RMS R325P User manual

R325PSingleAxisDriver

UserManual

AndCommandsGuide

Version1.00

RMSTechnologies

2533N.CarsonSt.#4698,CarsonCity,NV89706‐0147

R325PUserManual Page2of20 1/31/2013Version1.0

ThankyouforpurchasingtheR325PSingle‐AxisStep&DirectionDriver.Thisproductis

warrantedtobefreeofmanufacturingdefectsforone(1)yearfromthedateofpurchase.

PLEASEREADBEFOREUSING

Beforeyoustart,youmusthaveasuitablestepmotor,aDCpowersupplysuitableforthemotor

andacurrentresistor.Thepowersupplyvoltagemustbebetween4timesand20timesthe

motor'sratedvoltage.

DISCLAIMER

Theinformationprovidedinthisdocumentisbelievedtobereliable.However,noresponsibility

isassumedforanypossibleinaccuraciesoromissions.Specificationsaresubjecttochange

withoutnotice.

RMSTechnologiesreservestherighttomakechangeswithoutfurthernoticetoanyproducts

hereintoimprovereliability,function,ordesign.RMSTechnologiesdoesnotassumeany

liabilityarisingoutoftheapplicationoruseofanyproductorcircuitdescribedherein;neither

doesitconveyanylicenseunderitspatentrights,northerightsofothers.

SpecialSymbols

IndicatesaWARNINGandthatthisinformationcouldpreventinjury,lossof

property,orevendeath(inextremecases).

R325PUserManual Page3of20 1/31/2013Version1.0

R325PUserManual

Product:R325P

Version:1.00

Date:1/31/2013

VersionHistory

VersionDateDescriptionofChanges

1.0001/31/2013NewUserManual

R325PUserManual Page4of20 1/31/2013Version1.0

TableofContents

1.FEATURES ...........................................................................................5

2.ELECTRICALSPECIFICATIONS ......................................................................5

3.OPERATINGSPECIFICATIONS ......................................................................6

4.MECHANICALSPECIFICATIONS ....................................................................6

6.CONNECTIONSPECIFICATIONS ....................................................................8

ConnectingthePower ................................................................................................ 9

ConnectingtheMotor ................................................................................................ 9

ConfiguretheR325usingtheDIPSwitch.......................................................................... 10

DIPSwitchRunCurrentSettings ..............................................................................................10

DIPSwitchHoldCurrentSettings .............................................................................................11

DIPSwitchStepResolutionSettings..........................................................................................11

8.COMMANDTABLES ..............................................................................11

AxisConfigurationCommands..................................................................................... 11

GeneralOperationCommands..................................................................................... 11

9.COMMANDS ......................................................................................13

ProtocolSyntax ..................................................................................................... 13

10.Troubleshooting.................................................................................14

11.AppendixA......................................................................................15

11.AppendixB......................................................................................19

R325PUserManual Page5of20 1/31/2013Version1.0

1.FEATURES

SingleAxisDriverforBipolarstepmotors

Operatesfrom+12to48VDC

Phasecurrentsfrom0.3to3.0AmpPeak

NOTE:Phasecurrentof2.7AmpandaboveREQUIRESanadditionalheatsink,

makesurethetemperatureofthebracketdoesnotexceed45°C.

Holdcurrentreductioncapabilitywithadjustablecurrentandtimeoutsettings

SelectableStepResolutionfromFullStepto256xMicrostepping

Hasthreeopticallyisolatedcontrolinputsandoneopticallyisolatedcontroloutput

PoleDampingTechnology™integratedwithindriverboard

DipswitchesandaRS485interfacearebuilt‐intotheR325PController.AUSBconnectioncan

beusedbyusingtheUSB485ConverterCard(soldseparately).

2.ELECTRICALSPECIFICATIONS

SupplyVoltage: +12to48VDC

PhaseCurrent:0.3to3.0AmpsPeak

NOTE:Phasecurrentof2.7AmpandaboveREQUIRESanadditionalheatsink,

makesurethetemperatureofthebracketdoesnotexceed45°C.

I/OSpecifications

3xOpticallyIsolatedInputs(1fixed)

1xOpticallyIsolatedOutput

MinimumMotorImpedance:1.5mH

Note:Thedrivemaybehaveunpredictablyifthemotoryouareusinghasaninductanceless

than1.5mH.

