Rockford Systems, LLC

2Call: 1-800-922-7533

(Continued on next page.)

TABLE OF CONTENTS

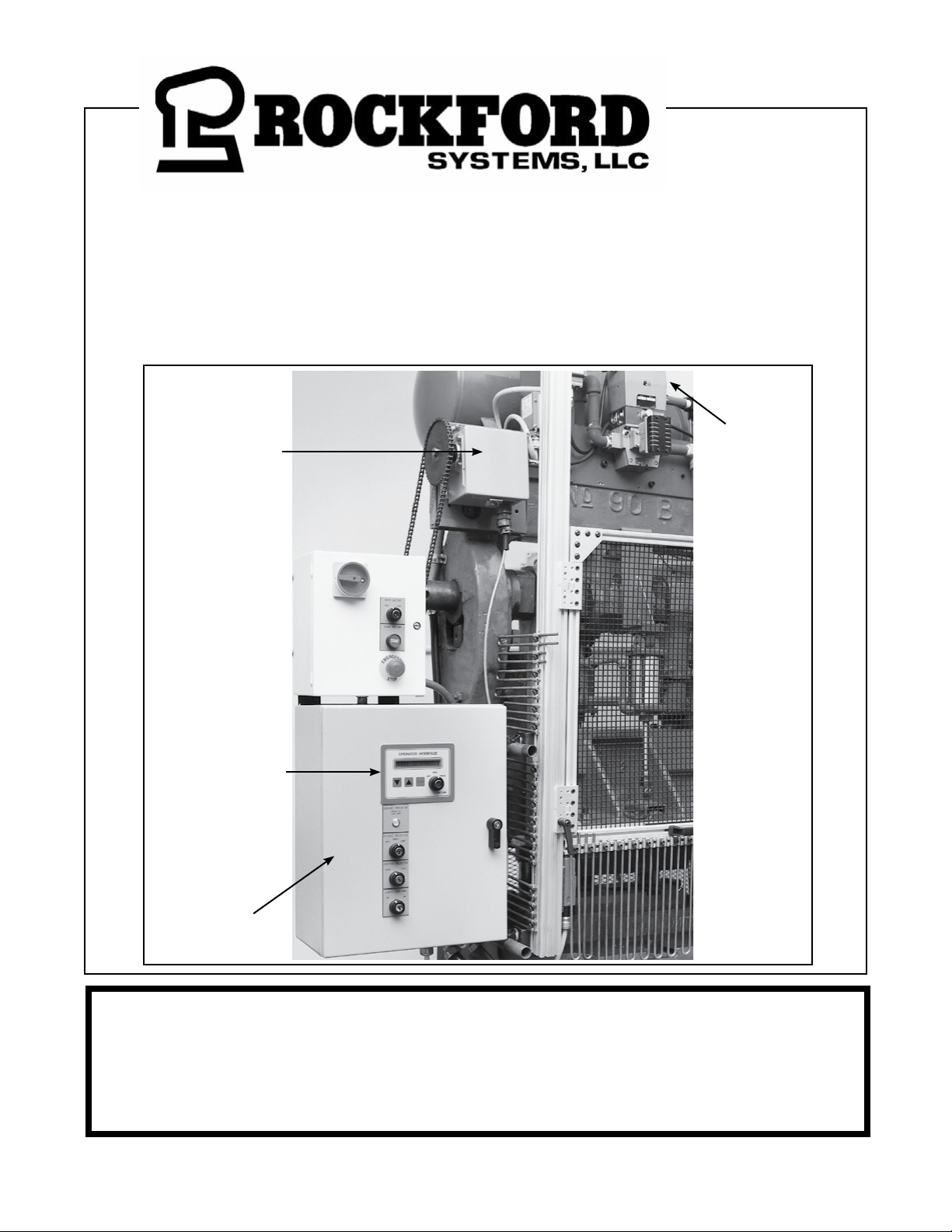

SSC-1000 Part Revolution Solid-State Control

Section 1—IN GENERAL ...................................................3 - 10

Section 2—INtroduction ................................................11 - 15

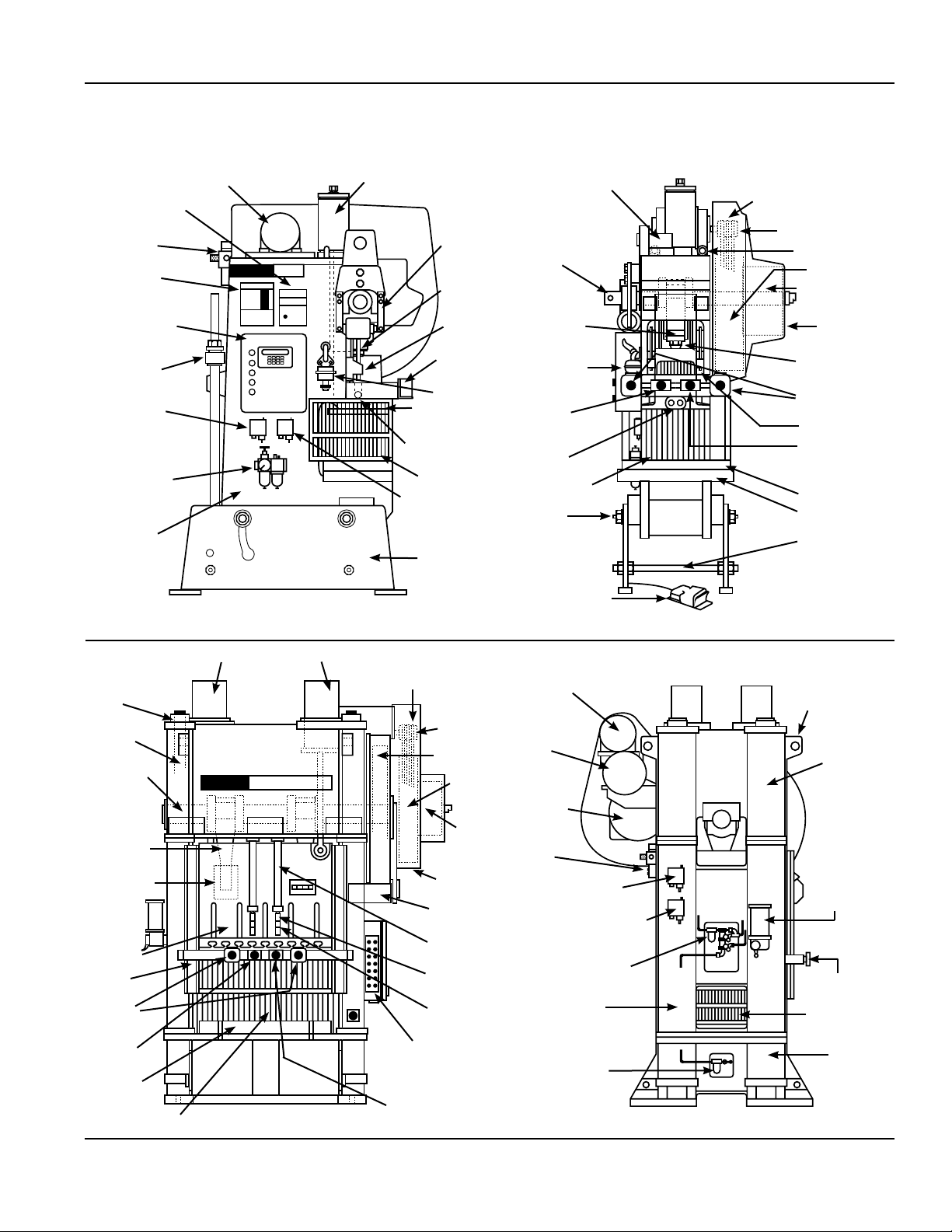

Section 3—INSTALLATION OF SSC-1000 CONTROL SYSTEM

Components.................................................................16 - 33

Literature Folder...................................................................16

Control Box.................................................................. 16 - 19

Dual Solenoid Air Valve and Muffler Assembly .......................20

Filter-Regulator-Gauge and Lubricator (FRL) Assembly ...........20

Air Pressure Switch..............................................................21

Check Valves for Counterbalance System ..............................21

Opti-CAM™ Assembly ................................................. 21 - 23

Sprocket Set .......................................................................23

Chain...................................................................................23

Palm Button Assembly.................................................. 24 - 27

Foot Switch (Optional)...........................................................27

Supervisory Control Station...................................................28

Lockout Air Valve ......................................................... 29 - 30

