- 18 -

FOR OPTIMAL APPLICATION AND USE OF THE STRABUC 918 AND STRABUC 930 PLEASE READ THE INSTRUCTIONS AND CONSULT EXPLANATORY DIAGRAMS.

IMPORTANT: ALL INSTALLATION OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN, IN OBSERVANCE OF THE EN 12453 - EN 12445 SAFETY REGULATIONS

AND MACHINERY DIRECTIVE 2006/42/CE.

CAREFUL RISK ANALYSIS IS REQUIRED UNDER APPLICABLE REGULATIONS.

GENERAL COMMENTS

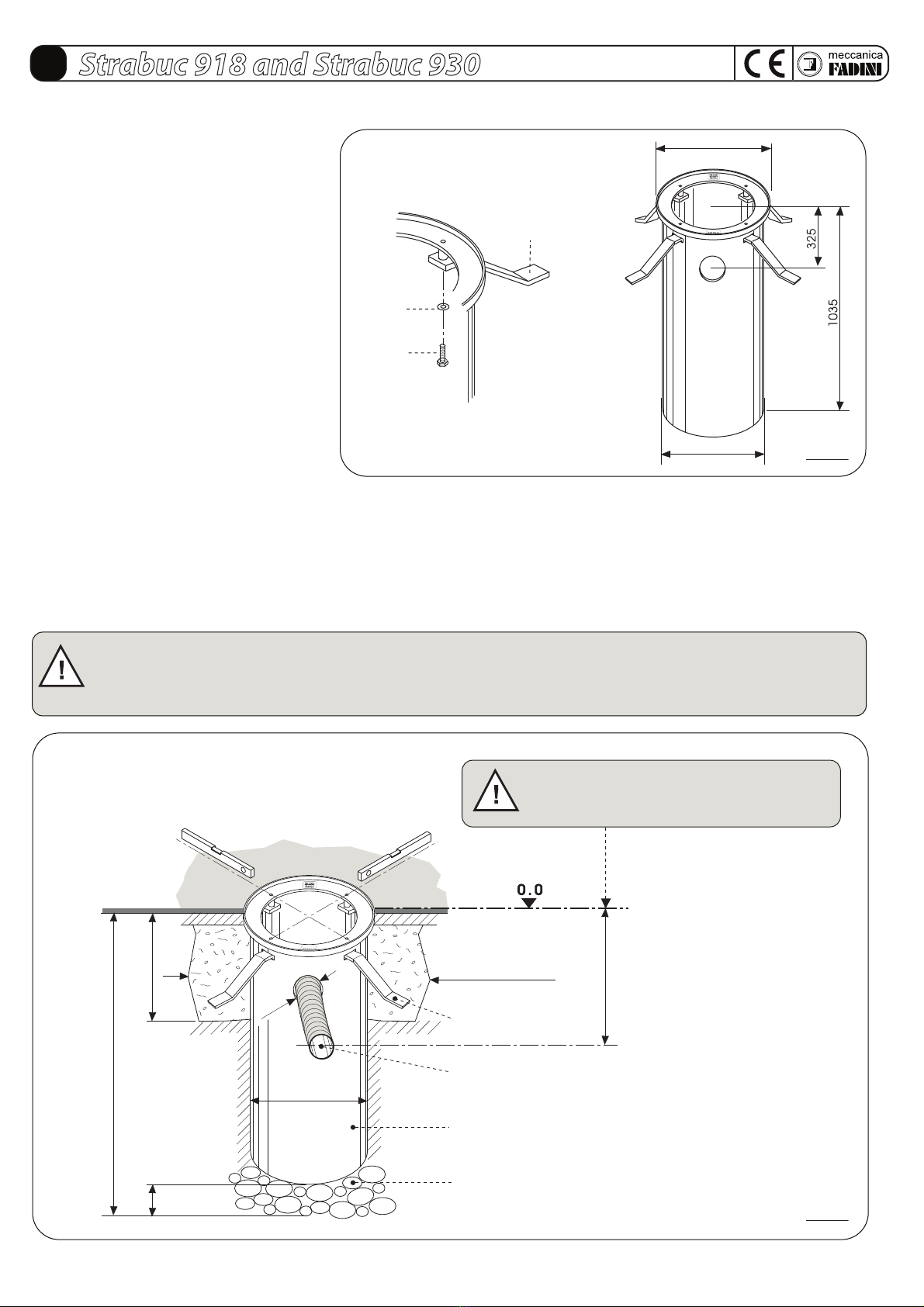

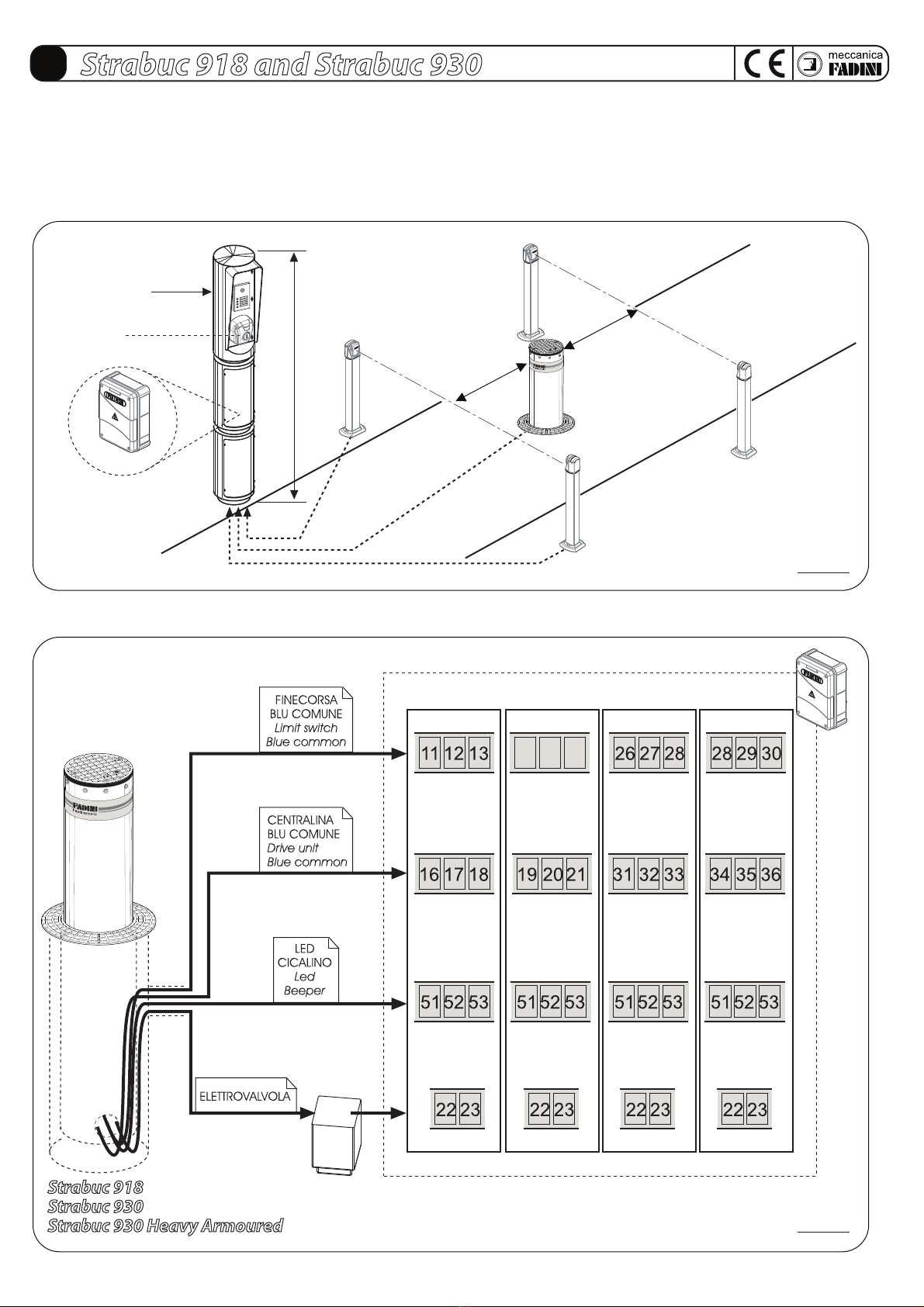

STRABUC 918 and STRABUC 930 are a fully retractable, belowground, oil-hydraulic steel trac control post intended to prevent unauthorised vehicular access. It is an

oil-hydraulic operator with a built-in hydraulic main unit. The Elpro S40 electronic programmer is installed externally, in a protected place. The trac control post comes

with a series of accessories that guarantee the necessary safety and the required operations, in order to make the operator suitable for installation in all public and

private settings.

