% is selected, each increment of the first 25% of the stick

range results in half the travel of the default setting. This feature is similar to

exponential travel adjustment in some transmitters. However scaled linear has the

advantage of consistent incremental travel over the first 25% of stick movement

whereas exponential is constantly varying.

Variable Speed

This feature is included for some non sailwinch applications where a certain

speed is important. Also some skippers may prefer a slower sailwinch response

to suit their particular sailing style. The default setting is maximum speed.

Input Dead band

Input dead band is the amount dithering in the RX signal that a servo can

tolerate without responding to by constantly jittering. This is now adjustable from

2 to 15 microseconds. Dead Band adjustment allows the optimisation of TX fine

trim control. The default setting is 10 microseconds.

SmartWinch User Guide page 3

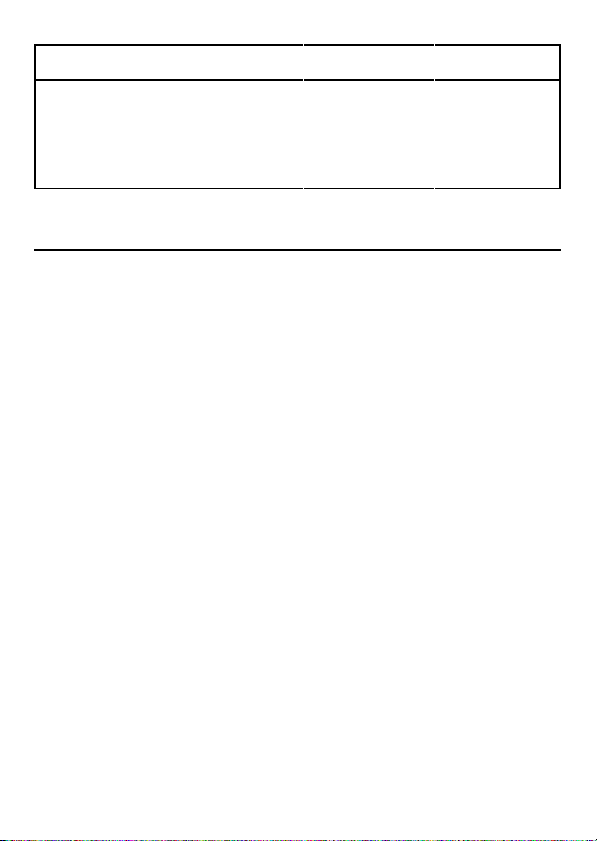

Table 1

Level Detect Warn Shutdown

1. 6V gel cell < 6.5 < 5.1 < 5.0

2. 5 cells > 6.5 < 5.5 < 5.0

3. 6 cells > 7.5 < 6.6 < 6.0

Battery Monitoring Voltages

4. Batteries

Voltage Range

Supply voltage range is from 3.8V to 9V. Should a voltage outside that range be

applied the winch will not operate. No damage can be done unless reverse

polarity or > 12 volts is used. While the winch will operate down to 3.8 volts, the

minimum should be a 4 pack of NiCad or NimH. This will give room for voltage

drop as the battery pack discharges.

Pack Size

The recommended battery pack is 5 or 6 NiCad or NimH cells or a 2 cell LiPo.

Alternatively a 6V sealed lead acid gel battery may be used. These days with

higher cell energy densities, AA size NiCad or NimH cells can have capacities of

up to about 2500 mAh. With these high capacities it is also feasible to use AAA

size cells with a significant weight saving.

Snap In Battery Holders

Snap in battery holders are not recommended. Their weak electrical connections

can result in severe voltage drop which may cause erratic winch behaviour.

Compounding this problem is that in most cases these packs only have servo size

wiring which can not supply the current required by the winch. 4, 5 or 6 cell

packs should be fully soldered.

Battery Life

Battery life depends on many variables. But as a rough guide, provided you have

a good low friction sheeting system, you could expect to get about 12 to 16 races

of about 10 to 15 minutes duration in conditions of around 8 to 10 knots from a 5

pack of 1000mAh AA's.

