Robert Sorby ProEdge User manual

THE ULTIMATE SHARPENING SYSTEM

INSTRUCTION MANUAL

The Robert Sorby ProEdge Sharpening System

Thank you for purchasing the Robert Sorby ProEdge sharpening system, it has been

designed using hundreds of years of tool manufacturing experience.

The simple set-up and operation of the ProEdge makes sharpening tools a pleasure and

gives the woodworker great satisfaction in achieving a perfect sharp edge every time.

EC DECLARATION OF CONFORMITY

Business Name & Address Of Responsible Person:

- Robert Sorby, Athol Road, Sheeld, S8 OPA England.

Capacity /Role of Responsible Person:

- Manufacturer

Description of Machine:

- ProEdge Sharpening System

Serial Number:

- Axed to machine and box lid

Relevant EC Directives & Regulations Complied with for Above Machine:

- Supply of Machinery (Safety) Regulations 1992 - Amended 1994: Machinery Directive 98/37 /EEC

Relevant EC Transposed Harmonised Standards

- BS.EN 1050; BS.EN 292; (ISO14121); BS.EN 953;

National Standards Used:

- BS.EN 5304 - Safety of Machinery

DECLARATION:

I certify that on completion of manufacture of the machine detailed above that a full conformity

assessment has been completed and relevant essential health & safety requirements complied with:

Name: Ian Finkill

Status within Company: General Manager

Signature:

2

3

WARNING

THESE INSTRUCTIONS MUST BE READ AND UNDERSTOOD

BEFORE OPERATING THE MACHINE

GROUNDING INSTRUCTIONS

All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding provides a path of least resistance

for electric current to reduce the risk of electric shock. This tool is equipped with an electric

cord having an equipment grounding conductor and a grounding plug. The plug must

be plugged into matching outlet that is properly installed and grounded in accordance

with all local codes and ordinances. Do not modify the plug provided - if it will not t the

outlet, have the proper outlet installed by a qualied electrician. Improper connection of

the equipment-grounding conductor can result in a risk of electric shock. The conductor

with insulation having an outer surface that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or replacement of the electric cord or plug is

necessary, do not connect the equipment grounding conductor to a live terminal.

Check with a qualied electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles

that accept the tool’s plug. Repair or replace damaged or worn cord immediately.

4

WARNING

• RISKOFINJURYDUETOACCIDENTALSTARTING-Do not use in an area where children may

be present

• KEEPGUARDSINPLACEand in working order

•REMOVEADJUSTINGKEYSANDWRENCHES.Form habit of checking to see that keys and

wrenches are removed from tool before turning it on

• KEEPWORKAREACLEAN.Cluttered areas and benches invite accidents

• DON’TUSEINDANGEROUSENVIRONMENT.Don’t use power tools in damp or wet locations,

or expose them to rain. Keep work area well lit

• KEEPCHILDRENAWAY.All visitors should be kept a safe distance from work area

• MAKEWORKSHOPCHILDPROOFwith padlocks, master switches, or by removing starter

keys

• DON’TFORCETOOL.It will do the job better and safer at the rate for which it was designed

•USERIGHTTOOL.Don’t force tool or attachment to do a job for which it was not designed

• USEPROPEREXTENSIONCORD. Make sure your extension cord is in good condition. When

using an extension cord, be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating

*Table 1 shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt,

use the next heavier gauge. The smaller the gauge number the heavier the cord.

WEARPROPERAPPAREL. Do not wear loose clothing, necktie’s, rings, bracelets, or other jewellery which

may get caught in moving parts. Non-slip footwear is recommended. Wear protective hair covering to

contain hair.

ALWAYSUSESAFETYGLASSES. Also use face or dust mask if cutting operation is dusty. Everyday

eyeglasses only have impact resistant lenses, they are NOT safety glasses.

Table 1 - Minimum gauge forcord

Amphere Rating

More Than Not More Than

Volts Total length of cord in feet

AWG

Not Recommended

120 V

240 V

25 ft.

50 ft.

50 ft.

100 ft.

100 ft.

200 ft.

150 ft.

300 ft.

0

6

10

12

6

10

12

16

18

18

16

14

16

16

16

12

16

14

14

14

12

12

5

WARNING

• SECUREWORK.Use clamps or a vice to hold work when practical. It’s safer than using

your hand and it frees both hands to operate tool

• DON’TOVERREACH.Keep proper footing and balance at all times

• MAINTAINTOOLSWITHCARE.Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories

• DISCONNECTTOOLSbefore servicing: when changing accessories and belts

• REDUCETHERISKOFUNINTENTIONALSTARTING.Make sure switch is in o

position before plugging in

• USERECOMMENDEDACCESSORIES.Consult the owner’s manual for recommended

accessories. The use of improper accessories may cause risk of injury to persons

• NEVERSTANDONTOOL.Serious injury could occur if tipped or if the cutting tool is

unintentionally contacted

• CHECKDAMAGEDPARTS.Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and

perform its intended function - check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that may aect its

operation. A guard or other art that is damaged should be properly repaired or replaced

• DIRECTIONOFFEED.Feed work into a blade or cutter against the direction of rotation

of the blade or cutter only

• NEVERLEAVETOOLRUNNINGUNATTENDED.TURNPOWEROFF.Don’t leave tool

until it comes to a complete stop

6

RESIDUAL HAZARDS

1.Frictionandabrasionarisingfromcontactwiththebeltsurfaceatthepointwhereitis

exposedforuse.