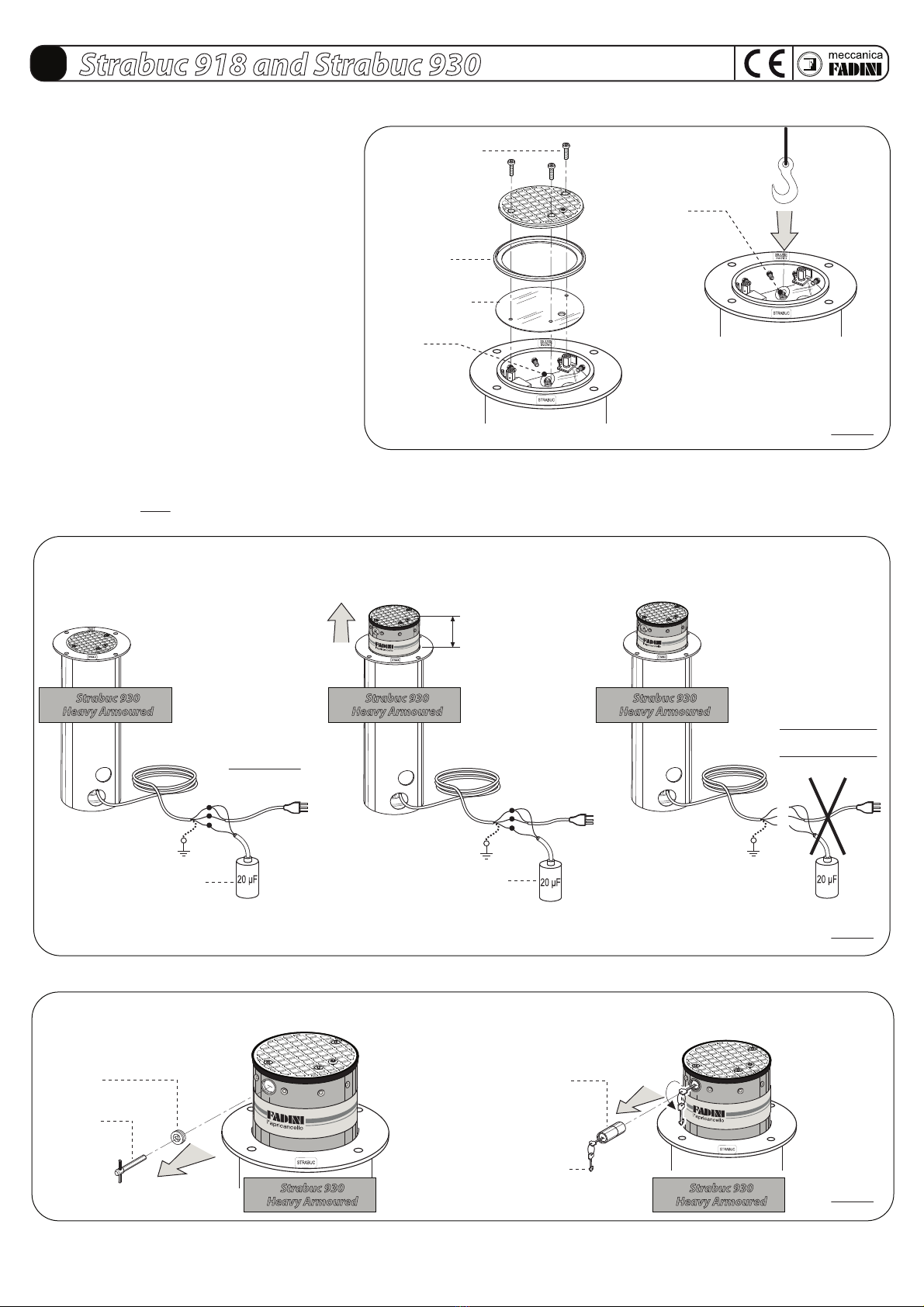

STRABUC 918: bollard with retractable post of steel, 4 mm thickness. Stainless steel option available. For both versions an optional electro/solenoid-valve is possible for

automatic lowering in case of power failure.

