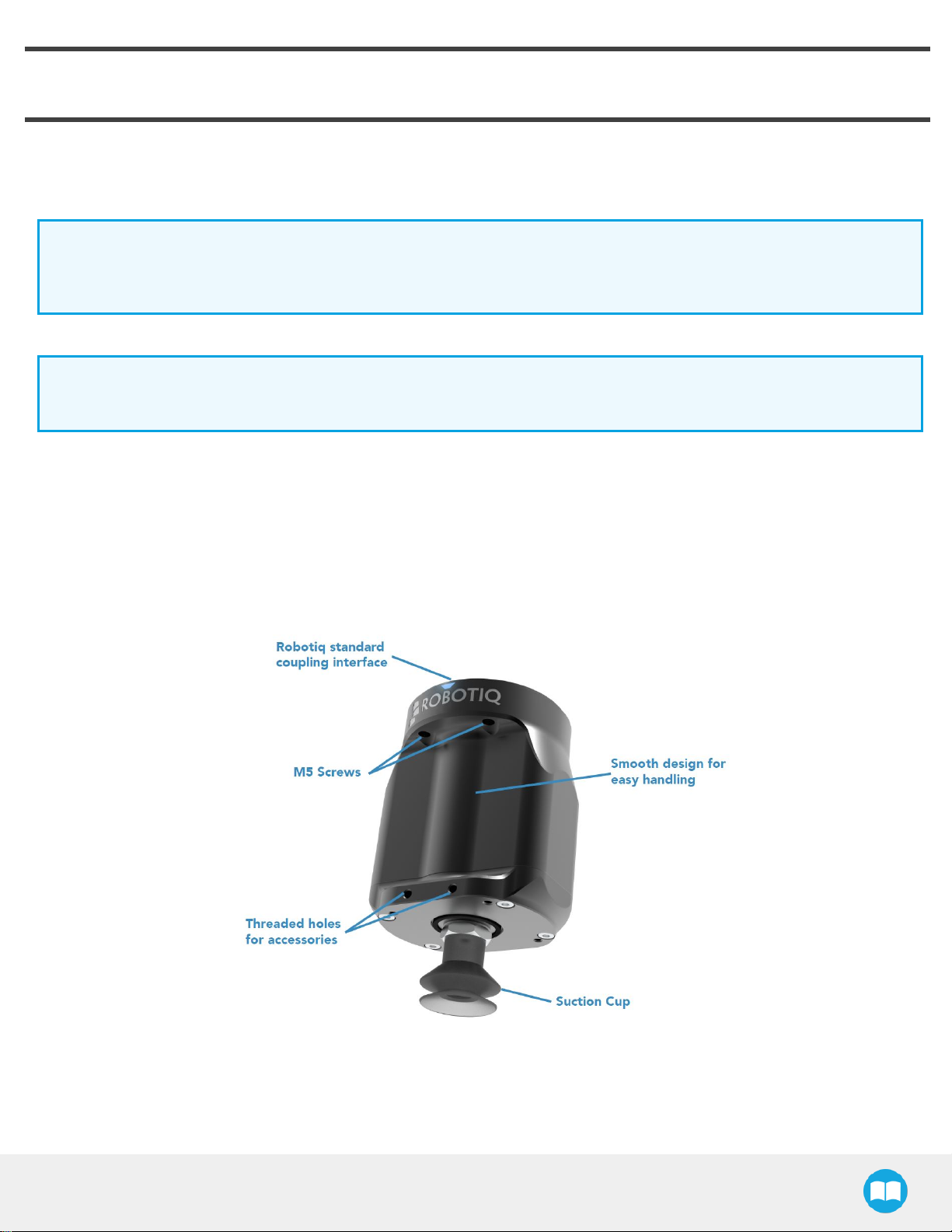

EPick- InstructionManual

1.2.Object picking

TheEPickGripperallows:

1. Mainunit suction cup

2. Auxiliarysystem with multiple suction cups

Warning

Object picking causesthecompressionof thesuctioncup(s),whichcanresult inpinching pointsbetweenthegripperand the

load.Avoid presenceof bodypartsinthiszoneduring operation.

Warning

Beforepicking anynewobject or material inautonomousmode,always checkthat the resulting vacuum level issufficient to

ensuresafe gripping,inorderto prevent dropping orejection of theload.

1.2.1.Main unit suctioncup

In order to use onlyonesuction cup,the single cup canbe mounted right intheport of thevacuum generator.

1.2.2.Auxiliarysystemwithmultiple suctioncups

A standard Suction Cup System can be attached to theEPick Vacuum Gripper.Thebracket normallyholdstwo or four suction cups

(corresponding to thefourportsof themanifold).

Anyunused manifold port should beblocked withamating plug to avoid airleakage.

Other custom mounting optionscanalso be used to benefit from a multiple suction cups solution

Caution

Custom brackets and platesmust meet the required technical specifications(refer to theTechnicaldimensionssection

subsection).

1.3.Setup and control

TheVacuum Gripperispowered and controlled directlyvia asingle devicecablethat carries24VDCpowerand ModbusRTU

communicationoverRS-485.

Info

Please referto the ElectricalSetup sectionsubsectionfor wiring information,and to theSoftware section for thecontrol of the

Vacuum Gripper.

Inorderto beused,theEPickGripperhasto beconnected to aGrippercoupling whichprovidesboththemechanicaland electrical

connectivityto the Gripper.

9