Precaution - no further enclosure is deemed to be practicable and therefore the appropriate

guides should be used when completing the sharpening operation and, furthermore, care

should be exercised by adopting safe working practice.

2.Trappointin-betweenthebeltandpulley.

Precaution - x side guard in position on delivery. This must always be replaced prior to use

whenever belts are changed.

During the belt changing operation, the machine should be disconnected from the electrical

supply with full isolation being retained until the guard is axed.

The moulded plastic retaining nuts must always be replaced prior to usage.

3.Machinesmovingortopplingoverduringusage.

Precaution - secure the machine to the workbench utilising the four holes in the base plate.

4.Ejectionhazards.Smallparticlesmaybeejectedfromthebeltandthetoolduringthe

sharpeningoperationorintheunlikelyeventofthebeltbreakingduringusage.

Precaution - wear suitable approved eye protection during usage.

5.Entanglementwithbungandpolishingattachments.Precaution-removejewelleryand

watchesandavoidlooseclothing.

6.Inhalationofdustarisingfromtheabrasivecoatingonthebeltandthetoolbeingsharpened.

Precautions - the normal usage of the ProEdge is such that it is highly unlikely that the dust

hazard would become a health risk. Not withstanding this, repeated and consistent use may

lead to signicant volumes of dust arising and it is therefore recommended that for high levels

of usage, the machines should be connected to an appropriate local exhaust ventilation system

(LEV) via the port at the bottom of the existing enclosure guard. Should the machine not be

tted to LEV, an appropriate cover plate should be tted over the aperture. Suitable EC

approved (or equivalent) respiratory protection (dust mask) should be worn when grinding

tools.

7.Manualhandling-eachProEdgeweighsapproximately31lbs(14kg).

Precaution-Careshouldbeexercisedwhenlifting.

