Road Widener FH User manual

OPERATOR, MAINTENANCE

AND PARTS MANUAL

Models FH and FH-R

• Single Discharge

• Dual Discharge www.roadwidenerllc.com

CONTENTS

GENERAL

INFORMATION..................................3

Introduction...................................3

ReadThisManualPriortoOperation .........3

ContactInformation..........................4

LimitedWarranty.............................4

Warranty .....................................4

Limitations ....................................4

Items Not Covered..............................5

Other Limitations ...............................5

Model and Serial Tag .........................5

6RGEKŞECVKQPU .................................6

Crating and Uncrating Instructions . . . . . . . . . . . 8

Assembly .....................................8

OptionalEquipment...........................8

RollerExtension...............................8

CurbAttachment .............................9

Installation ....................................9

PushPlate....................................13

Pairing the Remote Control...................13

HardwareTorqueChart......................14

ECDeclarationofConformity................15

SAFETY........................................16

SafetyDecals................................19

ControlAreaSafety..........................23

TRANSPORTING THE ROAD

WIDENER.......................................24

LiftTest......................................24

Loading......................................25

JOBSITE

PREPARATION..................................27

OPERATION....................................36

CurbAttachmentOperation..................40

Disconnecting Hydraulic and Electrical

Lines.........................................42

Hydraulic Solenoid Manual Override .........42

CurbAttachmentOperation..................49

DisconnectingHydraulicLines...............50

MAINTENANCE................................51

PeriodicMaintenanceChart..................51

GreasingtheMachine........................52

BeltStart-UpandMaintenance..............53

Checking Hydraulic Oil Level ................54

AdjustingConveyorBeltTension.............54

Hopper Rubber Flashing to Conveyor Belt

Clearance....................................55

Adjusting Conveyor Belt Drive Chain ........55

CheckingHydraulicHoses...................56

CleaningAfterOperation....................56

Remote Battery Replacement.................56

TROUBLESHOOTING...........................58

ILLUSTRATEDPARTSLIST....................62

3

GENERAL

INFORMATION 1

Introduction

Congratulations on your purchase of the Road Widener

material distribution machine. We would like to thank you

for purchasing the Road Widener. The Road Widener was

engineered and constructed to provide years of productive

results on the jobsite.

Manufacturer’s Limited Warranty terms are available if the

machine is registeredwithin 60 daysof delivery. Registration

can be completed online atwww.roadwidenerllc.com.

Please watch our operational and instructional video for

important instructions and tips on how to operate your

attachment.The video can be found on our website under

the RESOURCES page.

Password: widenroad

Read This Manual Prior

to Operation

This manual contains safety information, operating

instructions, lubrication and maintenance procedures, and

a spare parts list. Read this manual carefully to learn how

to operate and perform service on the machine correctly.

Failure to do so could result in personal injury or equipment

damage. In addition to the manual, a service and operation

video is available at www.roadwidenerllc.com and must be

viewed before operating the machine.

The Road Widener is available in either a left-hand, right-

hand or dual discharge model. All safety, operation and

maintenance procedures are the same whether you have

a left-hand, right-hand or dual discharge Road Widener

machine.

This manual should be kept nearby and be readily

accessible to the operator at all times. If this manual is lost

or damaged, contact your authorized Road Widener dealer

or the Road Widener LLC corporation immediately to order

a replacement.

Some photographs or illustrations in this manual may show

details or attachments that may be different from your

machine. Guards and covers may have been removed

for illustrative purpose. Guards should never be removed

during operation.

Operating procedures in this manual are basic. They

help with developing the skills and techniques required to

operate the machine efciently and economically. Skill level

and techniques will develop as the operator gains more

knowledge of the machine and its capabilities.

OPERATOR, MAINTENANCE AND PARTS

4

1

GENERAL INFORMATION

Contact Information

For additional information on Road Widener, go to

www.roadwidenerllc.com. To ask a service or sales question,

or to order spare parts, contact Road Widener at:

Road Widener LLC

514 Wells Street, Suite 1W

Delaeld, WI 53018

www.roadwidnenerllc.com

Phone: 844-494-3363

Limited Warranty

OTE:NTo be eligible for coverage under this Limited

Warranty (including with respect to any products,

parts or labor), you must complete and return to

Road Widener the Warranty Registration for this

product. The Warranty Registration can be found

on Road Widener’s website (www.roadwidenerllc.

com). Any questions or requests for assistance

in completing the Warranty Registration must be

directed to Road Widener’s Parts Department.

WAR R AN T Y

Subject to the limitations, exclusions, and claims procedures

set forth herein, ROAD WIDENER LLC warrants to the rst

original purchaser from ROAD WIDENER LLC or its authorized

distributor that this product will be free from material defects in

material and workmanship under normal use and service during

the warranty period.

If a material defect in material or workmanship is found, you must

notify your authorized ROAD WIDENER distributor or ROAD

WIDENER LLC in writing during the warranty period. ROAD

WIDENER LLC or an authorized distributor will, at ROAD

WIDENER LLC’s option, repair or replace the product or any

part of the product that ROAD WIDENER LLC determines has

failed to conform to the warranty during the warranty period, or

refund to the purchaser the purchase price received by ROAD

WIDENER LLC for the product or part in question.

The warranty period will begin upon initial delivery of the product

by ROAD WIDENER LLC or its authorized distributor to the

rst original purchaser, as such delivery date is identied in the

invoice to the purchaser, and will expire (12) months following

such delivery date.

Replacement parts manufactured by ROAD WIDENER

LLC are covered for the remainder of the warranty period

applicable to the product in which such parts are installed.

ROAD WIDENER LLC reserves the right for it or its authorized

distributor to utilize reconditioned, refurbished, repaired, or

remanufactured products or parts in the warranty replacement

process. Such products and parts will be reasonably

comparable in function and performance to an original product

or part.

