Roadefend RDT600 User manual

Installation

Instruction

RDT600 Proactive AI Safety System

RDT600 Installation Instruction Ver.1.1

1

Revision History:

Version

Number

Revised By

Revision Date

Revision Description

V1.0

Xu Zhiwu

2023.04.24

<1> First draft of integrated

release

V1.1

Xu Zhiwu

2023.06.25

<1> Update some images in the

instructions section of the web

side configuration tool

RDT600 Installation Instruction Ver.1.1

2

Table of contents

1. Overview........................................................................................................................................................................... 4

2. Product Configuration....................................................................................................................................................... 4

2.1 Product standard packing list ............................................................................................................................... 4

2.1.1 The standard package is as follows:......................................................................................................... 4

2.2 Product optional accessories list .......................................................................................................................... 5

2.3 Equipment Harness............................................................................................................................................... 5

2.3.1 Power harness.......................................................................................................................................... 5

2.3.2 4- core IO communication harness ( optional)......................................................................................... 6

2.3.3 8- core IO communication harness (optional).......................................................................................... 7

2.3.4 Aviation head interface camera adapter cable ......................................................................................... 7

3. Preliminary preparation.................................................................................................................................................... 8

3.1 Site condition preparation.................................................................................................................................... 8

3.1.1 Site terrain requirements.......................................................................................................................... 8

3.1.2 Installer Requirements ............................................................................................................................. 9

3.1.3 Vehicle information confirmation............................................................................................................ 9

3.2 Installation Tool List.............................................................................................................................................. 9

3.3 Device information confirmation........................................................................................................................ 10

3.3.1 Hardware information confirmation ...................................................................................................... 10

3.3.2 Software information confirmation........................................................................................................ 11

4. Installation Notes............................................................................................................................................................ 11

4.1 Equipment and wiring harness docking.............................................................................................................. 11

4.1.1 Host front and back view....................................................................................................................... 11

4.1.2 Host side view........................................................................................................................................ 11

4.1.3 System connection diagram................................................................................................................... 12

4.2 Equipment and wiring harness docking.............................................................................................................. 12

4.2.1 Installation location requirements.......................................................................................................... 13

4.2.2 Host wiring ............................................................................................................................................ 13

4.2.3 ADAS camera debugging ...................................................................................................................... 14

4.3 DMS camera installation and debugging ............................................................................................................ 15

4.3.1 Installation location requirements.......................................................................................................... 15

4.3.2 Installation steps .................................................................................................................................... 15

4.3.3 Routing and precautions ........................................................................................................................ 16

4.4 GPS antenna installation..................................................................................................................................... 16

4.5 Storage media and IoT card installation ( picture) ............................................................................................ 17

5. Use of web-side configuration tools ............................................................................................................................... 17

5.1 Login.................................................................................................................................................................... 17

5.1.1 Connect to WIFI hotspot........................................................................................................................ 17

5.1.2 Log in to the web tool............................................................................................................................ 18

5.2 Status query........................................................................................................................................................ 18

RDT600 Installation Instruction Ver.1.1

3

5.3 Parameter setting ............................................................................................................................................... 19

5.3.1 Set vehicle information.......................................................................................................................... 19

5.3.2 Set switch value ..................................................................................................................................... 19

5.3.3 Mirror/Flip Settings ............................................................................................................................... 19

5.3.4 Test mode............................................................................................................................................... 19

5.4 ADAS calibration ................................................................................................................................................. 20

5.5 Live image ........................................................................................................................................................... 21

6. Notice to users................................................................................................................................................................ 22

RDT600 Installation Instruction Ver.1.1

4

1. Overview

This article introduces in detail the composition of the RDT600 active safety intelligent prevention and

control system , the installation standards and precautions of the host and its accessories . Provide

reference and guidance for on-site installation personnel , provide construction personnel with

installation operation requirements , standardize the installation and commissioning process , Improve

construction efficiency , Make sure the equipment is working properly .

2. Product Configuration

2.1 Product standard packing list

Table 1: Standard product packing list

2.1.1 The standard package is as follows:

Figure 1 : Product standard packaging diagram

Serial

Number

Name

Quantity

Unit

Remark

1

RDT600 host

1

tower

2

Power Cable

1

root

3

G-mouse

1

indivua

4

Triangle certificate

1

pieces

RDT600 Installation Instruction Ver.1.1

5

2.2 Product optional accessories list

Serial

Number

Name

Quantity

Unit

Remark

1

DMS Camera

1

indivual

Optional according to project

requirements

2

OMS Camera

1

indivual

Optional according to project

requirements

3

Aviation head interface

camera adapter cable

1-4

root

This adapter cable is required when

the camera interface is a 4-pin

aviation head

4

BSD camera

1-2

indivual

Optional according to project

requirements

5

4-core IO cable

1

root

Optional according to project

requirements

6

8 core IO cable

1

root

Optional according to project

requirements

7

TF card

1-2

open

Single card supports up to 512G

8

IoT card

1

open

Middle card

Table 2: Product selection list

2.3 Equipment Harness

The wiring harness has a variety of function combination options , please consult sales or technical

support for details.

