Robit HYPER 181 User manual

11/03/2020 HYPER 181 – MAINTENANCE, OPERATING AND SERVICE MANUAL

HYPER181

DTH HAMMER

www.robitgroup.com

LIST OF CONTENTS

THE HYPER 181 HAMMER

HAMMER COMPONENTS 2

HAMMER PARTS LIST 3

HAMMER SPECIFICATIONS 4

AIR CONSUMPTION 5

MAINTENANCE OF THE HYPER 181 HAMMER

STRIPPING (DISMANTLING) THE HYPER 181 6

CHECKING FOR WEAR & DAMAGE 7-8

REBUILDING (ASSEMBLY) OF HYPER HAMMERS 9

BUTTON BIT FOOT VALVES DIAMETERS AND PROTRUSION HEIGHTS 10

LUBRICATION

RECOMMENDED LUBRICANTS AND LUBRICATION RATES 11

HAMMER STORAGE

HOW TO STORE YOUR HYPER 181 FOR LONG PERIODS 12

TROUBLE SHOOTING

HAMMER TROUBLE - PROBABLE CAUSE & REMEDY 13

APPENDIX

CHUCK RELEASE WASHERS A

CLAMPING POSITIONS B

The Robit Hyper 181 is a strong and robust tool of a simple and straight forward design to provide

maximum performance within a minimum of maintenance.

The Hyper 181 is designed to operate efficiently at air pressures between 100psi (7bar) and 225psi (15bar).

The Hyper 181 accepts Hyper 181 button bits (N180) as standard. In addition to this the Hyper 181 can

be modified to accept button bits with a Mission Sd18 shank design by simply replacing the chuck, piston

and bit retainers. A QL200 version is also available.

The Hyper 181 hammer is supplied as standard with a check valve arrangement. This is designed to

maintain pressure inside the hammer when the air is switched off and so help prevent contaminated

water from entering the hammer.

The Hyper 181 hammer standard backhead is 85∕8” API reg pin, but alternative thread or hexacon

connections can be supplied on request.

The Hyper 181 hammer is designed to give optimum performance with the minimum consumption of

compressed air. If however, for particular deep hole applications extra flushing air is required, the

hammer can be fitted with a choke system, that can easily be applied to suit your operational

requirements.

This manual is published by and copyright © of Bulroc (UK) Ltd. All Rights Reserved. Always operate your Bulroc

drilling equipment according to the instructions contained within this operating manual. Furthercopies of this manual

can be downloaded from the Bulroc website; www.bulroc.com. For urgent support or sales enquiries, call Bulroc

on +44 (0)1246 544700 or Skype BULROCUKSALES .

WARNING

ALWAYS THINK

SAFETY FIRST!