ROAD WIDENER LLC reserves the right to repair any part

in lieu of replacing it. The purchaser shall, at its expense and

risk, return defective products or parts, after pre-authorization

by ROAD WIDENER LLC, to the distributor or manufacturing

facility specied in such pre-authorization. This Limited Warranty

covers only repair or replacement at such facility and does not

include eld service, travel, or other expenses, and does not

include normal maintenance of products. Parts not manufactured

by ROAD WIDENER LLC and purchased by ROAD

WIDENER LLC or an authorized distributor are not warranted

by ROAD WIDENER LLC but may carry a warranty from the

manufacturer. ROAD WIDENER LLC will pass the warranty on

to the purchaser if permitted by the manufacturer and reasonably

practicable.

The purchaser is responsible for the costs and risks of

transporting the product or part from such facility following review

of the warranty claim or warranty service.

LIMITATIONS

1 ] ROAD WIDENER LLC has no obligation for any defects

caused in whole or in part by misuse, abuse, abnormal

use, neglect, tampering, misapplication, negligence,

damage in transit, damage due to environmental or natural

elements or accidents. ROAD WIDENER LLC has

no obligation for failure to maintain, store, install, or use

products or parts in accordance with ROAD WIDENER

LLC’s most current operating instructions.

2 ] ROAD WIDENER LLC has no obligation under this

Limited Warranty if there has been unauthorized service or

alteration of the product or parts.

3 ] ROAD WIDENER LLC has no obligation under this Limited

Warranty for defects caused in whole or in part by any

replacement parts or attachments not manufactured by or

approved by ROAD WIDENER LLC.

4 ] ROAD WIDENER LLC has no obligation under this

Limited Warranty if there has been a failure to conduct

normal maintenance and operating service including,

without limitation, providing lubricants, uids, inspections,

or adjustments.

5 ] ROAD WIDENER LLC has no obligation under this

Limited Warranty if there has been unreasonable delay,

as determined by ROAD WIDENER LLC, in making the

applicable products or parts available upon notication of

a service notice ordered by same.

6 ] This Limited Warranty sets forth the original purchaser’s

sole remedy, and ROAD WIDENER LLC’s sole

obligation, in connection with the ROAD WIDENER

LLC product covered by the Limited Warranty. ROAD

WIDENER LLC will not reimburse the purchaser for

any expenses incurred by the purchaser in repairing

OPERATOR, MAINTENANCE AND PARTS

5

GENERAL INFORMATION

or replacing products or parts unless an authorized

representative of ROAD WIDENER LLC approves

such costs in advance in writing. Any oral or written

description of a product or part is for the sole purpose

of identifying it and shall not be construed as an express

warranty. Any assistance ROAD WIDENER LLC or

its authorized distributor provides outside the terms or

limitations of this Limited Warranty does not constitute a

waiver of such terms or limitations, or extend or revive the

warranty. The limitations in this Limited Warranty apply

notwithstanding any failure of the essential purpose of the

limited remedies.

7 ] This Limited Warranty extends only to the rst original

purchaser, and is not transferable.

8 ] If any provision of this Limited Warranty shall be

determined to be invalid or unenforceable under any

applicable law, such provision shall be deemed null and

void to the extent of such invalidity or unenforceability and

the remainder of the Limited Warranty shall continue in full

force and effect.

9 ] Used products or used parts of any kind including, without

limitation, products that have been used personally or in

demonstration by an authorized distributor, are not covered

by this Limited Warranty, and there is NO WARRANTY on

such products or parts.

10 ] This Limited Warranty does not apply if defects are caused

in whole or in part by paint nish, corrosion, controller

keyboards, or consumables including, without limitation,

uids, lters, belts, hoses, and replaceable teeth.

11 ] This Limited Warranty does not apply if the claim is due

in whole or in part to normal wear and tear or operation

of the product outside ROAD WIDENER LLC’s

recommended operating parameters.

OTHER LIMITATIONS

The purchaser must satisfy the following obligations in order

to be eligible for coverage by this Limited Warranty. Prior to

using or permitting use of the products, the purchaser shall

determine the suitability of the products for the intended use

and the purchaser assumes all risk and liability whatsoever in

connection therewith. The purchaser shall familiarize itself with

and comply with all laws and regulations now or hereafter in

effect and applicable to the purchase, transport, use, supply,

storage, sale, offer for sale, lease, offer for lease, and/or

disposal of the products. The purchaser shall maintain and

provide to ROAD WIDENER LLC on request complete and

accurate service records for products with respect to which the

purchaser makes a warranty claim. The purchaser shall cause

any installation to be performed by an authorized distributor

of ROAD WIDENER LLC in accordance with product

specications, including torque.

THE EXPRESS WARRANTY DESCRIBED HEREIN IS

EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES

INCLUDING, WITHOUT LIMITATION, ANY IMPLIED

WARRANTIES OF MERCHANTABILITY, NON-

INFRINGEMENT OR FITNESS FOR A PARTICULAR

PURPOSE. ROAD WIDENER LLC DISCLAIMS AND

EXCLUDES ALL OTHER EXPRESS AND IMPLIED

WARRANTIES.

ROAD WIDENER LLC SHALL NOT BE LIABLE TO THE

PURCHASER, OR TO ANYONE CLAIMING UNDER

THE PURCHASER, FOR ANY OTHER REMEDIES,

OBLIGATIONS OR LIABILITIES IN CONNECTION

WITH PRODUCTS, THEIR USE OR PERFORMANCE

INCLUDING, WITHOUT LIMITATION, REMEDIES,

OBLIGATIONS, OR LIABILITIES ARISING OUT

OF BREACH OF CONTRACT OR WARRANTY,

NEGLIGENCE, OR OTHER TORT OR ANY THEORY OF

STRICT LIABILITY, WITH RESPECT TO THE PRODUCTS

OR ROAD WIDENER LLC’S ACTS OR OMISSIONS OR

OTHERWISE. No sales representative, distributor or other

party is authorized to modify or add to this Limited Warranty

in any manner without ROAD WIDENER LLC’s prior written

permission. No sales representative, distributor or other party is

authorized to bind ROAD WIDENER LLC to any representation

or warranty concerning the products except as specically set

forth in this Limited Warranty.