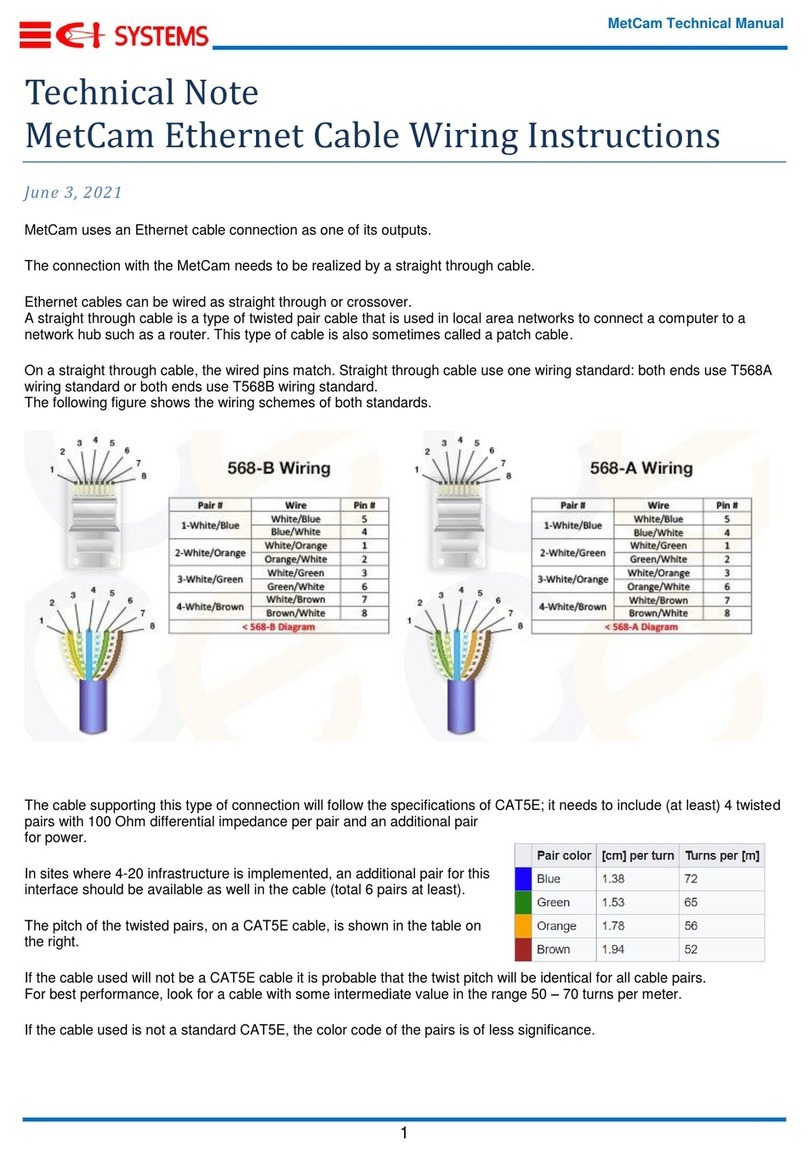

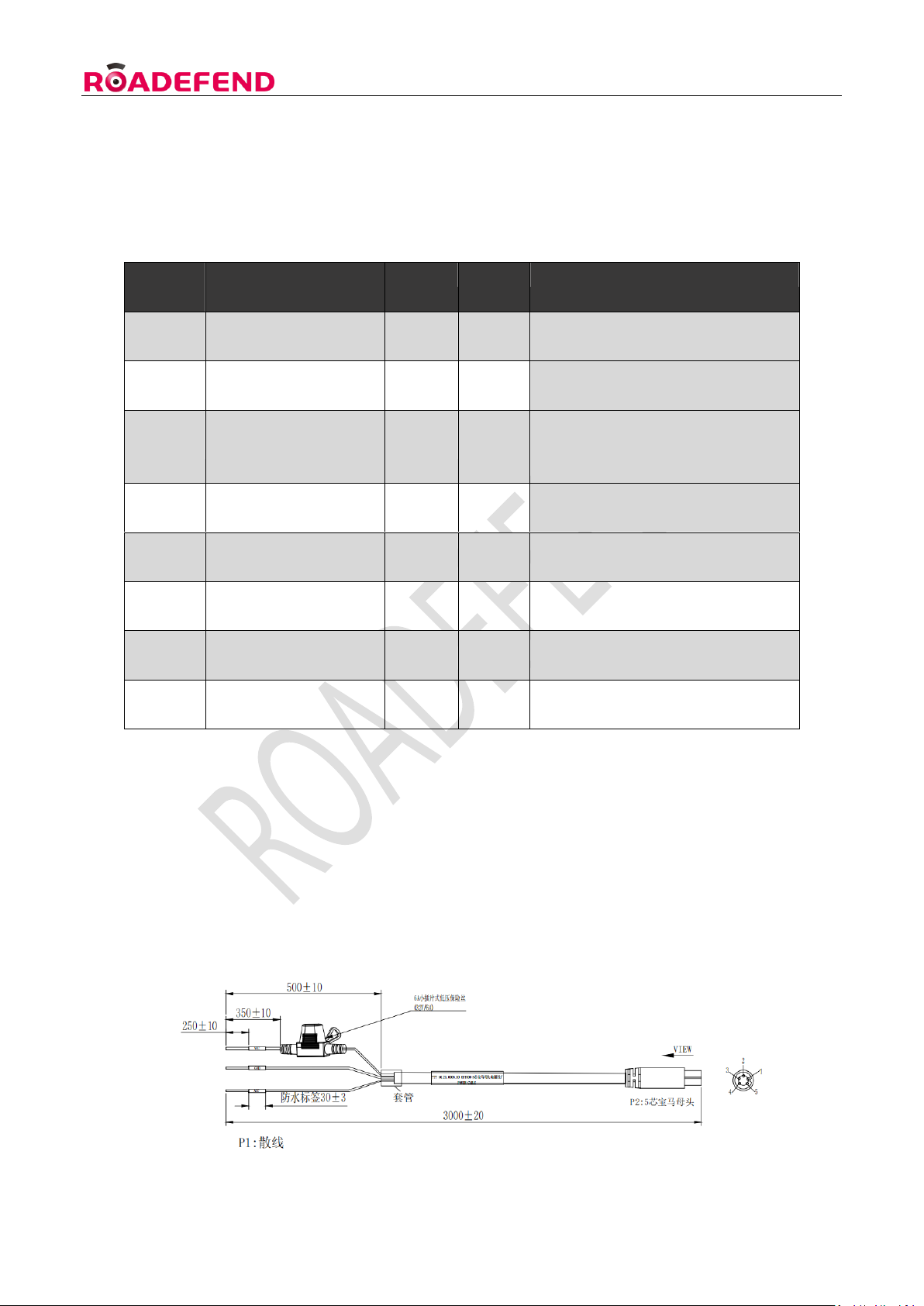

2.3.1 Power harness

RDT600 Installation Instruction Ver.1.1

6

Figure 2: Diagram of power harness

Table 3: Definition of harness pins

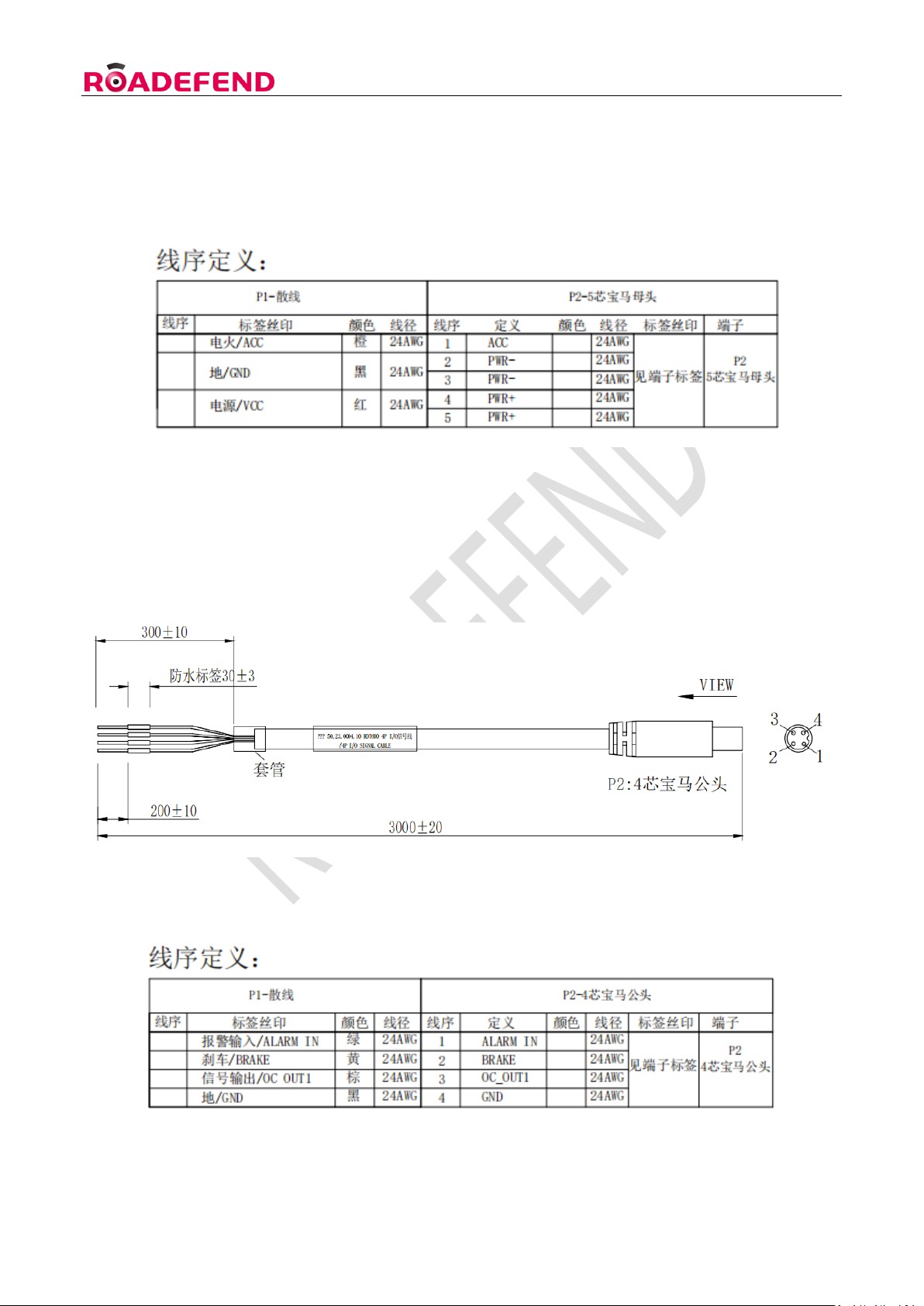

2.3.2 4- core IO communication harness ( optional)

Used to connect the body hardware line signal , Such as brakes , left/right turn signals , high/low

beams , CAN communication, etc. , for details, refer to the wiring harness definition.

Figure 3 4 -core IO communication line

Table 4 Pin definition of 4- core IO communication line

RDT600 Installation Instruction Ver.1.1

7

2.3.3 8- core IO communication harness (optional)