PISTON

HYPER 181

PISTONPISTON

BACKHEAD PISTON

WEARSLEEVE

BIT

TUBE

HOLDER

CHUCK

BEARING

BACKHEAD

‘O’RING

BREAKOUT

WASHER

SPRING

CHECK

VALVE

VALVE

CHEST

BUFFER

COVER

COMPRESSION

BUFFER

TUBE

BUFFER

CONTROL

TUBE

TUBE

‘O’RING CHUCK

BIT

RETAINING

RING

BREAKOUT

WASHER

2

DRIVE

PLATE

11

3

4

5

7

6

8

11

2

9

11

10

12

13

14

15

16

17

17

1214

15

16

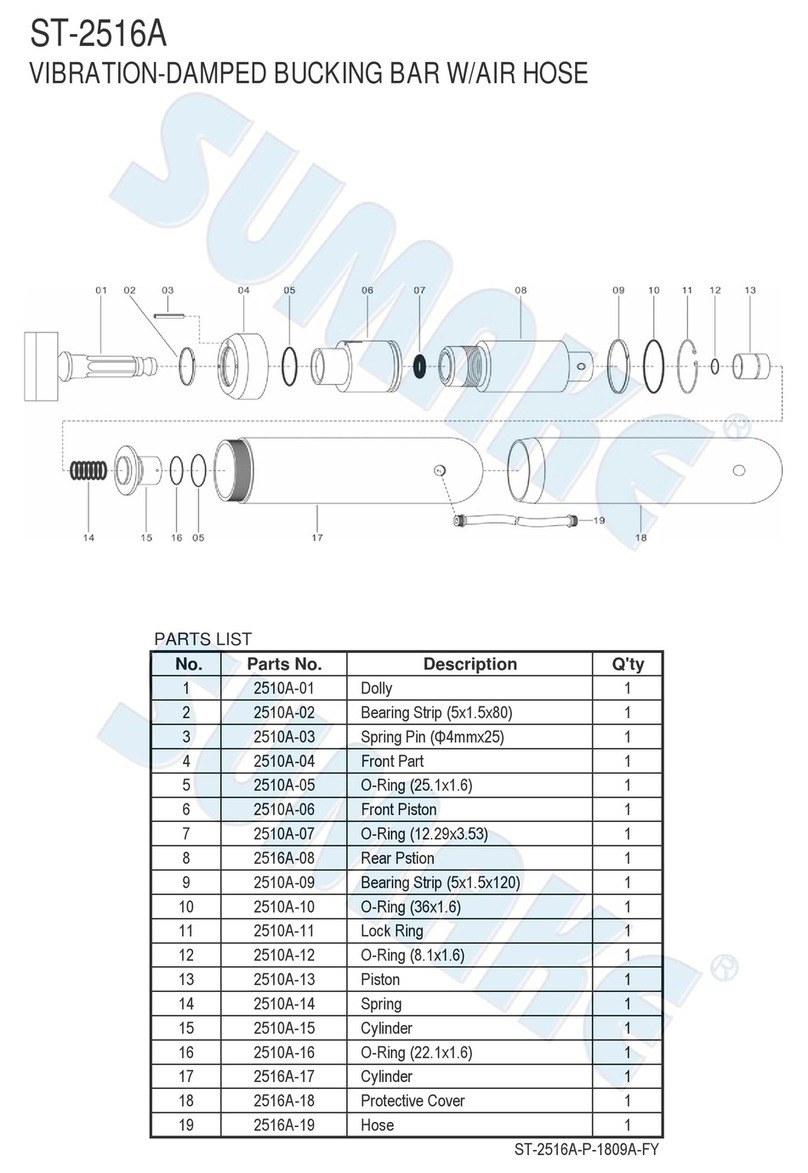

3HAMMER PARTS

Ref Description (N180) Part Number

1Backhead 85∕8” Reg Pin HSH1813882M

2Backhead ‘O’ Ring HSH18114

3Check Valve HSH18108

4Check Valve Spring HSH18110

5Diverter HSH18107

6Compression Buffer HSH18128

7Buffer Cover HSH18173

8Tube Holder HSH18131

9Tube Buffers (2) HSH18129

10 Tube ‘O’ Ring HSH18130A

11 Control Tube HSH18130

12 Piston HSH18103180

13 Wearsleeve HSH18100

14 Bit Retaining Ring HSH18137180

15 Chuck HSH18135180

16 Chuck Bearing HSH18135180BE

17 Breakout Washers HSH18126

Complete Hammer BR181H01

Ref

Description (SD18 Conv)

Part Number

1Backhead 85∕8” Reg Pin HSH1813882M

2Backhead ‘O’ Ring HSH18114

3Check Valve HSH18108

4Check Valve Spring HSH18110

5Diverter HSH18107

6Compression Buffer HSH18128

7Buffer Cover HSH18173

8Tube Holder HSH18131

9Tube Buffers (2) HSH18129

10 Tube ‘O’ Ring HSH18130A

11 Control Tube HSH18130

12 Piston HSH18103096

13 Wearsleeve HSH18100

14 Bit Retaining Ring HSH18137096

15 Chuck HSH18135096

16 Chuck Bearing HSH18135096BE

17 Breakout Washers HSH18126

Complete Hammer BR181H02

LENGTH WITHOUT BIT

OUTSIDE

DIAMETER

HAMMER SPECIFICATIONS

STANDARD

BACKHEAD

CONNECTION

8

¼”API

reg pin

CHUCK

CONNECTION

CONFIGURATION

HYPER 181

(N180) STD

OR Sd18

LENGTH

LESS

BIT

N180

86”

2185mm

OUTSIDE

DIAMETER OF

HAMMER

16”

406mm

OUTSIDE

DIAMETER OF

CHUCK

16”

406mm

BORE

DIAMETER

12.25”

311mm

PISTON

STROKE

5.75”

146mm

PISTON

WEIGHT

730lbs

330kgs

WEARSLEEVE

ACROSS FLATS

SIZE

15.5”

394mm

WEIGHT OF

HAMMER

LESS BIT

3545lbs

1608kgs

58

Specification

SD18

88.60”

2250mm

4

Drill through this face

should extra flushing

be required

Additional Flushing

The Hyper 181 has a control tube with a softened

face which can be easily drilled through to allow for

extra flushing air should this be required.