STRABUC 930 HEAVY ARMOURED: bollard with retractable post of steel, 12 mm thickness. On request the unit can be tted with an electro/solenoid-valve for automatic

lowering in case of power failure, and an armoured lock barrel, removable only by a custom-made key, to provide burglar-proof extra security to the post.

PRELIMINARY WARNINGS ON SAFETY AND GOOD OPERATION

Before commencing operator installation, it is essential to remember:

- That installation, checking, testing, risk analysis and subsequent maintenance work must be performed by authorised, qualied technicians.

- This operator has been designed for the use described in this manual only, and using at least the safety, control and indication accessoriesas here recommended.

- Any other application not explicitly indicated in this manual could cause malfunction, damage or personal injury.

- To check that the ground is stable, to avoid subsequent settling or deformation in the trac control post installation area.

- To check that there are no nearby buried utility pipes.

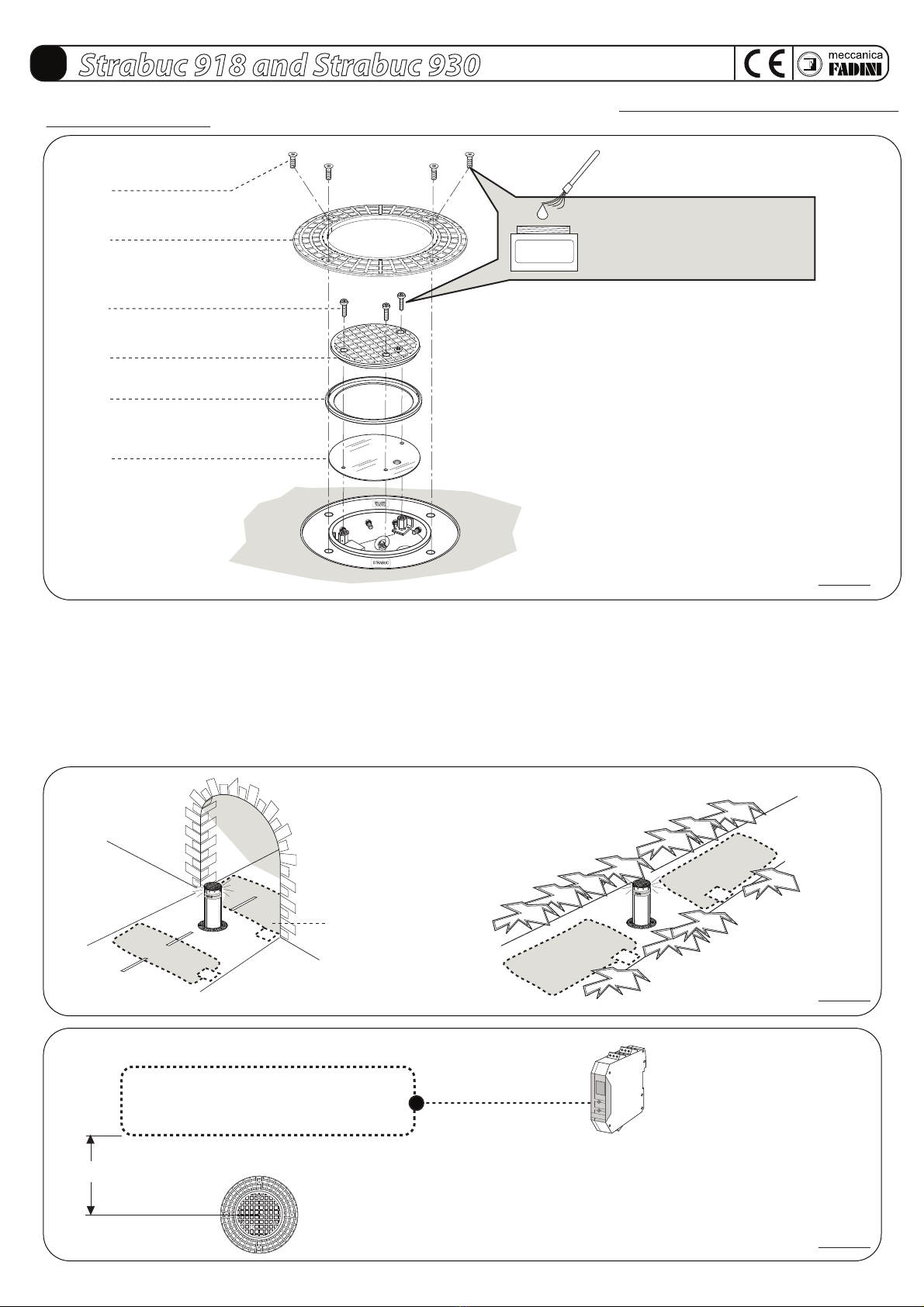

- To check that there are no sources of electromagnetic disturbance in the immediate vicinity of and below the installation accessories such as to conceal or inuence

the magnetic/electromagnetic detection of the metal detectors and/or other electronic system control and management appliances.