7

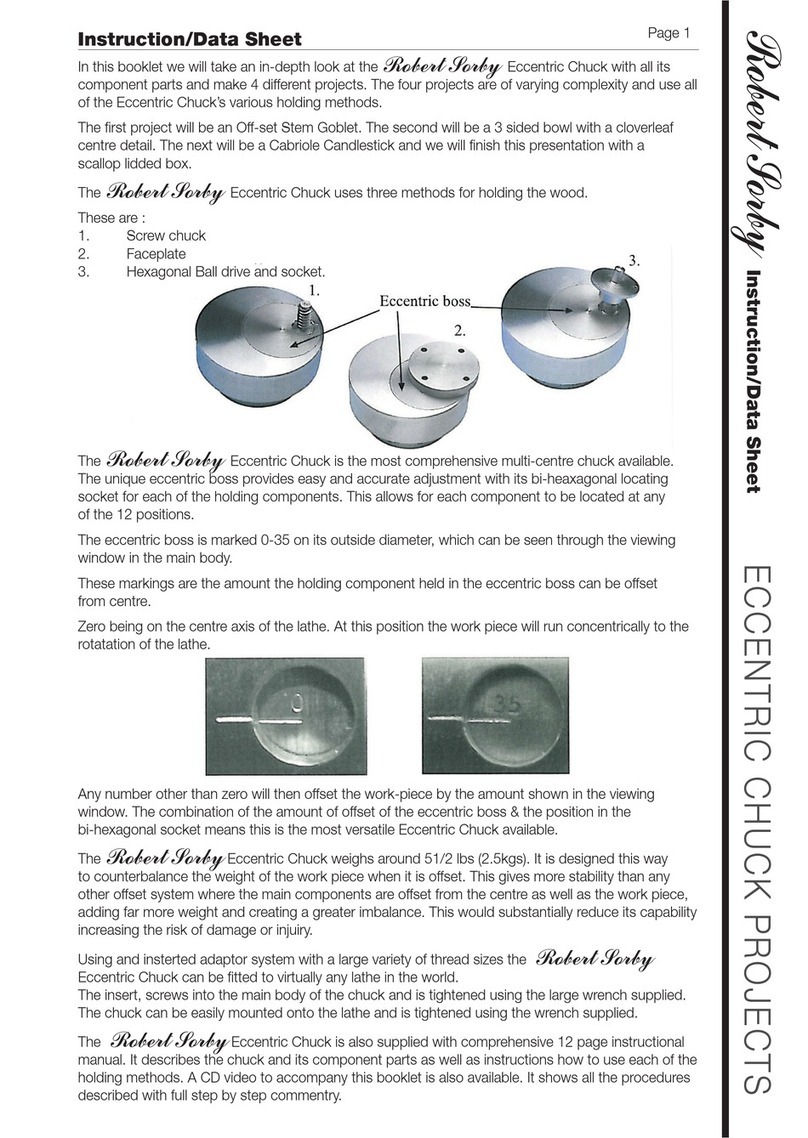

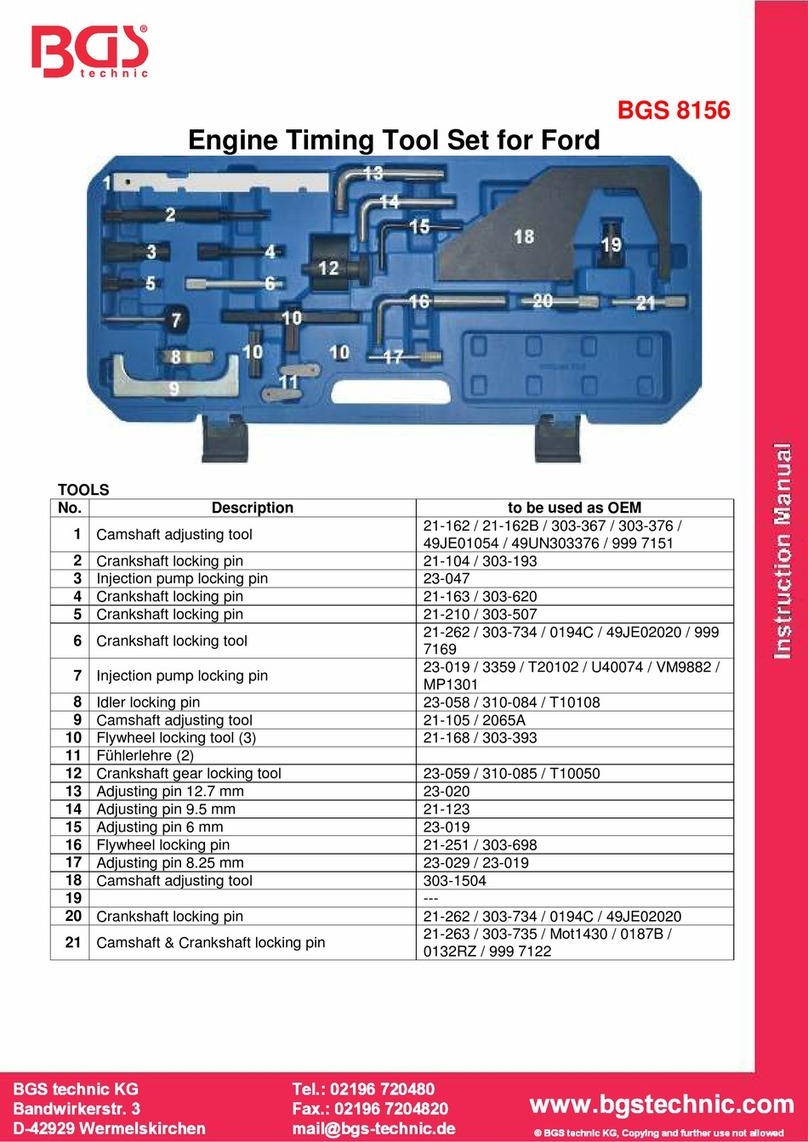

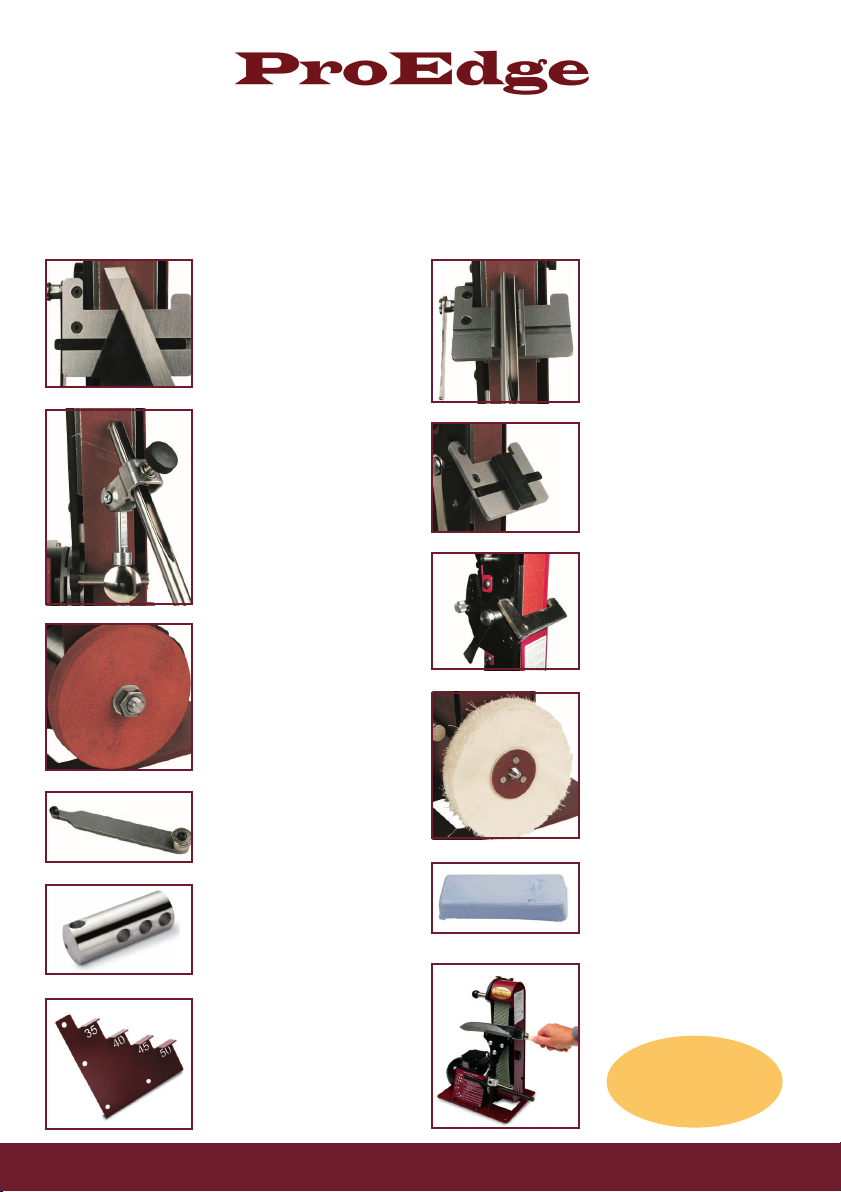

Angle setter

Angle selection pin

ASharpening belt

release lever

Belt tension spring

Belt tracking spindle

shaft and collar

B

Technical Details

Motor:1/2hpBeltWidth:2”BeltSpeed1400ft(440m)perminutetoachievethebestresultsfrom

yoursystem,pleasefamiliariseyourselfwithallofitspartsandaccessories.

Accessory

attachment hub

(Drive pulley)

Platform locking lever

On/O switch

Angle setter

information guide

Fingernail boss bar

Large tool platform

Jig location slot

Abrasive sharpening belt

Belt

assembly

swivel

screws

A

B

C

C

8

Accessories

A full list of all the accessories and sharpening belts is on the back page of this booklet. All the accessories

are available from Robert Sorby dealers. Those marked* are included in the ProEdge Plus.

Skew Chisel Jig*

Create the perfect bevel and

cutting edge on any skew chisel

Fingernail Prole Arm*

Maintain the desired ngernail

prole on any spindle & bowl

gouge from 1/4” (6mm) -

3/4” (19mm)

Honing Wheel & Arbor

Fixed to the accessory

attachment hub using the arbor.

The rubberised honing wheel can

be shaped to suit any tool

Cutter Holder

A multitude of cutters can be

sharpened by using this cutter

holder

Long Grind Jig

Allows 3 dierent types of prole

on bowl and spindle gouges-

ngernail, long and extra long

ProSet

Enables exact bevel angles

to be set