SmartWinch User Guide page 4

Fig. 1 Servo Connector

5. Wiring

Regulator

The SmartWinch contains a 5 volt regulator which can supply up to 1 amp of

current to the controller circuit, radio receiver (rx) and rudder servo. This allows

for the use of only one battery pack inside the yacht. The motor runs on the full

battery voltage via the MOSFET output circuit.

Supply Leads

Wiring and connectors from winch supply leads to battery pack must be at least

0.5mm cross section and rated at least 3 Amps. Switches used should be rated at

2

least 3 Amps also. Standard servo size wiring is not adequate. It will cause

severe voltage drop between battery and winch and should not be used. All joints

should be soldered and then coated with Vaseline petroleum jelly to protect from

corrosion (black wire). Use Vaseline on servo connectors also.

Supply Polarity

Power supply / battery lead connectors must be polarised so that it is impossible

to accidentally reverse the supply polarity. The control circuit and radio gear is

protected by the voltage regulator and will not be damaged by reverse polarity

but the output circuit could be seriously

damaged.

Servo Connector (RX Lead)

The connector supplied is compatible with JR,

Futaba, Hitec etc. Take care when inserting

connector into receivers other than JR or Hitec.

Make sure that polarity is correct. In the case of

Sanwa receivers, check the polarity of the Sanwa

servo leads first as early Sanwa receivers require

the centre lead to be negative. (see figure 1)

SmartWinch User Guide page 5

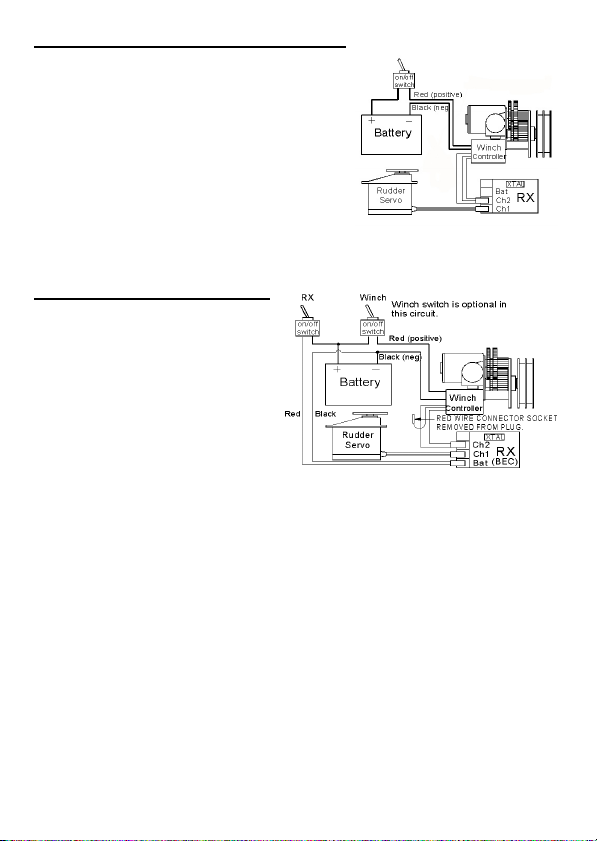

Fig. 3 Standard Connections

Fig. 4 Alternate Connections

6. Standard Connections

In most cases the best circuit for winch, radio

and battery is also the simplest as shown in

figure 3.

In this system there must be no receiver

battery connection. Power for receiver is

supplied by internal 5 volt regulator.

7. Alternate Connections

If more than just winch and a rudder

servo is used it is advisable to

bypass the winch's internal voltage

regulator and connect the battery

direct to the rx. See Figure 4. This

is because the winch regulator and

or servo lead may not be able to

supply the current needed by extra

servos causing a voltage drop.

Servo connector lead red wire must be disconnected when RX battery socket in

use. Remove the red wire socket from the connector and tape it back to the lead.

Winch switch can be omitted in this case as the winch will not operate when rx is

turned off. RX must be able to take full battery voltage.

SmartWinch User Guide page 6

Fig. 5 Mounting Dims.

Fig. 6 Mount Bracket

8. Mounting

Deck Mounting

The recommended method of mounting the winch is to fix it to the underside of

the deck with output shaft passing through the deck. Maximum deck thickness

3mm.