IN NO EVENT, WHETHER AS A RESULT OF BREACH OF

CONTRACT OR WARRANTY OR ALLEGED NEGLIGENCE

OR LIABILITY WITHOUT FAULT, SHALL ROAD WIDENER

LLC BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES INCLUDING, WITHOUT

LIMITATION, LOSS OF PROFIT OR REVENUE, COST OF

CAPITAL, COST OF SUBSTITUTED OR REPLACEMENT

EQUIPMENT, FACILITIES OR SERVICES, DOWNTIME

COSTS, LABOR COSTS OR CLAIMS OF CUSTOMERS,

PURCHASERS OR LESSEES FOR SUCH DAMAGES,

EVEN IF ROAD WIDENER LLC WAS ADVISED OF THE

POSSIBILITY OF SUCH DAMAGES. IN NO EVENT WILL

ROAD WIDENER, LLC BE LIABLE FOR AMOUNTS IN

EXCESS OF THE PURCHASE PRICE OF THE PRODUCT

RECEIVED BY ROAD WIDENER LLC.

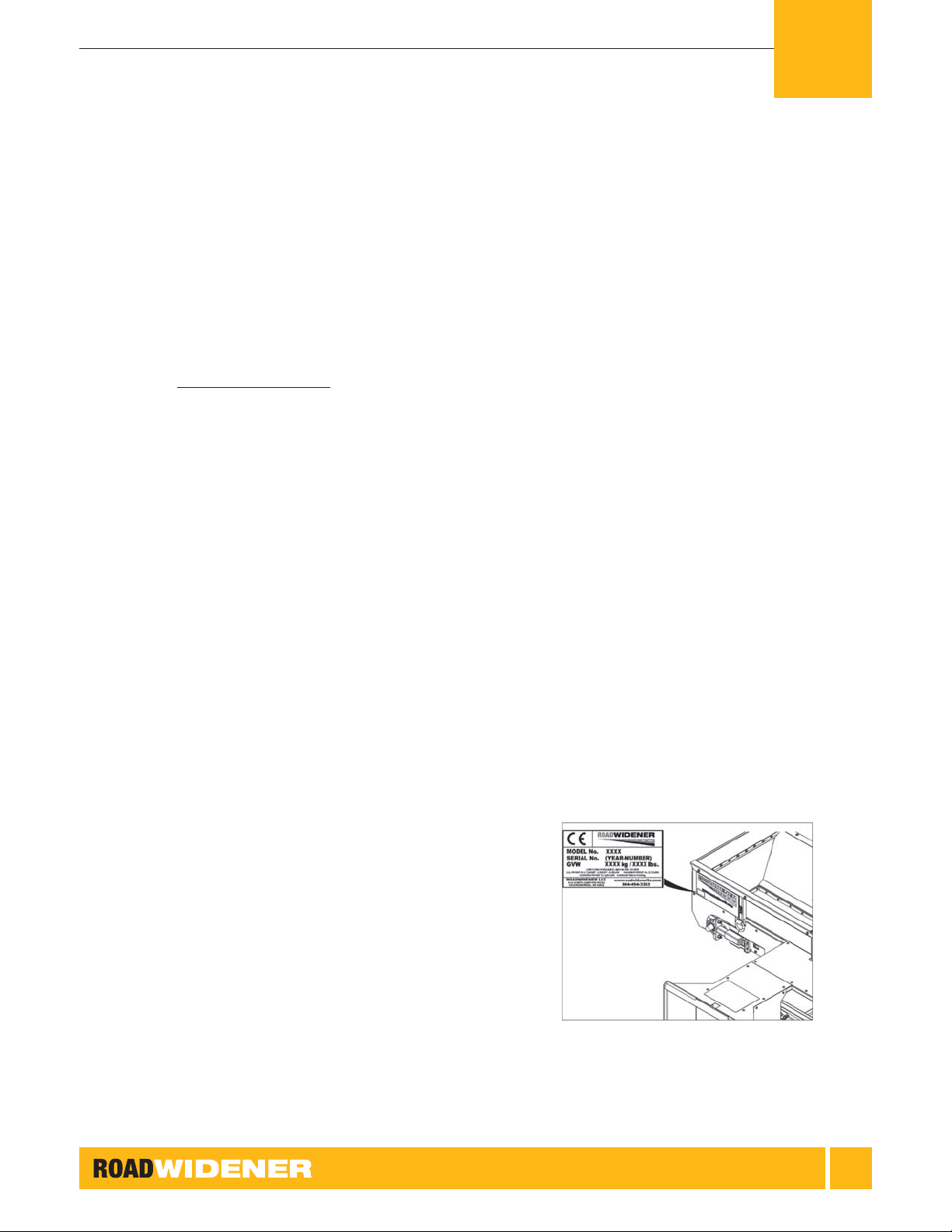

Model and Serial Tag

The model and serial number tag is located on the left side

of the hopper. Refer to this tag when needing any warranty

or service assistance. Also refer to this tag when ordering

any spare parts. This will help ensure that the correct part

is ordered.

1

OPERATOR, MAINTENANCE AND PARTS

6

6RGEKŞECVKQPU

Single Discharge Unit

Width of FH and FH-R Single Discharge Road Wideners 125 in. (3,175 mm)

Height of FH and FH-R Single Discharge Road Wideners 51 in. (1,300 mm)

Length of FH and FH-R Single Discharge Road Wideners 98 in. (2,489 mm)

Widths of Shoulders of Road Widening Material That Can Be Laid Down 12 in. (305 mm) to 48 in. (1,219 mm)

Number of Side Exit Chutes 1

Gross Weight of FH Single Discharge Road Wideners 2,900 lb (1,315 kg)

Height of Push Rollers 21 in. (530 mm)

Extra Amount Push Rollers Can Extend 12 in. (305 mm)

Conveyor Belt Type Rubber

Conveyor Belt Length and Width 8 ft (2.4 m) x 20 in. (508 mm)

Conveyor Speed Range 0-350 ft/min (1.8 m/sec)

Head and Tail Drum Diameter 10 in. (254 mm)

Typical Working Pressure 3,000 psi (207 bar)

Flow Rate 17.5 - 24.2 gal/min (79.6 - 111 l/min)

Hydraulic Fittings JIC and SAE

Maximum and Minimum Feed Rates 2.0 tons/hr (1.8 tonnes/hr)

Maximum Lump Size of Road Widening Material 10 in. (254 mm)

Optimum Traveling Speed Range While Laying Down Road Widening Material 0.5 to 1.5 mph (8.0 to 2.4 km/hr)