Standard Prole Gouge Jig*

Any standard prole gouge can

be sharpened quickly and easily

using this v-block skew chisel

Woodworking Chisel Jig

A simple way to achieve any

primary and secondary bevel

angles on all woodworking

chisels and plane irons

Short Tool Platform

This tool platform allows

tools with short blades to be

sharpened

Bung Mop & Pigtail Mandrel

Screwed onto the pigtail

mandrel, the loose leaf cotton

mop will produce a highly

polished nish on any tool when

used in conjunction with the

honing paste

Honing Paste

Used in conjunction with the

bung mop the honing paste

produces a very high polish on

any too

Knife Sharpening Jig

for sharpening carving, hunting,

pocket and kitchen knives

Full details of the sharpening

belts available on

page 12

Belts!

9

Preparingforuse

Sharpening Belt Alignment

Place the front edge of the base plate so that it is level with the leading edge of the worktop or

bench. Screw or bolt the base plate in this position.

Ensure the on/o switch is in the OFF position and plug into a standard electric wall socket. Check

the cable is in a safe position and that all moving parts of the machine are clear of any obstruction.

Switch on the power at the wall socket and switch the system on. Before operating the machine

please watch the belt to check for alignment, it has been pre-tracked in the factory but it may have

moved during transit.

Those marked* are included in the ProEdge Plus.

