Table of contents

Ed. 04/2012

1

TA LE OF CONTENTS

SECTION 1 GENERAL INFORMATION AND TECHNICAL SPECIFICATIONS..............3

1.1

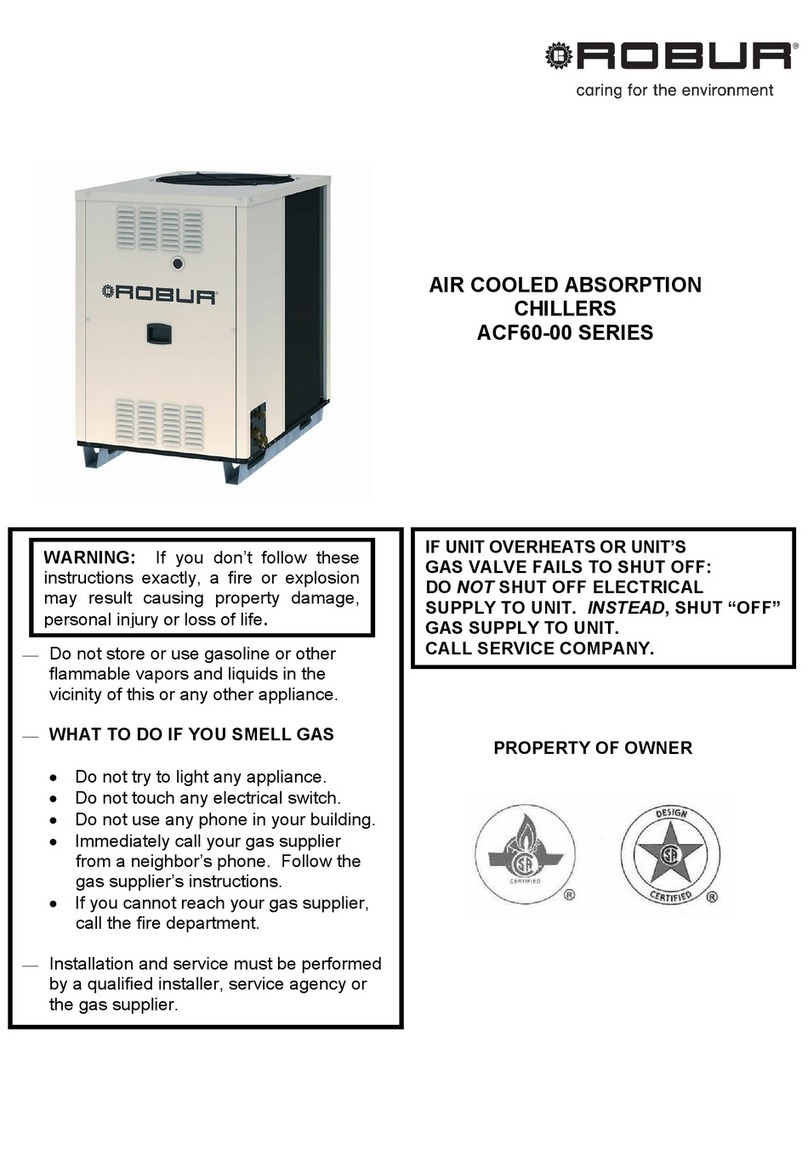

SAFETY WARNINGS .........................................................................................................................3

1.2

GENERAL INFORMATION.................................................................................................................

1.3

OPERATION OF THE ACF60-00 .......................................................................................................8

1.4

TECHNICAL SPECIFICATIONS.......................................................................................................11

1.

ACF DIMENSIONS AND SERVICE PANELS ..................................................................................26

SECTION 2 END USER ..................................................................................................29

2.1

COMMISSIONING (AND SHUTDOWN) OF THE ACF ....................................................................29

2.2

ON-BOARD ELECTRONICS ............................................................................................................30

2.3

SETTING OF OPERATING PARAMETERS ....................................................................................3

2.4

RESETTING......................................................................................................................................3

2.

WARNING AND ERROR CODES ....................................................................................................37

2.6

PROLONGED INACTIVITY ..............................................................................................................38

SECTION 3 PLUM ING INSTALLER.............................................................................39

3.1

GENERAL INSTALLATION PRINCIPLES........................................................................................39

3.2

POSITIONING OF THE ACF60-00 ...................................................................................................40

3.3

WATER CONNECTIONS..................................................................................................................42

3.4

GAS SUPPLY SYSTEM....................................................................................................................47

3.

FILLING OF THE WATER CIRCUIT.................................................................................................48

3.6

SETTING OF THE WATER PARAMETERS .................................................................................... 0

SECTION 4 ELECTRICAL INSTALLER .........................................................................53

4.1

OPERATION WITH CONTROL SWITCH......................................................................................... 3

4.2

APPLIANCE PUMP CONTROL ........................................................................................................

4.3

PUMP AND ELECTRICAL WIRING DIAGRAMS ............................................................................. 6

4.4

USE OF A DIRECT DIGITAL CONTROLLER (DDC) .......................................................................60

4.

HOW TO RESET THE FLAME CONTROLLER FROM REMOTE ...................................................72

SECTION 5 INITIAL STARTUP AND MAINTENANCE ..................................................73

.1

INITIAL STARTUP AND ADJUSTING ..............................................................................................73

.2

GAS CONVERSION..........................................................................................................................76

.3

MAINTENANCE ................................................................................................................................79

SECTION 6 ACCESSORIES...........................................................................................81

APPENDIX .................................................................................................................87

DECLARATION OF CONFORMITY.........................................................................................................87

APPENDIX....................................................................................................................... 83

WARNINGS AND ERRORS............................................................................................................................83

TABLE OF OPERATING CODES ...................................................................................................................83