1

GENERAL INFORMATION

OPERATOR, MAINTENANCE AND PARTS

7

Dual Discharge Unit

Width of FH and FH-R Dual Discharge Road Wideners 138 in. (3,505 mm)

Height of FH and FH-R Dual Discharge Road Wideners 51 in. (1,300 mm)

Length of FH and FH-R Dual Discharge Road Wideners 98 in. (2,489 mm)

Widths of Shoulders of Road Widening Material That Can Be Laid Down 12 in. (305 mm) to 48 in. (1,219 mm)

Number of Side Exit Chutes 2

Gross Weight of FH Dual Discharge Road Wideners 3,400 lb (1,542 kg)

Height of Push Rollers 21 in. (530 mm)

Extra Amount Push Rollers Can Extend 12 in. (305 mm)

Conveyor Belt Type Rubber

Conveyor Belt Length and Width 9.5 ft (2.9 m) x 21 in. (533 mm)

Conveyor Speed Range 0-350 ft/min (1.8 m/sec)

Head and Tail Drum Diameter 10 in. (254 mm)

Typical Working Pressure 3,000 psi (207 bar)

Minimum Flow Rate 17.5 - 24.2 gal/min (79.6 - 111 l/min)

Hydraulic Fittings JIC and SAE

Maximum and Minimum Feed Rates 2.0 tons/hr (1.8 tonnes/hr)

Maximum Lump Size of Road Widening Material 10 in. (254 mm)

Optimum Traveling Speed Range While Laying Down Road Widening Material 0.5 to 1.5 mph (8.0 to 2.4 km/hr)

1

GENERAL INFORMATION

OPERATOR, MAINTENANCE AND PARTS

8

Crating and Uncrating

Instructions

Type FH Single Discharge & Dual Discharge and FH-R

Single Discharge & Dual Discharge Road Widener

machines are generally shipped on an open, atbed truck.

For exports, the machines are packaged in shipping crates

that are designed to ensure that the components will not

be damaged during transport. Use caution when unpacking

the shipping crates as the contents may have shifted during

transit.

Assembly

The Road Widener machines come fully assembled from

the factory; however, some accessories weigh more than

30 lb (15 kg). When lifting accessories or components

more than 30 lb (15 kg), Road Widener recommends that

a minimum of 2 people and appropriate lifting devices be

used to assemble accessories or components.

Optional accessories weighing more than 30 lb (15 kg) are:

• Shoe Extension Kit

• Pintle Push Plate

• Push Roller Extensions (the push roller extensions are

not more than 30 lb (15 kg), but to install the push roller

extensions, lifting more than 30 lb (15 kg) is required)

Optional Equipment

Some optional equipment can be ordered from Road

Widener for your specic job if needed.

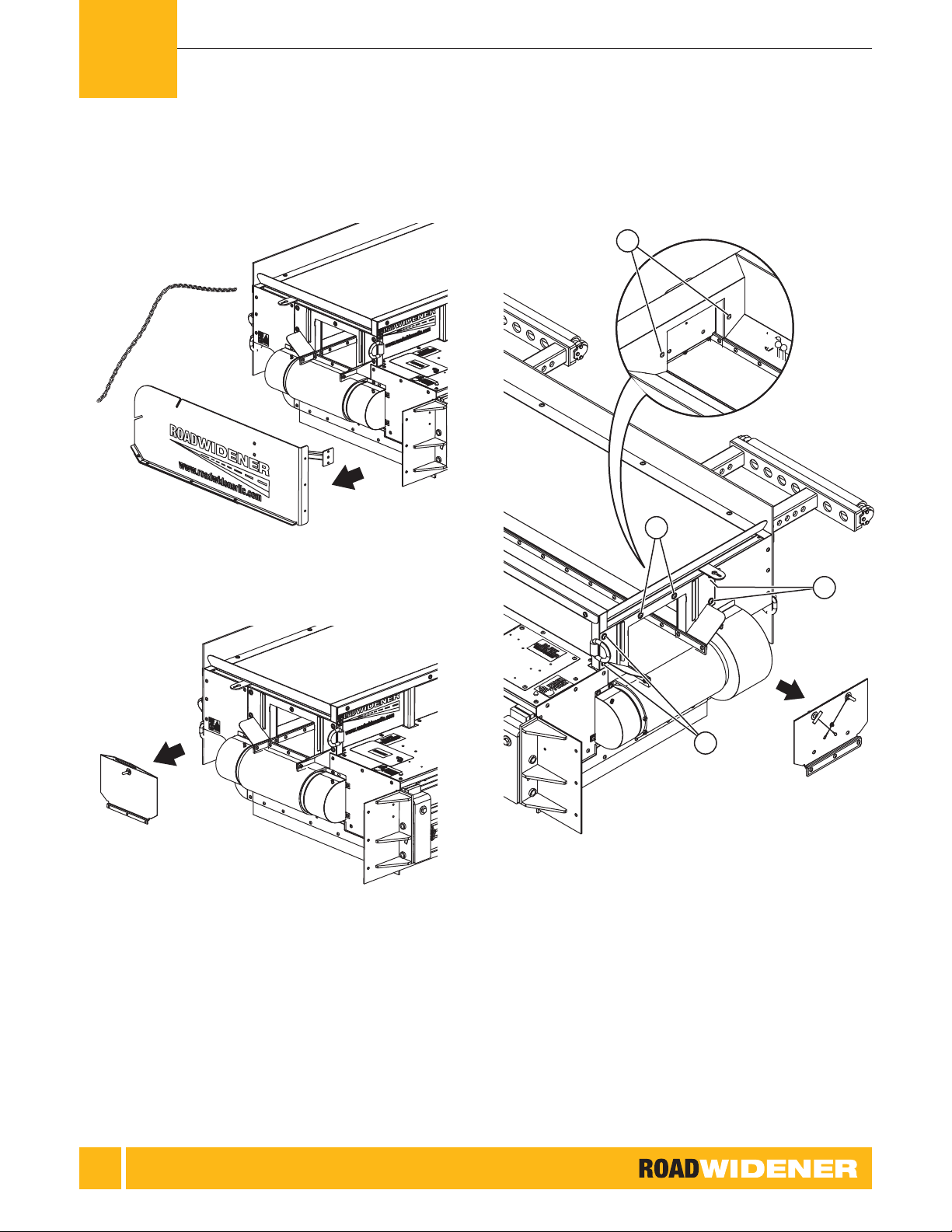

Roller Extension

If the rollers need to be extended closer to the dump

vehicle, roller extensions are available. The roller extensions

will extend the rollers an additional 12 in. (30 cm).