HowtoadjusttheBeltAlignment

While the system is running, place the two tracking adjustment bars into the holes in the spindle shaft

and the locking collar. Holdtheshaftstationaryandslackenthelockingcollar(anti-clockwise)

priortomovingthetrackingshaft. Small adjustments of the tracking shaft will move the belt to the

left and right on the pulley.

Please ensure the belt is tracked to the right hand edge of the backplate.

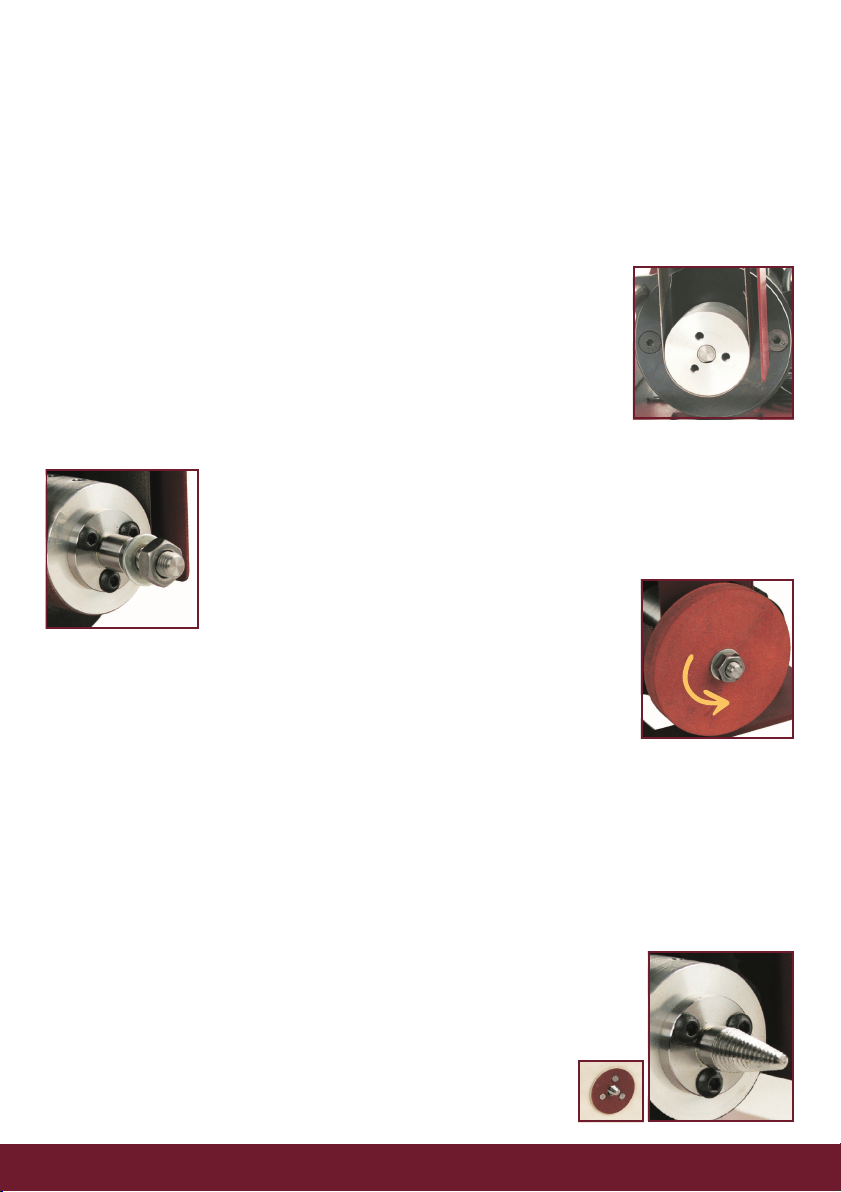

Tilting the Sharpening Belt Assembly

To assist in sharpening tools the ProEdge has a very useful feature in that the sharpening

belt assembly can be angled backwards to allow for a much more comfortable position when

sharpening at shallow angles.

- This is done by loosening the two screws by a quarter of a turn, next to the drive pulley and gently

moving the belt assembly to your desired angle

- When the belt assembly is tilted backwards the rear screw is accessed via the access slot in the

side guard as shown below

- When the desired angle is achieved, re-tighten the screws (nger tight) to secure the belt assembly

in place

Front screw

just below the

ngernail boss

bar - 1/4 of a

turn

Rear screw

- 1/4 of a turn

Access

slot

10

Using the Angle Setter

The unique Angle Setter allows the large tool platform to be set at any angle.

If a pre-set angle is required, for example 45

degrees (45˚), place the captive spanner over

the hexagonal locking bolt and loosen. Then

loosen the angle selection pin and move the

arm so that the selection pin locates into the

4th hole down from the top, as shown on the

Angle Setter guide

If a non pre-set angle is required, wind the

angle location pin back so that it is clear of the

location holes. Then position the tool platform

where it is required and tighten the locking

lever

The angle

selection pin in

the 4th hole from

the top, setting the

tool platform at

45 degrees (45˚)

The Angle Setter

with the angle

selection pin in the

top hole, which sets

the tool platform at

15 degrees (15˚)

11

12

Changing a Sharpening Belt

Firstly ensure the electric wall socket is switched o and remove the plug to ensure personal

safety.

