Installation Instructions

Original Instructions

PowerFlex 755T Frames 5 and 6 Marine Discharge Kits

Catalog Numbers

20-750-CMRN-F5, 20-750-CMRN-F6

Product Advisories

Required Tools

Topic Page

Product Advisories 1

Required Tools 1

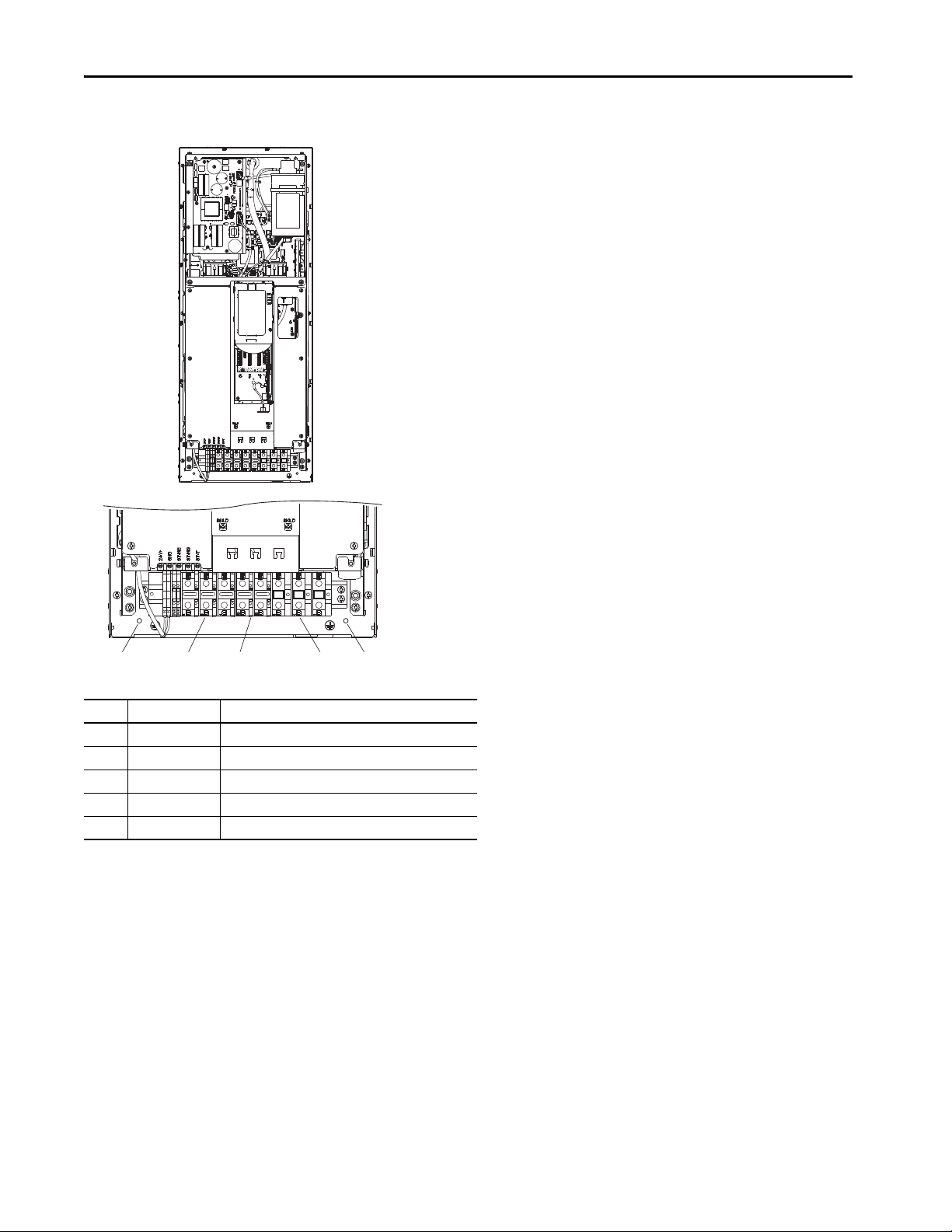

Frame 5 Marine Discharge Module and Conduit Box Kit Contents (Cat. No. 20-750-CMRN-F5) 2