R325PUserManual Page6of20 1/31/2013Version1.0

3.OPERATINGSPECIFICATIONS

MaximumStepFrequency: 2.5MHz

OperatingTemperature: Lowend–0°C

Highend–Dependentoncasetemperature,bracket

temperaturemustnotexceed45°C

AutomaticMotorHoldingCurrentreductionavailablefrom0.3to2.5Amps

LogicTiming

MinimumStepPulseWidth 200nanoseconds

MinimumStepLowTime 200nanoseconds

MaximumPower‐DownRecoveryTime20milliseconds

4.MECHANICALSPECIFICATIONS

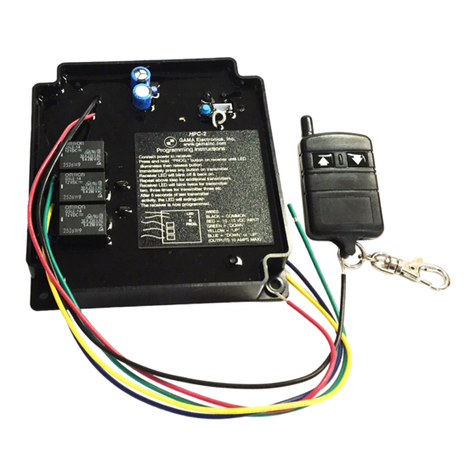

Size:3.00”x2.75”x1.42”

Weight:3.2oz

Mounting:Four#6‐32screws,2.42”x2.45”

Plate:Aluminum,HardAnodized

Figure3.1

R325PUserManual Page7of20 1/31/2013Version1.0

5.PINASSIGNMENTS

MatingConnectors

P1Amp 640441‐3

P3PhoenixContact1803675

P1–RS485busInterface

P1Configuration

PinNoFunction

1AInput(+ve)

2Ground

3BInput(‐ve)

Table5.1

P1Connector–Pin1Location

Image5.1

P3–Motor/Controls/PowerInterface

A12‐pinpluggableterminalstripconnectorP3providespowerandthestepanddirection

controlfunctionsforthemodule.Allofthesesignalsareopticallyisolated.Open‐collectordrives

arerequiredtoprovidepulsesforStep,levelsforDirection,andDisable.Thecommon+ve

supplyrangesfrom5VDCto30VDCwithrespecttothesignalinput;howeverifthesupplyis

greaterthan5VDCthenaresistormustbeinsertedinserieswitheachsignallinetolimitthe

currentto10mA.

P3Configuration

PinNoFunction

1Common+veExternal

2Step(in)

3Direction(in)

4+5VDCInternal

5Disable(in)

6MotorA+(out)

7MotorA‐(out)

8MotorB+(out)

9MotorB‐(out)

10FullStepOutput

11PowerGround

12PowerPositive

Table5.2

P3Connector–Pin1Location

Image5.2

R325PUserManual Page8of20 1/31/2013Version1.0

CAUTION:ConnectingMotorphases(A,ABar,B,BBar)totheincorrectlocation

whiletheR325Pispoweredwillcausetheboardtoburn.Besuretoinsertmotor

phasesintoPins6through9,intheorderofA,ABar,B,andBBar.Itis

recommendedthatpowerisconnectedlast,sothatallconnectionscanbechecked

beforepowerup.

6.CONNECTIONSPECIFICATIONS

WhenusingtheDriverOnlyportionoftheR325P,usethedipswitchesforstepresolutionand

currentsettings.

UsingtheR325PasaDriverUnitOnly

IfusingtheR325PasaDriveronly,besuretoconnectthepowersupplylast.

Pin1:ConnectPin1toPin4tousetheinternal+5VDC.Byusingtheinternal+5VDCtheI/O’s

willnolongerbeopticallyisolated.Ifopticalisolationisstilldesired,useaseparate+5VDC

supplyandconnectthePOSITIVEendofthesupplytoPin1.TheNEGATIVEendwillconnect

withtheNEGATIVEendofyourpulsegenerator.

Pin2:UseapulsegeneratororfunctiongeneratortoreceivepulsesintotheR325P.Connect

thePOSTIVEendofthepulsegeneratortoPin2.TheNEGATIVEendwillbeconnectedtothe

NEGATIVEendofthe+5VDCsupplyifusingaseparatepowersource.Ifusingtheinternal

+5VDCsupply,connecttheNEGATIVEendofthepulsegeneratortoPowerGROUND.