Remove the two Robert Sorby t-bar screws from the belt assembly and remove the guard.

Lift the belt release lever and pull it towards the front of the system.

The belt is now free and can be removed by sliding it o the top and

bottom pulleys.

The new belt can now be tted by sliding it over the two pulleys at

the same time, ensuring it is lined up in the centre of both pulleys.

Lift the release lever to apply the tension on the belt and return it to

its original position at the rear of the system. Replace the side guard

and secure in place with the two t-bar screws.

Return the electric plug into the wall socket and switch on. Now switch on the ProEdge and check

for the belt alignment. If it is not correct, adjust as described on page 9.

Choosing the Correct Sharpening Belt

Abrasive belts cut cleaner and more eciently than a grinding wheel and will produce a much

cleaner cutting edge.

There are three options available to use with the ProEdge system.

1.AluminiumOxide60,120*&240*grit: Ideal for sharpening woodworking

chisels, carving tools and pirons.

2.Zirconium60*&120grit: Designed for HSS tools,drill and router bits.

3.Ceramic60&120grit:Very hard-wearing and long-lasting

suitable for heavy material removal.

4.Trizact600,1200,3000grit.Enables knives to be sharpened to a

razor edge of 2 microns - equivalent to a disposable razor blade.

5.Thediamondabrasivegrainachievesoutstandingresultson

tungsten carbide, ceramic, glass and natural stone as well as

manyotherresistantmaterials. Full details of accessory parts

and sharpening belts, please

see back page

Accessories!

13

UsingtheAccessories

The relevant jigs t into the slot of the tool platform. This allows the jig to slide from side to side

so that all of the sharpening belt can be utilised.

The accessories marked * are included in the ProEdge Plus.

Sharpening a Skew Chisel

The skew chisel needs to be extremely sharp to work correctly and safely,

using the skew jig* makes this achievable in seconds.

Tilt the belt assembly backwards as instructed on page 10.

Now set the angle setter (page 11) to the top hole (15 degrees) or the

desired angle and re-tighten using the locking lever.

The tool platform is now set to the desired angle and the

skew jig can be placed as shown.

Ensure there is nothing to obstruct the jig from sliding

sideways.

Switch on the ProEdge and ensure the belt is aligned

correctly. If it is not then refer to page 9 ‘Abrasive belt

alignment’.

If the belt is correctly aligned, place the skew onto the jig as shown and slowly push the skew chisel

forward so that it makes contact with the belt.

Hold the skew chisel against the jig to maintain the correct cutting angle and slowly slide the jig and

skew chisel side to side moving across the width of the belt.

When the rst side has

been sharpened turn the

skew over and place it

against the other side of

the jig and continue as

before, until the tool is

razor sharp.

14

SharpeningFingernailProleBowl&SpindleGouges

Sharpening a ngernail prole bowl or spindle gouge can be one of the most dicult jobs for

any woodturner.

The ngernail prole arm* will produce a ngernail prole on any spindle or bowl gouge from a

1/4” (6mm) to 3/4” (19mm) and it allows for any combination of bevel angle and wing sweep to be

readily achieved.

Slide the boss over the ngernail boss bar and place the arm into the

location hole. The arm is factory set at 120 degrees (120˚) to give a normal

ngernail prole.

To produce a ngernail prole, slide the gouge

into the clamp until the bevel is at against

the abrasive belt. Tighten the clamp screw to

hold the gouge in place and allow the gouge to

move away from the belt prior to switching on

the ProEdge.

If a dierent bevel angle is required it is just a matter of sliding the tool

further through the clamp and more material will be taken from the heel

of the tool making the bevel angle shallower. If a steeper bevel angle is

required then the tool needs to be drawn back in the clamp so that more

material is removed from the nose.

When the correct angle has been established, switch on the system and

move the gouge forward so that the right wing touches the abrasive belt.

With a small amount of pressure allow the gouge to roll with the arm to

produce the ngernail prole with a perfect cutting edge.

The sensibly priced ProSet enables exact

repeatability of angles. See page 19

Useful tip !

Using the LongGrindJig on the ngernail proler

allows for three dierent types of prole.

See page 18

Useful tip !

SharpeningStandardProleGouges

Used in conjunction with the very ne abrasive sharpening belts, the woodworking chisel jig

will give a perfect cutting edge on any woodworking chisel and plane iron.

The Angle Setter has all the recommended bevel angles, depending

on the wood being used, for woodworking chisels such as bevel edge,

paring and framing chisels .