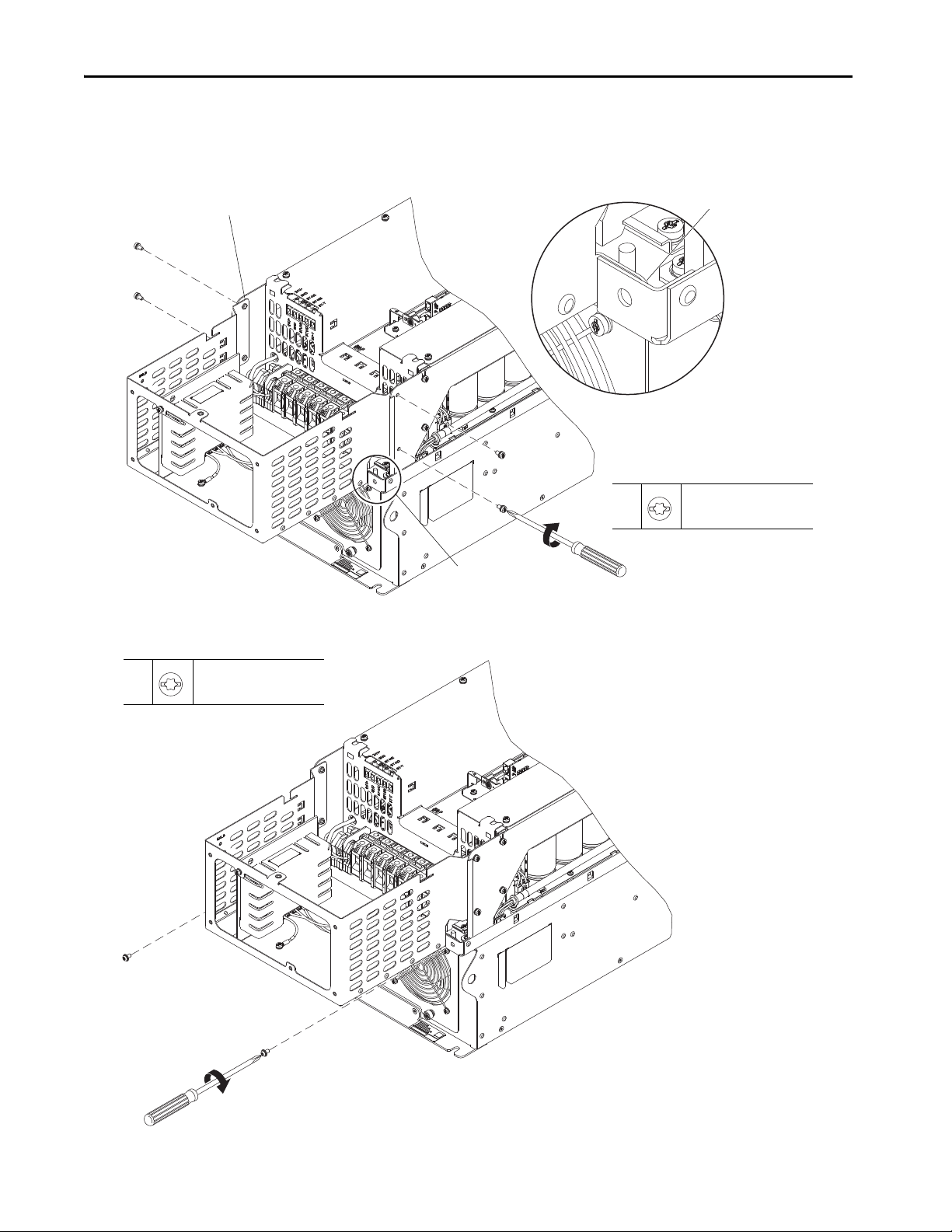

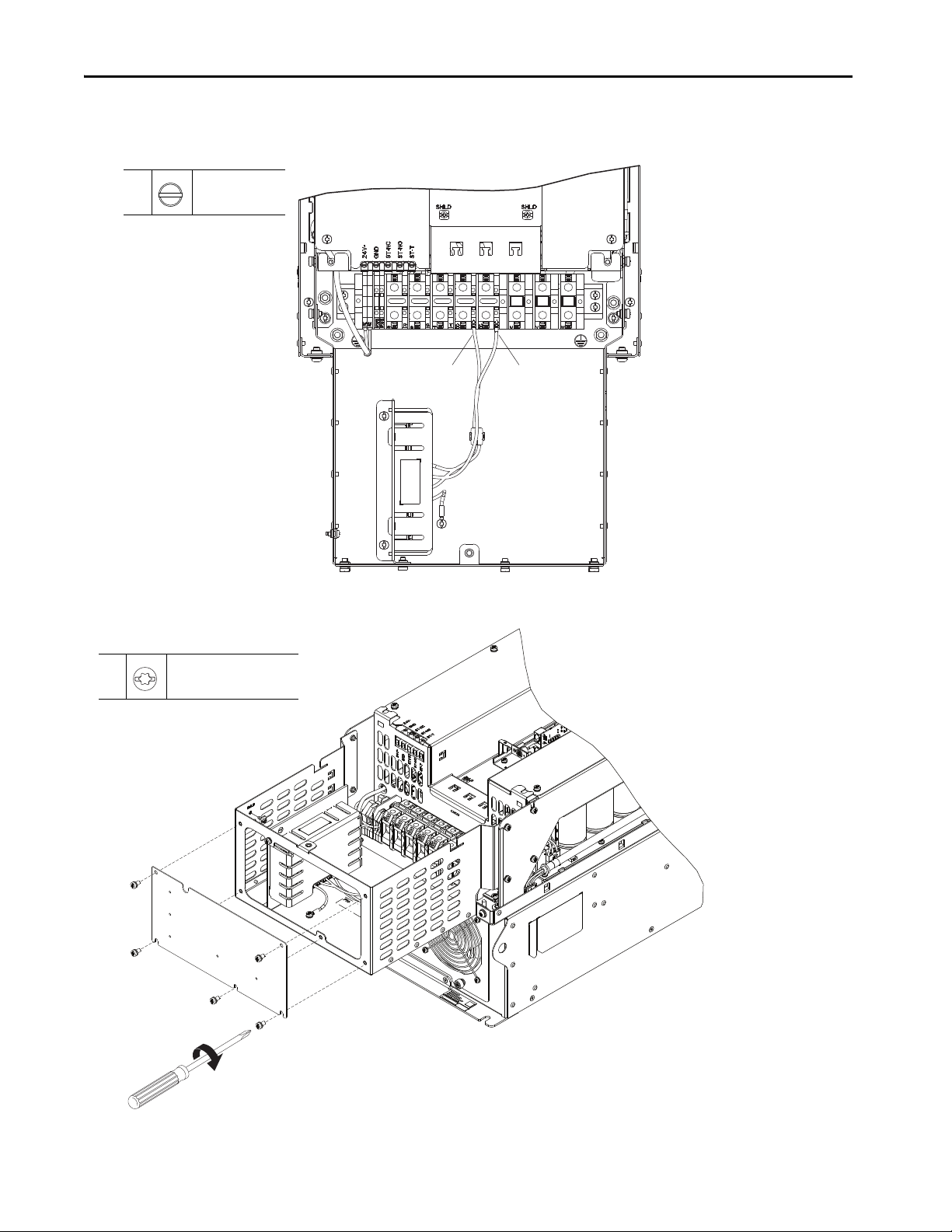

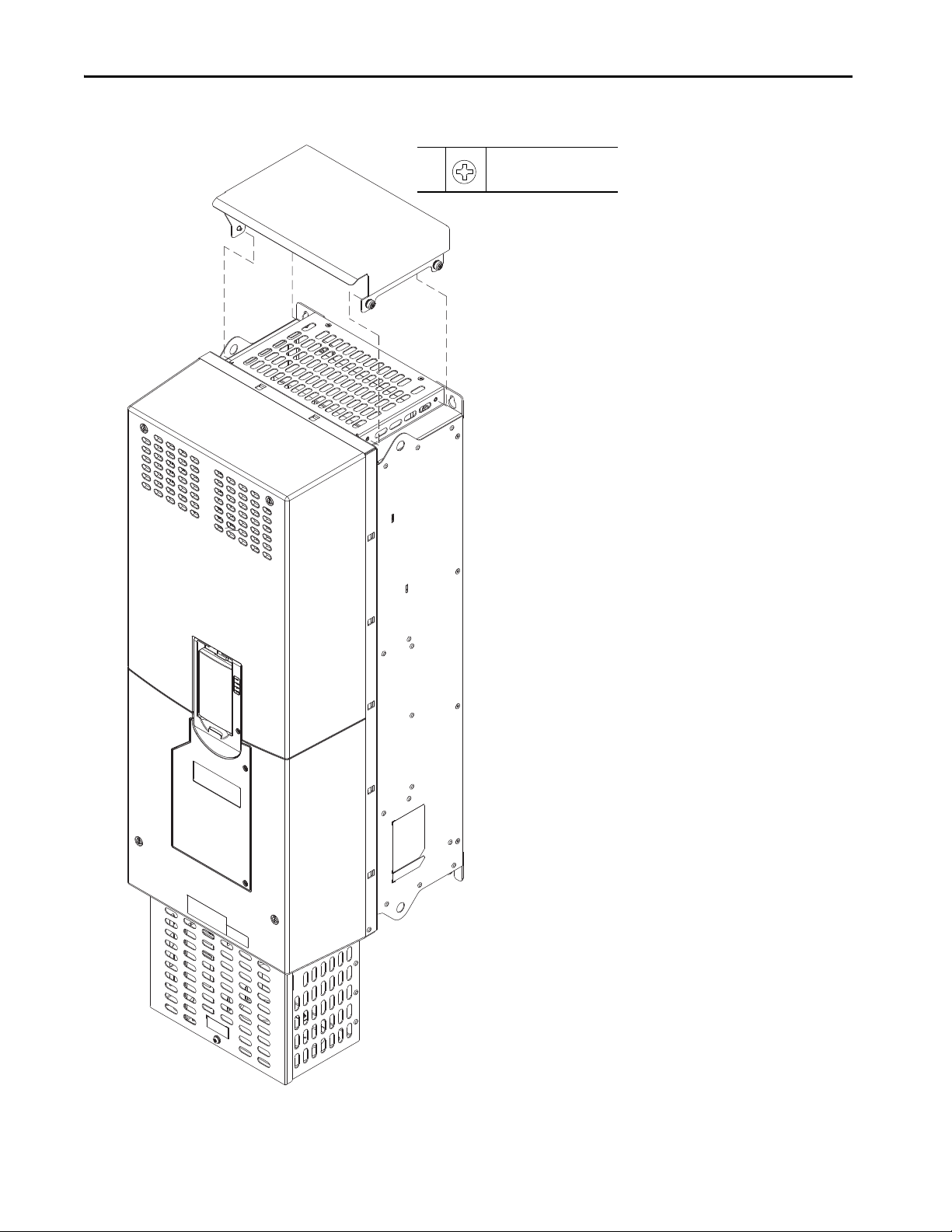

Frame 5 Marine Discharge Module Installation 3

Frame 6 Marine Discharge Module Kit Contents (Cat. No. 20-750-CMRN-F6) 10

Frame 6 Marine Discharge Module Installation 10

Additional Resources 15

ATTENTION: Only qualified personnel, who are trained and approved to install PowerFlex® 755T products and familiar with associated machinery, should plan or

implement the installation, startup, and subsequent maintenance of the system. Failure to comply can result in personal injury and/or equipment damage.

ATTENTION: The information that is contained in this publication is merely a guide for proper installation. Rockwell Automation®, Inc. cannot assume

responsibility for the compliance or the noncompliance to any code, national, local or otherwise for the proper installation of this drive or associated equipment.

A hazard of personal injury and/or equipment damage exists if codes are ignored during installation.

ATTENTION: This product contains Electrostatic Discharge (ESD) sensitive parts and assemblies. Static control precautions are required when you install these

assemblies. Component damage can result if ESD control procedures are not followed. If you are not familiar with static control procedures, reference any

applicable ESD protection handbook.

Tool Description Details

Allen (hex) socket wrench 4 mm

Electric drill and bits (Bit sizes to meet conduit size requirements)

Flat-nose screwdriver 6.4 mm (0.25 in.)

Torx, star, or hexalobular screw driver/bit #20, #25, #30

Torque wrench 1...12 N•m (8.8…106 lb•in)

Torque wrench 6...50 N•m (53…443 lb•in)