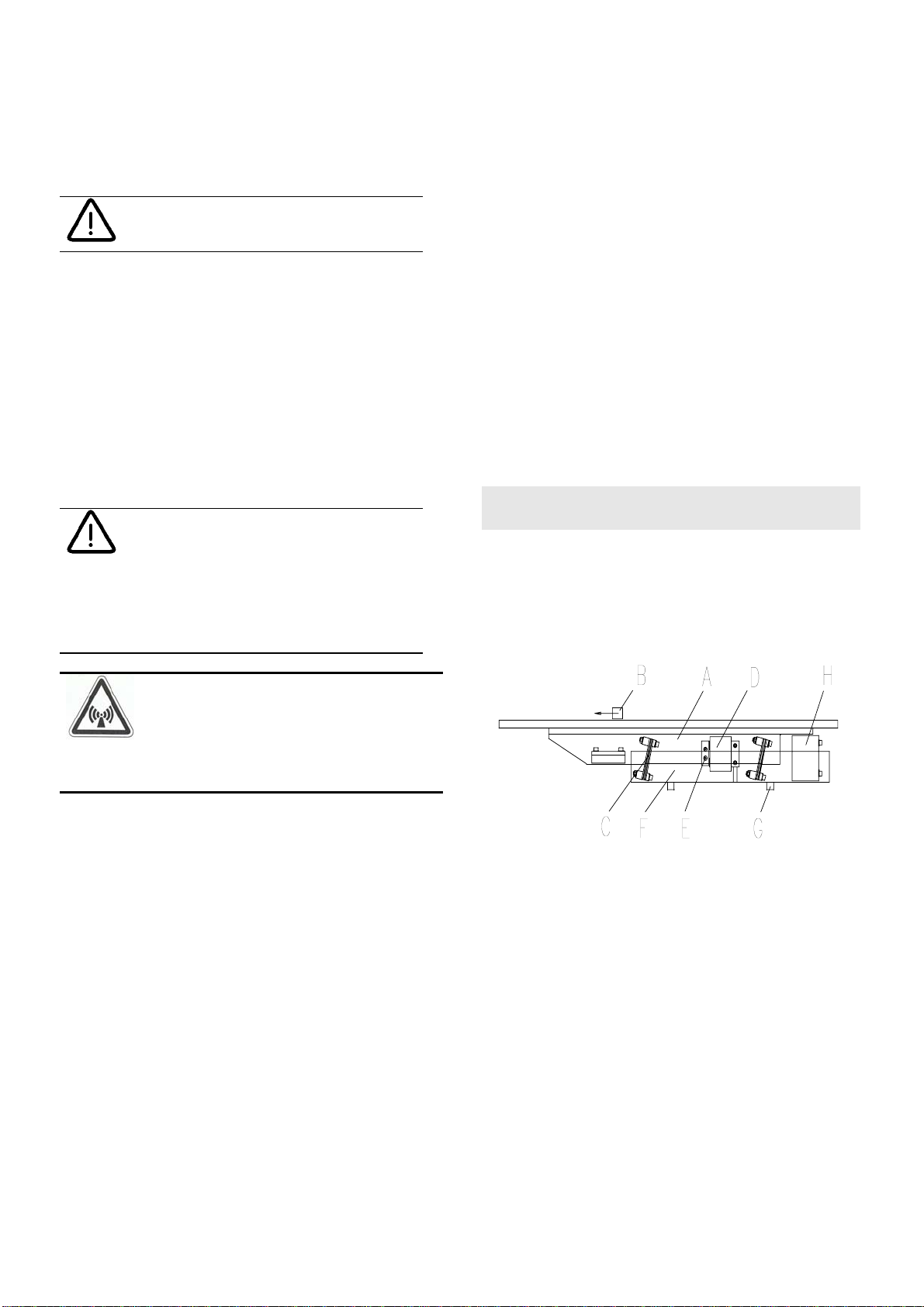

Rhein - Nadel Automation GmbH Seite 8 Bedienungsanleitung Linearförderer Typ SLL / SLF