Ensure that the desired sharpening belt is tted, the angle setter is set

to the required angle and tighten the

locking bolt. Check that the slot in

the tool rest is clean and place the key of the straight edge jig

into it. Switch on the ProEdge and carefully place the tool to be

sharpened against the guide bar of the jig.

15

SharpeningStandardProleGouges

Keeping a gouge in a consistent position whilst maintaining the required bevel angle takes

many hours of practice with a lot of frustration along the way.

The Standard Prole gouge jig* allows the gouge to sit in the same

position and allows it to roll in a constant axis giving a single faced

bevel. Set the angle setter to the required pre-set or preferred angle

and lock into place with the locking lever.

Sit the locating key of the block into the slot in the tool platform.

Switch on the ProEdge and gently place the gouge into the

v-shape of the block. Push the tool up against the abrasive belt

and slowly roll it from one side to the other.

Carefully push the tool forward until the bevel makes contact with

the sharpening belt. Hold the blade against the jig and slowly slide

it from side to side.

16

Sharpening Cutters & Tips

To sharpen a tool cutter is normally done using a diamond le or honing stone across the top

face. This is a simple and convenient way to maintain a good cutting edge while keeping the

cutter attached to its respective tool.

Using the ProEdge and the cutter holder, allows the cutter to be

sharpened, giving a consistent crisp edge whilst maintaining the

original shape of the cutter. It also can be used to re-prole cutters

and tips to a preferred shape.

Sharpening Cutters using the Cutter Holder

Lay the cutter to be sharpened at onto the top face of the holder or into the

clamp and secure in place with the screw. Set the angle location pin on the Angle

Setter to the desired position and tighten the tool platform locking lever. Slowly

push the cutting edge up to the belt and carefully follow the prole of the cutter

until the desired edge is achieved.

Using the Clamp

Place the cutter into the clamp and secure by tightening the screw. Set the Angle Selection pin into the

second from last hole at the bottom which will give 80 degrees (80˚) and tighten the platform locking

lever to secure. Switch on the ProEdge and lay the cutter holder at onto the platform and slowly push

the cutting edge up to the abrasive belt and carefully follow the prole of the cutter.

Sharpening Small & Short Bladed Tools with the Short Tool Platform

The Short Tool Platform allows for small tools like the micro range and short bladed tools such as

many of the carving tools to be sharpened on the ProEdge.

To use the Short Tool Platform the original Tool Platform must be removed by completely unscrewing

the locking lever and screw. Now place the locking lever and screw into the hole in the arm of the Short

Platform Tool and tighten to hold the platform in place. Also unscrew the locating pin from the original

arm and screw it into the hole in the Short Tool Platform arm to use the angle setter.

The Short Tool Platform can now be adjusted to the desired angle in the same way as the standard tool

platform.

At one end of the cutter holder there is a screw in a nger shape to allow dierent cutters to be held and

the nger shape allows for all round access. In the other end is a clamp to hold cutters from the Robert

Sorby Multi-tipped Hollowing tool (RS200KT) and the Hollowmaster(RS230KT).

17

HONING TOOLS

SAFETY - The abrasive belt should be removed before using the honing wheel to reduce the

number of moving parts. Ensure the electric wall socket is switched o to ensure personal safety.

Ideal for honing the utes of carving chisels and other gouges this rubberised abrasive wheel

can be shaped to suit the tool to be sharpened.

Fitting the arbour and wheel

Undo and remove the two t-bar screws and remove the side guard from the

belt assembly then remove the belt as described on page 12.

Place the arbour against the accessory hub and secure with the three screws.

Remove the nut, place the wheel over the arbour and replace the nut securing

the wheel up to the shoulder.

UsingtheHoningWheel

The outside face and the outer diameter of the wheel can be used to achieve

the high polish that is required. As the wheel is manufactured in a rubber

compound it is easy to shape the edge using a sharp tool or abrasive paper

such as the belts from the ProEdge. This is ideal for honing the utes of gouges.

When sharpening tools on the outside diameter ensure

that the cutting edge is facing away from the direction of

rotation so it is recommended that the tool is underneath

the wheel. When using the face of the wheel to at hone the bevel of any tool

always use the bottom portion to avoid the tool cutting edge digging into the

wheel.

PolishingToolsandWoodenProjects

SAFETY - The abrasive belt should be removed (see page 12) before using the bung mop to reduce

moving parts. Ensure the electric wall socket is switched o and the plug is removed to ensure

personal safety. Please remove the cotton bung mop when using the abrasive belt due to the

potential re risk from sparks.

Fitting the Pigtail Mandrel and Mop

Unscrew and remove the two t-bar screws and remove the side guard from the

belt assembly, then remove the belt as described on page 12. Place the mandrel

against the accessory hub and secure with the three screws. The mop has a

thick leather washer on one side and a bre washer on the other holding the

loose leaves together.

Screw the leather washer side onto the mandrel to ensure a good tight t.

