Noise emission

The noise level at the place of use depends on the complete line into which the hopper will be incorporated and on the

material to be conveyed. For this reason, sound pressure levels in accordance with the 'Machinery' directive can only

be determined at the place of installation. If the noise level at the place of use exceeds the permissible, sound-

insulating hoods can be installed which we can offer on request.

2.1. Applicable directives and standards

The linear feeder has been manufactured in accordance with the following directives:

2006/42/EC Machinery Directive

2014/35/EU Low Voltage Directive

2014/30/EU Electromagnetic Compatibility Directive

We assume that our product will be incorporated into a stationary machine.

The applicable standards are specified in the Declaration of Incorporation (according to Annex II B of the Machinery

Directive).

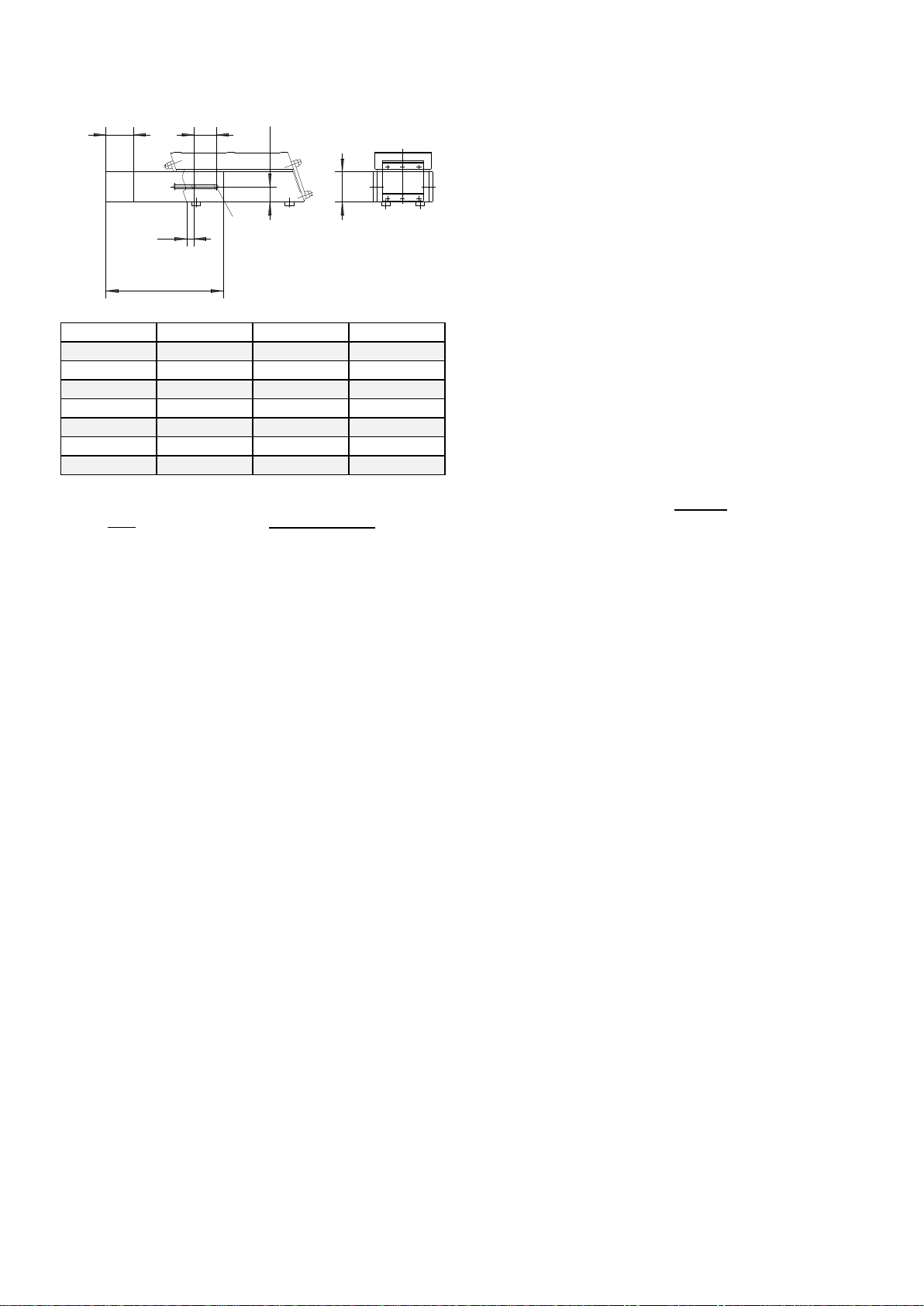

3. Design and functional description of linear feeder

Intended use of linear feeders is the feeding of parts. The driving force is provided by an electromagnetic coil. The

figure below is a schematic representation of a linear feeder:

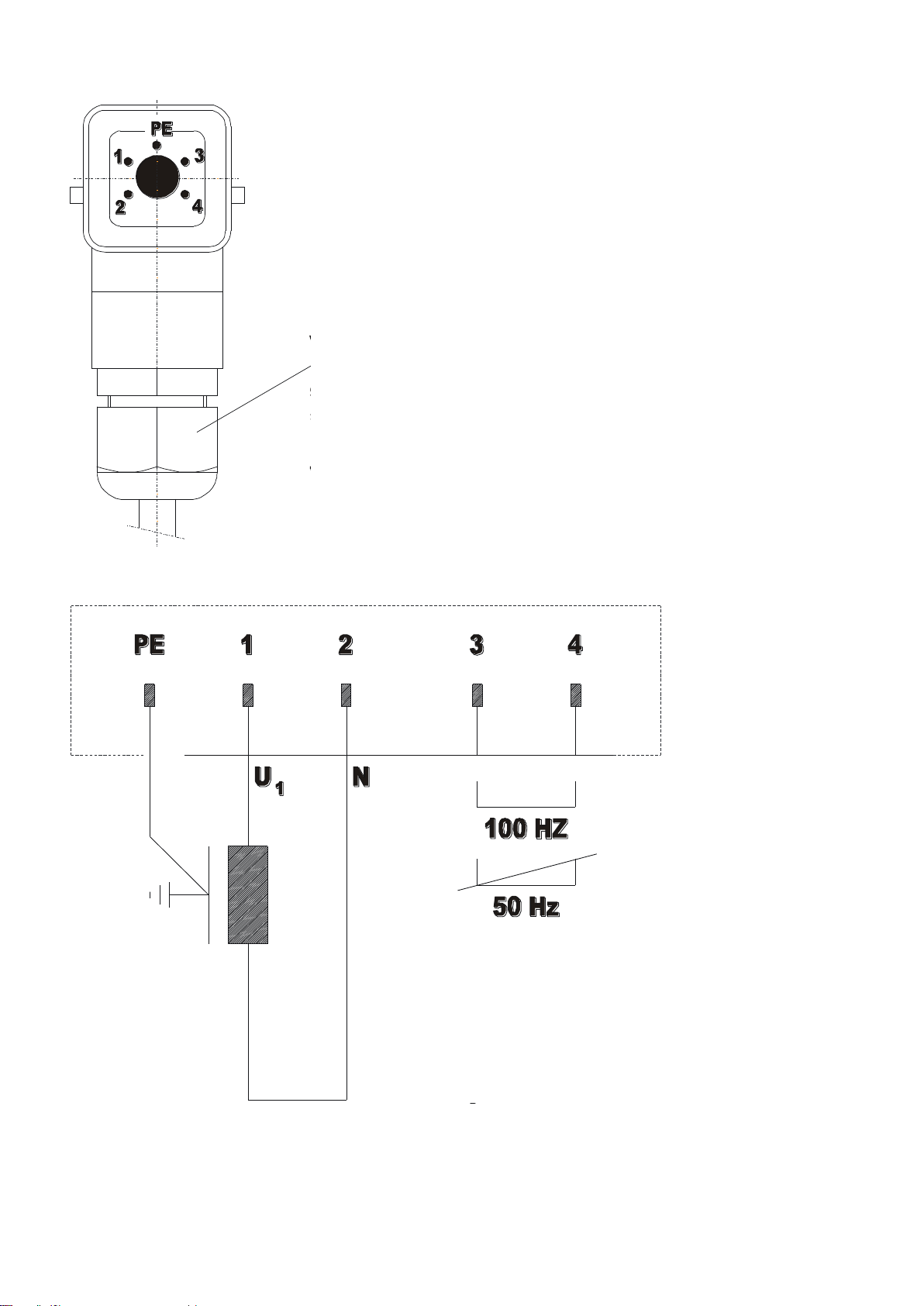

The linear feeder belongs to the family of vibratory feeders, but produces a straight-line motion. Electromagnetic

oscillations are converted into mechanical vibrations that are used for conveying a material B. When current is applied

to magnet D which is rigidly connected to counter mass F, the magnet exerts a force which attracts and releases

armature E in synchronism with the mains frequency. Within each period of the 50 Hz A.C. mains supply, the magnet

will achieve its maximum power of attraction twice as this force builds up independently of the current flow direction.

Accordingly, the vibration frequency is 100 Hz in this case. If one half-wave is removed, the vibration frequency is 50

Hz. The vibration frequency of your linear feeder is indicated in the 'Technical data' table in Section 1.

A linear feeder is a resonant system (spring-mass system). As a result, its factory set-up will rarely meet your on-site

requirements. Section 5 describes in detail how you can adapt the feeder to your specific requirements.

The linear feeder is controlled by a low-loss electronic control unit (type ESG 2000 or ESG 1000). The linear feeder

control unit is supplied loose (not installed). The controller has a 5-pin connector on its front panel for connection to the

linear feeder.

For assignment of the socket pins refer to the technical data in Section 1.