Figure 1: Roller Extension with Pins and Tubes Removed

1 ] Remove the pins holding the roller brackets to the

frame and remove the roller assembly.

2 ] Insert the roller extension tubes into the frame and pin

them in place.

3 ] Install the roller assembly into the extension tubes and

pin the roller assemblies in place.

1

GENERAL INFORMATION

OPERATOR, MAINTENANCE AND PARTS

9

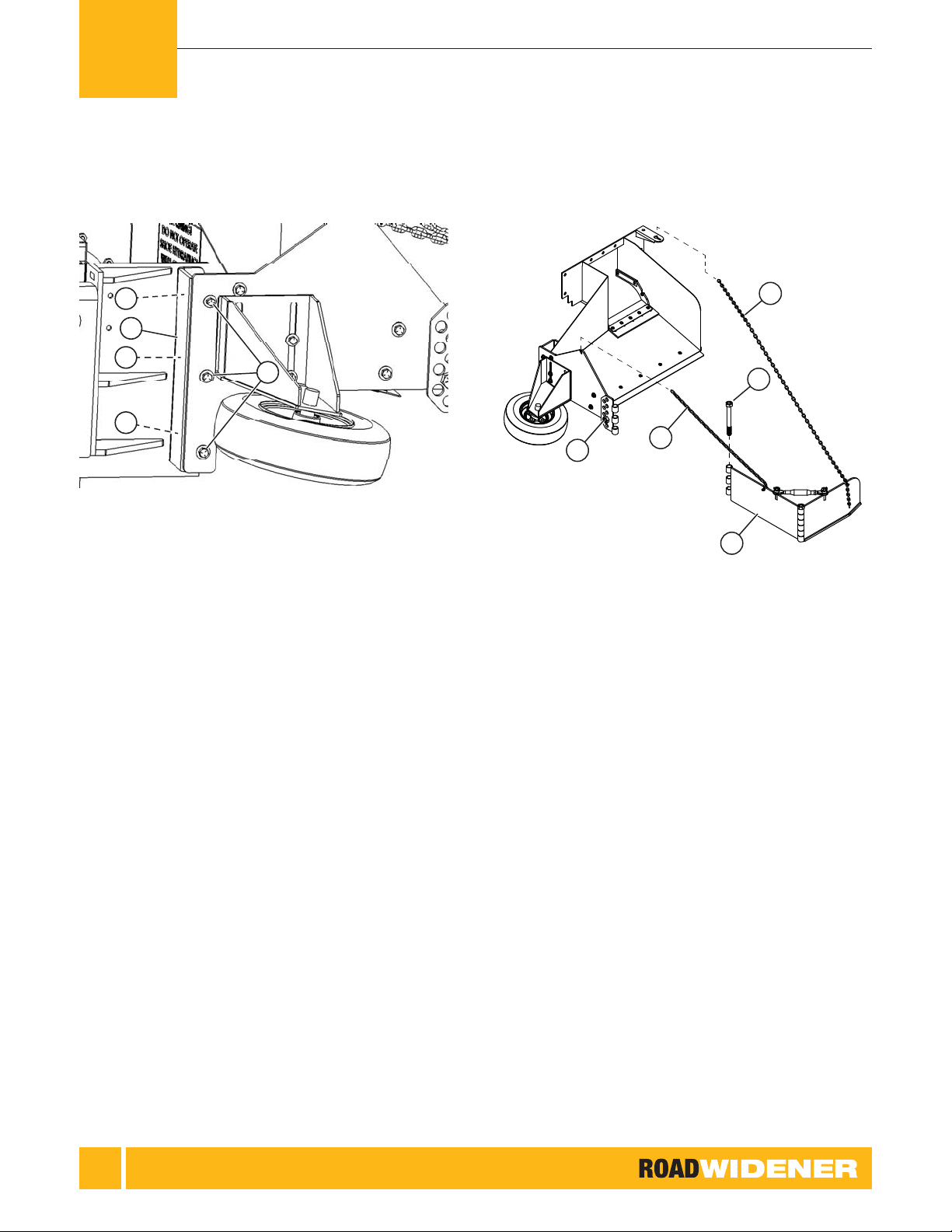

Curb Attachment

The curb attachment extends the hopper and allows the

shoe to be extended up over a curb to spread material

outside the curb. The roller wheel acts as a guide and

rides on the inside of the curb. It can be installed on a right

discharge, a left discharge or either side of a dual discharge

machine.

Figure 2: Curb Attachment Installed on Single Discharge Unit

INSTALLATION

OTE:NFor easier installation have the machine

mounted on a skid steer. An assistant may be

required for the removal and the installation

of some of the parts. This procedure shows

mounting the curb attachment onto a right

side single discharge machine. Mounting on

a left side discharge or a dual discharge is

similar.

1 ] Park the machine on a at, level surface.

3

4

2

1

Figure 3: Shoe Hardware Removal

1. Support Bracket Socket Head Screws

2. Shoe Mounting Bolts and Locknuts

3. Chain

4. Shoe

2 ] Remove the 2 bolts for the support bracket.

3 ] Remove the shoe mounting bolts and locknuts.

4 ] Unhook the chain and remove the shoe.

1

GENERAL INFORMATION

OPERATOR, MAINTENANCE AND PARTS

10

Figure 4: Shoe Removal

Figure 5: Discharge Plate Removal

5 ] On dual discharge units remove the closure plate if

required.

1

1

3

2

Figure 6: Chute Guide Plate

1. Socket Head Cap Screws

2. Outer Mounting Bolts

3. Inner Mounting Bolts

1

GENERAL INFORMATION

OPERATOR, MAINTENANCE AND PARTS

11

6 ] Remove the 4 socket head cap screws.

7 ] Remove the 2 outer mounting bolts.