Figure 4 8- core IO communication line

Table 5: Pin definition of 8- core IO communication line

2.3.4 Aviation head interface camera adapter cable

For host and 4- core aerial camera

RDT600 Installation Instruction Ver.1.1

8

Picture 6 Aviation head interface camera adapter cable

3. Preliminary preparation

3.1 Site condition preparation

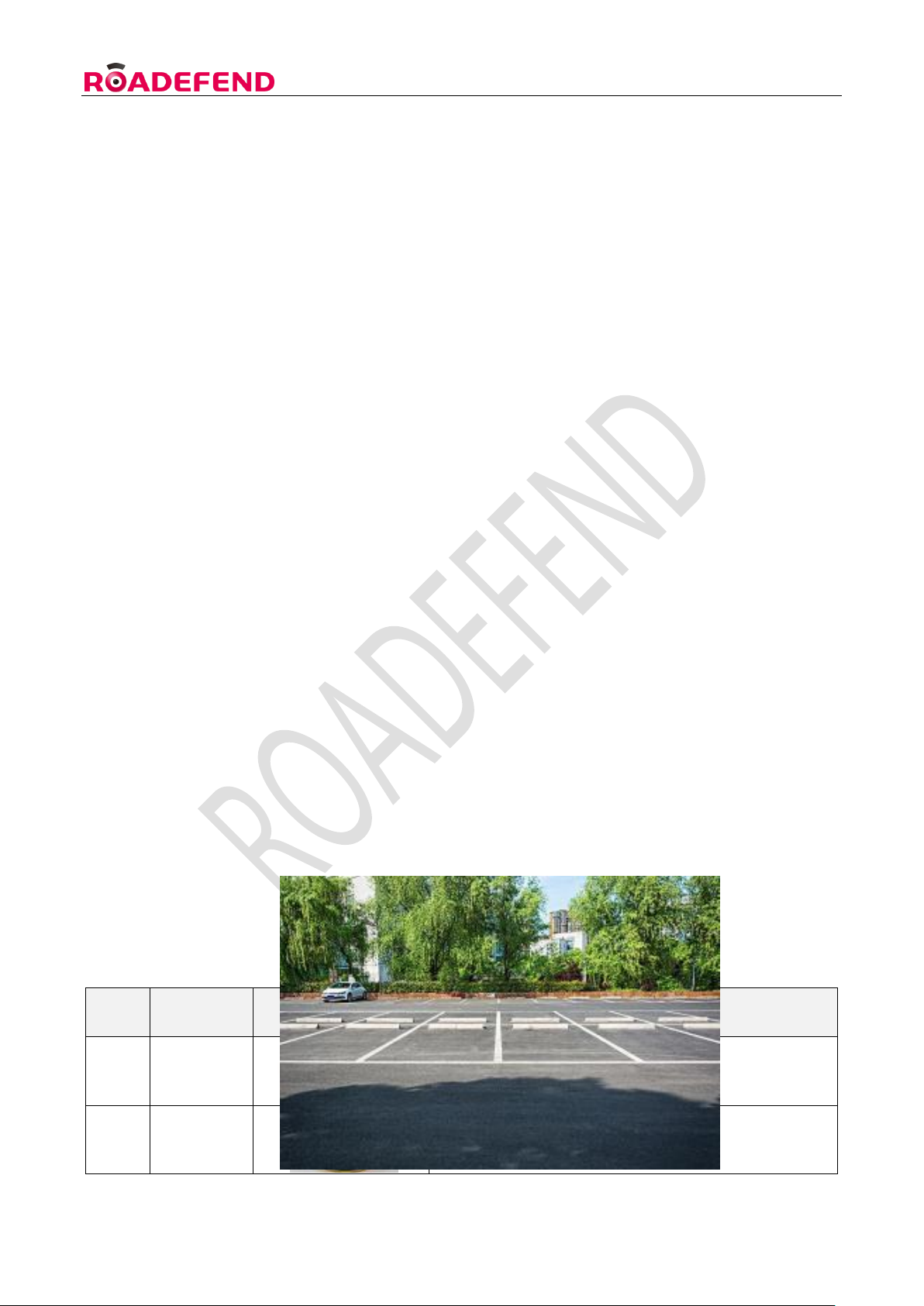

3.1.1 Site terrain requirements

Find an open area before installation . In principle, it is required to be on a flat road with a wide view

(you can see the skyline ) , Areas with lane lines for installation and calibration . Considering the actual

situation , At least install and calibrate on level ground .

Stop the vehicle horizontally , and it is forbidden to tilt the vehicle when the equipment is installed and

calibrated . There are two methods for specific site requirements :

Method 1 : Find a straight lane to ensure that the front view is wide and you can see the distant skyline .

Park the vehicle in the center of the long straight horizontal lane , and ensure that the vehicle stops

straight , as shown in the left picture below :

Method two : Find a flat open space , Make sure that the ground where the vehicle is parked is not

sloped .There is no less than 5 meters of open space in front of the installation site vehicle , which is

convenient for the installation personnel to calibrate , as shown in the right picture above :

RDT600 Installation Instruction Ver.1.1

9

3.1.2 Installer Requirements

On-site construction personnel should be familiar with the functions and applications of the product ,

understand the composition and working principle of the entire system , and be familiar with the internal

structure and electrical circuits of motor vehicles , etc. Have experience in the installation and

construction of common in-vehicle equipment . Need to know the installation location in advance ,

Know the vehicle model where the device is installed , Host and camera installation location selection,

Various cable lengths required for installation, Prepare the necessary auxiliary materials in advance,

Ensure the smooth completion of equipment installation and commissioning .

3.1.3 Vehicle information confirmation

Before the equipment is installed , On-site construction personnel must confirm the electrical

information of the vehicle . The step is vehicle damage (in case of occurrence ) .The basis for the

division of responsibilities involved , the following operations must be checked and correct before

proceeding to the next step of installation :

Whether the vehicle can ignite normally .

Whether the vehicle power system is intact , Whether there are other electrical faults, etc.

the vehicle has any external damage .

3.2 Installation Tool List

Serial

Number

Name

Real

Specification

1

Wire Stripper

Universal type for stripping and cutting lines

2

Tape

Measure

Exceed 5M

RDT600 Installation Instruction Ver.1.1

10

3

Electric Pen

Universal

4

Screwdriver

Set

Length greater than 20cm , with a cross and a cape

5

Multimeter

General purpose , for measuring voltage , left and

right turn signals , brake signal etc.

6

Bellows

2cm straight , Beautiful packaging for wiring , Prevent

leakage line damage

7

Utility Knife

Used for cutting corrugated pipes , rolling strips and

other items

8

Insulation

Black Tape

Universal type, for wrapping wire ends

9

Cable Ties

7cm long for fixing the harness

10

3M Glue

Universal type , used to fix the DMS base when drilling

is not possible

11

Electrical tools

For fixing screws , And opening holes when walking

dark lines

12

R v wire

Used to connect vehicle power lines , signal power

lines , and signals to equipment to extend the

function; Power wire diameter 1.5mm², Signal

wire diameter 0 . 5 mm ²

13

IoT card

IoT card - medium card (China Mobile , China Unicom

or China Telecom ) is used for communication

between devices and platforms

14

Storage

medium

Support 2 TF cards . It is used to store videos and

needs to be purchased in advance .