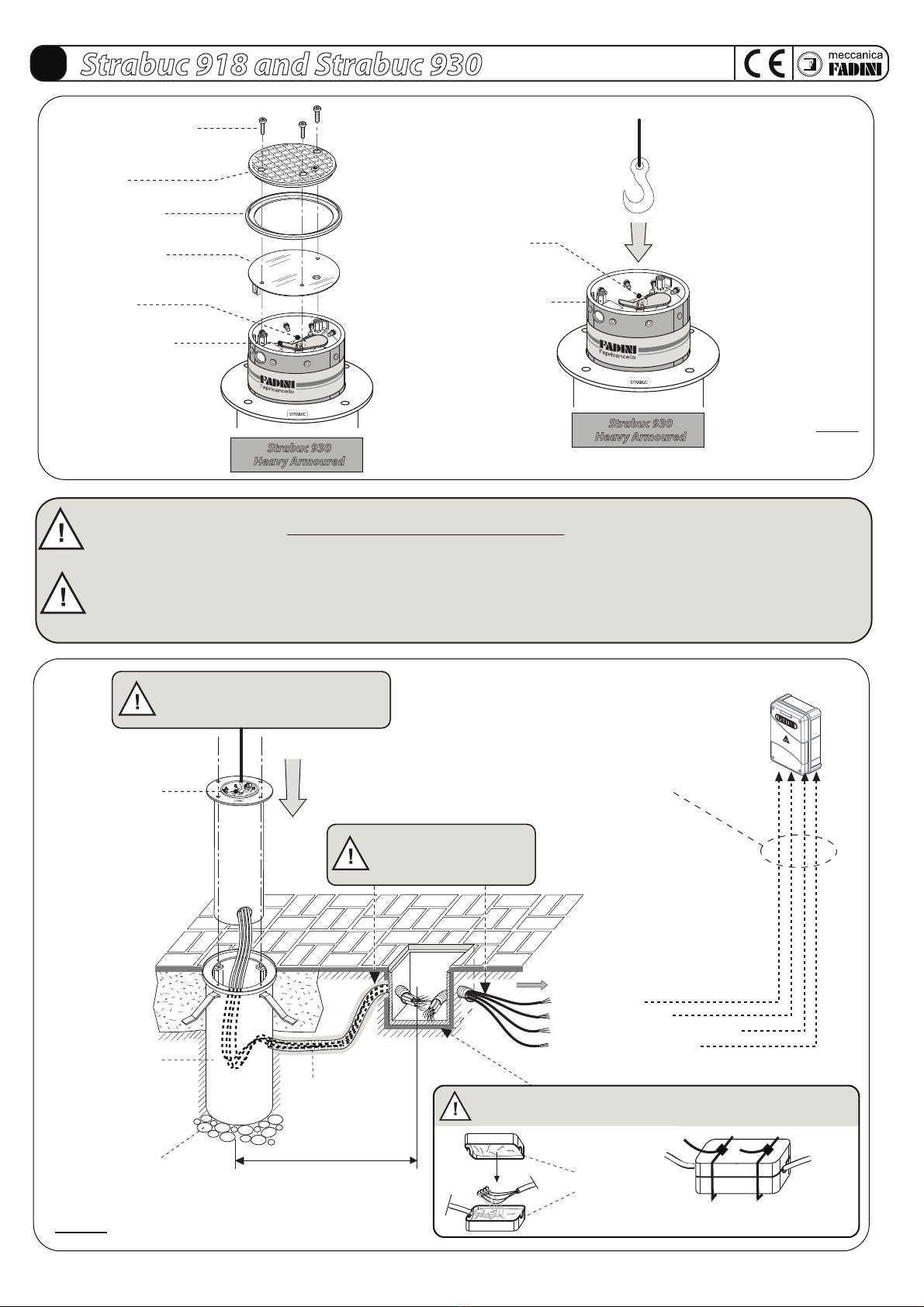

- To check that the mains supply and voltage to the electric motor is 230 V at 50 Hz.