Sealing

Prior to fixing the winch to the underside of the deck, the mounting face, spigot

and "V" ring seal on the shaft immediately below the hexagonal section of the

output shaft should be given a liberal coating of Vaseline petroleum jelly or

Silicone grease to form a seal. Coat the two M3 mounting screws as well. Before

fitting the drum give the area around the 'V' ring seal an extra coat of Vaseline.

Below Deck Mount

For below deck mounting it is usually best to mount the winch with shaft

horizontally. You may wish to make a bracket such as the one at left to assist in

below deck installation.

SmartWinch User Guide page 7

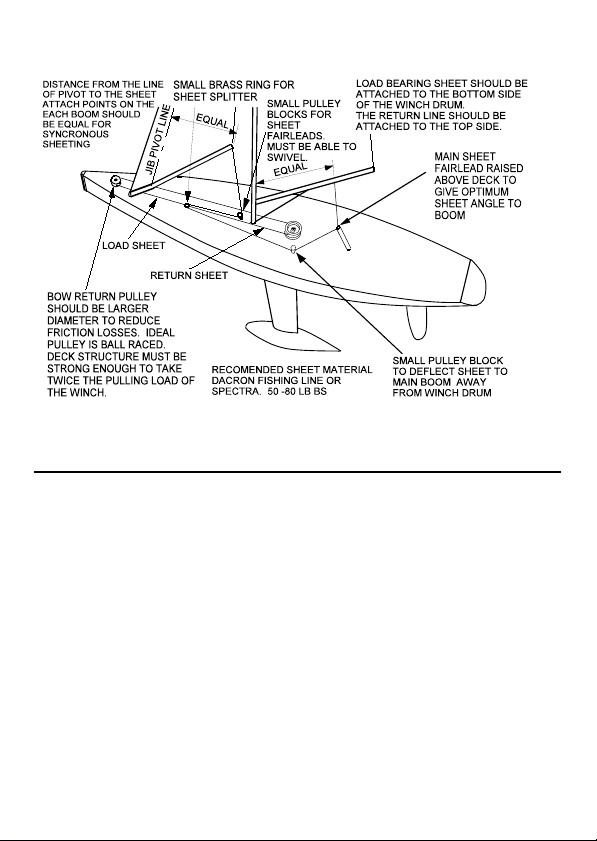

9. Sheeting

Drum Size vs Performance

Unless specified otherwise when ordering, the 280D and 280DL are supplied

with a 26mm drum. The 380D and 380HD are supplied with a 32mm drum. If

faster or slower performance is desired an extra drum may be purchased. Write or

phone for pricing. Our web site has details of several other drum options.

The size of drum affects the way the winch performs. Smaller diameter means

more revolutions are required therefore sheet speed is slower. However with

smaller diameter a higher sheeting force is achieved. And vice versa if larger

diameter is used. Similar changes in sheeting performance can be achieved by

changing the supply voltage.

Sheeting Systems

There are many ways to approach the sheeting on an R/C yacht and no one

method can be considered to be "the best way". The two main categories of

sheeting systems used on drum type winches are described below. Either system

can be used above or below deck.

#Single sheet - tension line.This is where only one side of the

drum is used and light tension is applied by an elastic tension line

which is attached to the deck. It's purpose is to prevent the loss of

wraps around the drum during sheeting out.

#Double sheet - return line. Where instead of an elastic tension

line a return line is attached the top side of the drum. As the winch

sheets out the return line is winding in maintaining tension on the load

sheet. As the winch is sheeted in the return line will wind out.

Figure 7 shows a typical arrangement for a double sheet above deck system. To

make this a single sheet tension line system, simply replace the return line with

an elastic tension line. Attach it to the sheet splitter and a fixed point near the

stern to give as much length to the elastic material as possible.

SmartWinch User Guide page 8

Fig. 7 Sheeting

10. Setting Up

It is not essential to perform the setup procedure to use the winch. Each winch

has “factory default” settings. However, setting TX end points and Travel is

recommended to give the overrun protection.