3.3 Device information confirmation

3.3.1 Hardware information confirmation

RDT600 Installation Instruction Ver.1.1

11

Before installation, check whether the equipment is complete and whether there is any damage , etc.

The specific equipment list is subject to the project plan .

3.3.2 Software information confirmation

Check the shipping information sheet before installation to confirm the correctness of the factory

version of the device software.If you find that the device software version is inconsistent with the

required version , you need to contact the person in charge immediately to check and deal with it .

Perform upgrade operations when necessary.Confirmation method : After the device is powered on,

check whether the firmware version information and patch number are consistent with the factory

shipment information through the web page .

4. Installation Notes

4.1 Equipment and wiring harness docking

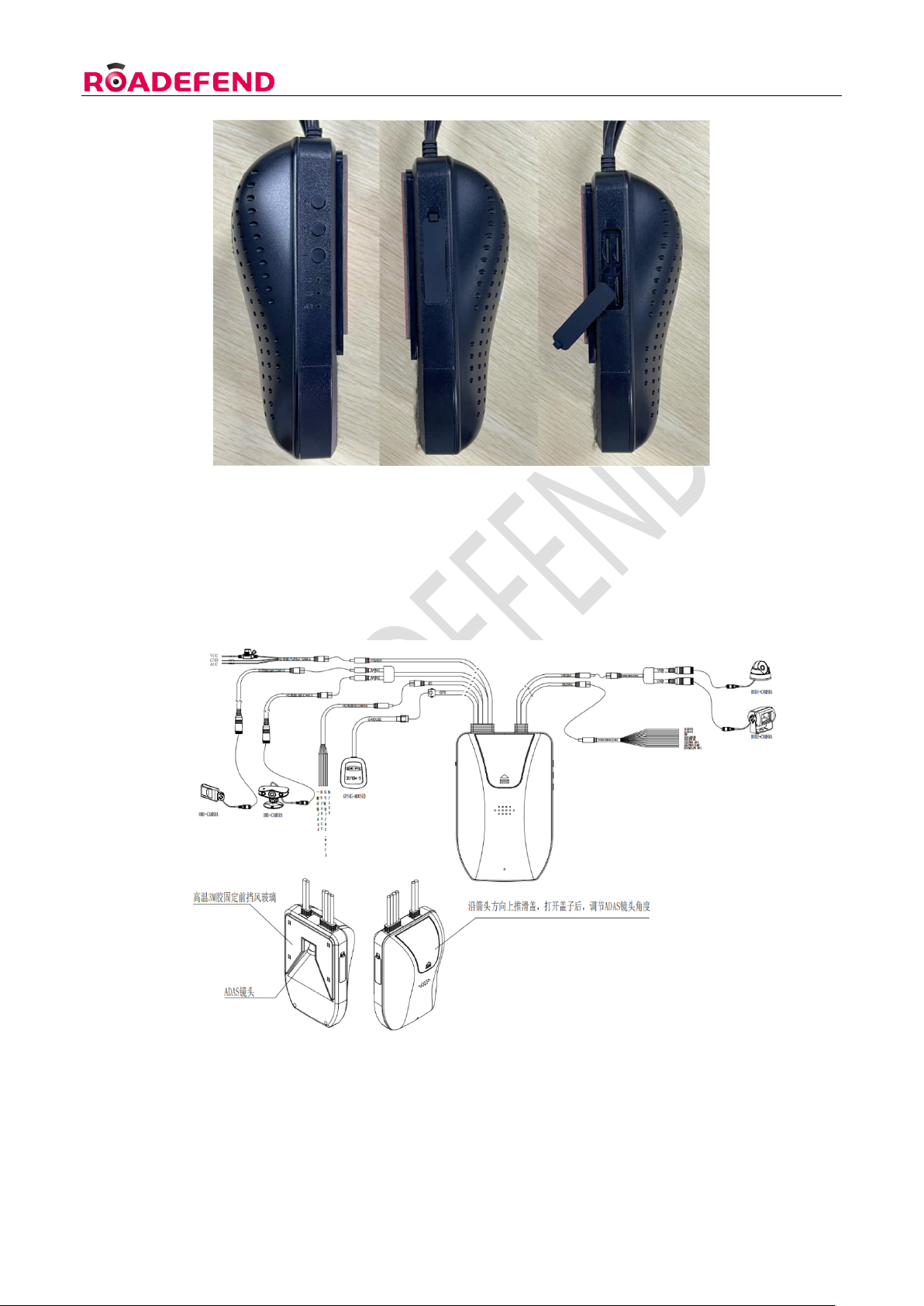

4.1.1 Host front and back view

4.1.2 Host side view

RDT600 Installation Instruction Ver.1.1

12

4.1.3 System connection diagram

4.2 Equipment and wiring harness docking

RDT600 Installation Instruction Ver.1.1

13

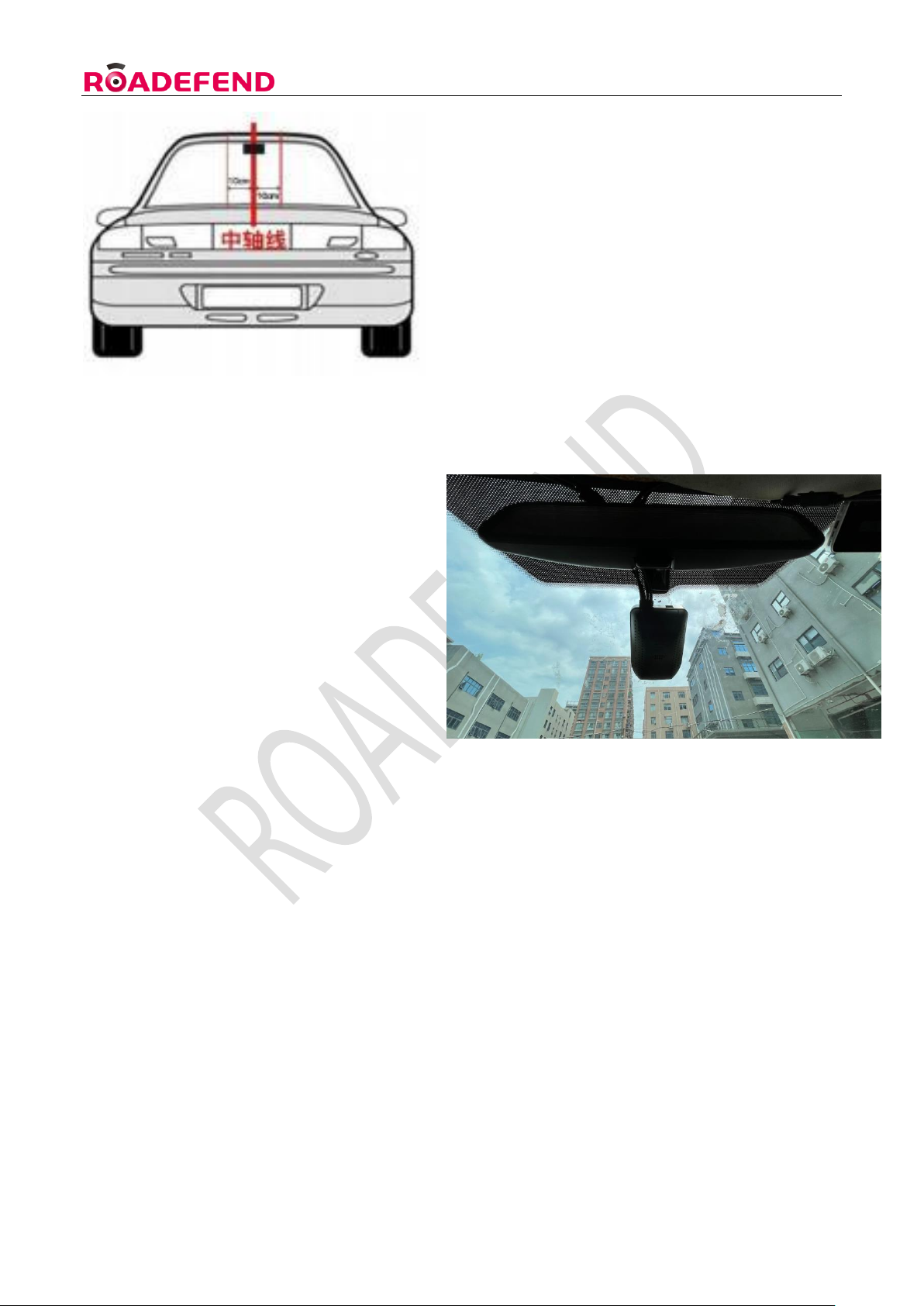

4.2.1 Installation location requirements

1). The host is fixed near the rearview mirror of the front windshield (the top function line is hidden in

the roof compartment), and it is as close as possible to the middle of the entire width of the windshield.

2). Before installing and fixing, ensure that the ADAS camera is horizontally illuminated on the road

surface and does not deviate from the straight line of the road. It is required to check whether there is

any potential risk of line damage or equipment failure on the vehicle at the selected location.

3). If there is a lens from another manufacturer occupying the position, use the "overlay method" to

install and fix it, and try to ensure that the lens is centered.

4). After determining the installation location of the host, wipe the windshield of the installation area

with cleaning paper to ensure that the relevant area is clean.

5). Take off the ADAS camera lens sticker, tear off the 3M adhesive sticker of the main unit and stick it

well.

6). After pasting the main unit, press it hard to make the main unit firmly stick to the glass, so as to