In certain drilling conditions extra flushing air may be

required to overcome increasing back pressure and

maintain the necessary up hole velocity to ensure

efficient hole cleaning. In such conditions, a small

hole can be drilled into the face of the control tube

which will allow extra live air to be delivered directly

to the bit face. The size of the hole will determine

the extra volume of air delivered to the bit face

depending on the operating pressure.

5AIR CONSUMPTION

PRESSURE (PSI) PRESSURE (BAR) AIR

CONSUMPTION

litres/second

AIR

CONSUMPTION

litres/minute

AIR

CONSUMPTION

cubic metre/min

AIR

CONSUMPTION

cubic feet/minute

100 7513 30806 31 1088

125 9718 43053 43 1520

150 10 943 56595 57 1999

175 12 1189 71317 71 2518

200 14 1452 87133 87 3077

225 15 1733 103971 103 3672

COMPONENT PARTS

1. First remove the chuck assembly. This comprises the button bit,

drive - plates (or drive pins with the SD 18 conversion), chuck release

washer, chuck ‘O’ ring, and bit retainers.

2. With the hammer laid horizontal, unscrew the backhead and

remove it from the wearsleeve. The valve chest along with the check

valve arrangement can now be pulled from the backhead end.

The remaining buffer cover, compression buffer and control tube

assembly can be removed by lifting the chuck end of the wearsleeve

which will allow the piston to push the parts up to the end face, from

where they can be removed by hand.

3. Lifting the Chuck end of the Wearsleeve again will allow the Piston

to slide to the end face from where it can be removed.

Backhead

Backhead ‘O’Ring

Breakout Washer

Check Valve

Check Valve Spring

Valve Chest

Buffer Cover

Check Valve

Compression Buffer

Control Tube

Assembly

Wearsleeve

Assuming both the chuck and the backhead threads

have been loosened either on the drilling rig or by using

a hydraulic splitter, the stripping procedure is as follows

NOTE:- All components must be washed clean and

laid out on a dirt free surface to enable inspection

to take place. The stripping procedure is explained

in the following section,

Note:- On no account should the wearsleeve be

impacted by a hand hammer or splitting be

assisted by use of localised heat: ie. welding/blow

torch, this will invalidate the warranty

Should splitting prove difficult, the breakout

washers can be ground out, taking care not to

deface other pieces of the drill, to relieve

pressure and help splitting,

Wearsleeve

Chuck

0.3” Breakout

Washer

STRIPPING THE HAMMER 6

0.300”

0.740”

Premature wear to internal parts is a result of either:-

1. Insufficient or incorrect lubrication.

2. The ingress of debris in the hammer.

3. Incorrect service and storage.

The maximum wear allowance shown in this section are a guide as to when to replace parts. In

certain conditions parts may need to be replaced before they reach the sizes shown.

Body dia

Footvalve

Bore dia

Control Tube

Bore dia

Striking Face

PISTON

1. There are two main areas to examine on a used piston:-

Check the body diameter for signs of pick-up and burning (both are signs of poor lubrication).

Using a micrometer, measure the diameter and refer to the quoted minimum size above.

Any light ‘Pick up’ marks can be removed using emery cloth, however if there are signs of

overheating and cracking, the piston should be replaced and the lubrication system examined.

2. Secondly, using a micrometer, measure the diameter of the bore at both ends of the piston and

refer to the maximum quoted sizes.

3. Examine the striking face. Distortion is acceptable proving there are no signs of cracking. Burrs

and dents can be removed with an emery stone.

7CHECKING FOR WEAR AND DAMAGE

Body dia

Max footvalve bore (SD18) 3.670” (93.2mm)

(N180) 3.740” (95.0mm)

Max control tube bore 4.517” (114.7mm)

Min body dia 12.220” (310.1mm)

CHECKING FOR WEAR AND DAMAGE

Fig.1 New Piston Face Fig. 2 Worn Piston Face

Fig. 3 Area to be machined

During the working life of the hammer the Striking Face

on the Piston may become dented or deformed (see

fig.2). To prevent this face from cracking, or chipping,

the Piston should be returned to a lathe where the

strking face can be re-machined flat and then have

the outer radius and inner chamfer reformed (see fig.3)..