Pin3:Toswitchthedirectionofmotorrotation,connectPin3withPin11,PowerGround.An

openorclosedconnectiontoPowerGroundwillchangethedirection.

Pin4:Thisistheinternal+5VDC.Usethisfortestingpurposesorifopticalisolationoftheinputs

isnotdesired.Itcanoutputamaxof50mAmps.

Pin5:ToenablethedriveleavethisPinopen,disablethedriveconnectPin5withPin11(Power

Ground).AnopenorclosedconnectiontoPowerGroundwillenableanddisablethedrive,

respectively.

Pin6:PhaseAMotorConnection

Pin7:PhaseAMotorConnection

Pin8:PhaseBMotorConnection

Pin9:PhaseBMotorConnection

CAUTION:ConnectingMotorphases

(A,ABar,B,BBar)totheincorrect

locationwhiletheR325Pispowered

willcausetheboardtoburn.Besure

toinsertmotorphasesintoPins6through9,in

theorderofA,ABar,B,andBBar.Itis

recommendedthatpowerisconnectedlast,so

thatallconnectionscanbecheckedbefore

powerup.

Pin10:TheFullStepoutputisnotavailableforthebasicR325P.Thisfeatureisusedonthe

R325PE.

Pin11:ConnecttheNEGATIVEofthePowerSupplytothisterminal.

Pin12:ConnectthePOSITIVEofthePowerSupplytothisterminal.(+12to48VDC)

R325PUserManual Page9of20 1/31/2013Version1.0

ConnectingthePower

TheR325Prequiresasupplyvoltagebetween12‐48VDC.First,connectthepositiveendofthe

powersupplytopositiveterminal(Pin12),andthenconnectthenegativeofthepowersupply

totheGround(Pin11)ontheR325P.

WARNING!Becarefulnottoreversethepolarityfromthepowersupplytothe

driver.Reversingtheconnectionwilldestroyyourdriverandvoidthewarranty.

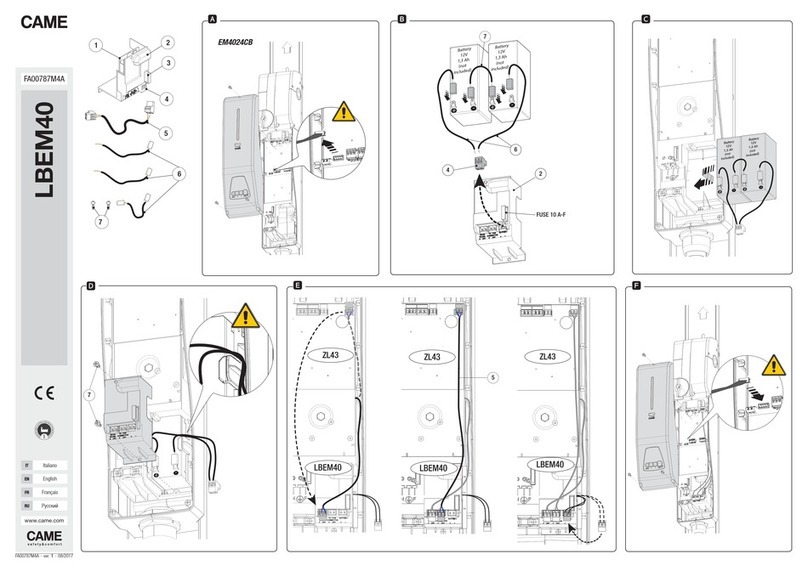

ConnectingtheMotor

WARNING!MakesurethepowerisOFFwhenconnectingordisconnecting

motorsfromtheR325P.Damagewilloccurifthepowerisbeingsupplied.

Pleaserefertoyourmotordocumentationforwiringcolorcode.

ConnectthecorrespondingPhasefromthemotortotheproperpinontheR325P.

MotorPhase P1Connector

PhaseA Pin6

PhaseA‐ Pin7

PhaseB Pin8

PhaseB‐ Pin9

Figure6.1

R325PUserManual Page10of20 1/31/2013Version1.0

UsingtheR325Pwithmorethan5V

YoucanchoosetosupplytheoptoswiththeR325P’sinternal5Vsupplybyjumpingpins1to4.