prevent the main unit from loosening or falling off.

4.2.2 Host wiring

The wiring of the equipment should be as dark as possible . Ensure that the operating table is clean

and beautiful ; The wiring harness exposed outside the cab ( if any) needs to be protected by corrugated

tubes , And need to avoid frequently moving parts , Prevent damage to the wire harness due to

vibration and pulling during use .

First find the body's constant power line (Vin) , car ignition switch line (ACC) , ground line (GND) , left

and right steering and brake signal lines . Usually available

RDT600 Installation Instruction Ver.1.1

14

Find the corresponding wiring position through the instructions of the body fuse box , As shown below :

If the description of the fuse box is vague and cannot be judged , The corresponding wiring harness

can be found through the electric pen measurement method . The judgment method is as follows :

Normal power line (Vin ) : When the vehicle is turned off, use an electric pen to measure whether the

line has electricity . If there is electricity, it can be judged that the line is a normal power line , and then

measure the voltage , Make sure it is within the range of use of the device .

Ignition signal wire (ACC ) : Through electric pen measurement , if the line voltage is 0V , the line is

charged after the vehicle is ignited , then it can be judged that the line is the ignition signal line . Then

make a voltage measurement , Make sure the voltage is working properly .

Brake and left and right turn signal lines : Measured by electric pen , When the vehicle does not

turn on the left and right turn signals, the line has no voltage , There is voltage on the line when the

vehicle turns left and right . It means that the line is the left and right steering signal line ; The same

goes for the brakes . If the signal line cannot be determined through the above methods , Please

contact the team or other professional auto repair shop for assistance .

According to different customer needs , other unused wiring harnesses such as 485 communication wires ,

etc. , can not be connected if there is no requirement , but must be wrapped with insulating tape to

ensure that the exposed part of the wire does not contact any part of the vehicle body .

