Robitronic Pro-Master Manual General Information

1

Contents

General information

Introduction...................................................................2

Scope of delivery ...........................................................2

Safety precautions..........................................................3

Pro-Master operating instructions

Setup.............................................................................4

Pro-Master keys and operation.......................................4

Selecting a function........................................................5

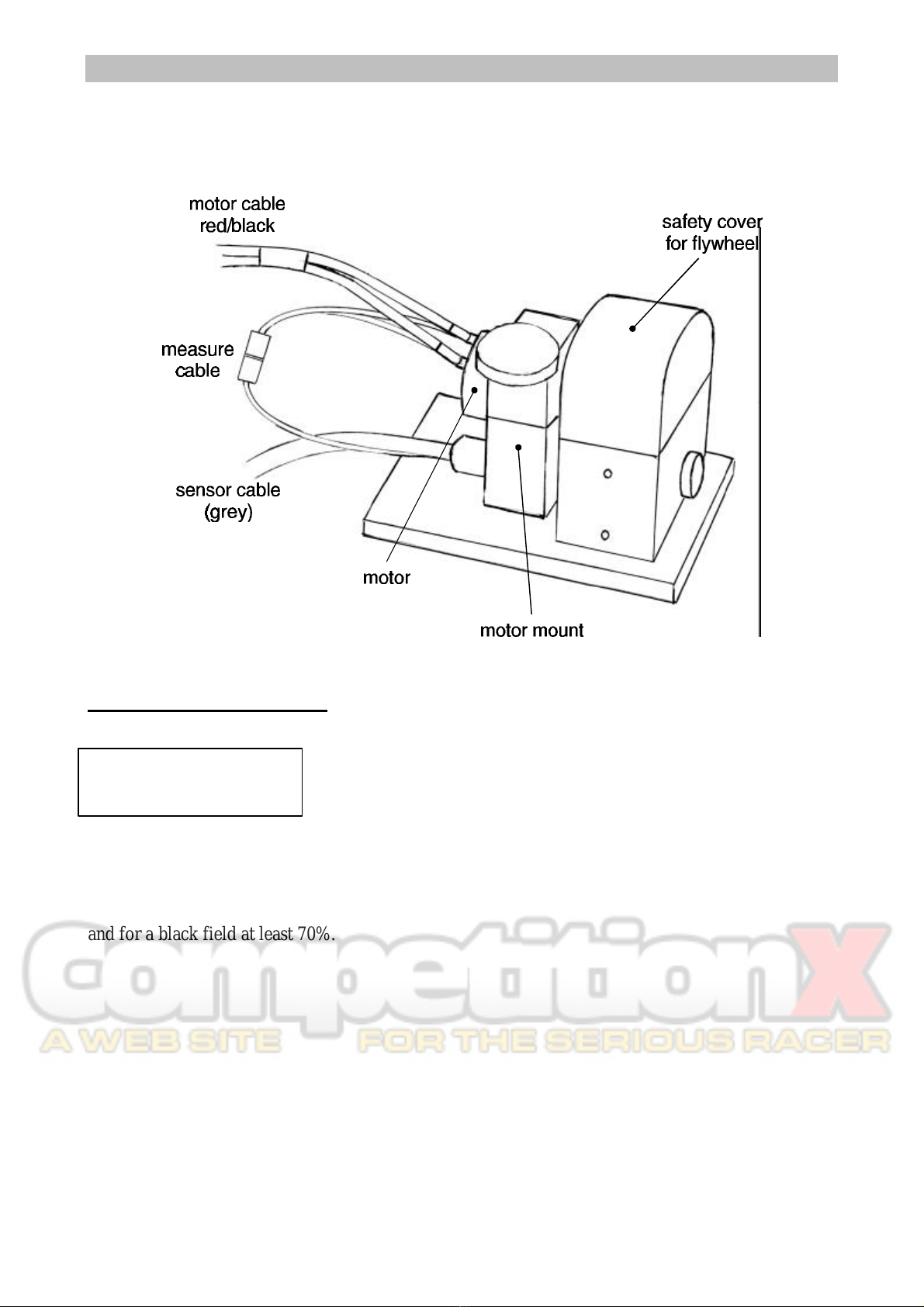

Preparing for the motor check........................................6

Checking the RPM sensor..............................................7

Starting the measurement...............................................8

Displaying motor data..................................................10

Printing on the protocol printer ....................................11

Setting parameters for a motor check...........................12

Ending the motor check ...............................................14

Charging battery packs.................................................15

Function diagrams........................................................18

PC Software

System requirements....................................................20

Keyboard layout...........................................................20

Key to symbols ............................................................20

Installing the PC software ............................................21

Connecting Pro-Master to a PC....................................21

Selecting a function......................................................22

Loading motor data......................................................23

Display modes for motor data ......................................24

Meaning of motor data.................................................25

Loading benchmark data ..............................................26

Motor data in table view ..............................................27

Printing motor data......................................................28

Program settings..........................................................28

Motor check ................................................................30

Saving motor data........................................................31

Example of setting motor timing...................................32

Overview of function keys............................................34

Test results ..................................................................35