- The power supply to the operators are built-in motor must be made using electricity cables with a 1,5 mm² section for a maximum distance of 50 metres.

For distances of over 50 metres, use electric cables with sections suited to the installation.

- Always use the original components indicated by the manufacturer to replace elements or accessories.

- Meccanica Fadini declines all responsibility for improper use not specically indicated in this manual and any malfunction deriving from the use of materials or

accessories other than those indicated by the manufacturer.

- The manufacturer reserves the right to make changes to this manual without giving notice.

GB Strabuc 918 and Strabuc 930

The manufacturer, Meccanica Fadini, is not responsible for non-observance of good

installation practice and applications not indicated in this manual.

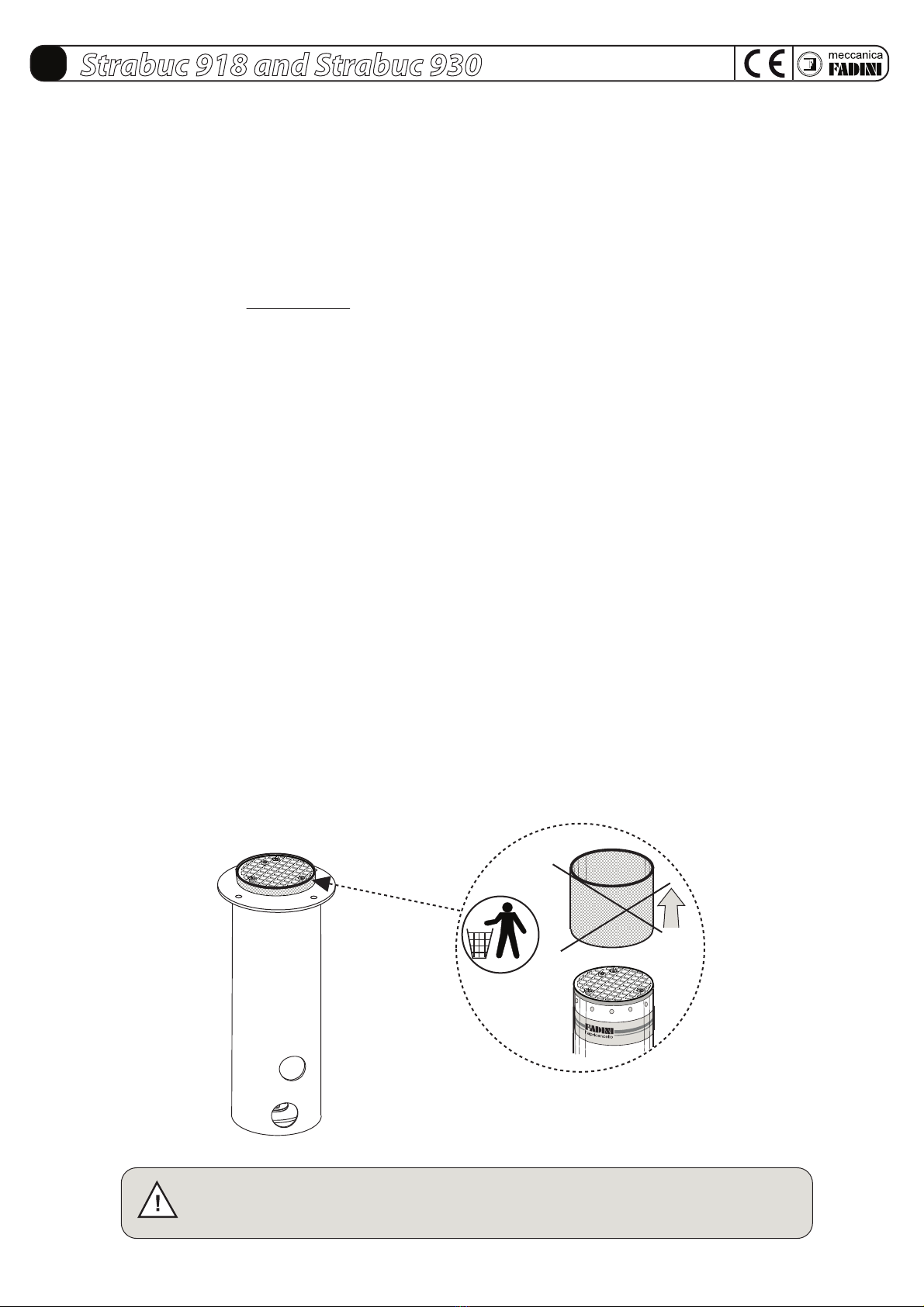

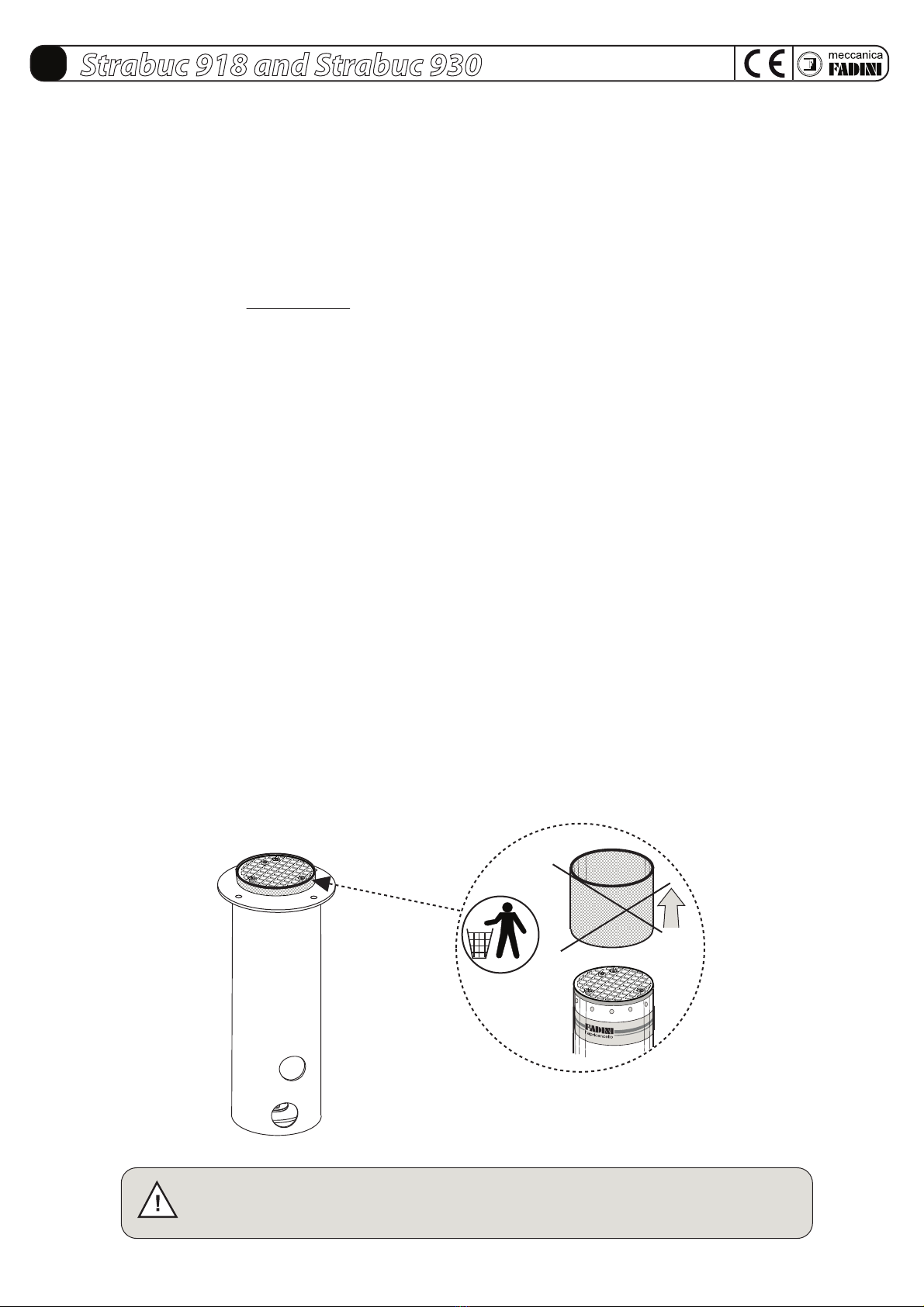

When the post is rst made to rise,

remove the rubber protection band

that is tted for

transport reasons.