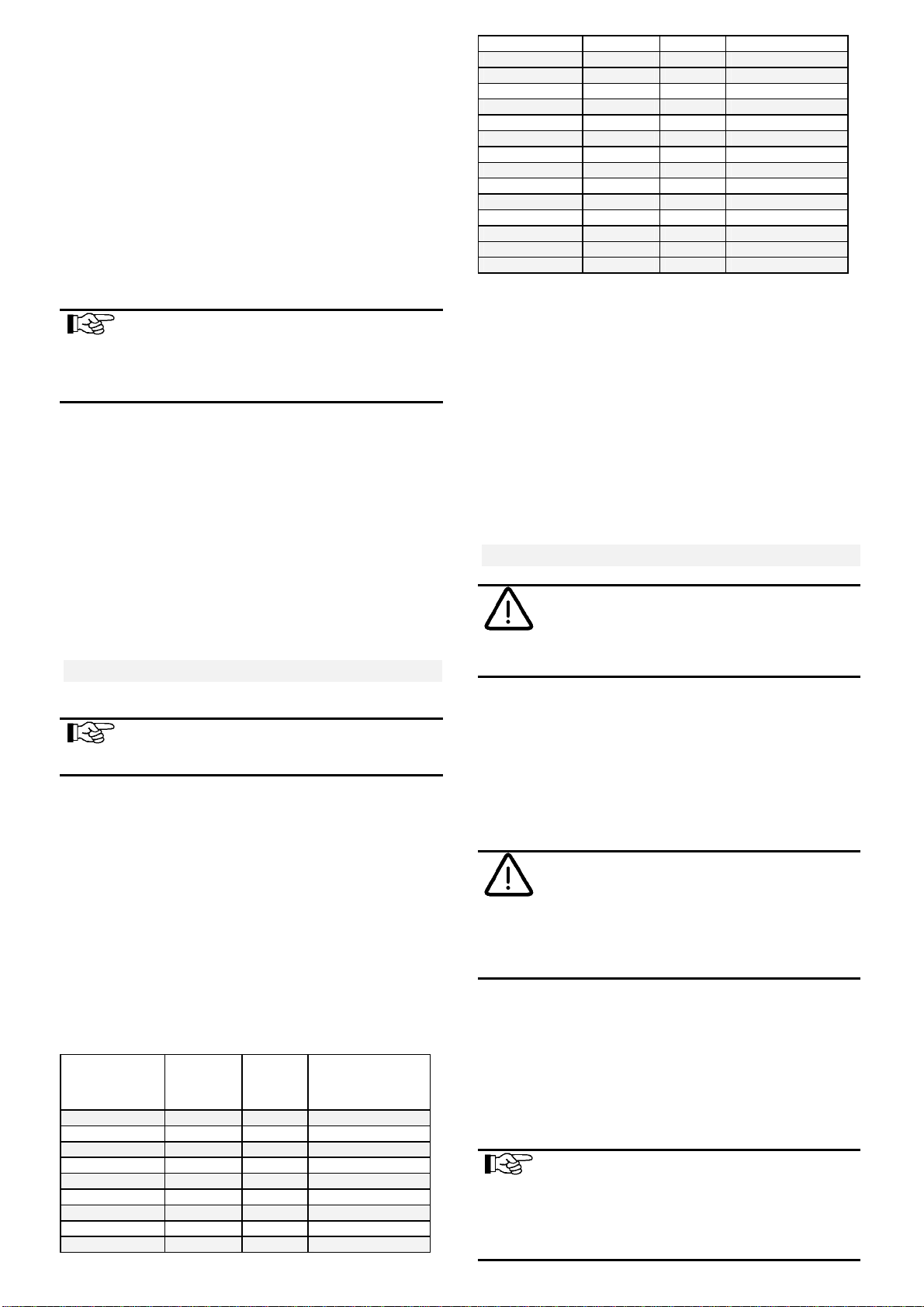

A linear feeder is a resonant system (spring-mass-

system). The result is that the adjustment made at the

factory will rarely meet your requirements. Chapter 5

describes in detail how your linear feeder is adapted

to your requirements.