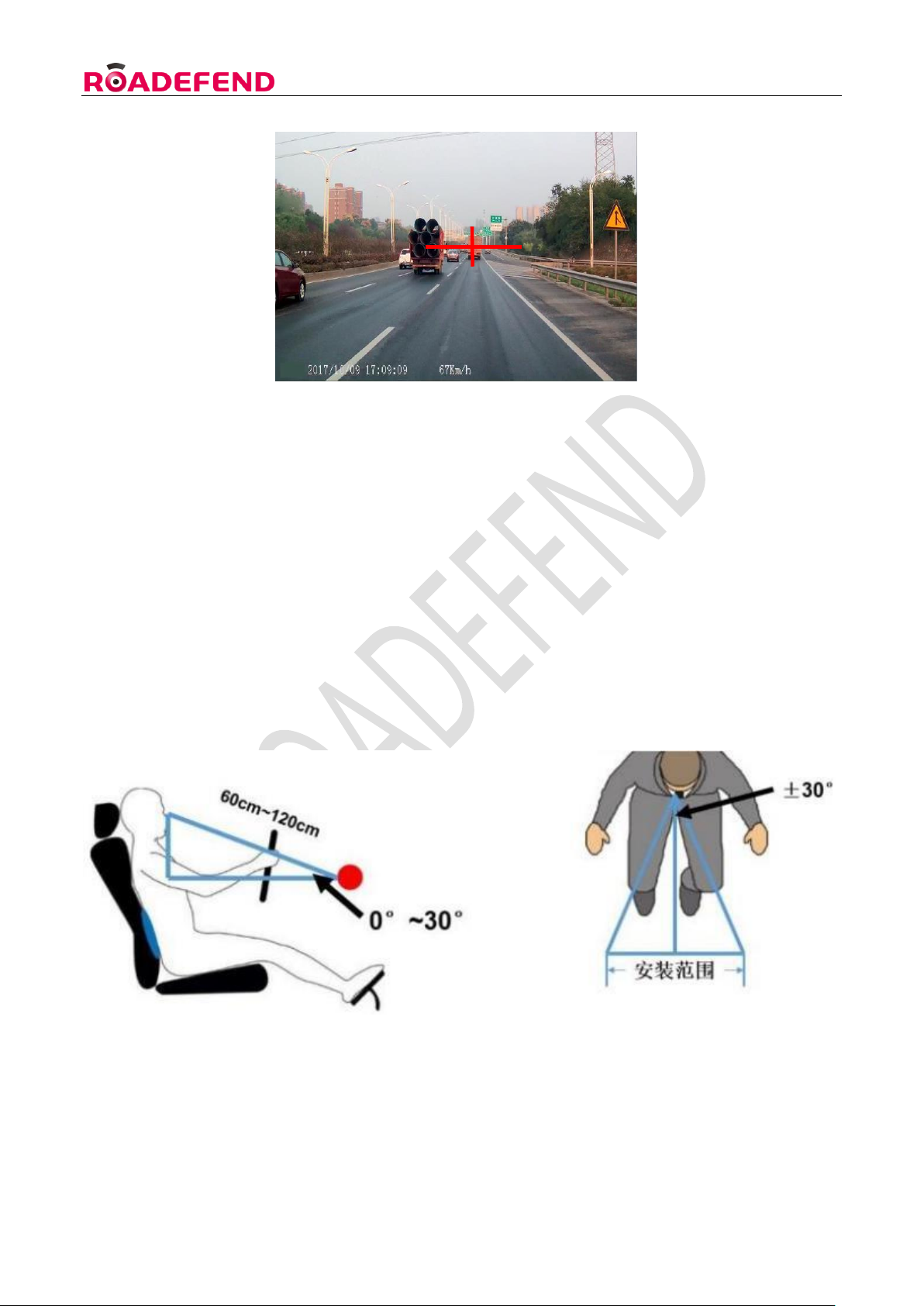

4.2.3 ADAS camera debugging

Open and log in the mobile APP , preview the real-time video of the ADAS channel, adjust the camera

angle so that the horizontal line of the cross star in the image is flush with the skyline of the road, and

the vertical line is flush with the center of the lane.

RDT600 Installation Instruction Ver.1.1

15

4.3 DMS camera installation and debugging

4.3.1 Installation location requirements

DMS The camera is installed in front of the driver , distance from driver's face 60cm~ 120cm range ,

The angle between the normal line of the face and the driver is required to be less than ±30° when

looking straight ahead ; the angle between the normal line of the face and the face in the vertical

direction is less than 30° , as shown in the figure below .

4.3.2 Installation steps

Step 1: According to the installation location requirements, find a suitable installation location on the

RDT600 Installation Instruction Ver.1.1

16

front windshield near the left A- pillar (you can power on the device first, and check the DMS video

screen through the mobile APP real-time video to confirm whether the installation location is suitable) ,

and use a paper towel Or clean the installation position with a dry towel, tear off the 3M adhesive

sticker on the base of the DMS camera , stick the base to the installation position on the windshield

and use a little force to make it stick firmly .

Step 2: When adjusting the angle, the installer needs to fasten the seat belt, open and log in the

mobile APP, preview the real-time video of the DMS channel, and adjust the camera angle so that the

driver's face is in the center of the screen as much as possible, as shown in the figure below (the

position inside the red dotted line box in the figure ):

4.3.3 Routing and precautions

Since the camera is installed in front of the drive, it must be

ensured that it will not block the driver's vision after installation .

In the camera image, it should be ensured that the steering wheel does not block the driver's face. If

there is a need for occlusion, the installation location needs to be changed .

The wiring of the equipment should try to ensure that the dark line is used.Ensure that the operating

table is clean and beautiful,Exposed wiring harnesses need to be protected by bellows,Prevent breakage

during later use .

4.4 GPS antenna installation

The installation position of the GPS antenna is preferably on the roof, and the wiring can be drilled into

the car through holes or along the door gap. If it cannot be installed on the roof, it is recommended to

RDT600 Installation Instruction Ver.1.1

17

install it on the console in front of the passenger seat, as close to the window as possible. The distance

from the electronic equipment is more than 50cm, pay attention to the receiving side of the antenna

facing up, and tear off the 3M adhesive protective film and stick it on the table to ensure that the antenna

is stable during driving. It is strictly forbidden to stick the GPS antenna on the equipment.