18

FittingthePigtailMandrel&Mop(continued)

The blue honing paste contains a variety of materials within it and is specically designed to give

a highly polished cutting edge to carbon and High Speed Steel tools. When applying the honing or

other polishing compound and also when using the mop, always use the bottom portion of it, so

that the direction of rotation is away from you.

Apply the bung paste little and often.

Replace the electric plug into the wall socket,

switch on the power and switch on the ProEdge.

Apply a small amount of honing paste to the mop as mentioned above, now

the tool or project can be polished. Maintaining a good hold of the tool,

apply a light pressure onto the mop with the tool, so that the mop does not

displace too much and gently move around the mop to ensure the desired eect.

TheRobertSorbyKnifeSharpeningJig

The Robert Sorby Knife Sharpening Jig will enable the sharpening of carving, hunting, pocket

and everyday kitchen knives.

There are two models available each consisting of a new back

plate with a raised wear plattern attached, a universal arm and a

choice of either a small or a large knife holder. The small one will

hold knives upto 8” and the large will hold blades over 8”. A set

of instructions is also included. The jig can be easily tted to the

ProEdge in a matter of minutes and the only equipment needed is

a 13mm wrench.

The versatility of the two dierent knife holders means that any

type of knife can be brought back into life quickly and easily using

this system.

Once the blade is clamped into the holder the knife is gently drawn across the surface of the

abrasive belt following the desired bevel angle.

The knife holders are interchangeable and are available individually.

Using the long grind jig on the ngernail proler allows for three dierent

types of prole to be produced on bowl and spindle gouges. It will produce

a ngernail prole, a long grind and an extra long grind depending on

which location hole the proling arm is placed in. It replaces the standard

boss which is supplied with the ProEdge.

19

WoodturningToolBevel&ClearanceAngles

The diagrams on this page show details of the angles and proles supplied on Robert Sorby

tools. The images are broken into four sections from left to right.

1.Ageneralview

2.Anendviewshowingtheactualcuttingedgeprole

3.Atopviewshowingtheshapeofthecuttingedgeasseenwhenusingthetool,togetherwithanyrelevant

proleangle

4.Asideviewwiththerecommendedbevelorclearanceangledependingonthetypeoftoolbeingsharpened.

WoodworkingChisel&PlaneIronBevelAngles

The diagrams below show all the views as described above but with the addition of the two

showing the primary and secondary bevel angles depending on the type of wood to be worked.

Please refer to the angle setter information guide on the front of the system for more recommended bevel angles.

Achieving the exact bevel angle on any ngernail or long grind gouge has

never been easier than with the ProSet.

By placing the gouge into the clamp of the prole arm and then extending

the gouge upto the required stop and locking it into place the turner will

be able to obtain precise and repeatable bevel angles.

Parts List

The ProEdge is just one of many innovative ideas from Robert Sorby.

For all the latest tools and products as well as a large selection of useful and informative video clips

and information on demonstrations, log on to our website:

www.robert-sorby.co.uk

For more details on additional accessories as well as replacement and additional sharpening belts, contact your local stockist or Robert Sorby.

RobertSorbyLtd,AtholRoad,Sheeld,S80PA,England.

Tel:+44(0)1142250700Fax:+44(0)1142250710

Email:sales@robert-sorby.co.uk

RegisteredinEngland:CompanyNo3464018,Registeredoce:AtlasWay,AtlasNorth,Sheeld,S47QQVATNo.GB172401984

Allsizesanddimensionsstatedarenominal.Itisourpolicytocontinuouslyimproveproductsandhencewereservetheright

tochangedesignswithoutpriornotice.E&OE

Jigs&Accessories

Description

Skew Jig

Fingernail Proler

Standard Gouge Jig

Woodworking Chisel Jig

Woodworkers Square Guide

Pigtail Madrel

Bung Mop

Wheel Arbor

Honing Wheel

Cutter Holder

Honing Paste

Short Tool Platform

Knife Sharpening Jig - Small

Knife Sharpening Jig - Large

Knife Holder - Small

Knife Holder - Large

Long Grind Jig

ProSet

Product Code

PESKEW

446/447UPG

PEVB

PESQ

PESQW

PEPIG

PEMOP

PEARBOR

PEBOND

472

475

PESPC

PEKJIGS

PEKJIGL

PEKHS

PEKHL

PELGJ

PROSET

Sharpening Belts

Description

Aluminium Oxide

Aluminium Oxide

Aluminium Oxide

Zirconium

Zirconium

Ceramic

Ceramic

Trizact

Trizact

Trizact

Diamond

Grit

60

120

240

60

120

60

120

600

1200

3000

200

Product Code

PE60A

PE120A

PE240A

PE60Z

PE120Z

PE60C

PE120C

PE600T

PE1200T

PE3000T

PEDIA

PatentNo.2438962

PROUDLYMADE IN

SHEFFIELD, ENGLAND

This manual suits for next models

20

Table of contents

Other Robert Sorby Tools manuals