BGS technic KG

Bandwirkerstr. 3

D-42929 Wermelskirchen

Tel.: 02196 720480

Fax.: 02196 7204820

mail@bgs-technic.de

www.bgstechnic.com

© BGS technic KG, Copying and further use not allowed

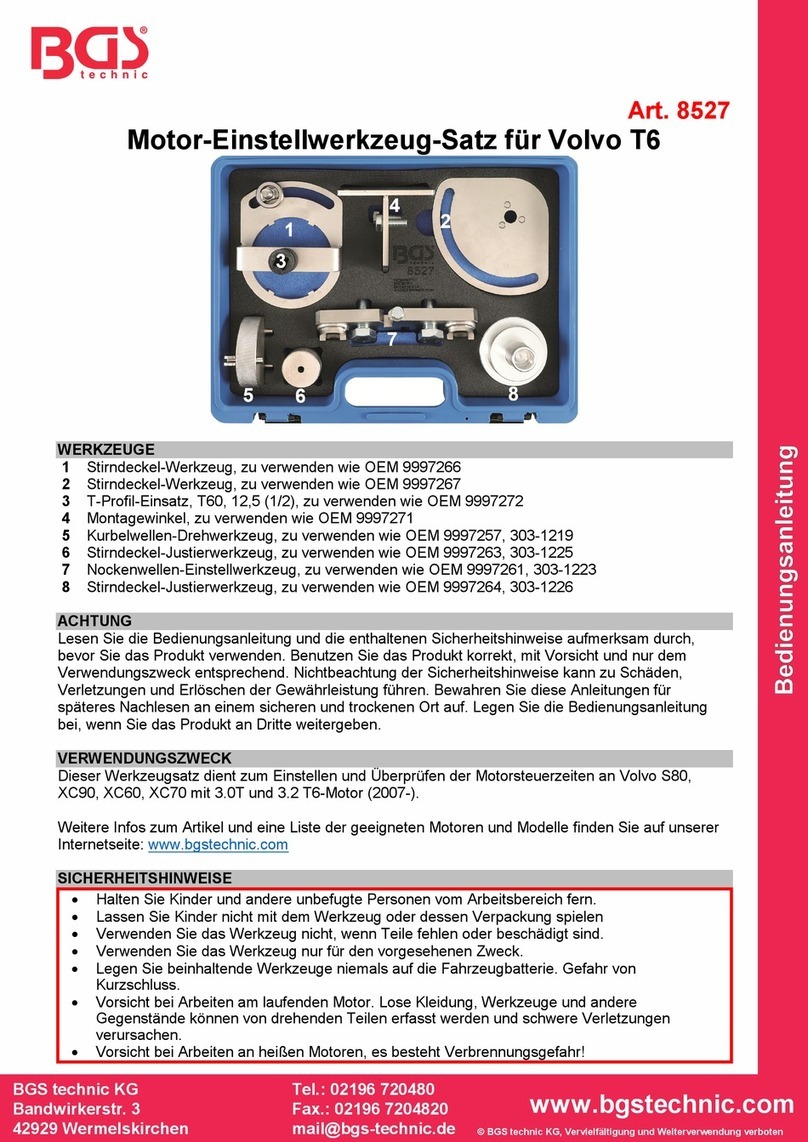

INTENDED USE

This tool set is used for adjusting and checking the engine timing on e.g. following Ford models /

engines.

Fiesta 89

Fiesta 96

Puma

Focus

Escort / Orion

Mondeo 93

Mondeo 98

Mondeo 01

Galaxy I

1.25 L 16V Zetec SE

1.4 L 16V Zetec SE

1.7 L 16V Zetec SE

1.6 L 16 V Zetec SE

1.6 L 16V Zetec

1.8 L 16V Zetec

2.0 L 16V Zetec

1.6 L 16V Zetec E

1.8 L 16V Zetec E

2.0 L 16V Zetec E

1.4 L D

1.6 L TD

1.8 L TD

More information regarding this item and a list of suitable engines and models can be found on our

website: www.bgstechnic.com

SAFETY INFORMATIONS

•Do not use the tool if parts are missing or damaged.

•Use the tool for the intended purpose only.

•Never place the tool on the vehicle battery. There is a risk of a short circuit.

•Be careful when working with the engine running. Loose clothing, tools and other objects can

be caught by rotating parts and cause serious injury.

•Keep children and other unauthorized persons away from the work area.

•Do not allow children to play with the tool or its packaging.

•Be careful when working on hot engines because of the risk of burn injuries.

•If you remove the ignition key before repairing, you can prevent the engine from being started

accidentally and resulting in engine damage.

•This manual serves as a brief guide and does not replace a workshop manual. Always refer to

the vehicle-specific service literature, particularly the technical data such as torque values and

instructions for disassembly/assembly, etc.

•After repair or before starting the engine, turn a minimum of 2 turns by hand and check the

timing again.

•

Turn the engine only in the normal direction of rotation (clockwise unless otherwise specified)