Setup can be performed as many times as desired. Each time setup is performed,

the previous settings are overwritten.

Normal Operation

To use the winch, the TX must be switched on before the SmartWinch. If the TX

is switched on after the SmartWinch, the SmartWinch will not operate other than

to allow entry to setup mode. Setup mode is not entered unless a long beep is

heard. The earliest this can happen is 10 seconds after turning the winch on. If

setup mode is accidentally entered, just turn the SmartWinch off then restart with

the TX on.

SmartWinch User Guide page 9

11. Setting TX End Points, Travel and Battery Monitoring

These settings must be done in sequence. For example, to make an adjustment to

travel, the TX end points must be set at the same time.

1 Start with; Winch off, TX on, RX lead plug out of RX, TX stick

at close hauled and trim set to minimum.

When the winch is switched on with the plug out ouf RX, it will countdown by

sounding a single beep once per second for the first 9 seconds.

2. Turn winch on and wait 10 seconds till the 3 quick beep

signal then push plug into the RX within 2 seconds.

If a single long beep is heard, setup mode has been entered and the TX end point

for close hauled position has been sampled. If not then restart the procedure..

3. Pull plug out of RX.

4. Move TX stick (not trimmer) to opposite end for sails full out

then push plug into RX.

A long beep will indicate that the TX end point for sails full out position has

been sampled.

5. Pull plug out of RX

A 3 beep signal indicates that the TX end points have been stored. The winch

can be turned off now if travel or battery setting changes not needed. Otherwise

continue on to step 6.

6. Detach the sheet lines or remove the drum.

When the plug is next inserted, the winch will drive itself to the travel starting

point. The winch must be free to drive to this position. If not sure then remove

the drum or disconnect the sheets.

7. Move TX stick back to close hauled then push plug in RX.

Once travel starting point is reached, it will sound 2 beeps. You can now drive

the winch using the TX. Install the drum and setup the sheets so that the main

boom is at close hauled when TX stick is at close hauled. Take care when

driving the winch with sheets attached as it is set for maximum travel at this time

and it would be easy to overrun. The winch will drive at 1/3rd normal speed

during this travel setting phase of setup.

SmartWinch User Guide page 10

8. Drive winch out (using TX stick) till the main boom is at the

desired fully sheeted out position. With the winch in this

position, pause for at least one second without moving the

winch, then remove RX plug.

Three beeps indicates that the new travel setting is stored. If you do not wish to

make any changes to your battery monitoring settings, switch winch off now and

setup is complete.

Or if you wish to change the existing battery monitoring settings then perform

either step 9a or 9b.

9a To enable battery monitoring, push plug into RX and wait till you

hear either 1, 2 or 3 quick beeps. Battery must be fully

charged for correct detection of number of cells.

9b To disable battery monitoring, push plug into RX and

immediately pull it out again (within about 1 second).

If three rising tones have sounded, 9b was performed and battery monitoring is

now off. If 1, 2 or 3 quick beeps were heard then step 9a was performed and

battery monitoring is turned on. The number of beeps corresponds to the battery

monitoring level set. See table 1.

Once setup is complete, the winch must be switched off.

12. Adjusting Dec Rate, Scaled Linear Travel, Speed & Dead Band

For a description of these features, see page 2. Each of these settings has a

separate entry point and can be adjusted independently. For optimum setting of

these features it is important to already have the SmartWinch set for TX end

points. However setting end points does not need to be done each time one of

these adjustments is made.

For each setting, start with; SmartWinch turned off, TX turned on, TX trim set to

minimum, RX lead plug out of RX and TX stick in desired position. For each

adjustment, select close hauled for minimum, full out for maximum or an

intermediate position as desired. Note that the SmartWinch will not drive while

making these adjustments. There is no need to remove drum or sheets.

SmartWinch User Guide page 11

Deceleration Rate Adjustment

1 Turn Winch on and wait 14 seconds till the 3 rising tones

signal then push plug into RX within 2 seconds.

If a single long beep is heard, the adjustment has been noted. If not then the

plug was not inserted in time so turn winch off and start again.

2 Pull plug out of RX.

A 3 quick beeps signal will indicate the new setting has been saved. Turn winch

off.