Butifyouchoosetousemorethan5V,forexample,a24Vsupplyandthesteppulsetrainisalso

a0to24Vlow‐highsignal,pleaseusethefollowingrecommendedresistortolimitthecurrentto

10mAmps.Note:noresistorwillbeneededontheactualoptosupplyline,pin1.

Step&Directionlineshavea470ohminternalresistor

Voltage:5V10V15V24V

Ohmsneeded:050010002000

Wattagerating:0¼watt¼watt¼watt

Table6.1

Disablelinehasa1kohminternalresistor

Voltage:5V10V15V24V

Ohmsneeded:0100020003800

Wattagerating:01/8watt1/8watt¼watt

Table6.2

ConfiguretheR325PusingtheDIPSwitch

R325PDIPSwitchSettings

RunCurrent

FunctionSW1SW2SW3SW4

0.3AONONONON

0.4AOFFONONON

0.5AONOFFONON

0.6AOFFOFFONON

0.8AONONOFFON

1.0AOFFONOFFON

1.2AONOFFOFFON

1.4AOFFOFFOFFON

1.6AONONONOFF

1.8AOFFONONOFF

2.0AONOFFONOFF

2.2AOFFOFFONOFF

2.4AONONOFFOFF

2.6AOFFONOFFOFF

2.8AONOFFOFFOFF

3.0AOFFOFFOFFOFF

Table6.3

WARNING:Currentof2.7AmpandaboveREQUIRESanadditionalheatsink;make

surethetemperatureofthebracketdoesnotexceed45°C

R325PUserManual Page11of20 1/31/2013Version1.0

HoldCurrent(PercentofRunCurrent)

FunctionSW5SW6

0%ONON

33%OFFON

66%ONOFF

100%OFFOFF

Table6.4

StepResolution

FunctionSW7SW8SW9SW10

FullStep*OFFOFFOFFOFF

2XONOFFOFFOFF

4XONONOFFOFF

8XONOFFONOFF

16XONONONOFF

32XONOFFOFFON

64XONONOFFON

128XONOFFONON

256XONONONON

Table6.5

*ThepowermustbeturnedOFFwhenswitchinginandoutofFullStepmode.

7.COMMANDTABLES

AxisConfigurationCommands

FunctionQuery/NewCodeValueMinimumMaximumDefault

HoldTimeoutQ/NHTNumeric1005000500

PercentFastDecayQ/NPFNumeric032

Table7.1

GeneralOperationCommands

FunctionQuery/NewCodeValueMinimumMaximumDefault

FirmwareRev.QFRNumeric‐ ‐ ‐

Table7.2

R325PUserManual Page12of20 1/31/2013Version1.0

CommunicatingwiththeR325P

1. ConnectP1toPCviaRS485‐232ConverterCardorUSB485ConverterCard.

2. SetupHyperTerminalbyselectingcorrectCOMport

3. SettingsforHyperTerminalisasfollows:57600,8bits,None,1,None

4. TheR325PDriveronlyversionallowsforchangingtheholdtimeoutsettings,the

amountofmixeddecay,andtocheckthefirmwarerevisionlevel.

RS485‐232ConverterCard

Image7.1

USB485ConverterCard

Image7.2

R325PUserManual Page13of20 1/31/2013Version1.0

8.COMMANDS

ProtocolSyntax

CommandFormat:#<Address><Command><value><CR><LF>

Example:#AHT1000<CR><LF>

SetstheHoldTimeoutforDriverAto1000

Toqueryacommandusethefollowingformat

QueryFormat:#<Address><Command><CR><LF>

Example:#AFR<CR><LF>

QueriesDriverAforthecurrentFirmwareRevision

Theresponsewouldbeinthefollowingformat

ResponseFormat:*<Address><value>

Example:*AFR325100

R325Pfirmwarerevision1.00

<CR><LF>standfor"CarriageReturn"and"LineFeed"respectively.TheseareNOTcharactersto

betypedin.Fordirectkeyboardusers,thesevaluesareexecutedwhenthe"Return"keyis

pressed.Forprogrammers,a"CarriageReturn"and"LineFeed"(alsoknownasa"NewLine")

commandneedstobeexecutedaftereachcommand.