8 ] Remove the 2 inner mounting bolts.

Figure 7: Chute Guide Plate Removal

9 ] Remove the chute guide plate.

Figure 8: Install Curb Attachment

10 ] Mount the curb attachment frame using the socket

head cap screws and the outer and inner mounting

bolts removed earlier.

1

GENERAL INFORMATION

OPERATOR, MAINTENANCE AND PARTS

12

3

2

2

2

1

Figure 9: Spacer Plate

1. Spacer Plate

2. Spacer Plate Inner Mounting Bolts

3. Spacer Plate Outer Mounting Bolts

11 ] Mount the spacer plate between the Road Widener

frame and the curb attachment using 6 bolts.

2

4

3

1

5

Figure 10: Installing Shoe and Chains

1. Shoe

2. Bolt

3. Rear Chain

4. Front Chain

5. Hinge

12 ] Install the shoe to the frame using the bolt. The shoe

hinge must pivot up and down.

13 ] Install the front and rear chains.

1

GENERAL INFORMATION

OPERATOR, MAINTENANCE AND PARTS

13

Push Plate

The push plate is used to push the dump vehicle when

not using the rollers. It usually pushes on the trailer hitch

receiver or the pintle hitch.

Figure 11: Push Plate with Four Pre-threaded Holes

1 ] Hold the push plate in place on the front of the

machine.

2 ] Attach the push plate to the frame at the four

pre-threaded holes using the approved hardware.

Pairing the Remote

Control

Your remote control comes factory paired. Almost never

will you need to pair your remote and receiver. The system

will behave like it is not paired if less than 12 volts DC and

10 amps are not present. If for some reason your remote

does not work, double-check the power supply(s). In the

unlikely event that pairing is required, see the separate

paring instructions that were supplied with the machine or

go to www.roadwidenerllc.com for the pairing procedure.

Remote systems require a 12-volt DC accessory socket

to be a 10-amp continuous solid-state connection. Using

lower than a 10-amp DC accessory socket will cause the

machine to not function. The handheld remote requires (2)

AAA batteries and the host machine must deliver 12 volts

DC and 10 amps. Connect your machine to a known

power source to verify! A direct circuit to the host machine’s

battery with a solid-state 10-amp fused circuit is advisable if

your remote does not function at initial start-up. USB ports

and some machine circuits provide less than 10 amps; if

your host machine falls into this category, adding a circuit

will be required.