Care should be taken to remove the minimum amout of

material during this re-machining process and at no

point should more than 2mm be removed from the face.

Pistons with wear patterns, or indentations deeper

than 2mm should be replaced.

The table below contains useful machine information for

reforming the piston face.

RADIUS “A”

CHAMFER “B”

IN BORE

MACHINE DETAIL

HAMMER RADIUS “A” CHAMFER “B”

HYPER 181 0.125” 0.250” @45

M

M

a

a

i

i

n

n

t

t

a

a

i

i

n

n

i

i

n

n

g

g

t

t

h

h

e

e

p

p

i

i

s

s

t

t

o

o

n

n

f

f

a

a

c

c

e

e

7

CCHHEECCKKIINNGGFFOORRWWEEAARRAANNDDDDAAMMAAGGEE8866

Diameter ‘A’

Control Tube

Control Tube

Minimum Dia

Examine the control tube diameter ‘A’, using a micrometer, check the diameter has not worn

under the specified minimum.

If there are signs of pick-up they should be removed by using emery cloth.

Wearsleeve Diameter ‘B’

Diameter ‘B’

Using either a micrometer or vernier,

measure the outer diameter ‘B’ of the

wearsleeve. If it is below the minimum it

must be replaced. The wear rate of the

wearsleeve can be slowed by replacing the

chuck before the wear areas reaches the

wear sleeve.

If there are signs of pick-up they should

be removed by using emery cloth.

Wearsleeve

Minimum Dia

If a piston has broken within the wearsleeve it is imperative that the bore is honed to remove any

burrs or ‘pick-up’

Failure to do so will result in ‘pick-up’ on the replaced piston and will lead to early failure of this

component

4.492” (114mm)

15.7” (399mm)

CHECKING FOR WEAR AND DAMAGE

8

Backhead

Checkvalve

Assemby

Compression

Buffer

Control Tube

Assembly

Piston

Chuck

Assembly

1. Ensure all the maintenance work outlined in the

previous section has been completed.

2. Lay the wearsleeve on two wooden blocks, support

the chuck end so as to raise the sleeve 50mm -

70mm off the ground this will make it easier to screw

in the chuck assembly.

3. Assemble the chuck, chuck release washer and bit

retainers around the bit ensuring the chuck and bit

retainers (SD18 only) are fitted with new ‘O’ rings.

check the condition of the drive plates (or pins) and

the chuck bearing and replace if necessary. Cover

the threads with a copper based grease. Then screw

the chuck fully in until there is no gap between the

wearsleeve and the chuck release washer.

4. Coat the piston with rock drill oil and slide it into the

backhead end of the wearsleeve. (Ensure the piston

striking face enters first).

5. Assemble the two control tube buffers and the ‘O’

ring around the control tube, then push the assembly

into the tube holder. Coat the outside of the assembly

with rock drill oil and insert it into the backhead end of

the wearsleeve

6. Slide the compression ring on to the control tube

assembly.

7. Insert the spring into the check valve and then

slide the assembly into the valve chest. Fit the buffer

cover to the valve chest. Push the whole assembly

down onto the compression ring.

8. Fit a new ‘O’ Ring to the backhead and coat the

threads in copper based grease. Fit the backhead

breakout washer. Screw the backhead into the

wearsleeve until it is hand tight, then measure the

gap between the wearsleeve face and the lock-up

face on the backhead. This gap should be a minimum

of 2mm, - if the gap is smaller the ring should be

removed and replaced with a new compression ring.

When the gap exceeds 2mm the backhead should be

fully tightened using the appropriate backhead

spanner.

9. Pre torque the whole assembly to 944 Kgm torque

before use.

REBUILDING HYPER HAMMERS

CCHHEECCKKIINNGGFFOORRWWEEAARRAANNDDDDAAMMAAGGEE8866

9

The Robit Hyper 181 hammer is designed to be used with

Foot Valves that are to the following specifications:

To guarantee the diameter and protrusion height are correct it is

recommended the correct insertion tool is used.

Using Foot Valves which are larger in diameter than the sizes

shown, will result in premature failure of the Foot Valve.

Foot Valves which are much smaller in diameter than the

sizes shown will reduce the performance of the hammer.

