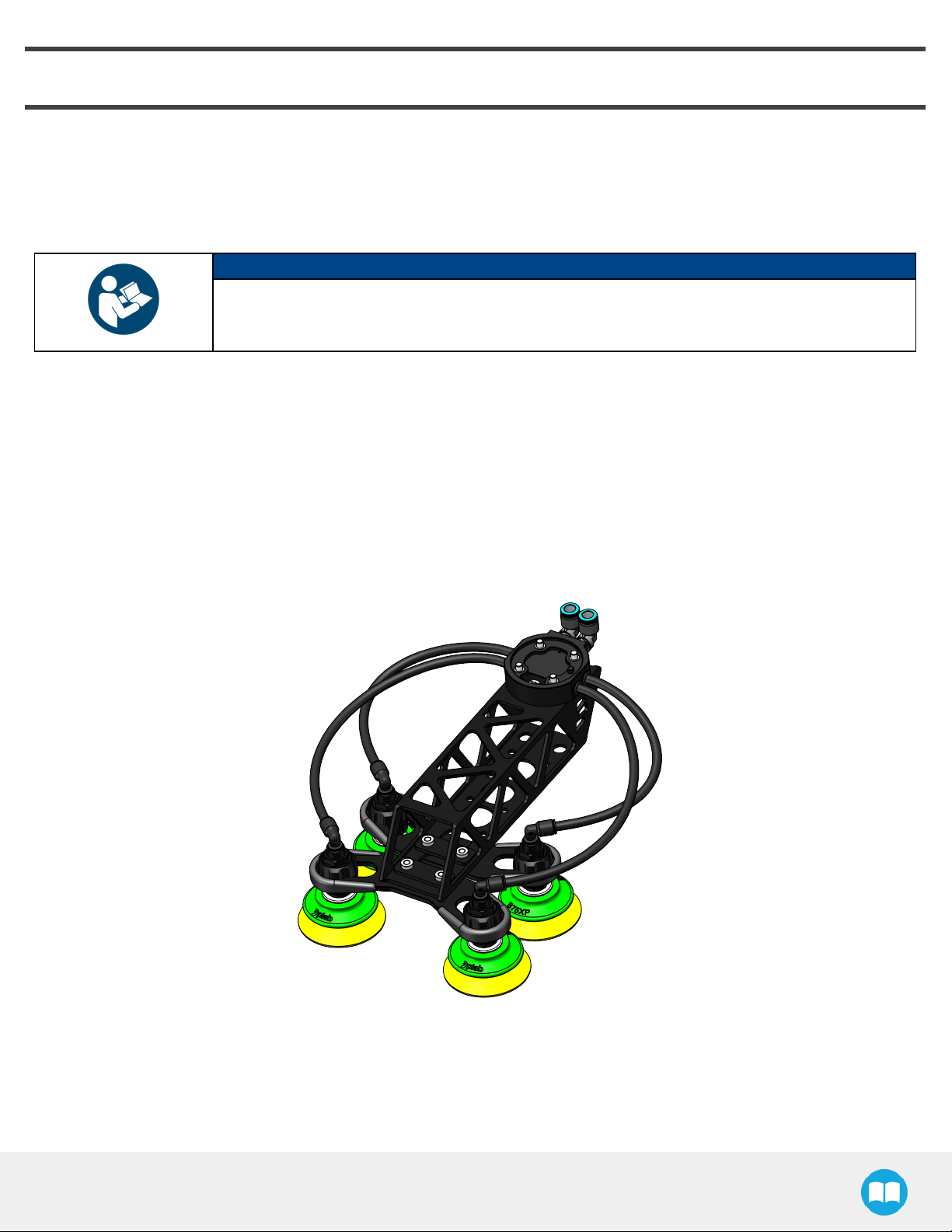

PowerPick10 - Instruction Manual

2.2. Risk Assessment

2.2.1. General Risk Assessment

The robot, the Gripper and any other equipment used in the final application must go through a comprehensive risk assessment

process before they can be used.

The following non-exhaustive list presents risks that must be assessed during the integration process:

lRisk of contact between body parts and the Gripper and/or suction cups;

lRisk of load ejection resulting from loss of vacuum;

lRisk of load dropping resulting from loss of vacuum;

lRisk of load ejection resulting from loosened fasteners on the end effector;

lRisk of pinching between the Gripper and the items being handled, or other objects in the environment;

lRisk of injury resulting from misuse of the product;

lRisk of entanglement of the tool cables resulting from inappropriate robot cable management.

Depending on the application, configuration and items being handled, additional hazards may be present. For instance, the boxes

handled by the Gripper could be inherently dangerous to the operator. Such hazards may require additional protection or safety

measures (e.g., light curtains, safety scanners, enclosure, etc.).

To ensure an adequate level of safety, floor markings must be applied to delineate safe zones around the work cell. It is the

responsibility of the integrator to establish the proper safe distance from the work cell to protect the user.

The software allows for the limiting of the robot's speed, force and working area in order to reduce residual risk. These measures

can namely give the operator more time to react appropriately, and reduce the robot’s brake time.

WARNING

Collisions between a person and the PowerPick10 Gripper may result in material damage, bodily

injury and even death. Anyone in the vicinity of the work cell should take the necessary precautions.

lMake sure no individual or asset are in the vicinity of the robot and/or Gripper prior to initializing the

robot.

lAlways keep body parts and clothing away from the Gripper while the device is powered on.

lDo not use the Gripper on people or animals.

lNever stand under suspended loads held by the Gripper.

lSecure the Gripper properly before operating the robot.

lAlways meet the Gripper payload specifications.

10