1

GENERAL INFORMATION

OPERATOR, MAINTENANCE AND PARTS

14

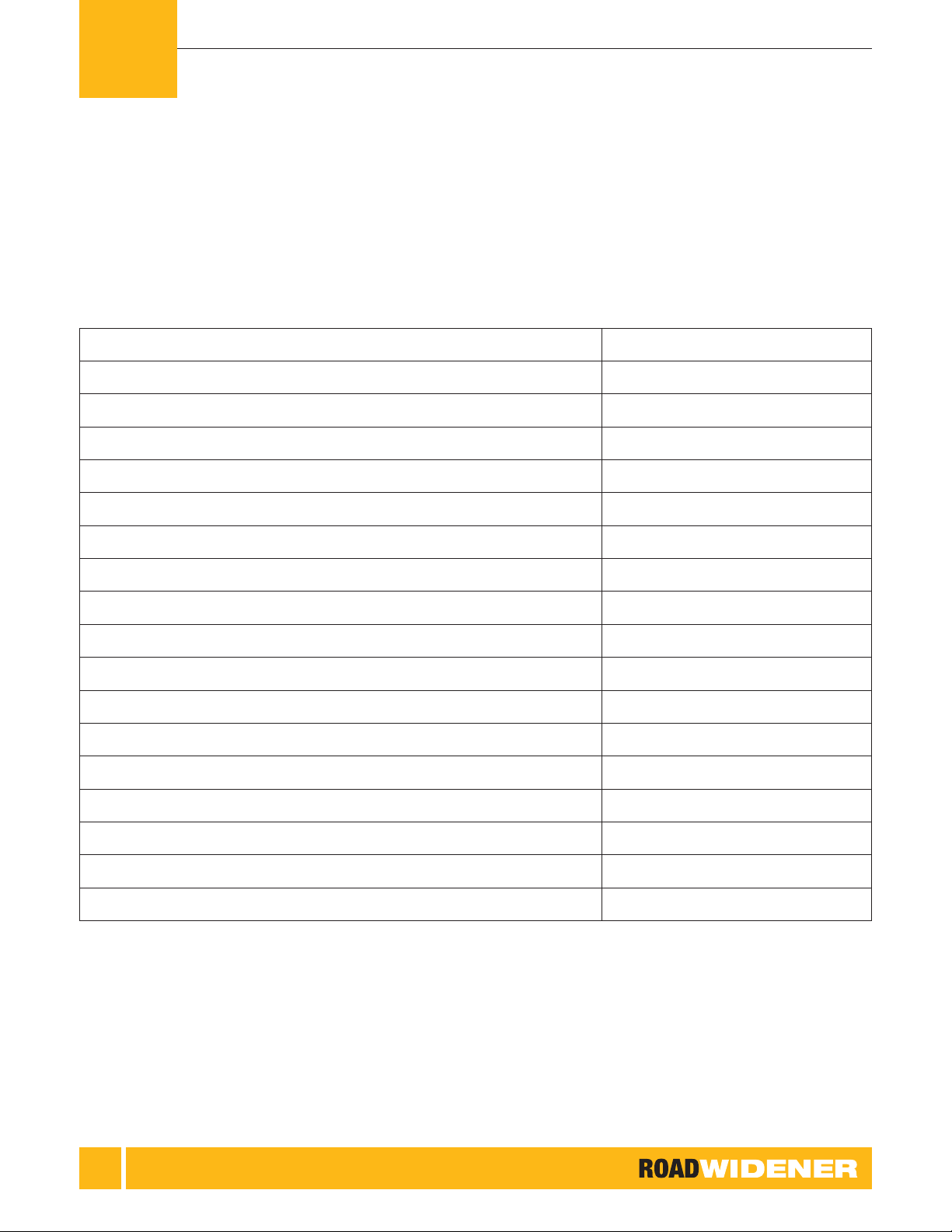

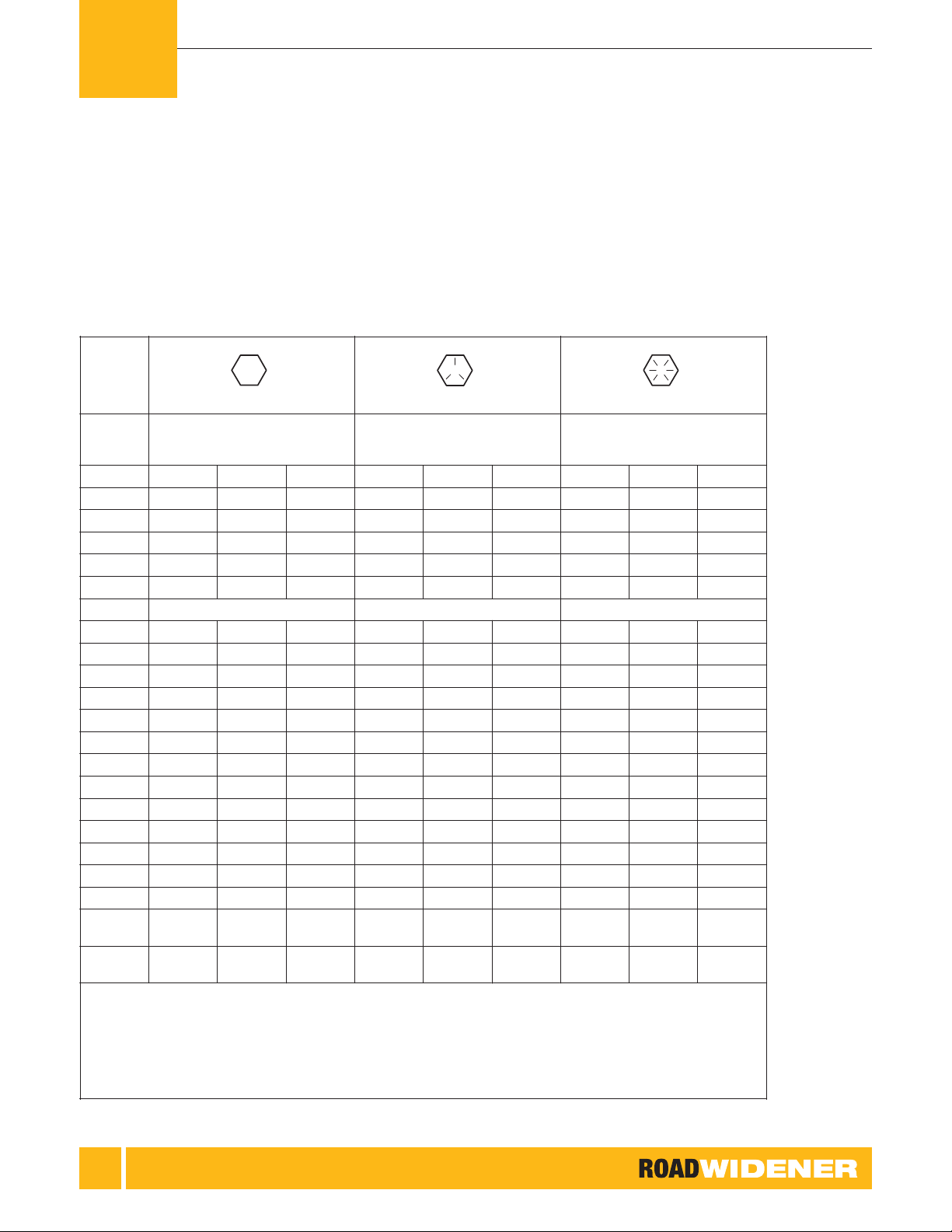

Hardware Torque Chart

Use this chart when tightening hardware to the proper torque value.

U.S. Standard Cap Screw Torque Values

SAE

GRADE

NUMBER

GRADE 1 OR 2 GRADE 5 GRADE 8

SIZE/

THREADS

PER INCH

TORQUE in.-lb (N·m) TORQUE in.-lb (N·m) TORQUE in.-lb (N·m)

THREADS DRY OILED PLATED DRY OILED PLATED DRY OILED PLATED

1/4 – 20 62 (7) 53 (6) 44 (5) 97 (11) 80 (9) 73 (8) 142 (16) 133 (15) 124 (14)

1/4 – 28 71 (8) 62 (7) 53 (6) 124 (14) 106 (12) 97 (11) 168 (19) 159 (18) 133 (15)

5/16 – 18 133 (15) 124 (14) 106 (12) 203 (23) 177 (20) 168 (19) 292 (33) 265 (30) 230 (26)

5/16 – 24 159 (18) 142 (16) 124 (14) 230 (26) 203 (23) 177 (20) 327 (37) 292 (33) 265 (30)

3/8 – 16 212 (24) 195 (22) 168 (19) 372 (42) 336 (38) 301 (34) 531 (60) 478 (54) 416 (47)

ft-lb (N·m) ft-lb (N·m) ft-lb (N·m)

3/8 – 24 20 (27) 18 (24) 16 (22) 35 (47) 32 (43) 28 (38) 49 (66) 44 (60) 39 (53)

7/16 – 14 28 (38) 25 (34) 22 (30) 49 (56) 44 (60) 39 (53) 70 (95) 63 (85) 56 (76)

7/16 – 20 30 (41) 27 (37) 24 (33) 55 (75) 50 (68) 44 (60) 78 (106) 70 (95) 62 (84)

1/2 – 13 39 (53) 35 (47) 31 (42) 75 (102) 68 (92) 60 (81) 105 (142) 95 (129) 84 (114)

1/2 – 20 41 (56) 37 (50) 33 (45) 85 (115) 77 (104) 68 (92) 120 (163) 108 (146) 96 (130)

9/16 – 12 51 (69) 46 (62) 41 (56) 110 (149) 99 (134) 88 (119) 155 (210) 140 (190) 124 (168)

9/16 – 18 55 (75) 50 (68) 44 (60) 120 (163) 108 (146) 96 (130) 170 (230) 153 (207) 136 (184)

