Makita DHR182 User manual

Other Makita Tools manuals

Makita

Makita DTM40 User manual

Makita

Makita BV4500-118 User manual

Makita

Makita HR3540C User manual

Makita

Makita BHR242 User manual

Makita

Makita BHR162 User manual

Makita

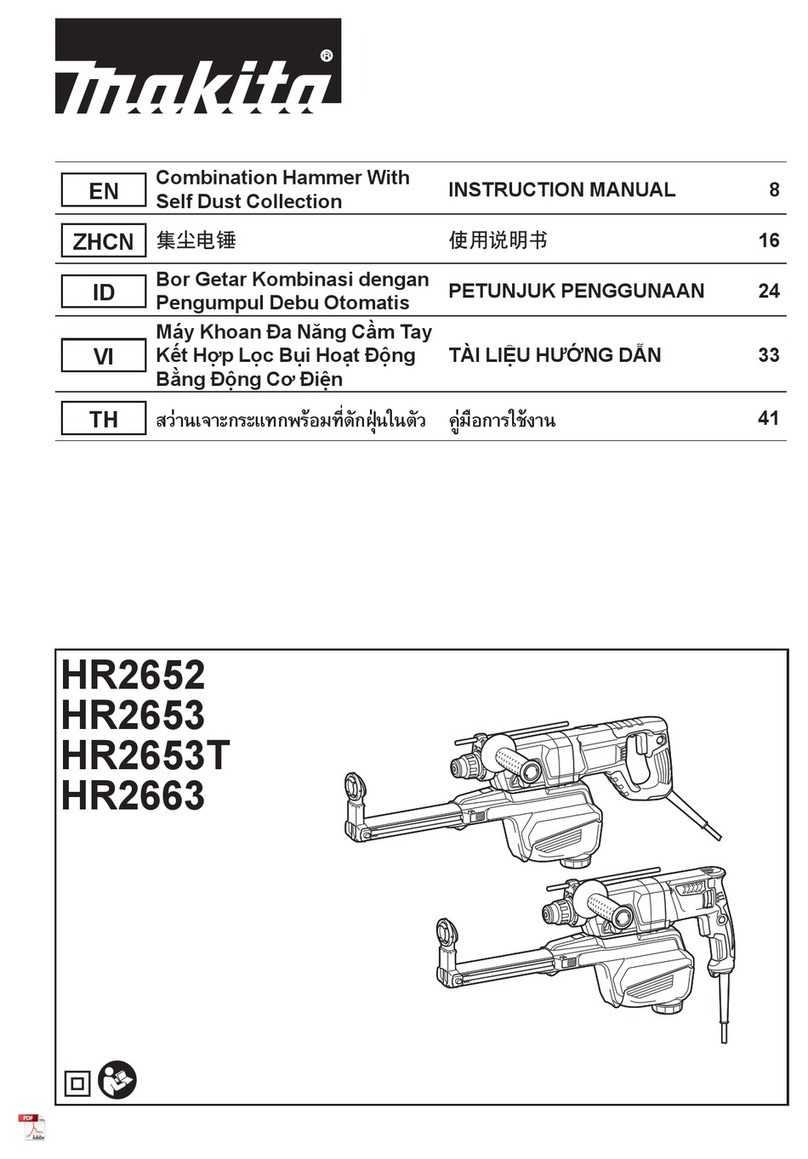

Makita HR2652 User manual

Makita

Makita HR2631FTJ User manual

Makita

Makita DTM40 User manual

Makita

Makita DTM52 User manual

Makita

Makita HR007G User manual

Makita

Makita HR2631F User manual

Makita

Makita HR3540C User manual

Makita

Makita HM1317C User manual

Makita

Makita TM3000C User manual

Makita

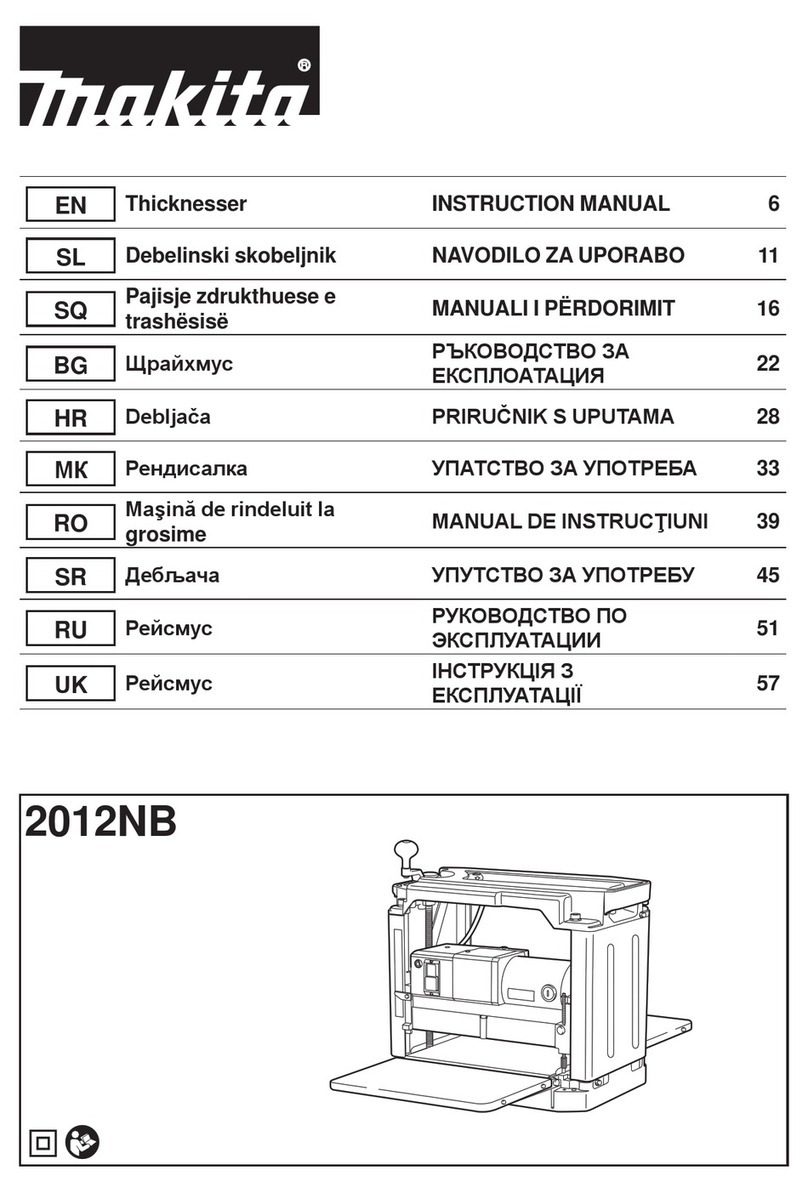

Makita 2012NB User manual

Makita

Makita M2401 User manual

Makita

Makita EY403MP User manual

Makita

Makita UX01GD201 User manual

Makita

Makita DCJ201 User manual

Makita

Makita DTM41 User manual