4.5 Storage media and IoT card installation ( picture)

5. Use of web-side

configuration tools

5.1 Login

5.1.1 Connect to WIFI hotspot

Open the WiFi connection interface on the mobile phone, and you can see the hotspot with the WiFi

name "RDT600-the last six digits of the device number", such as RDT600-000949,

Connect to this WiFi hotspot, the WiFi hotspot password of all RDT600 is uniform: 12345678, after the

RDT600 Installation Instruction Ver.1.1

18

connection is successful, go to the next step.

5.1.2 Log in to the web tool

Open the mobile browser, enter " 192.168.1.1 " in the URL bar , click Go, and enter the login page; After

verifying the consistency between the device number and the actual device number, enter the username

and password (please request from the manufacturer), click Login to enter the home page of the web

tool .

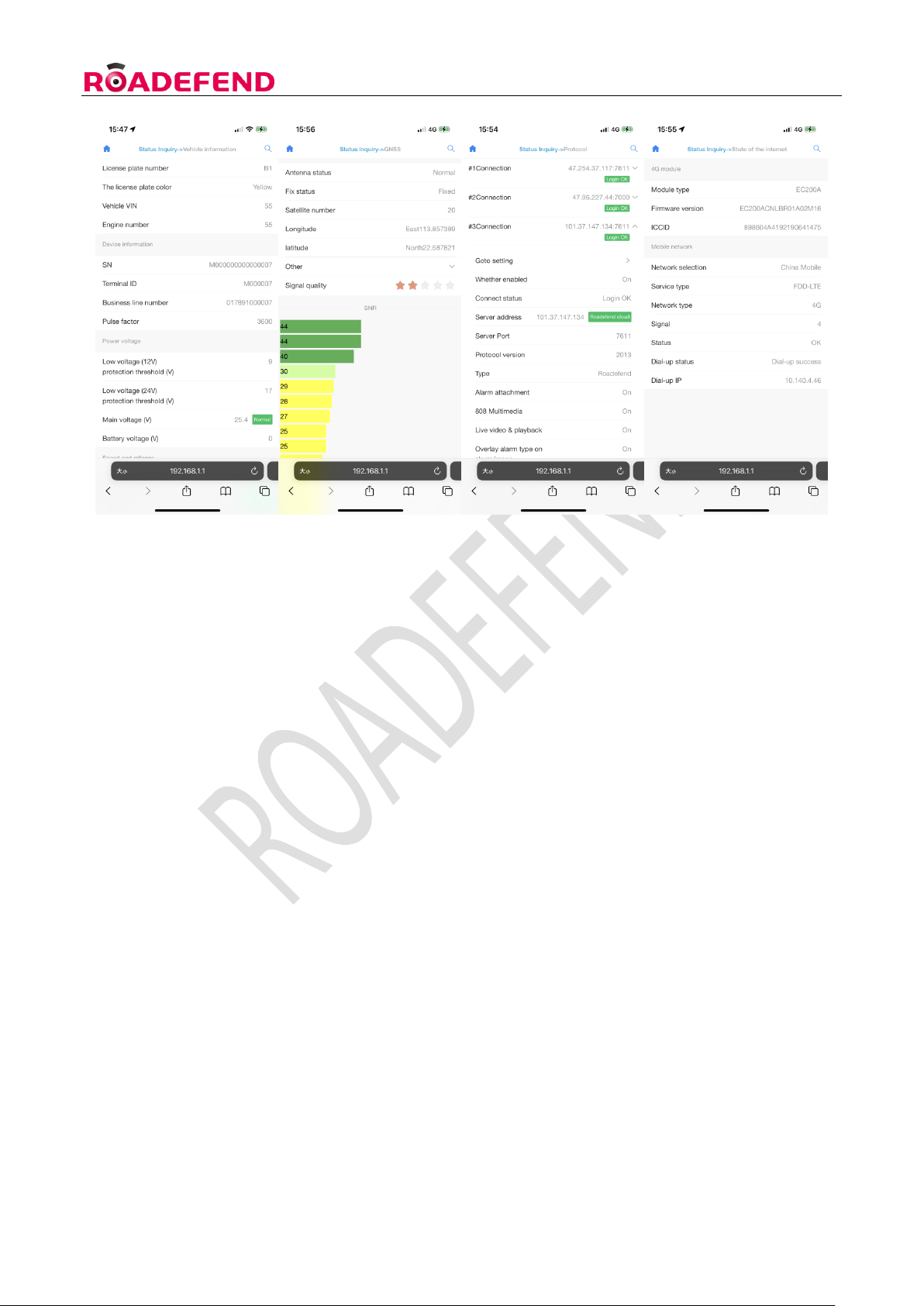

5.2 Status query

Click "Status Query" to enter the status query page. The status query includes: version information ,

vehicle information , storage , GPS , protocol , switching value status , networking status , etc.

RDT600 Installation Instruction Ver.1.1

19

5.3 Parameter setting

5.3.1 Set vehicle information

Click "Parameter Settings-General-Vehicle Information" to set the license plate number, license plate

color , etc. The online number can be clicked on the right " +"

Select "Freight" or "Default" (recommended to choose "Freight") or fill in according to your needs .

5.3.2 Set switch value

Click "Parameter Settings-General-Switch Volume", and set each switch volume to be active at high

level or low level according to the actual situation

5.3.3 Mirror/Flip Settings

According to actual project needs, click on "Parameter Settings-Video-Mirror Flip" to set the mirror/flip

settings for a certain channel screen.

5.3.4 Test mode

Click "Parameter Settings-Active Safety-Test Mode", the device enters the test mode, and can perform

Table of contents