5/8 – 11 83 (113) 75 (102) 66 (89) 150 (203) 135 (183) 120 (163) 210 (285) 189 (256) 168 (228)

5/8 – 18 95 (129) 86 (117) 76 (103) 170 (230) 153 (207) 136 (184) 240 (325) 216 (293) 192 (260)

3/4 – 10 105 (142) 95 (130) 84 (114) 270 (366) 243 (329) 216 (293) 375 (508) 338 (458) 300 (407)

3/4 – 16 115 (156) 104 (141) 92 (125) 295 (400) 266 (361) 236 (320) 420 (569) 378 (513) 336 (456)

7/8 – 9 160 (217) 144 (195) 128 (174) 429 (582) 386 (523) 343 (465) 605 (820) 545 (739) 484 (656)

7/8 – 14 175 (237) 158 (214) 140 (190) 473 (461) 426 (578) 379 (514) 675 (915) 608 (824) 540 (732)

1.0 – 8 235 (319) 212 (287) 188 (255) 644 (873) 580 (786) 516 (700) 910

(1,234)

819

(1,110) 728 (987)

1.0 – 14 250 (339) 225 (305) 200 (271) 721 (978) 649 (880) 577 (782) 990

(1,342)

891

(1,208)

792

(1,074)

NOTE:

• Dry torque values are based on the use of clean, dry threads.

• Oiled torque values have been reduced by 10% when engine oil is used as a lubricant.

• Plated torque values have been reduced by 20% for new plated cap screws.

• Oiled torque values should be reduced by 10% from dry when nickel-based antiseize compound is used as a lubricant.

• Cap screws which are threaded into aluminum may require a torque reduction of 30% or more.

• The conversion factor from ft-lb to in.-lb is ft-lb x 12 equals in.-lb.

1

GENERAL INFORMATION

OPERATOR, MAINTENANCE AND PARTS

15

EC Declaration of

Conformity

Single and Dual Discharge Road Wideners

Models FH & FHR (Full Hydraulic & Full Hydraulic Remote)

1

GENERAL INFORMATION

16

!This safety alert symbol appears with most

safety statements. It means attention, become

alert, your safety is involved! Please read and

abide by the message that follows the safety alert symbol.

The words DANGER, WARNING, CAUTION and NOTICE

are used throughout this manual to highlight important

information.

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

DANGER

!

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

WARNING

!

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

CAUTION

!

Indicates a situation which can cause damage to the Road

Widener, personal property, and/or the environment, or cause

the equipment to operate improperly.

NOTICE

OTE:NIndicates a procedure, practice or condition

that should be followed in order for the Road

Widener to function in the manner intended.

!WARNING

Before starting and operating the

Road Widener, be sure to read and

understand the content and safety

messages within this manual as well as

the safety labels on the Road Widener.

The operator is responsible for safe

operation of the Road Widener. Be sure

all potential users of the Road Widener

also understand these instructions.

Always keep your Road Widener in

proper working condition.

SAFETY2

OPERATOR, MAINTENANCE AND PARTS

17

It is the operator’s responsibility to read and

understand the skid steer or wheel loader safety

messages and proper operation and capabilities.

Only qualied and responsible operators should

be permitted to operate the machinery.

WARNING

!

Know the total rated operating capacity of

the skid steer or wheel loader which you will

be attaching to the Road Widener. The total

operating capacity should exceed the weight of

the Road Widener.

WARNING

!

!WARNING

Never operate the machine while under

the inuence of alcohol or drugs. Their

effect on vision and judgment make

operating the machine dangerous.

Road Widener machines should never be

operated with the casters off the ground.

Forward tipping may result. Road Widener

machines should be lifted off the casters while

loading and unloading only.

WARNING

!

Never operate the machine with the guards

missing or damaged. Tampering with or

modifying the guards may result in injury or

premature wear on the machine.

WARNING

!

!WARNING

Before operating the machine, read the

skid steer or wheel loader operation

manual and know what the acceptable

grade requirements are. The Road

Widener attachment will usually add

to the drive machine’s stability. Road

Widener assumes no responsibility of

tipping due to the angle of use.

Never allow an operator to sit or stand on Road

Widener attachment while in operation. A non-

slip surface is provided near the attachment plate

for entering and exiting skid steer only. Horizontal

surfaces may support maintenance personnel.

This should only occur with machinery stopped

and fully disconnected from power source.

WARNING

!

2

SAFETY

OPERATOR, MAINTENANCE AND PARTS

18

!WARNING

ALWAYS wear the appropriate personal

protective equipment as required by the

task at hand, including but not limited

to:

• Relatively tight and belted clothing

• Safety gloves

• Safety shoes/boots

• Safety eye glasses/goggles/shields

• Hearing protection, ear plugs

• Head protection, hard hats

Operating the machine requires the full

attention of the operator. Do not wear

radio or music headphones that may

interfere with jobsite communications

or monitoring the machine in operation.

!WARNING

Use extreme caution when near rotating

parts. Rotating parts can entangle

hands, feet, hair, clothing and/or

accessories. Traumatic amputation or

severe laceration can result.

• Keep hands and feet away from

rotating parts.

• Tie up long hair and remove jewelry.

• Operate equipment with all guards in

place.

• DO NOT wear loose-tting clothing,

dangling drawstrings or items that

could become caught.

Stay clear of all moving parts, rollers,

conveyor belt and skid steer when the

Road Widener is in operation.

Do not drive the Road Widener through gravel piles or asphalt

spills. Material can accumulate inside the belt and the belt

rollers causing premature belt wear or belt failure.

NOTICE

Always be environmentally responsible.

• Follow the guidelines of the EPA or other governmental

agencies for the proper disposal of hazardous materials.

Consult the local authorities or reclamation facility.

• NEVER dispose of hazardous materials irresponsibly

by dumping them into a sewer, on the ground, or into

groundwater or waterways.

• Failure to follow these procedures may seriously harm the

environment.

NOTICE

Inspect all hoses, ttings and hydraulic components on both

the Road Widener attachment and the drive machine before

operation of the hydraulic system. Repair any problems that

are discovered.

NOTICE

Do not lift with material in the hopper.

NOTICE

2

SAFETY

This manual suits for next models

1

Table of contents