Command

(CaseSensitive)OperandExampleDescription

HT100‐5000#AHT100

SetstheHold

Timeoutto100

mS

HoldTimeout‐CommandorQuery,Default=500

‐Readsorsetsthetimeintervalinmillisecondsafteranymotor

movement,beforethemotorcurrentischangedfromRunCurrent

toHoldCurrent.

PF0‐3#APF1

SetsMixed

Modedamping

to48%

PercentFastDecay‐CommandorQuery,Default=2

‐AllowstheDampingModeofthedriverICtobeset.

0=SlowDecay

1=MixedMode15%

2=MixedMode48%

3=100%FastDecay

Theoptimumsettingwillvarywithmotorinductanceandsteprate;

howeverthedefaultMixedModesettingwillworkwithmostmotors

FR‐ #AFRFirmwareRevision‐QueryOnly

‐Returns3digitpartcodefollowedby3digitfirmwarerevision.

Reply:*AFR325100//R325Pfirmwarerevision1.00

SD‐ #ASDSaveData–Afteralldesiredchangeshavebeenmade,type#ASDin

ordertosavethedatatomemory.

LD‐ #ALDLoadDefaultSettings–Usedtorevertbacktodefaultsettings.

TI‐ #ATITestInputs–QueryOnly

‐Thiscommandwillreturnavaluewhichcorrespondstothe

ON/OFFsequenceofall3inputs

R325PUserManual Page14of20 1/31/2013Version1.0

9.Troubleshooting

R325Pisnotfunctioningcorrectly

TryputtingtheR325PintoTESTmodebyplacingajumperonPins3&4ofJ1asshownbelow.

ThemotorshouldtwitchbackandforthslightlyiftheR325Pisfunctioningproperly.

R325Pnotmovingthemotor(Step/Dip)

Verifythatthe5VisbeingsuppliedtoPin1.

TheR325Piscausingthemotortovibrateandjitterbackandforth

AretheMotorphasesswitched?BesuretocheckthatmotorwiresareconnectedtoPins6

through9,intheorderofA,ABar,B,BBar.Tocheckwhichwiresbelongtoonephase,takea

Metertomeasureresistancebetweenanytwowires.Ifthereisafinitevaluebetweentwoof

them,insertthewiresintopins6and7,ORpins8and9.Inserttheremainingtwowires

accordingly.

TechnicalSupport

ByTelephone:408‐919‐0200

(Monday‐Friday;8:00AM‐5:00PMPacific)

OntheWeb:www.linengineering.com

Ourtechnicalsupportgroupisgladtoworkwithyouinansweringyourquestions.Ifyoucannot

findthesolutiontoyourparticularapplication,or,ifforanyreasonyouneedadditional

technicalassistance,pleasecalltechnicalsupportat408‐919‐0200.

R325PUserManual Page15of20 1/31/2013Version1.0

10.AppendixA:RecommendedCable

RecommendedCableConfigurations:DCSupplytoDriver

Cablelength,wiregaugeandpowerconditioningdevicesplayamajorroleintheperformance

ofyourRMSTechnologiesDriverandMotor.

NOTE:ThelengthoftheDCpowersupplycabletotheDrivershouldnotexceed50feet.

ExampleA–CablingUnder50Feet,DCPower

ExampleAdemonstratestherecommendedcableconfigurationforDCpowersupplycabling

under50feetlong.Ifcablingof50feetorlongerisrequired,theadditionallengthmaybe

gainedbyaddinganACpowersupplycable.

CorrectAWGwiresizeisdeterminedbythecurrentrequirementpluscablelength.Pleasesee

theDriverSupplyCableAWGTableinthisAppendix.

R325PUserManual Page16of20 1/31/2013Version1.0

NOTE:TheserecommendationswillprovideoptimalprotectionagainstEMIandRFI.Theactual

cabletype,wiregauge,shieldtypeandfilteringdevicesusedaredependentonthecustomer’s

applicationandsystem.

DriverSupplyCableAWGTable

1Amp(Peak)

Length(Feet)102550*75*100*

MinimumAWG2020181816

2Amps(Peak)

Length(Feet)102550*75*100*

MinimumAWG2018161414

3Amps(Peak)

Length(Feet)102550*75*100*

MinimumAWG1816141212

*UsethealternativemethodsillustratedinExamplesBandC

whenthecablelengthis≥50feet.Also,usethesamecurrent

ratingwhenthealternateACpowerisused

DriverSupplyCableWireSize

NOTE:AlwaysuseShielded/TwistedPairsfortheDriverDCSupplyCable,theACSupplyCable

andtheDrivertoMotorCable.