Main Power Disconnect Switch .............................................30

Motor Starter .......................................................................31

Custom or Special Control Box..............................................31

Flywheel and Gear Covers ....................................................31

Collateral Equipment ............................................................31

Point-of-Operation Safeguards..............................................31

Other Installation Considerations ..................................31 - 33

Section 4—PROGRAMMING ...........................................34 - 49

Setup of Control System ........................................................34

Initial Setup Procedure .........................................................34

Programming Overview..........................................................35

Brake Monitor ms.................................................................36

Clear Stroke.........................................................................37

Clear Batch..........................................................................37

Batch Preset ........................................................................38

Timed-Inch ms.....................................................................38

Anti-tie-down ms .................................................................39

PLS Output ..........................................................................39

PLS Delay ms ......................................................................40

PLS On Time ms..................................................................40

PLS Counter ........................................................................41

User Inputs .................................................................. 41 - 42

Stop-Time Measurement Test ms .........................................43

Reference Cycle...................................................................44

Automatic Single Mode.........................................................45

Automatic Single Timer sec ..................................................45

Inch/Top-Stop Mode............................................................45A

SPM Display Calibration %...................................................45A

Default Settings...................................................................45B

Variable Continuous Top-Stop....................................... 46 - 47

Optional Modes of Operation .........................................48 - 49

Section 5—OPERATING CONSIDERATIONS.................... 50 - 51

Section 6—FAULT MESSAGES .......................................52 - 54

Section 7—MAINTENANCE & INSPECTION .................... 55 - 56

Section 8—METHODS OF SAFEGUARDING ...................57 - 58

RETURN MATERIALS REQUEST FORM ....................................59

ORDER FORM ..........................................................................60

FIGURES

Figure 2.1 Block Diagram .........................................................14

Figure 3.1 Opti-CAM™ & Tachometer Generator.......................22

Figure 3.2 Cam and Switch Settings..........................................22

Figure 3.3 Palm Button Assembly Installation.............................24

Figure 3.4 Illustration of Electrical System..................................28

Figure 3.5 Illustration of Lockout Installation ..............................29

Figure 4.1 Initial Setup Procedure Flowchart ..............................34

Figure 4.2 Initial Information on Display .....................................34

Figure 4.3 Main Program Menu Flowchart .................................35

Figure 4.4 Brake Monitor Flowchart...........................................36

Figure 4.5 Clear Stroke Flowchart .............................................37

Figure 4.6 Clear Batch Flowchart ..............................................37

Figure 4.7 Batch Preset Flowchart.............................................38

Figure 4.8 Timed Inch Flowchart ...............................................38

Figure 4.9 Anti-tie-down Flowchart............................................39

Figure 4.10 PLS Output Timing Chart ........................................39

Figure 4.11 PLS Delay Flowchart...............................................40

Figure 4.12 PLS On Time Flowchart ..........................................40

Figure 4.13 PLS Counter Flowchart ...........................................41

Figure 4.14 User Input Fault Messages Chart.............................41

Figure 4.15 Input # 1 - 4 Flowchart ..........................................42

Figure 4.16 STM Test Flowchart................................................43

Figure 4.17 Reference Cycle Flowchart......................................44

Figure 4.18 ASingle Mode Flowchart .........................................45

Figure 4.19 ASingle Tmr Flowchart............................................45

Figure 4.19A Inch/Top-Stop Mode Flowchart ............................45A

Figure 4.19B SPM Display Calibration Flowchart.......................45A

Figure 4.19C Default Settings Flowchart...................................45B

Figure 4.20 Top-Stop Chart ......................................................46

Figure 4.21 Var SPM Low Lim Flowchart ...................................47

Figure 4.22 Var SPM High Lim Flowchart...................................47

Figure 4.23 Var SPM Flowchart.................................................47

Figure 4.24 Optional Modes Setup Flowchart.............................48

TABLES

Table 3.1 OSHA Safety Distance Chart.......................................25

Table 3.2 Lockout Air Valve Part No. Chart.................................30

Table 4.1 Quick Reference Table...............................................49

Table 6.1 Fatal Fault Messages ........................................ 52 - 53

Table 6.2 General Fault Messages ............................................54

© 2017 Rockford Systems, LLC All rights reserved. Not to be reproduced in whole or in part without written permission. Litho in U.S.A.