PROTRUSION

HEIGHT ‘A’

FOOT VALVE

Ø’B’

INSERTION TOOL

SHANK

TYPE PROTUSION

HEIGHT ‘A’ FOOTVALVE

DIAMETER ‘B’

SD18 2.75” 69.85mm 3.61” 91.7mm

Numa 180 3” 76.2mm 3.68” 93.5mm

The Hyper 181 piston oscillates at 650 bpm at 150 psi (10bar). It is therefore extremely important that

an adequate supply of the correct type of rock drill oil is constantly fed to the hammer whilst it is

operating.

Failure to do so will quickly lead to excessive component wear and if the oil supply is cut of for any

reason, the piston will quickly seize inside the wearsleeve, resulting in irreparable damage to both

components.

An air line lubrication system should be installed, preferably on the drill rig. The lubricator reservoir

should be of sufficient capacity to supply the required volume of rock drill oil for a full shift. With larger

hammers, this may be impractical but the capacity should be sufficient for at least half a shift.

This is equally important that the lubricator system must be adjustable and have a visual check to

ensure the lubricator does not run out of oil.

As a good general guide, all Robit Hyper hammers require a third of a pint of oil per 100cfm of air

through the hammer ( 0.07 litre per metre cubed)

Eg Hyper 181 operating at 150psi = 2016cfm = 6.7 pints per hour

10.3bar = 57cmm = 4 litre per hour

The amount of lubricating oil should be increased by 50% when drilling with water or foam.

When new drill pipes are added to the drill string, it is recommended that a half pint ( a quarter of a litre)

of rock drill oil is poured into the pipe to provide a good internal coating and helps prevent the hammer

from running dry at any time. The grade of rock drill oil will be determined by the ambient temperature at

the drilling site. If the ambient temperature is between 0 and 25 degree centigrade, then a 30 grade oil

should be used. If the ambient temperature is greater than 25 degree centigrade, use a 50 grade oil.

Robit supply their own recommended rock drill oil and this is detailed below, together with other brands

of suitable oils.

BUTTON BIT FOOTVALVES

11 LUBRICATION

10

MAKE TYPE 30 GRADE TYPE 50 GRADE

ROBIT T220 T320

BP ENERGOL RD-E 100 ENERGOL RD-E 300

CHEVRON ARIES 100 ARIES 320

SHELL TORCULA 100 TORCULA 320

ESSO/EXXON AROX EP100 AROX EP320

We recommend following the points listed below when removing a 'down hole hammer' from service.

This will ensure trouble free operation once the hammer starts work again.

The hammer should be stripped and cleaned and free of all water/moisture as possible.

Robit T220 or similar rock drill oil should be poured into backhead (see chart below for quantity)

allowing all parts to be coated throughout the hammer.

Both ends of the hammer should be then covered to prevent the ingress of dirt, etc.

It should be then laid horizontally in a dry environment ready for use next time.

Model Qty in UK Pints Qty in litre's

Hyper 181 2 1.25

If this procedure is followed then apart from protecting the hammer from corrosion it will protect the

parts from premature wear and of course reduce 'down time' and eventual repair costs.

However we strongly recommend that the hammer, especially if stored for any long periods of time

should be stripped, cleaned, inspected and re-oiled prior use to be sure of smooth drilling.

HAMMER STORAGE PROCEDURES

TROUBLESHOOTING

12

13

PROBLEM PROBABLE CAUSE REMEDY

INOPERATIVE DRILL Drill bit blowholes blocked Unblock holes

Dirt inside drill Strip and clean drill

Worn or damaged parts Replace damaged parts

Insufficient lubrication Check oil level, adjust lube needle value

Excessive lubrication Adjust lube needle value

Hanging Piston

Pistion stuck. Polish out the score marks

Insufficient air pressure Check compressor discharge and

increase to operational value

SLOW PENETRATION Insufficient air pressure Increase discharge pressure

Dull drill bit Re-grind or change bit

Worn drill parts Replace worn parts

Too much or too little lubrication Check oil level and if necessary adjust

lube needle value

Dirt in drill Strip and clean

LOW RETURN AIR VELOCITY Insufficient hole flushing air passing

through hammer Drill or increase hole size through the

piston

Drill bit exhaust holes blocked Clean out blockage

SPASMODIC OPERATION Failed or damaged parts Overhaul drill

Lack of oil Check lubrication

Drill bit broken Replace bit

Dirt in drill Strip and clean

A. CHUCK RELEASE WASHERS

Chuck Release Washers are fitted to the Robit Range of Hyper Hammers to assist the removal of the

Chuck from the Wearsleeve after drilling.