Scaled Linear Travel Adjustment

1 Turn Winch on and wait 17 seconds till the 2 quick beeps

signal then push plug into RX within 2 seconds.

If a single long beep is heard, the adjustment has been noted. If not then the

plug was not inserted in time so turn winch off and start again.

2 Pull plug out of RX

A 3 quick beeps signal will indicate the new setting has been saved. Turn winch

off.

Speed Adjustment

1 Turn Winch on and wait 20 seconds till the 3 quick beeps

signal then push plug into RX within 2 seconds.

If a single long beep is heard, the adjustment has been noted. If not then the

plug was not inserted in time so turn winch off and start again.

2 Pull plug out of RX

A 3 quick beeps signal will indicate the new setting has been saved. Turn winch

off.

Input Signal Dead Band Adjustment

1 Turn Winch on and wait 23 seconds till the 4 quick beeps

signal then push plug into RX within 2 seconds.

If a single long beep is heard, the adjustment has been noted. If not then the

plug was not inserted in time so turn winch off and start again.

2 Pull plug out of RX.

A 3 quick beeps signal will indicate the new setting has been saved. Turn winch

off.

SmartWinch User Guide page 12

13. Maintenance

• Spray the winch motor only with water repellant lubricating sprays.

Apply the spray directly into the motor. Avoid getting spray on

electrical wires or feedback potentiometer and controller enclosure

grommet. Note: These sprays contain flammable propellants and

solvents. Allow a few minutes for the flammable components to

evaporate before running the winch.

• Maintain a coating of white petroleum jelly (Vaseline) or Silicone

grease on all electrical connectors inside the yacht to protect against

'black wire' corrosion.

• Regularly re-pack the white petroleum jelly or Silicone grease under

the drum of deck mounted winches to protect the ball bearing.

Regularly remove the drum and re-coat the area around the shaft.

• Drain the boat of water as often as is required to keep the level of

water in the boat to an absolute minimum. After each days sailing

drain boat and leave hatch off to allow the boat to breathe and dry out.

This is important for all of the boat’s electrics.

• Do not attempt to seal the motor in any way. It must be able to breathe

for cooling purposes and also to dry out should moisture get in.

• Try to keep gears clean. Greasing is not necessary. Grease will only

attract grit which can damage the gears and will make the winch very

noisy.

14. Warranty

Your new SmartWinch is covered by a 12 month warranty. Should

any faults be found and are considered by RMG SailWinch to be our fault, we

will repair and return the winch to you free of charge.

SmartWinch User Guide page 13

15. Mechanical Specifications Table 2

Specification 280D (DL) 380D (HD) Unit

Max Power 10.7 14.3 W atts

No Load Speed 4.4(3.1) 3.5 revs/sec

No Load Speed 359 (286) 312 mm/sec

Stall Torque 15.9 (19.9) 29.9 kg.cm

Standard Drum 26 32 mm

Maximum Turns 4.8 (6) 6 (9.6) revs

Travel Range 70-405 (85-490) 80-610 (130 - 975) mm

Dimensions 74x54x59 79x54x60 mm

W eight 134 168 (175) gm

16. Electrical Specifications Table 3

Specification 280D (DL) 380D (HD) Unit

Idle (Stationary) Current 23 23 mAmps

No Load Running Current 550 650 mAmps

Stall Current 12 18 Amps

Maxim um Supply voltage 9 9 Volts

Minimum Supply voltage 3.8 3.8 Volts

Performance specifications based on a constant voltage supply of 6V and

standard drum size. Performance specifications may vary depending on supply

battery voltage and capacity and drum size etc.

This manual suits for next models

3

Table of contents

Popular Marine Equipment manuals by other brands

ESP

ESP MAGDUO MAGDUOSRSQ Installation and maintenance instructions

Allen-Bradley

Allen-Bradley PowerFlex 755T installation instructions

Venitem

Venitem ONDA Technical manual

Nexus 21

Nexus 21 Autopilot Installation and operation manual

Teledyne

Teledyne RIVERRAY Deployment guide

Teledyne

Teledyne PINNACLE 45 Deployment guide