Page3

Section 1. General Specification - DualAir® Unit

1.1 Basic Information

1.1.2 Description

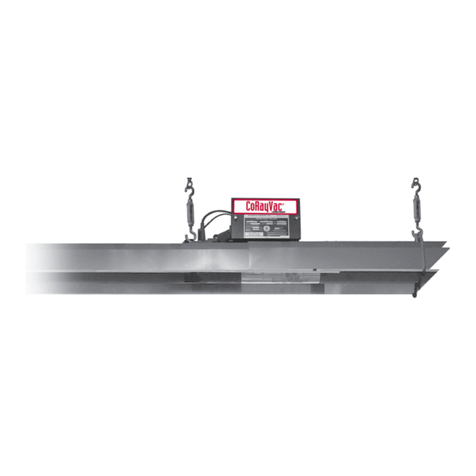

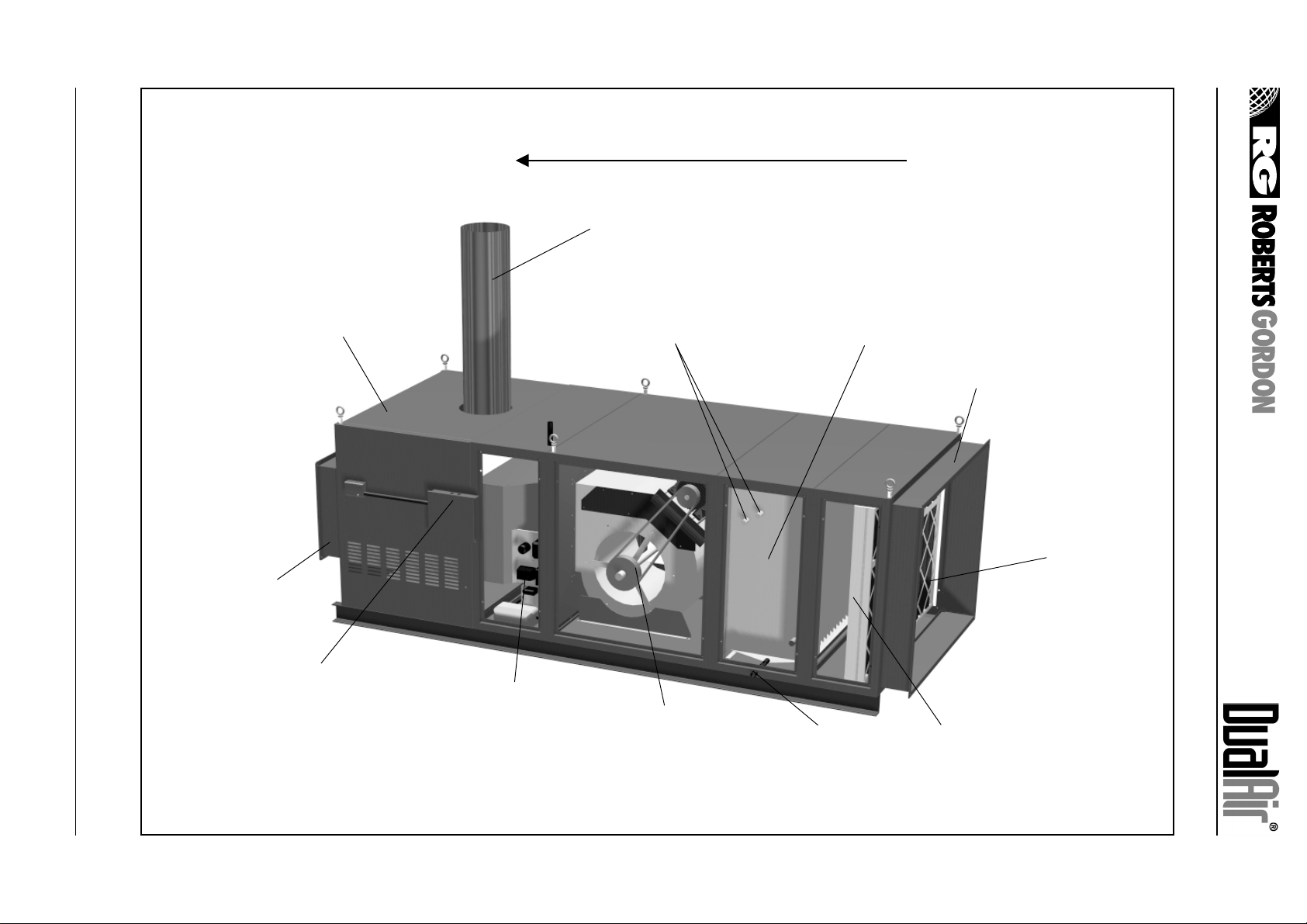

The DualAir® combined heating and cooling unit is formed by four sections combined into a single

unitand deliveredas acomplete assemblyreadyfor installationon site.The DualAir®unit isdesigned

to be installed with the air flow from right to left as shown in Fig 1.1. Units with opposite air flow

direction are available by special order.

The four sections are as follows:-

1.1.3 Gas Fired Heater Section

The heater section is a CUHD/A 300 or the CUHD/A 380 automatic ignition unit heater and contains

the burner controls, the electrical terminal box for the system, the control relays for the operation of

the heater/cooling equipment, and the transition piece between the heater and the fan compartment.

The heater is an open flued gas fired heater of flue type B11 for vertical flue.

The On/Off heaters are Cat II 2H3+ appliances for use with Natural Gas or L.P.G. as stated on the

heater data plate (Modulating and High/Low burners are Cat I2H for use with Natural Gas only), and

are intended for indoor installation only. They must be installed and commissioned in accordance

with local regulations and the requirements of Section 3 of these Instructions.

Apermanent electricalsupply of400 volts50 Hz,threephase andNeutral isrequired forthe operation

of the heater and fan and all models must be earthed. (Note the burner operates on 230v 50 Hz taken

internally from the above supply).

1.1.4 Fan Section

The fan section houses the double-inlet, belt-drive centrifugal blower fan and three phase electric

motor. This section of the cabinet is fully insulated with foil faced glass fibre insulation.

The fan rotation is counter clockwise viewed from the control side as marked on the fan case.

1.1.5 Cooling Coil

DualAir® units can be fitted with either a DX or Chilled Water cooling coil:

1.1.5.1 DX Coil

The DX cooling coil is installed into the DualAir® unit with the two refrigerant circuits sealed ready for

site connection. There are no other refrigerant controls supplied with the coil and all refrigerant pipe-

work and controls must be supplied by the installer to suit the equipment being installed with the

condenser units.

DXcoils aredesignedfor operationat anambienttemperature of28°Cusing R22orR407C refrigerant

evaporating at 6°C.

Theinstallation ofthecooling condensersandtherefrigerantcircuitsmustbe carriedoutin accordance

with the condenser manufacturers instructions.