The Chuck Release Washer is manufactured from a composite material that reduces the friction between the

lock up faces on the Chuck and Wearsleeve making it easier to overcome the tensional loading applied

to these parts during the drilling process.

Due to the forces applied to the Chuck Release Washer you may find that its thickness ("W") is reduced

during the drilling cycle and it is therefore recommended that a new Washer be fitted each time the

Chuck is removed.

It is possible that on some of the larger Hammers in the Robit range, when drilling with large diameter

Button Bits or Overburden Systems, certain conditions can generate higher torques than normally

expected, resulting in difficulties when trying to remove the Chuck from the Wearsleeve. Should this occur

then the removal of the Chuck can be achieved by cutting away the Chuck Release Washer. We do

however stress at this point that cutting away the Chuck Release Washer is a final option and should

not be done until all other options have proved unsuccessful.

If the cutting away of the Chuck Release Washer is necessary for the removal of the Chuck then it must

be done with extreme care to avoid damage to either the Chuck or the Wearsleeve. The composition

of the Chuck Release Washer allows for it to be cut with either a hacksaw or a small hand grinder equipped

with a slitting wheel. The hacksaw method is much safer and less likely to damage the Chuck or Wearsleeve,

but obviously much slower than the hand grinder with a slitting wheel. To remove the Chuck Release Washer

a cut must be made in the centre of the washer all the way around it's circumference, and

completely through the Washer, thus transforming the single washer into two thinner washers that will

then spin freely. Great care must be taken, especially if the Washer is cut with a slitting wheel, to ensure

that the cut only penetrates the Washer and does not pass through into the body of the Chuck.

The size shown as 'D" in the above table should be your MAXIMUM depth of cut, and it is recommended

that either the saw blade or the slitting wheel are marked in some way so as to indicate when they have

achieved this depth.

CHUCK RELEASE WASHERS

HAMMER MODEL “W” “D”

HYPER 181 0.300” - 7.62mm 0.740” - 18.80mm

There are many different “Splitting” Machines available for unscrewing the threaded connections on a Robit

Hyper Hammer, some are attachments to the Drill Rig, others are independent hydraulic units, or purpose made Bench

arrangements. Regardless of which machine is chosen they all require some method of securing the Wearsleeve whilst

applying a torque to either the Chuck or Backhead.

The most common machines use either Clamps or Chains around the O/D of the Wearsleeve and the positioning of these

is very important, if they are placed too close to the joint being “Split” they will in effect increase the frictional forces on the

threaded connection making it impossible to unscrew the component from the Wearsleeve.

The above table shows the correct position for the clamping mechanism to ensure no additional load will be applied to the

threaded connection, thus making the joint easier to split.

Due to the high torque loads applied to a Hammer during its drilling cycle, equally high loads are required to “Split” the

Chuck and Backhead away from the Wearsleeve and because of this the clamping arrangement around the Wearsleeve

must generate enough friction to prevent it from spinning during the process.However great care must be taken to make

sure the clamps or chains are not over-tightened as this can cause deformation to the Wearsleeve that can result in both

Wearsleeve failure and Piston seizure once the Hammer is returned to service.

TohelpincreasetheWearsleeve’sresistancetodeformationitisrecommendedthattheHammerPistonisfirstslidtothe

end of the Hammer being “split”, before clamps of chains are attached. By doing this the Piston O/D will limit the amount of

deformation in the Wearsleeve bore if too much clamping pressure is applied.

NOTE:

The use of Chain type Hydraulic Breakers can leave deep intrusions in the O/D of the Wearsleeve which may result in stress

concentrations that could lead to premature failure of the Wearsleeve.

CLAMP POSITIONS

HAMMER MODEL “X” DISTANCE FROM

WEARSLEEVE END FACE

HYPER 181 CHUCK 8.250” / 210mm

B. CLAMPING POSITIONS

HYPER 181 BACKHEAD 9.000” / 229mm

CHUCK

BACKHEAD

11/03/2020 HYPER 181 – MAINTENANCE, OPERATING AND SERVICE MANUAL

www.robitgroup.com

Table of contents

Other Robit Tools manuals