Controlling of the linear feeder takes place by a low

loss electronic control unit type ESG N 80 or type

ESG 90. The control unit of the linear feeder is sepa-

rately delivered. At its front panel it is provided with a

7-pole plug-in connection, by which it is connected to

the linear feeder.

The pin assignment of the socket is shown in the table

"technical data" (chapter 1).

Notice

Detailed information on the complete

range of control units may please be taken

from the operating instructions for control

units..

All control units have got two main operating ele-

ments:

• By the mains switch the linear feeder is switched

on or off.

• By the turning knob the conveying capacity of the

transport unit is set.

4 Transport and mounting

Transport

Notice

Take care that the linear feeder cannot

dash against other things during transport.

The weight of the linear feeder is please taken from

the table "technical data" (chapter 1).

Mounting

The linear feeder should be mounted on a stable sub-

structure (available as an accessory part) at the place

where it is used. The substructure must be dimen-

sioned in a way that no vibrations of the linear feeder

can be carried away.

Linear feeders are fastened to the shock absorbers

from below (part G in the general drawing chap. 3).

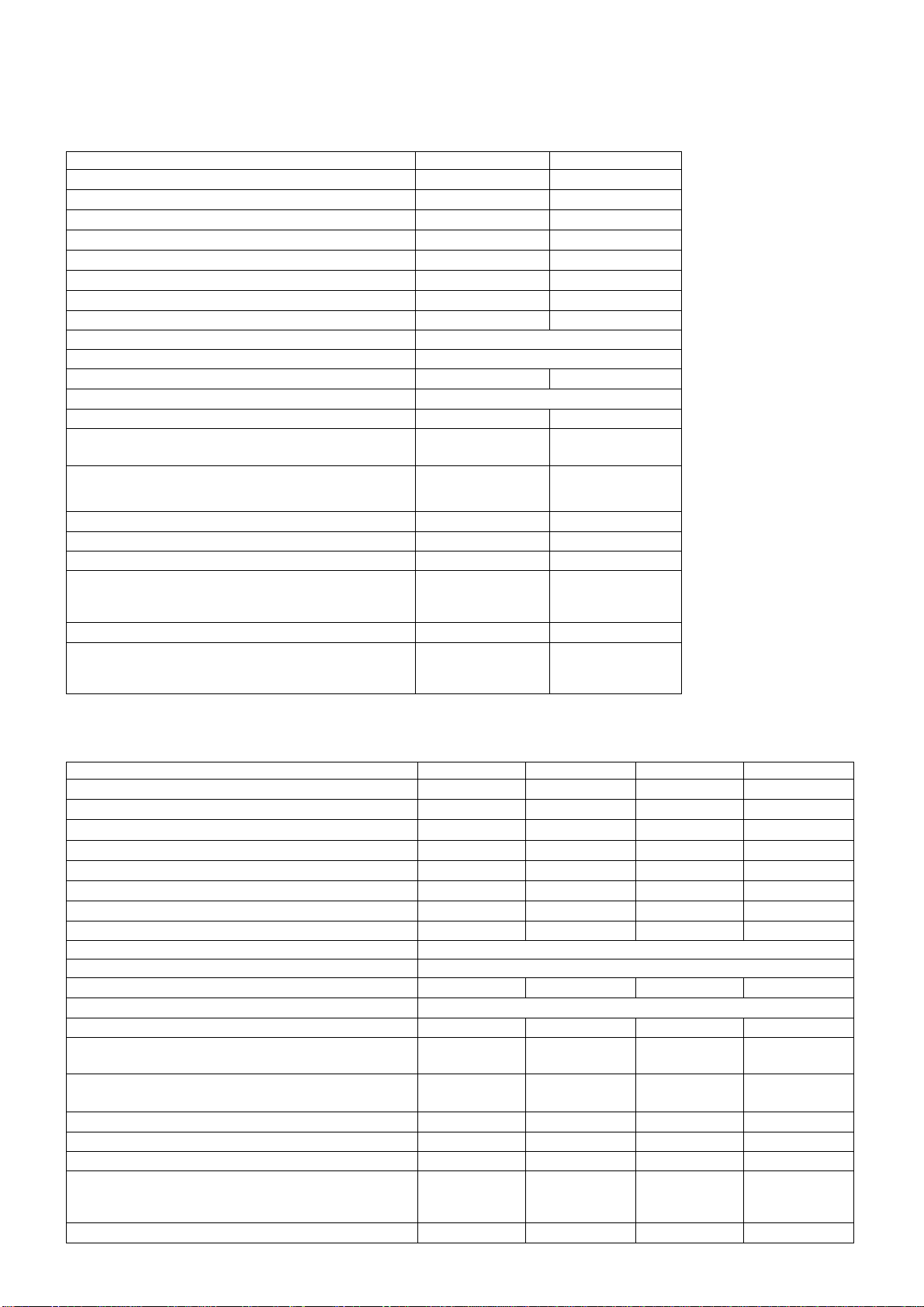

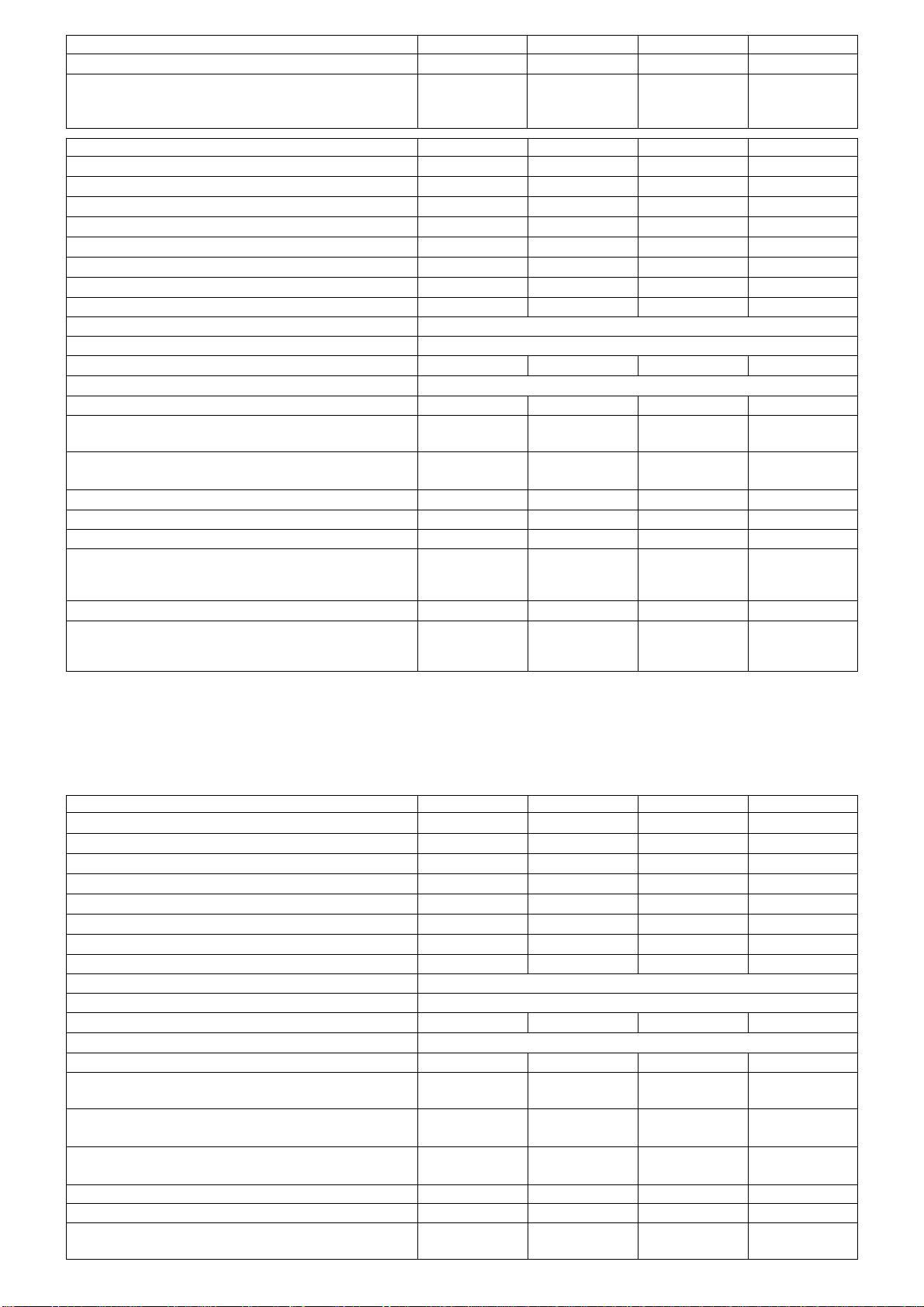

The following table will give you a summary of the

bore data of the various types:

Linear

feeder type Length

in mm Width

in mm Shock ab-

sorber

thread

SLL 175-175 125 37 M3

SLL 175-250 175 37 M3

SLL 400 - 400 200 60 M 4

SLL 400 - 600 300 60 M 4

SLL 400 - 800 450 60 M 4

SLL 400 - 1000 500 60 M 4

SLL 800 - 800 300 83 M 6

SLL 800 - 1000 450 83 M 6

SLL 800 - 1200 600 83 M 6

SLL 800 - 1400 750 83 M 6

SLL 800 - 1600 900 83 M 6

SLL 800 - 1800 1.050 83 M 6

SLL 800 - 2000 1.200 83 M 6

SLL 804 - 800 300 87 M 8

SLL 804 - 1000 450 87 M 8

SLL 804 - 1200 600 87 M 8

SLL 804 - 1400 750 87 M 8

SLL 804 - 1600 900 87 M 8

SLL 804 - 1800 1050 87 M 8

SLL 804 - 2000 1200 87 M 8

SLL 804 - 2400 1500 87 M 8

SLL 804 - 2800 1800 87 M 8

SLF 1000-1000 370 130 M 10

SLF 1000-1500 870 130 M 10

Tabelle: Bohrdaten

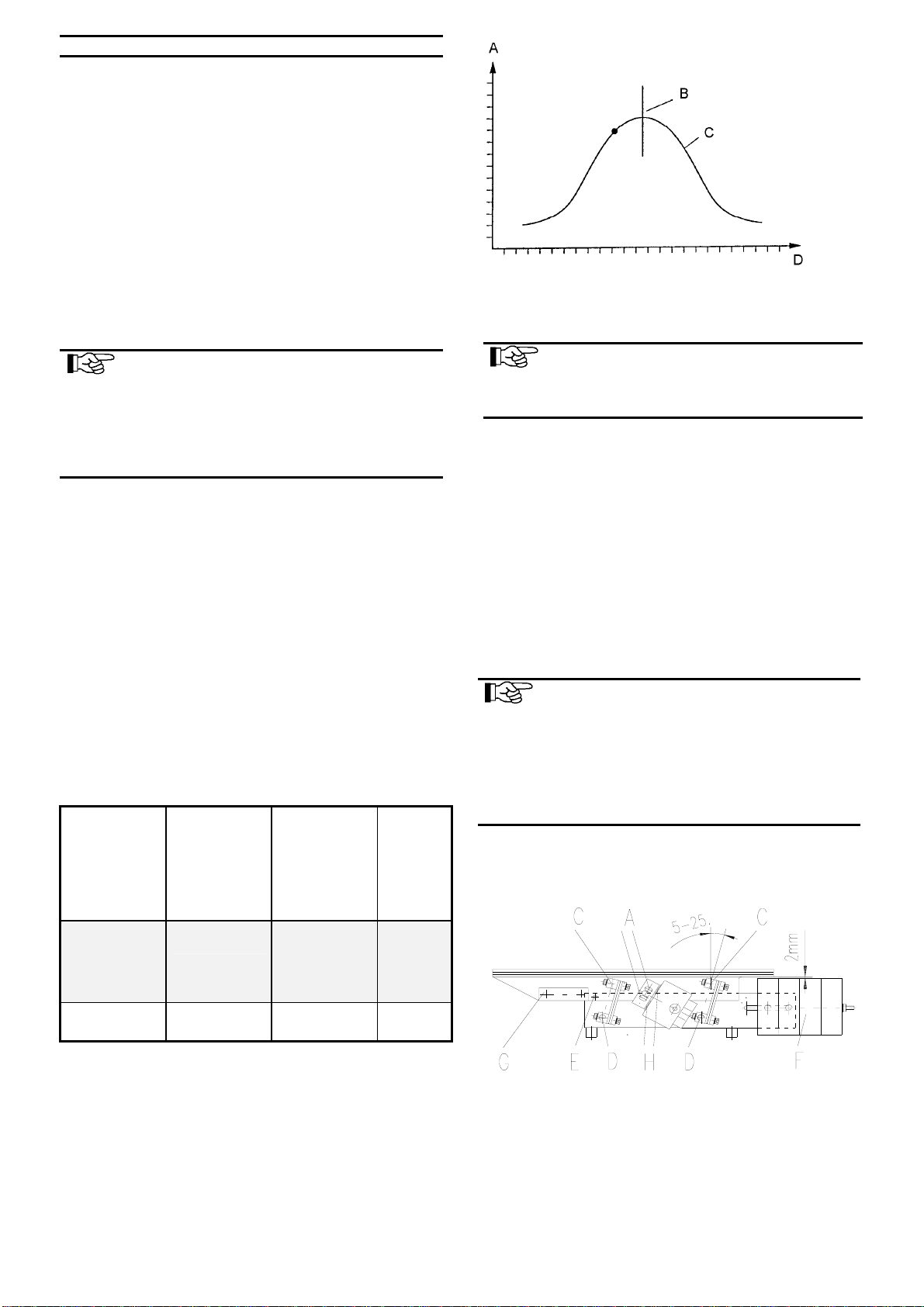

Make sure that the linear feeder cannot come into

contact with other devices during operation.

Further details on the control unit (bore plan, etc.) can

be taken from the operating instructions of the control

unit separately delivered.

5 Starting

Notice

Ensure that the frame ( stand, base, frame

etc.) is connected with the ground wire.

(PE) If necessary, predection earthing on

spot should be provided.

Check, whether

• the linear feeder stands in an isolated position and

does not come in securely with a solid body

• the linear track is screwed down and adjusted

• the connecting cable of the linear feeder is plugged

in at the control unit.

Attention

The electric connection of the linear feeder

may only be made by trained personnel

(electricians)! In case modifications are

made at the electric connection, it is abso-

lutely necessary to observe the operating

instructions "control units".

• The available supply voltage (frequency, voltage,

output) is in accordance with the connection data

of the control unit (see type plate at the control

unit).

Plug in the mains cable of the control unit and switch

on the control unit by the mains switch.

Notice

At linear feeders which are delivered as a

completely adjusted system, the optimal

conveying capacity is already set at the

factory. It is marked on the scale of the

turnin

knob with a red arrow. In this case