R325PUserManual Page17of20 1/31/2013Version1.0

RecommendedCableConfigurations:DrivertoMotor

Cablelength,wiregaugeandpowerconditioningdevicesplayamajorroleintheperformance

ofyourDriverandMotor.

NOTE:ThelengthoftheDCpowersupplycablebetweentheDriverandtheMotorshouldnot

exceed50feet.

ExampleAdemonstratestherecommendedcableconfigurationfortheDrivertoMotorcabling

under50Feetlong.

CorrectAWGwiresizeisdeterminedbythecurrentrequirementpluscablelength.Pleasesee

theDrivertoMotorCableAWGTableinthisAppendix.

ExampleA‐CablingUnder50Feet,DrivertoMotor

Ifcablingof50feetorlongerisrequired,theadditionallengthcanbegainedbyaddingCommon

ModeLineFilters(2x)

*L≈0.5MH

R325PUserManual Page18of20 1/31/2013Version1.0

*0.5MHisatypicalstartingpointfortheCommonModeLineFilters.Byincreasingor

decreasingthevalueofLyoucansetthedraincurrenttoaminimumtomeetyour

requirements.

DrivertoMotorCableAWGTable

1Amp(Peak)5Amp(Peak)

Length(Feet)10255075100Length(Feet)10255075100

Minimum

AWG2020181816 Minimum

AWG1616141212

2Amp(Peak)6Amp(Peak)

Length(Feet)10255075100Length(Feet)10255075100

Minimum

AWG2018161414 Minimum

AWG1414141212

3Amp(Peak)7Amp(Peak)

Length(Feet)10255075100Length(Feet)10255075100

Minimum

AWG1816141212 Minimum

AWG1212121212

4Amp(Peak)

Length(Feet)10255075100

Minimum

AWG1816141212

DrivertoMotorSupplyCableWireSize

NOTE:TheserecommendationswillprovideoptimalprotectionagainstEMIandRFI.Theactual

cabletype,wiregauge,shieldtypeandfilteringdevicesusedaredependentonthecustomer’s

applicationandsystem.

NOTE:AlwaysuseShielded/TwistedPairsfortheDriverDCSupplyCable,theACSupplyCable

andtheDrivertoMotorCable.

R325PUserManual Page19of20 1/31/2013Version1.0

11.AppendixB:PFValue

Forapplicationsrequiringultimatesmoothnessofmotionandextremeaccuracy,theR325P

drivercanbeprogrammedviaRS485tochangethePercentFastDecayrate,or,thePFvalue.

ThePercentFastDecaydefaultis2,oramixedmodeof48%.

MixedmodeisadampingtechniquedonetothedriverIC.Thefollowingvaluesindicatethe

choicesforPercentFastDecay:

PFValues(0through3):

0=SlowDecay

1=MixedMode15%

2=MixedMode48%

3=100%FastDecay

Generallyspeaking,applicationsthatrunatslowspeedsarerecommendedtouseaPFvalueof

1orless.FastspeedsshoulduseaPFvalueof2ormore.SincethebestPFvalueisdependent

onthemotorwinding,loads,powersupplyvoltage,andotherfactors,itisbesttousean

oscilloscopeandacurrentprobedevicetoviewthecurrentwaveformandtrydifferentPF

values.ThefollowingexamplesshowgoodandbadwaveformswhenchoosingdifferentPF

values.

PFvalue1

Slowspeeds

Goodwaveform

R325PUserManual Page20of20 1/31/2013Version1.0

PFvalue3

Slowspeeds

Badwaveform

PFvalue1

Fastspeeds

Badwaveform

Table of contents

Other RMS Controllers manuals

Popular Controllers manuals by other brands

Genebre

Genebre 3264 quick start guide

ABB

ABB PSTX30 370 Series installation instructions

Murphy

Murphy Cascade CD101 Installation and operation manual

fluidra

fluidra Astral Pool SLX Light Connect Lite installation instructions

Johnson Controls

Johnson Controls M9220-GGx-3 series installation instructions

Carel

Carel FCR3 user manual